Polyimide film and graphite film

A technology of polyimide film and diamine monomer, which is applied in the direction of inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of graphite film thermal conductivity and unsatisfactory mechanical properties, and achieve increased molecular weight accumulation force and thermal conductivity Excellent mechanical properties and high birefringence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

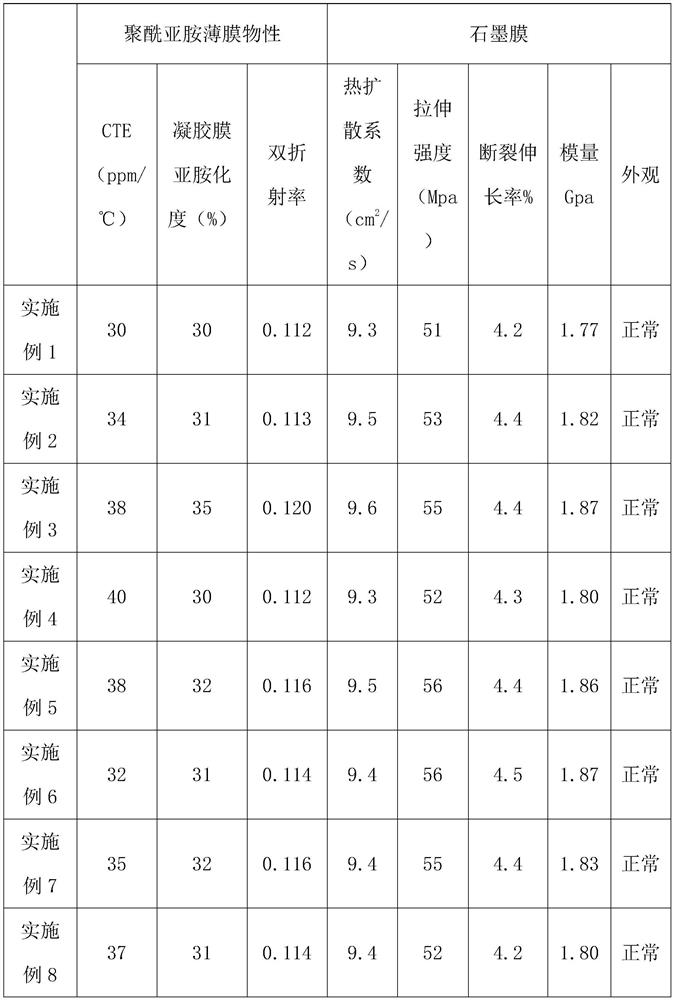

Examples

preparation example Construction

[0023] About the preparation of polyimide film

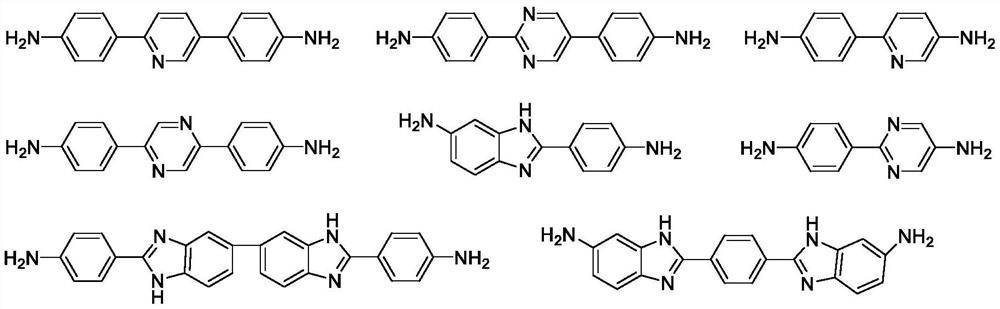

[0024] The raw materials used in the synthesis of the polyimide of the present invention include pyromellitic dianhydride (PMDA), 4,4'-diaminodiphenyl ether (ODA) and at least one second diamine monomer. The second diamine monomer is a nitrogen-containing heterocyclic diamine monomer. The nitrogen-containing heterocyclic diamine monomer is selected from diamine monomers containing imidazole, pyridine, pyrazine or pyrimidine structures.

[0025] The diamine monomer containing imidazole structure is selected from 2-(4-aminophenyl)-5-aminobenzimidazole, 2,2'-bis(4-aminophenyl)-5,5'-bisbenzone One or both of imidazole and 1,4-bis(5'-aminobenzimidazole-2'-)benzene; the diamine monomer containing pyridine structure is selected from 2,5-bis(4-aminophenyl ) pyridine or 2-(4-aminophenyl)-5-aminopyridine; the diamine monomer containing pyrimidine structure is selected from 2,5-bis(4-aminophenyl)pyrimidine or 2-(4-aminophenyl )-5-pyrimi...

Embodiment 1

[0043] Polyimide film:

[0044] 4,4'-diaminodiphenyl ether, pyromellitic dianhydride, 2-(4-aminophenyl)-5-aminobenzimidazole, according to the molar ratio of 90:100:10, in N, N - in dimethylacetamide, react while stirring, and react at 40°C for 4h to obtain a polyamic acid slurry with a solid content of 20%;

[0045] The filler calcium hydrogen phosphate, with an average particle size of 3 μm, was added to N,N-dimethylacetamide, and dispersed by high-speed stirring to prepare a solid content of 10% calcium hydrogen phosphate slurry; the filler ferric oxide, with an average particle size of 3 μm, Adding N, N-dimethylacetamide, using high-speed stirring to disperse, and preparing ferric oxide slurry with a solid content of 10%;

[0046] Add the calcium hydrogen phosphate slurry and the ferric oxide slurry to the prepared polyamic acid slurry, control the filler content in the calcium hydrogen phosphate slurry to be 0.5% of the solid weight of the polyimide film material, and th...

Embodiment 2

[0050] 4,4'-diaminodiphenyl ether, pyromellitic dianhydride, 1,4-bis(5'-aminobenzimidazole-2'-)benzene in a molar ratio of 90:100:10, in N , in N-dimethylacetamide, react while stirring, and react at 40° C. for 4 hours to obtain a polyamic acid resin solution with a solid content of 20%. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com