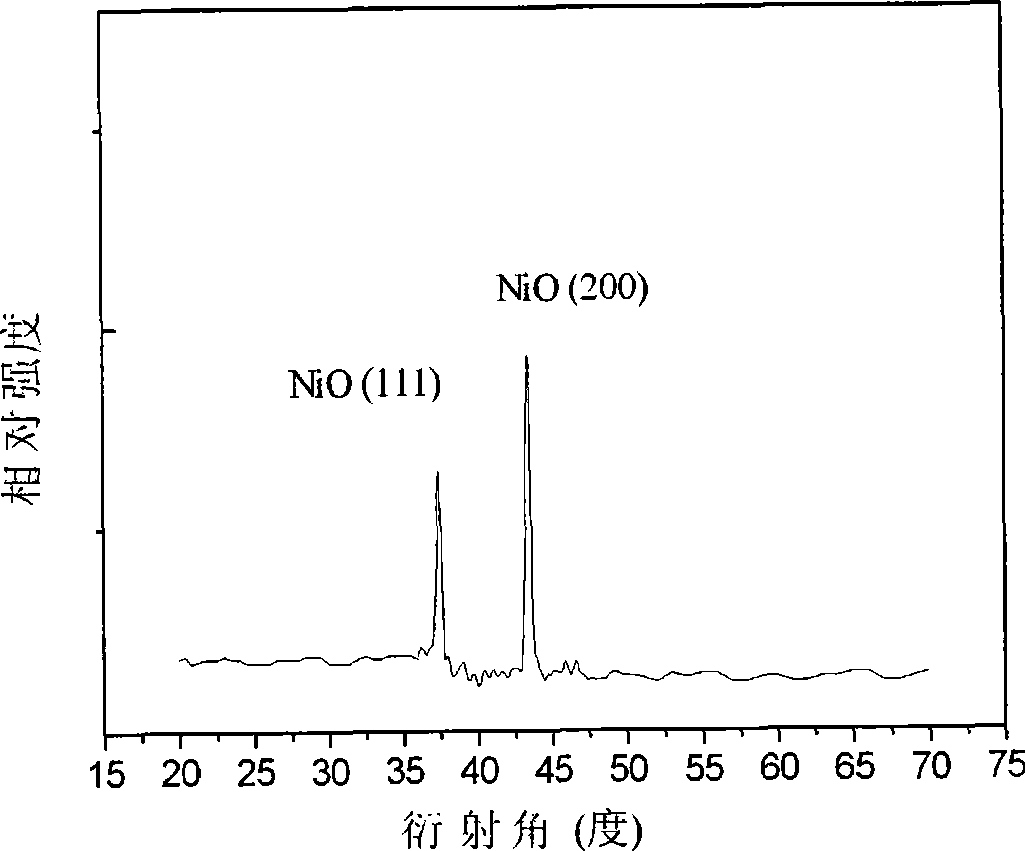

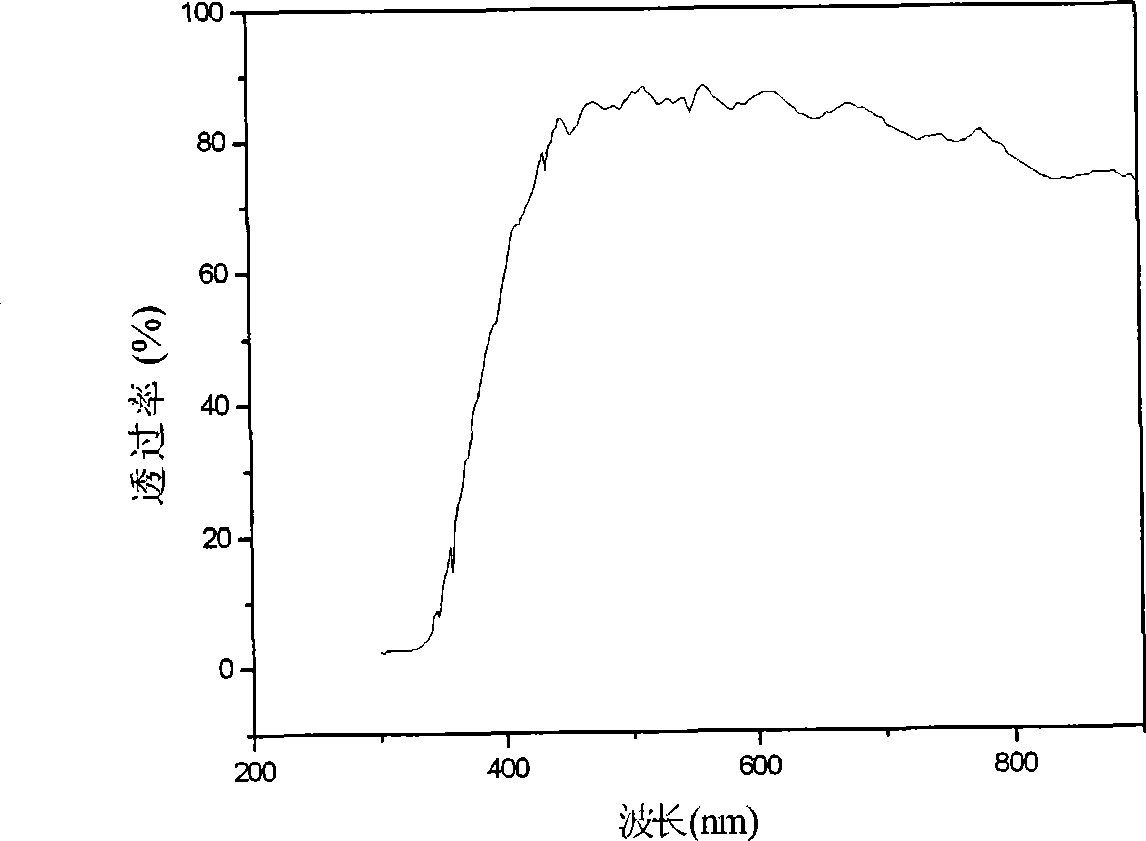

Method for preparing NiO transparent conductive film by two steps

A technology of transparent conductive film and film, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problem of reducing the conductivity and optical transmittance of NiO transparent conductive film, and the carrier mobility in the film Reduced, many film defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] After cleaning the substrate, put it into a magnetron sputtering vacuum chamber, and adjust the distance between the Ni target and the substrate within the range of 5-10 cm. Then the Ni film is prepared by sputtering the Ni target, the sputtering time is 30-60 minutes, the sputtering power is 100-200W, the substrate is always kept at the same temperature, that is, a certain temperature in the range of 25-500°C, and the sputtering gas is a single Argon. Then, the substrate coated with the Ni film is placed in a high-temperature oxidation furnace, and oxygen is introduced at a flow rate of 5-15 l / min. The temperature of the high-temperature oxidation furnace is raised to a temperature in the range of 500-1200°C at a heating rate of 3-8°C / min, the thermal oxidation time is 30-180 minutes, and then the high temperature is lowered at a cooling rate of 2-8°C / min. The temperature of the oxidation furnace is lowered to room temperature.

[0008] Below is a specific example. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com