A kind of precursor and the method and application of preparing carbon nanomaterial

A carbon nanomaterial and precursor technology, applied in the field of nanomaterials, can solve the problems of large volume expansion rate of iron oxide, complex preparation method, poor cycle performance, etc., and achieve the effects of high versatility, simplified synthesis process, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Preparation of carbon nanomaterials

[0050]Dissolve 5.0g of ethylene glycol citrate, 2.0g of carboxymethylcellulose ammonium, and 5.0g of ferric nitrate nonahydrate in 100mL of water, stir evenly, and concentrate the liquid to 8mL at 120°C. Then the mixed gel-like liquid was placed in a 300 mL cylindrical ceramic crucible with a cover, and the crucible was placed in a constant temperature furnace at 300° C., and taken out after 5 minutes to obtain carbon nanomaterials.

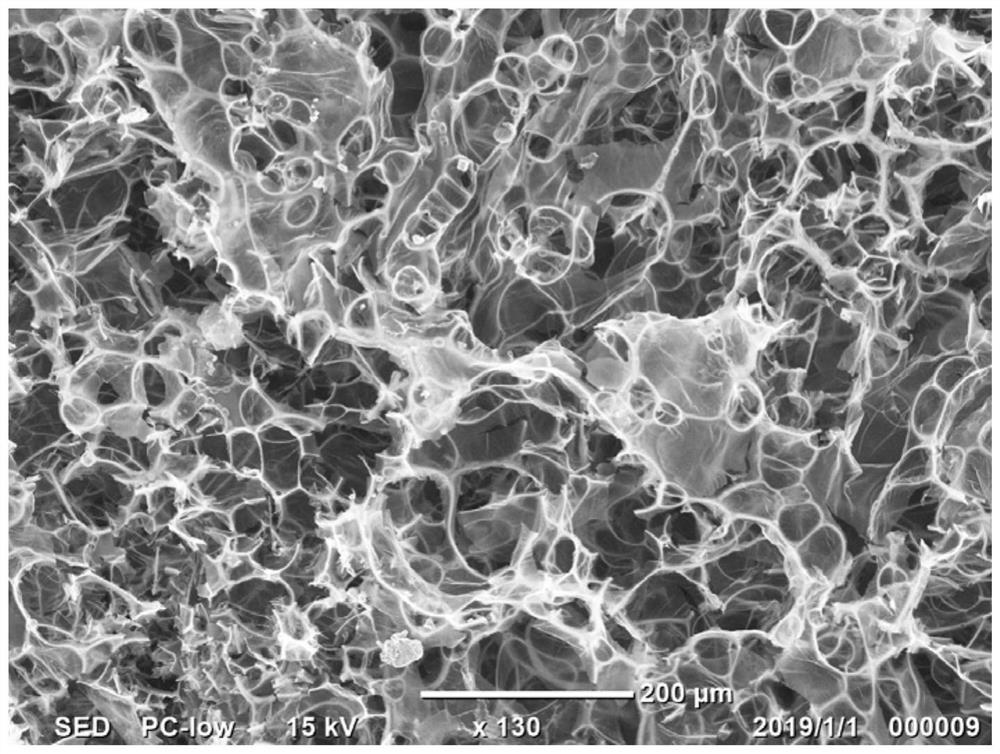

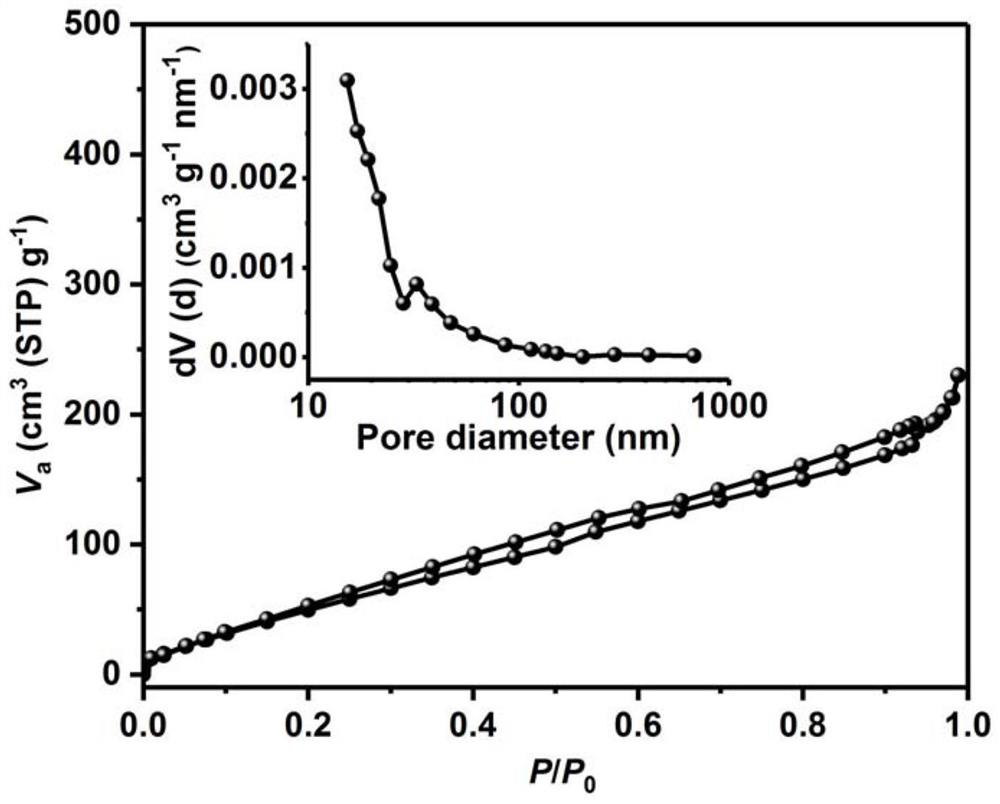

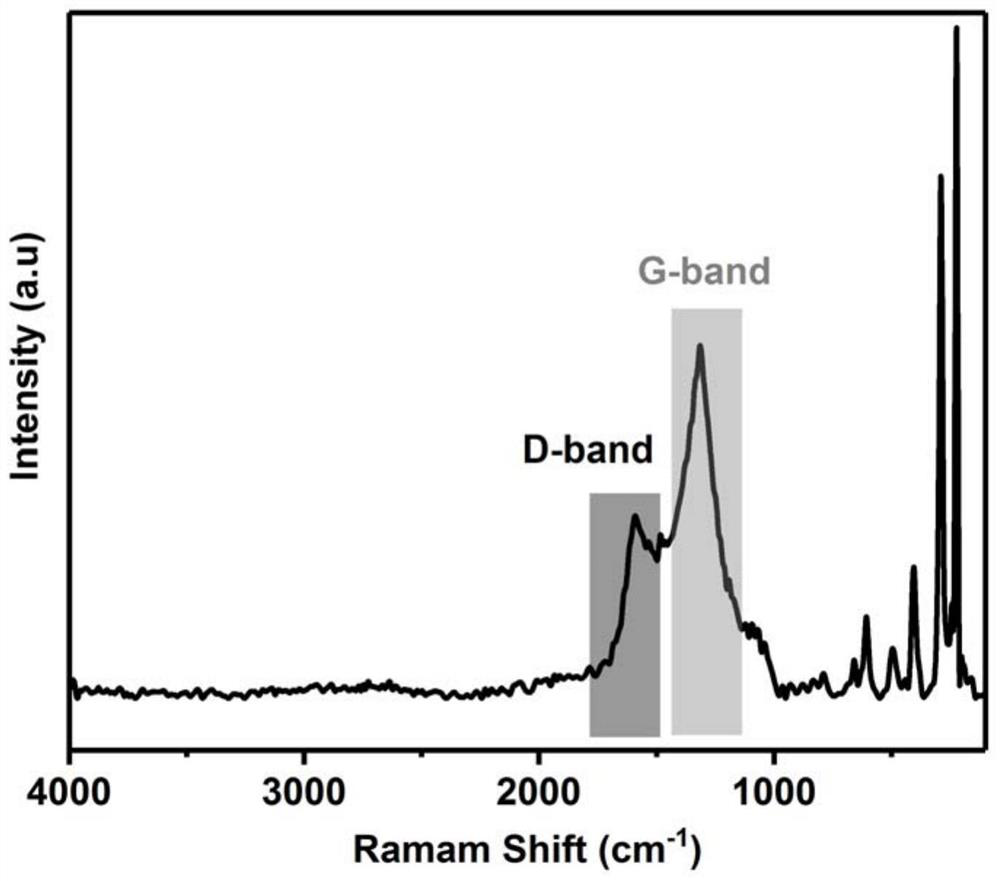

[0051] After testing by the applicant, the SEM photos of the obtained carbon nanomaterials are as follows: figure 1 Shown, N 2 The adsorption-desorption curve and pore size distribution are as follows: figure 2 As shown, the Raman spectrum is shown as image 3 shown. It can be seen from the figure that the obtained carbon nanomaterial is a porous material composed of carbon nanofibers and carbon nanosheets, and its Brunauer–Emmett–Teller (BET) specific surface area is 202.5m 2 / g, which is at ...

Embodiment 2

[0057] 1. Preparation of carbon nanomaterials

[0058] Dissolve 5.0g of ethylene glycol citrate, 1.0g of carboxymethylcellulose ammonium, and 5.0g of manganese nitrate tetrahydrate in 50mL of water, stir evenly, and concentrate the liquid to 10mL at 120°C. Then the mixed gel-like liquid was placed in a 300 mL cylindrical ceramic crucible with a cover, and the crucible was placed in a constant temperature furnace at 350° C., and was taken out after 3 minutes to obtain a carbon nanomaterial.

[0059] After testing by the applicant, the SEM photos of the obtained carbon nanomaterials are as follows: Figure 4 Shown, N 2 The adsorption-desorption curve and pore size distribution are as follows: Figure 5 As shown, the Raman spectrum is shown as Image 6 shown. It can be seen from the figure that the obtained carbon nanomaterial is a porous material composed of carbon nanofibers and carbon nanosheets, and its BET specific surface area is 282.9m 2 / g, which is at 1360cm -1 and...

Embodiment 3

[0065] 1. Preparation of carbon nanomaterials

[0066] Dissolve 5.0g of ethylene glycol citrate, 1.0g of carboxymethylcellulose lithium, and 8.0g of nickel nitrate hexahydrate in 50mL of water, stir well, and concentrate the liquid to 10mL at 120°C. Then the mixture was placed in a 300mL cylindrical ceramic crucible with a cover, and the crucible was placed in a constant temperature furnace at 400°C, and it was taken out after 2 minutes.

[0067] After testing by the applicant, the SEM photos of the obtained carbon nanomaterials are as follows: Figure 7 Shown, N 2 The adsorption-desorption curve and pore size distribution are as follows: Figure 8 As shown, the Raman spectrum is shown as Figure 9 shown. It can be seen from the figure that the obtained carbon nanomaterial is a porous material composed of carbon nanofibers and carbon nanosheets, and its BET specific surface area is 350.6m 2 / g, which is at 1360cm -1 and 1589cm -1 Two distinct Raman peaks are shown, belo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com