Wide-band-gap perovskite solar cell and preparation and application thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of toxic reserves, complex process, high photoelectric conversion efficiency, etc., achieve device performance and stability improvement, simple operation, and reduce preparation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

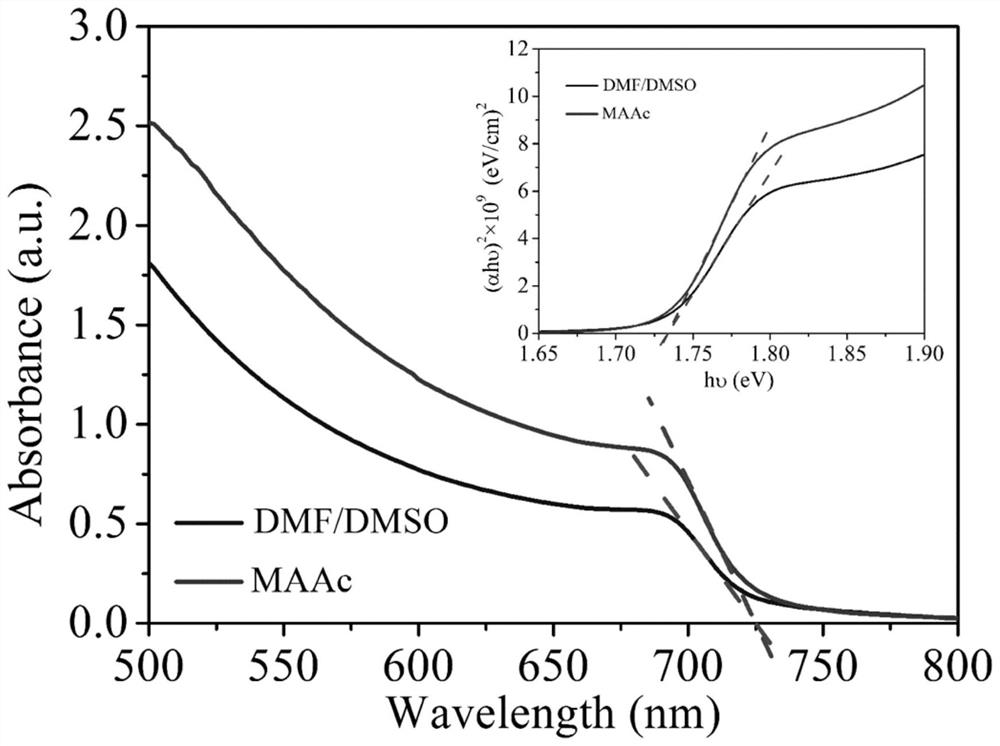

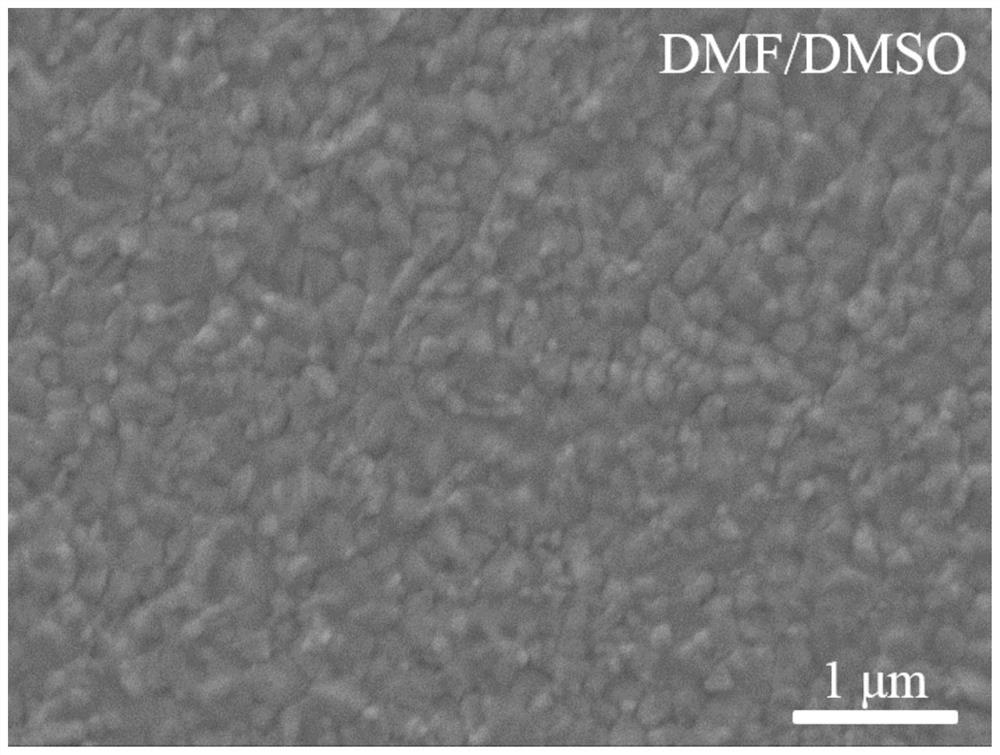

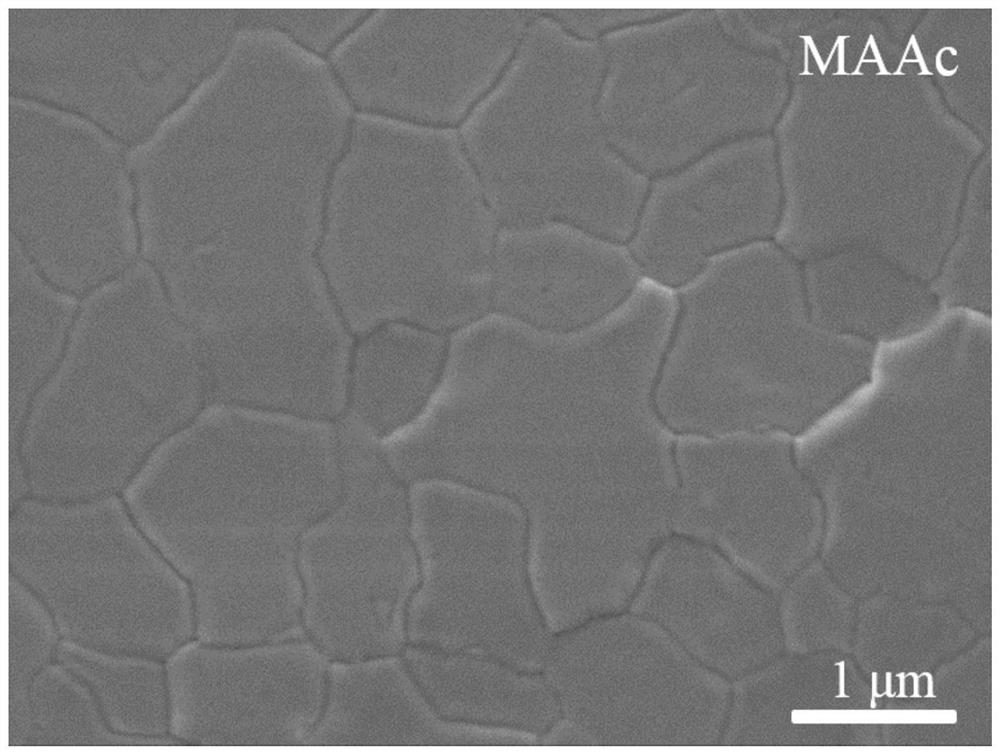

[0057] This embodiment is an inventive method for preparing a wide bandgap perovskite solar cell and the perovskite solar cell thereof. In this embodiment, the wide bandgap perovskite solar cell has a dense and smooth surface, high crystallinity, low defect state density and good crystal orientation. It mainly includes the following steps:

[0058] Step 1) Sonicate the etched ITO conductive glass in ethanol, ultrapure water plus cleaning agent, ultrapure water, acetone, and ethanol for 20 minutes respectively. After blowing dry with nitrogen gas, put it into an oven at 120° C. and bake for 30 minutes to obtain a clean ITO substrate.

[0059] Step 2) dissolve the lead iodide of 236.93mg, the methyl ammonium iodide of 81.18mg, the lead bromide of 62.87mg, the methyl ammonium bromide of 19.01mg in the ionic liquid methyl ammonium acetate, stir at 60 ℃ for 12 Hour.

[0060] Step 3) Dissolve 73.2 mg of Spiro-OMeTAD in 1 mL of chlorobenzene; dissolve 520 mg of lithium salt in 1 mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com