ZnO-based transparent conductive film co-doped with Al-F and preparation method thereof

A transparent conductive film and co-doping technology, which is applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of difficult preparation of high-quality target materials, volatile, complex process, etc., to improve conductivity and visible light transmittance, good crystal orientation, simple coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

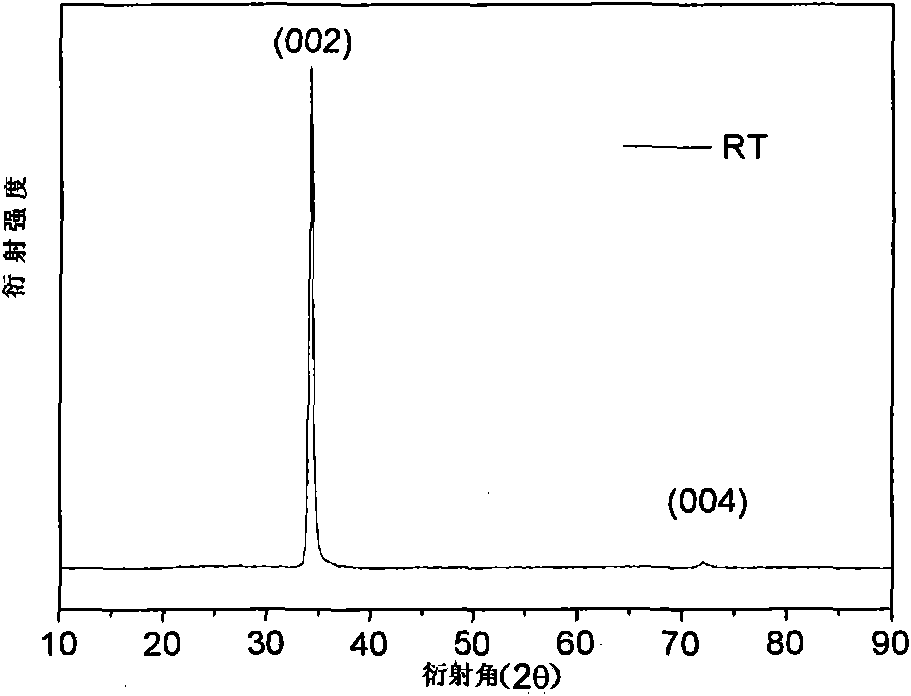

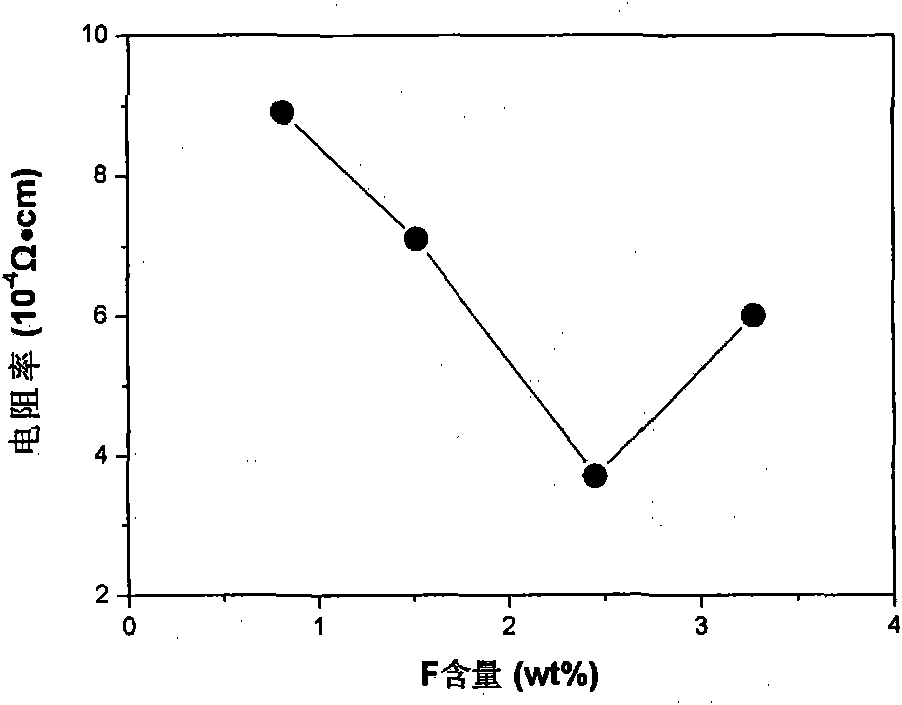

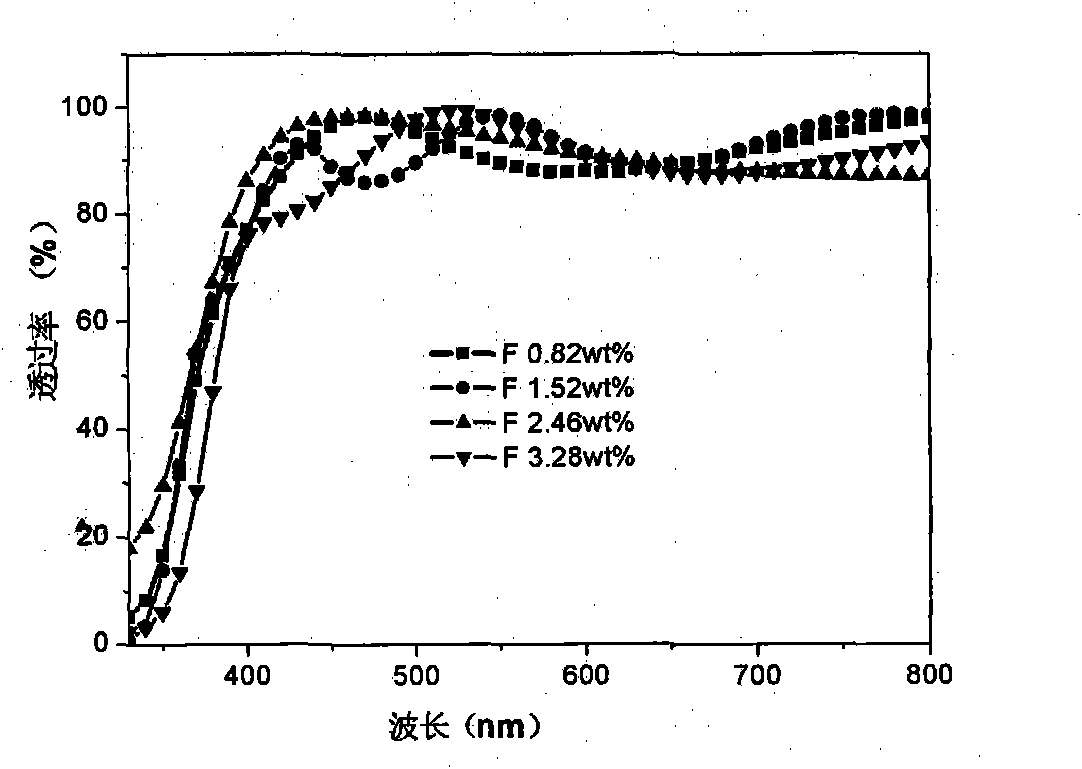

[0019] Al and F co-doped n-type transparent conductive zinc oxide films were prepared, and the F content in the films was 2.46wt%.

[0020] 1. Prepare the ZAFO target material, select the ZAFO target material of Φ50mm×4mm, the target material uses 3.62wt% AlF 3 +0.75wt%Al 2 o 3 and ZnO powder, the target contains 1.55wt% Al and 2.46wt% F;

[0021] 2. Install the co-doped ZAFO target made in step 1 in the vacuum chamber of the radio frequency magnetron sputtering deposition equipment, and use a mechanical pump and a molecular pump to pump the vacuum of the vacuum chamber to 5×10 -4 Pa, the substrate is heated to a temperature of 300°C;

[0022] 3. Radio frequency magnetron sputtering coating, by adjusting the process parameters, using radio frequency magnetron sputtering to prepare ZAFO transparent conductive film on the substrate.

[0023] Deposition process parameters: the vacuum degree of the vacuum chamber is 5×10 -4 Pa; the sputtering atmosphere is high-purity Ar gas,...

Embodiment 2

[0027] An Al and F co-doped n-type transparent conductive zinc oxide film is prepared, and the F content in the film is 3.28wt%.

[0028] 1. Prepare the ZAFO target material, select the ZAFO target material of Φ50mm×4mm, the target material uses 4.83wt% AlF 3 and ZnO powder, the target contains 1.55wt% Al and 3.28wt% F;

[0029] 2. Install the co-doped ZAFO target made in step 1 in the vacuum chamber of the radio frequency magnetron sputtering deposition equipment, and use a mechanical pump and a molecular pump to pump the vacuum of the vacuum chamber to 5×10 -4 Pa, the substrate is heated to a temperature of 400°C;

[0030] 3. Radio frequency magnetron sputtering coating, by adjusting the process parameters, using radio frequency magnetron sputtering to prepare ZAFO transparent conductive film on the substrate.

[0031] Deposition process parameters: the vacuum degree of the vacuum chamber is 5×10 -4 Pa; the sputtering atmosphere is high-purity Ar gas; the flow rate is 30s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com