Experimental system for testing performance of methyl iodide adsorption material

An experimental system and iodine adsorption technology, applied in the field of nuclear radiation protection, can solve the problems of human injury, difficulty in measurement, and low content of organic iodine, and achieve the effects of comprehensive functions, reduced experimental errors, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

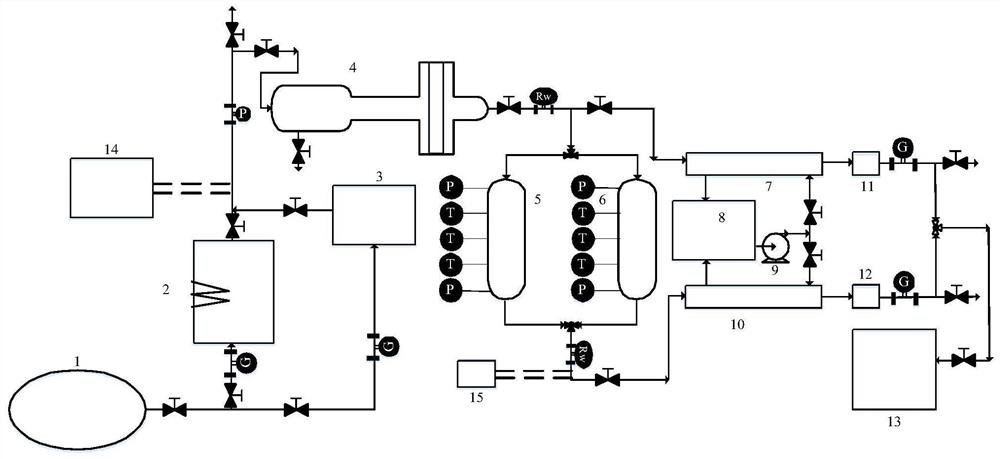

[0047] Specific embodiments of the present invention is described in further detail below in conjunction with the accompanying drawings and.

[0048] like figure 1 A method for methyl iodide adsorbent performance testing experimental system shown, can be applied to up to 200 ℃, 1MPa at the high temperatures and pressures, including 1, 2 compressor steam supply means, the supply means methyl iodide 3, steam-water separation apparatus 4, 5 experimental adsorption bed, the bed control 6, a condenser A7, cooling water tank 8, a pump 9, BlO condenser, steam separator A11, steam separator B12, GC 13, a data acquisition system 14 the temperature control system 15.

[0049] Means methyl iodide, and 2 are connected to a steam supply device 3 is supplied through the two branch pipes at the rear of the compressor 1.

[0050] Behind the steam supply means 2 and methyl iodide supply device 3 is connected to the separation means 4 soda. Two manifolds provided at the rear end of the steam-water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com