Method for loading platinum on heteroatom-doped carbon nanohorn, catalyst and application of catalyst

A carbon nanohorn and heteroatom technology, which is applied in the field of catalytic material preparation, can solve the problems of difficulty in obtaining unique structure carbon nanohorn supporting platinum, complicated processing steps, low doping amount of heteroatoms, etc., and achieves low production cost and simple equipment. , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

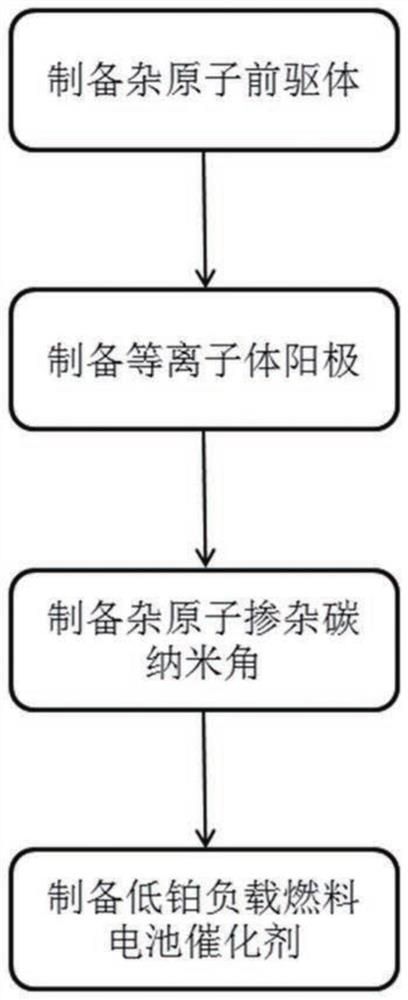

[0073] (1) Preparation of heteroatom precursor: Mix sulfur element and graphite powder in a mass ratio of 1:5, and mix for 20 min.

[0074] (2) Preparation of plasma anode: The heteroatom precursor in step (1) is poured into a graphite rod with a hole diameter of 4 mm, and compacted with a rod with a diameter equal to the hole diameter.

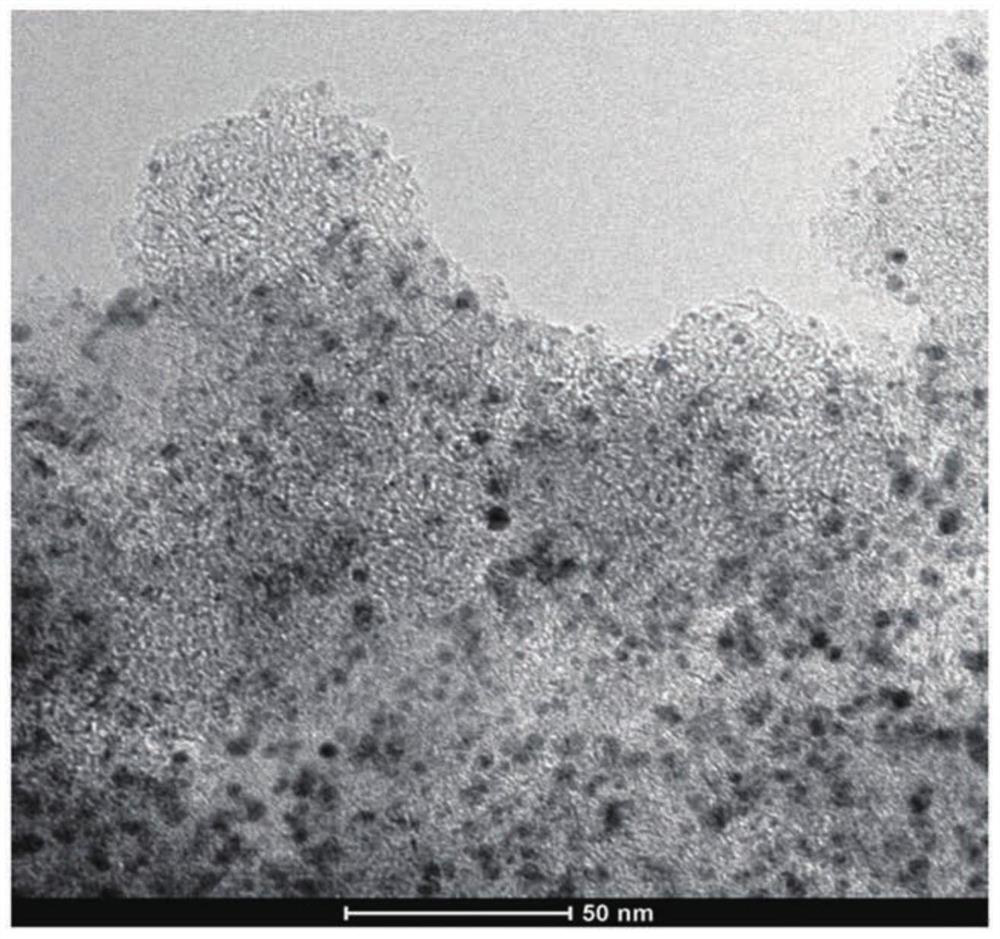

[0075] (3) Preparation of heteroatom-doped carbon nanohorns: the anode material in step (2) is placed in a plasma furnace as an anode, a graphite rod with one end sharpened as a cathode, and plasma treatment is performed under a nitrogen atmosphere of 70kPa . The working current is 200A. Finally, stand for 1 h, collect the product, and obtain nitrogen-sulfur atom-doped carbon nanohorns.

[0076] (4) Preparation of heteroatom-doped carbon nanohorns loaded with platinum: disperse the heteroatom-doped carbon nanohorns in 40 ml of ethylene glycol solution, stir for 15 min, and then add 1 ml of 0.05 mol·L -1 chloroplatinate ethylene glycol solu...

example 2

[0079] (1) Preparation of heteroatom precursor: Cetyltrimethylammonium chloride (CATC) and graphite powder were mixed in a mass ratio of 1:3 for 30 min.

[0080] (2) Preparation of plasma anode: The heteroatom precursor in step (1) is poured into a graphite rod with a hole diameter of 3 mm, and compacted with a rod with a diameter equal to the hole diameter.

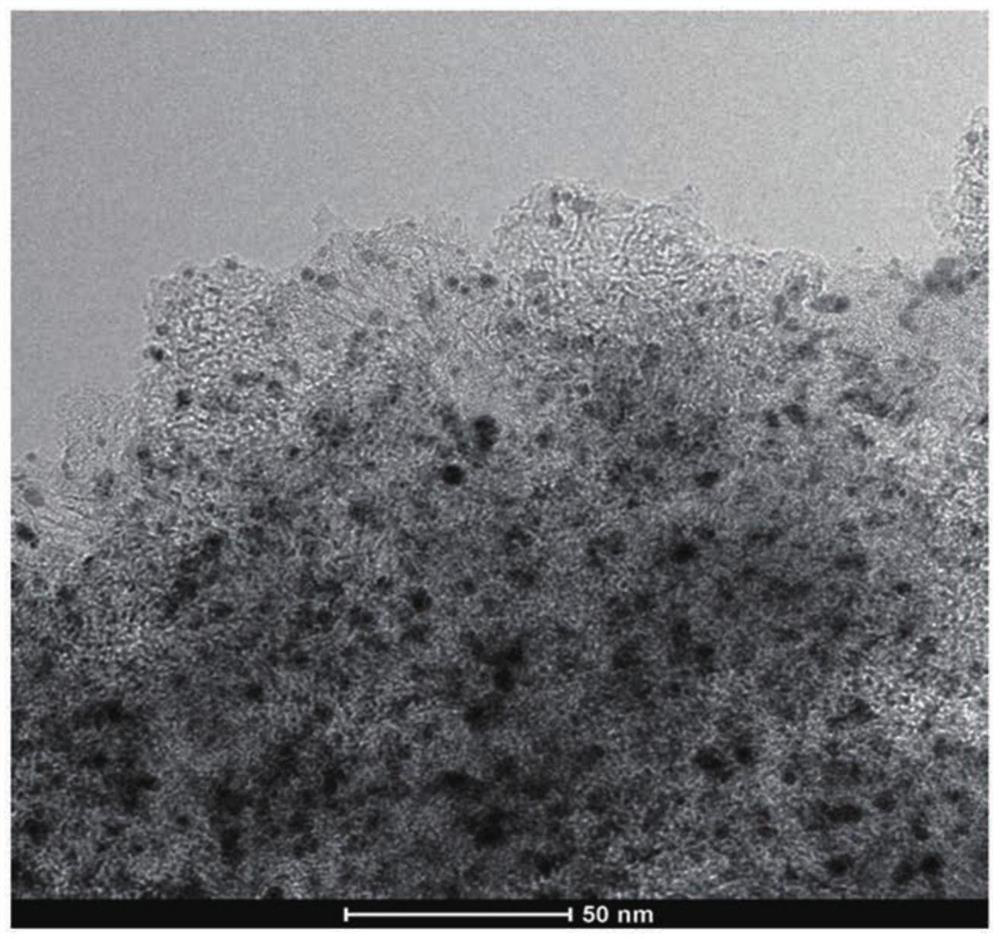

[0081] (3) Preparation of heteroatom-doped carbon nanohorns: the anode material in step (2) is placed in a plasma furnace as an anode, and a graphite rod sharpened at one end is used as a cathode, and plasma treatment is performed under a nitrogen atmosphere of 80kPa . The working current is 200A. Finally, after standing for 1 h, the product was collected to obtain carbon nanohorn doped with nitrogen and chlorine atoms.

[0082] (4) Preparation of heteroatom-doped carbon nanohorns loaded with platinum: disperse the heteroatom-doped carbon nanohorns in 40 ml of ethylene glycol solution, stir for 10 min, and then add 1 m...

example 3

[0085] (1) Preparation of heteroatom precursor: polyvinylidene fluoride (PVDF) and graphite powder were mixed in a mass ratio of 1:3 for 20 min.

[0086] (2) Preparation of plasma anode: The heteroatom precursor in step (1) is poured into a graphite rod with a hole diameter of 4 mm, and compacted with a rod with a diameter equal to the hole diameter.

[0087] (3) Preparation of heteroatom-doped carbon nanohorns: the anode material in step (2) is placed in a plasma furnace as an anode, a graphite rod with one end sharpened as a cathode, and plasma treatment is performed under a nitrogen atmosphere of 70kPa . The working current is 180A. Finally, it was left to stand for 1 h, and the products were collected to obtain carbon nanohorns co-doped with nitrogen and fluorine atoms.

[0088] (4) Preparation of heteroatom-doped carbon nanohorns loaded with platinum: disperse the heteroatom-doped carbon nanohorns in 40 ml of ethylene glycol solution, stir for 15 min, and then add 0.5 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com