Polyimide film for artificial graphite film, preparation method of polyimide film and artificial graphite film

A technology of polyimide film and artificial graphite, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of graphite film thermal conductivity and unsatisfactory mechanical properties, and achieve high birefringence and orientation Good, the effect of improving the degree of imidization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

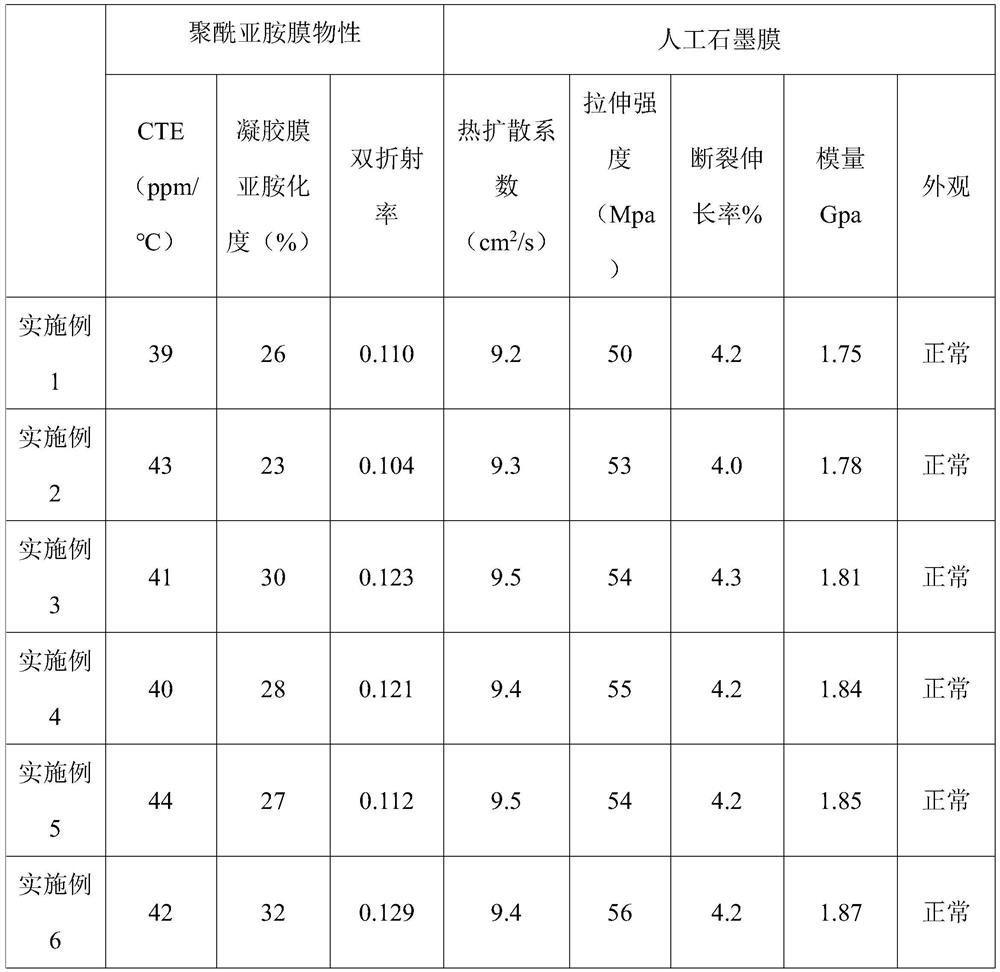

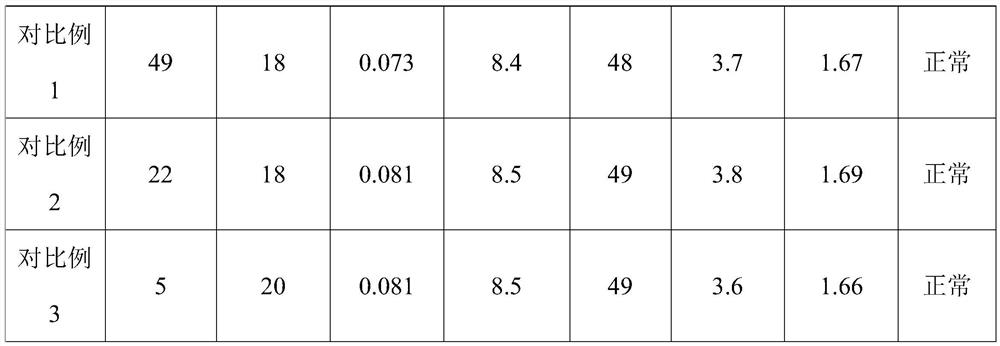

Examples

preparation example Construction

[0021] About the preparation of polyimide membrane

[0022] When preparing the polyimide film for artificial graphite film, the present invention adopts "two-step method" to obtain the polyimide precursor-polyamic acid first, and then through thermal imidization, chemical imidization or thermal imidization Combination of chemical imidization and chemical imidization to obtain polyimide films. Thermal imidization is preferred in the present invention.

[0023] Wherein, the concrete process of preparing polyamic acid can be specified by following content:

[0024] When obtaining a polyamic acid from a dianhydride and a diamine, it can carry out under conventionally known conditions, and the addition order and addition method of a dianhydride and a diamine monomer are not specifically limited. For example, the diamine monomer can be dissolved in an organic solvent, then the dianhydride monomer can be added, and the polymerization reaction can be carried out at a suitable reacti...

Embodiment 1

[0034] Polyimide film:

[0035] Add 4,4'-diaminodiphenyl ether (ODA), pyromellitic dianhydride (PMDA), and 1,4,5,8-naphthalene tetracarboxylic dianhydride in a molar ratio of 100:90:10 In N,N-dimethylacetamide, react while stirring, and react at 30° C. for 4 hours to obtain a polyamic acid slurry with a solid content of 20%;

[0036] The filler calcium hydrogen phosphate, with an average particle size of 3 μm, was added to N,N-dimethylacetamide, and dispersed by high-speed stirring to prepare a solid content of 10% calcium hydrogen phosphate slurry; the filler ferric oxide, with an average particle size of 3 μm, Adding N, N-dimethylacetamide, using high-speed stirring to disperse, and preparing ferric oxide slurry with a solid content of 10%;

[0037] Add the calcium hydrogen phosphate slurry and the ferric oxide slurry into the polyamic acid slurry, control the filler content in the calcium hydrogen phosphate slurry to be 0.5% of the solid weight of the polyimide film, and t...

Embodiment 2

[0041] Add 4,4'-diaminodiphenyl ether (ODA), pyromellitic dianhydride (PMDA), and binaphthic anhydride in a molar ratio of 100:90:10 to N,N-dimethylacetamide During the reaction while stirring, the reaction was carried out at 40°C for 4 hours to obtain a polyamic acid slurry with a solid content of 20%; the others were the same as in Example 1, and an artificial graphite film of 24 μm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com