Preparation of nanocrystalline lead zirconat-titanato-quartz composite structure piezoelectric sensing material

A crystalline lead zirconate titanate and composite structure technology are applied in the fields of biological detection, piezoelectric material lead zirconate titanate, composite structure sensing material, nanocrystalline lead zirconate titanate-quartz composite structure piezoelectric sensing material , which can solve the problems of sensor sensitivity and detection rate limitation, low resonant frequency, reduction and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

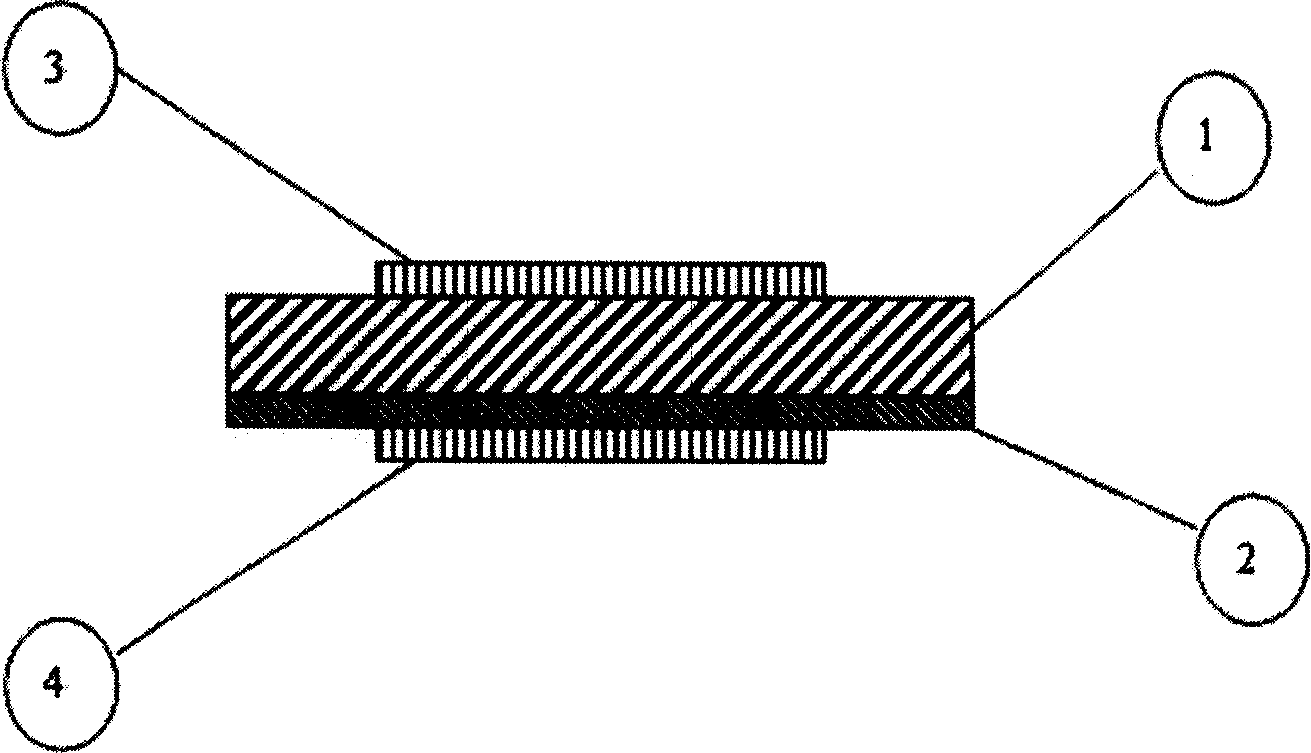

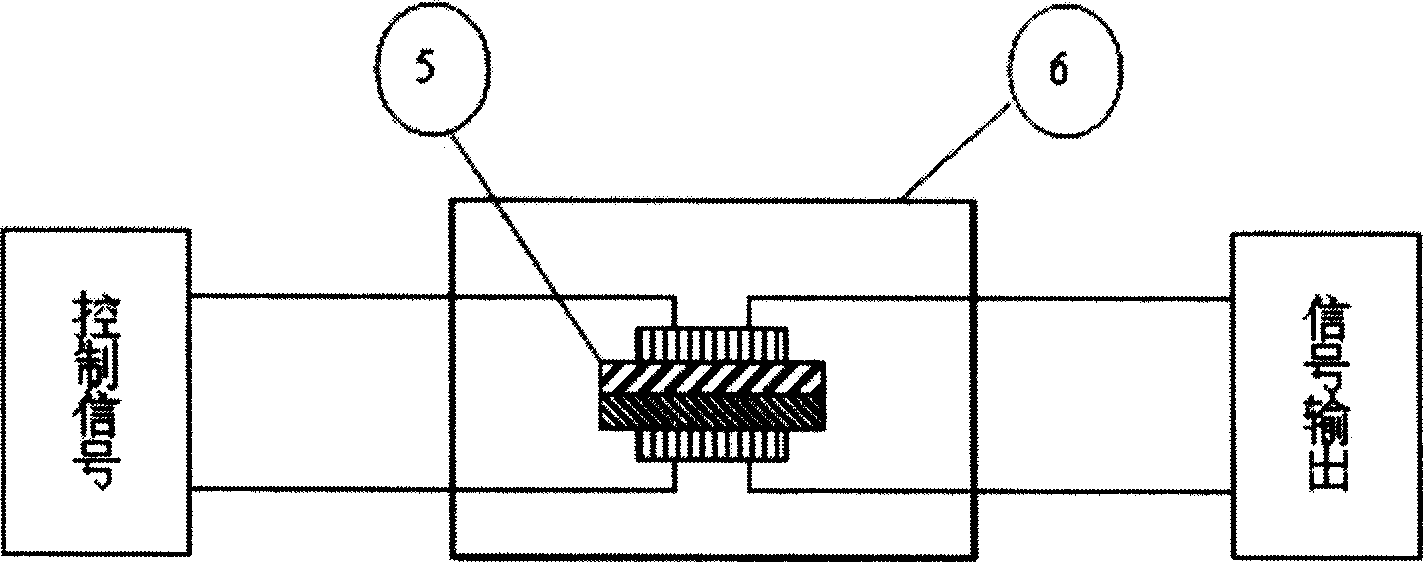

Image

Examples

Embodiment 1

[0023] 1. Use lead acetate, tetrabutyl titanate and tetrabutyl zirconate as raw materials, weigh the raw materials according to the molar ratio of Pb:Zr:Ti=1.04:0.5:0.5, and set aside.

[0024] 2. Mix the prepared raw materials tetrabutyl titanate and acetylacetone at a molar ratio of 1:2, stir at 20°C for 1 hour, then add the prepared raw material tetrabutyl zirconate, and continue stirring until the mixture is uniform to obtain zirconium titanium mixture solution.

[0025] 3. Dissolve the prepared lead acetate in ethylene glycol methyl ether at a concentration of 0.2g / ml, stir at 120°C for 30 minutes, cool to 80°C, and then add the previous The homogeneously mixed zirconium-titanium mixture solution was stirred at 80° C. for 30 minutes to obtain a pale yellow PZT precursor sol.

[0026] 4. Perform vacuum distillation and vacuum drying on the precursor sol of lead zirconate titanate to obtain PZT xerogel.

[0027] 5. Dissolving the PZT xerogel in ethylene glycol methyl ethe...

Embodiment 2

[0031] 1. Use lead acetate, tetrabutyl titanate and tetrabutyl zirconate as raw materials, weigh the raw materials according to the molar ratio of Pb:Zr:Ti=1.05:0.5:0.5, and set aside.

[0032] 2. Mix the prepared raw material tetrabutyl titanate and acetylacetone according to the molar ratio of 1:2, stir at 20°C for 1.5 hours, then add the prepared raw material tetrabutyl zirconate, and continue to stir until the mixture is uniform to obtain zirconium titanium mixture solution.

[0033] 3. Dissolve the prepared lead acetate in ethylene glycol methyl ether at a concentration of 0.25g / ml, stir at 120°C for 30 minutes and cool to 80°C, then add the previous The homogeneously mixed zirconium-titanium mixture solution was stirred at 80° C. for 30 minutes to obtain a pale yellow PZT precursor sol.

[0034] 4. Perform vacuum distillation and vacuum drying on the precursor sol of lead zirconate titanate to obtain PZT xerogel.

[0035] 5. Dissolving the PZT xerogel in ethylene glyco...

Embodiment 3

[0039] 1. Use lead acetate, tetrabutyl titanate and tetrabutyl zirconate as raw materials, weigh the raw materials according to the molar ratio of Pb:Zr:Ti=1.06:0.5:0.5, and set aside.

[0040] 2. Mix the prepared raw materials tetrabutyl titanate and acetylacetone at a molar ratio of 1:2, stir at 30°C for 2 hours, then add the prepared raw material tetrabutyl zirconate, and continue stirring until the mixture is uniform to obtain zirconium titanium mixture solution.

[0041] 3. Dissolve the prepared lead acetate in ethylene glycol methyl ether at a concentration of 0.3g / ml, stir at 120°C for 30 minutes, then cool to 80°C, and then add the previous The homogeneously mixed zirconium-titanium mixture solution was stirred at 80° C. for 30 minutes to obtain a pale yellow PZT precursor sol.

[0042] 4. Perform vacuum distillation and vacuum drying on the precursor sol of lead zirconate titanate to obtain PZT xerogel.

[0043] 5. Dissolve the PZT xerogel in ethylene glycol methyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com