Patents

Literature

316 results about "Pyromellitic acid dianhydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

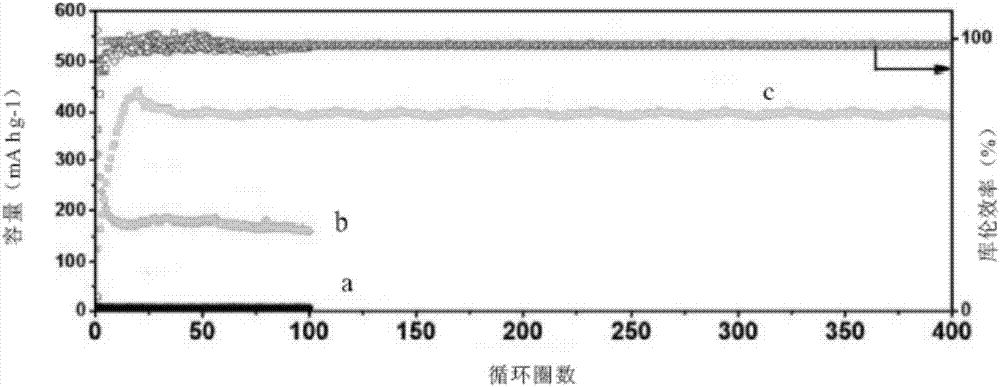

Preparation method and application of perylene diimide and graphene composite material

InactiveCN106876674AHigh specific capacityImprove cycle stabilityCell electrodesSecondary cellsEthylenediamineCyclic process

The invention belongs to the preparation field of a positive electrode material of a rechargeable battery, and particularly relates to a preparation method and an application of a perylene diimide and graphene oxide composite material. The preparation method for the perylene diimide and graphene oxide composite material comprises the steps of performing synthesizing on perylene-3,4,9,10-tetracarboxylic dianhydride and N, N-dimethyl-1, 2-ethylenediamine to prepare perylene diimide; performing a solvent thermal reaction on graphene oxide and perylene diimide to obtain a composite material precursor; and performing heat treatment on the composite material precursor in a protective gas to obtain the perylene diimide and graphene composite material. The composite material disclosed by the invention can be applied to a lithium ion battery as well as a novel sodium ion battery, so that the application field of the composite material is expanded; compared with solvent thermal compounding, the specific capacity of the composite material can be further improved after heat treatment; and in addition, the cycling process is higher in stability without obvious attenuation.

Owner:SHANGHAI JIAO TONG UNIV

Polyimide film, method of manufacture, and metal interconnect board with polyimide film substrate

InactiveUS6908685B2Synthetic resin layered productsWood working apparatusMetal interconnectFlexible circuits

The invention provides a polyimide film manufactured from a polyamic acid prepared from pyromellitic dianhydride in combination with 10 to 60 mol % of phenylenediamine and 40 to 90 mol % of 3,4′-oxydianiline, based on the overall diamine. The polyimide film, when used as a metal interconnect board substrate in flexible circuits, chip scale packages (CSP), ball grid arrays (BGA) or tape-automated bonding (TAB) tape by providing metal interconnects on the surface thereof, achieves a good balance between a high elastic modulus, a low thermal expansion coefficient, alkali etchability and film formability.

Owner:DUPONT TORAY CO LTD +1

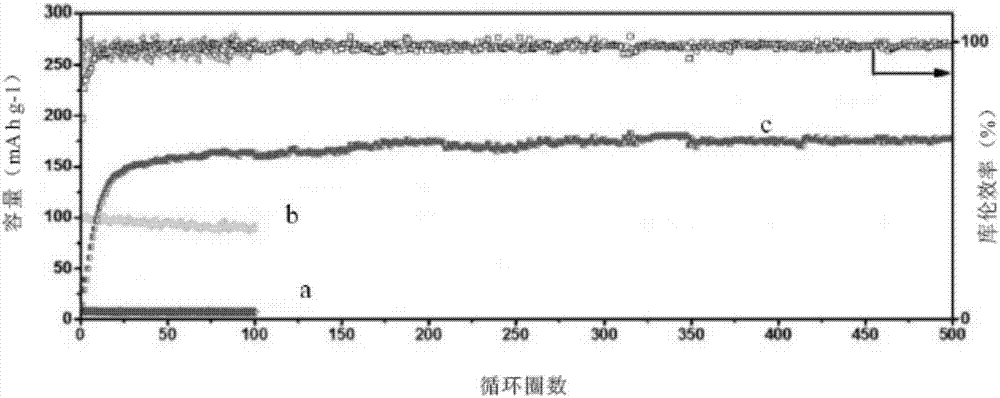

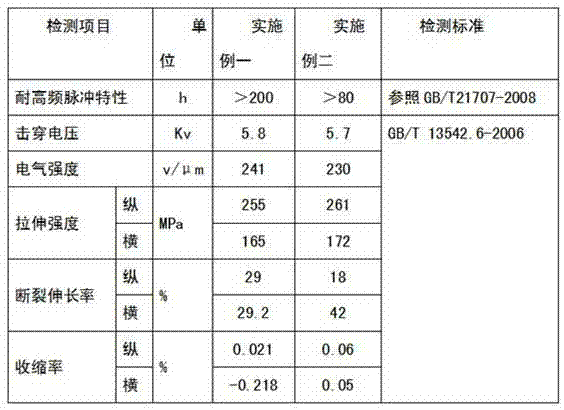

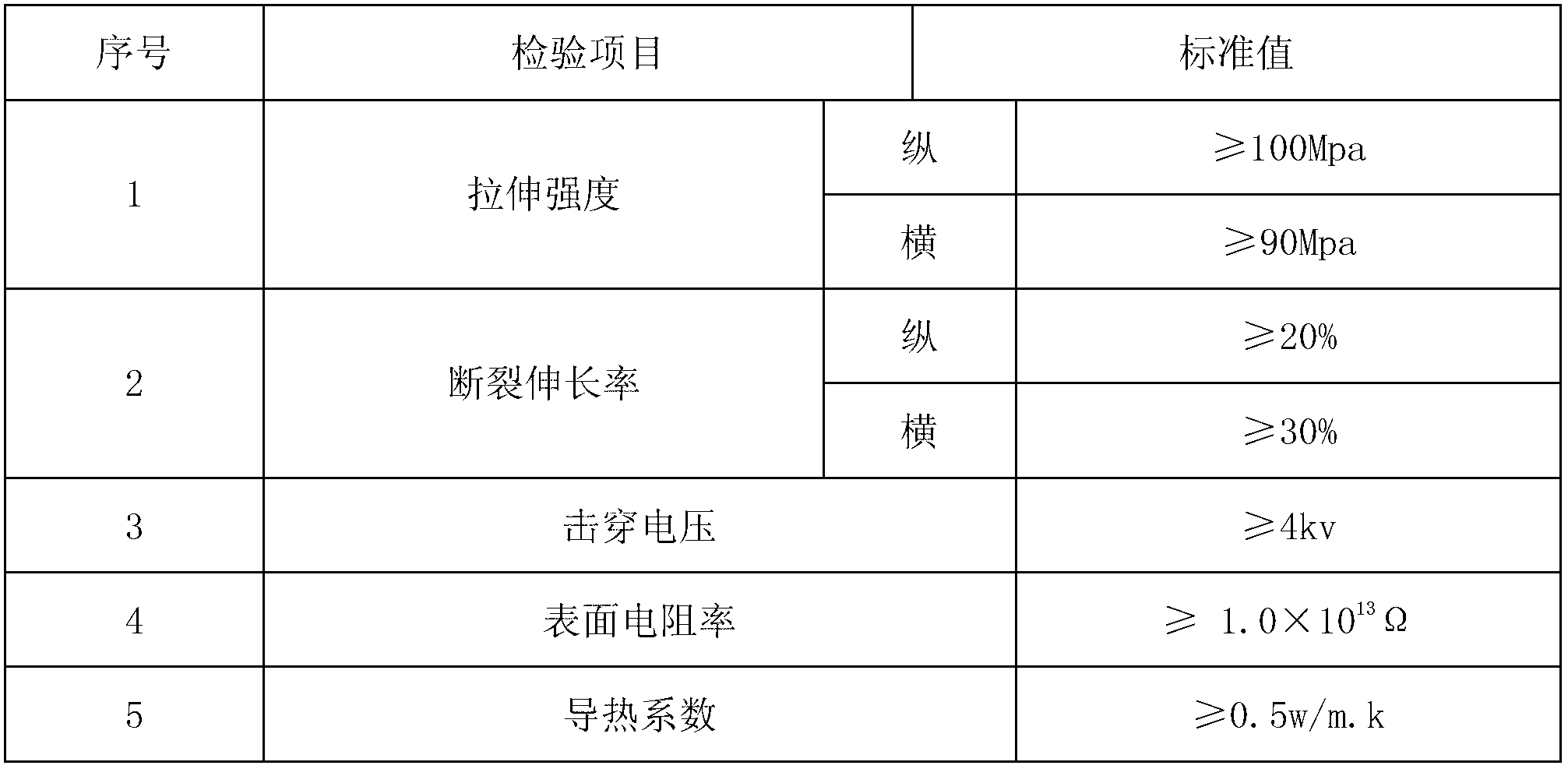

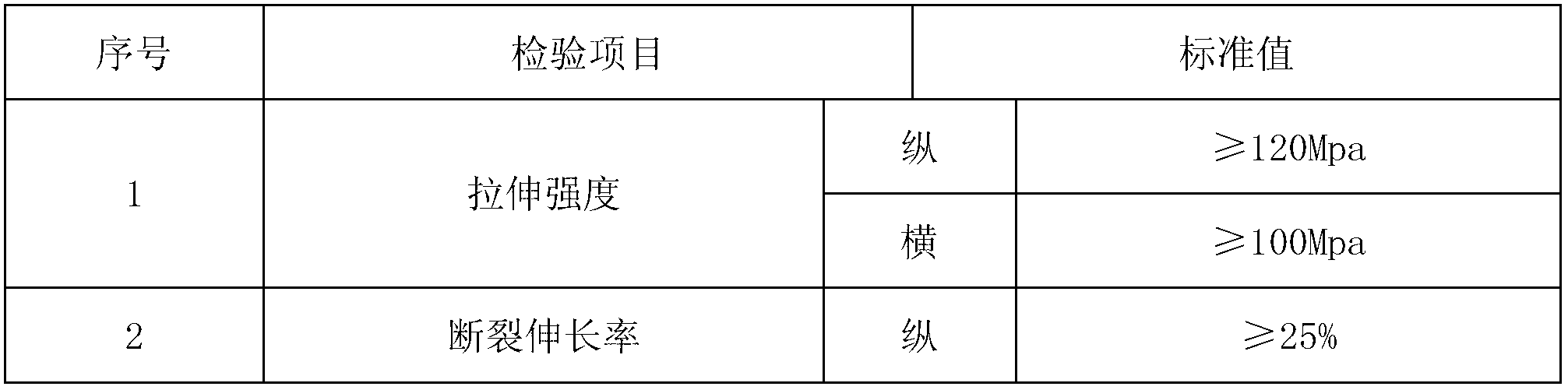

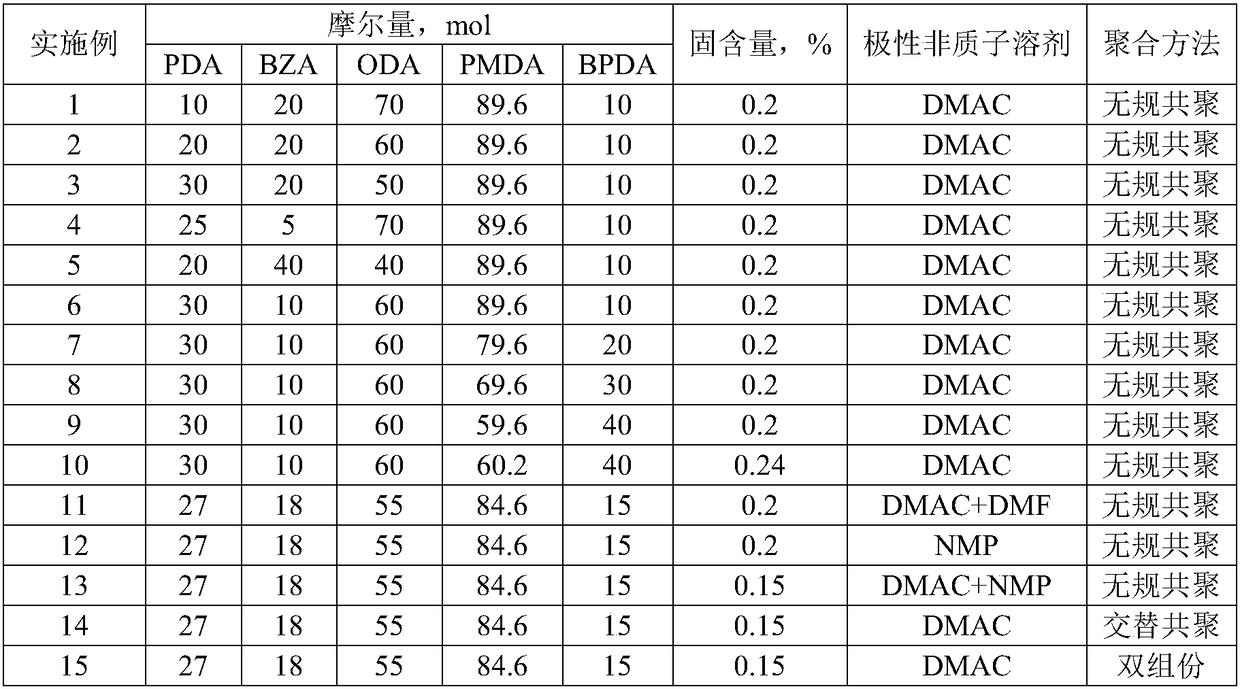

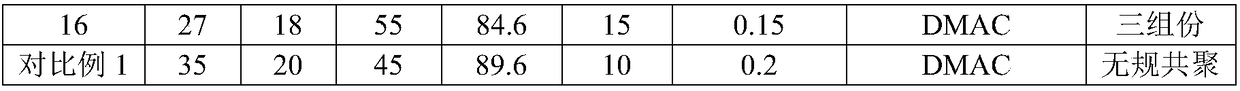

Biaxially oriented polyimide film for flexible printed circuit board base material and preparation method of biaxially oriented polyimide film

ActiveCN102391532AGood chemical propertiesMeet the requirementsCoatingsDiaminodiphenyl etherEngineering

The invention relates to a biaxially oriented polyimide film for flexible printed circuit board base material and a preparation method of the biaxially oriented polyimide film. The method is characterized by mainly comprising the following steps of: (1) polymerizing: preparing a basic solution of polyimide acid according to the following proportions: 1-5% of p-phenylenediamine, 2-8% of biphenyltetracarboxylic dianhydride, 5-10% of diaminodiphenyl ether, 8-15% of pyromellitic dianhydride and 62-84% of dimethylacetylamide; (2) salivating the solution into a film; (3) longitudinally stretching the film according to the stretching ratio of 1:1.02-1.15; (4) transversely stretching the film according to the stretching ratio of 1:1.05-1.2 and carrying out imidization; (5) cutting the edge and rolling up the film; (6) postprocessing the film; and (7) cutting and packaging the film. The special biaxially oriented polyimide film material conforming to the flexible printed circuit board base material can be obtained by using the preparation method provided by the invention.

Owner:朱宏清

Preparation method of graphene/polyimide composite material

InactiveCN105820569AEnhanced interface bindingImprove mechanical propertiesCell component detailsMeth-Diaminodiphenyl ether

The invention discloses a preparation method of a graphene / polyimide composite material, belonging to the technical field of composite materials. The preparation method comprises the following steps: performing ultrasonic dispersion of graphene oxide in a dimethyl sulfoxide solvent to obtain graphene oxide dispersion; crosslinking and coupling the graphene with 2-vinyl-5-aminothiophenol under the effect of a coupling agent vinyldimethoxysilane and a crosslinking agent N,N-methylene bisacrylamide to obtain modified graphene containing mercapto, carbon-carbon double bond and amino cross-linkable groups; condensing 4,4-diaminodiphenyl ether and pyromellitic dianhydride to obtain polyamide acid; and crosslinking the modified graphene containing different cross-linkable groups with polyamide acid to obtain a modified graphene / polyimide composite material. In the invention, the interface bonding between graphene and polyimide matrix is strong, the compatibility with a polymer is good, and the mechanical properties of the material are improved.

Owner:CHANGZHOU DAAO NEW MATERIAL TECH CO LTD

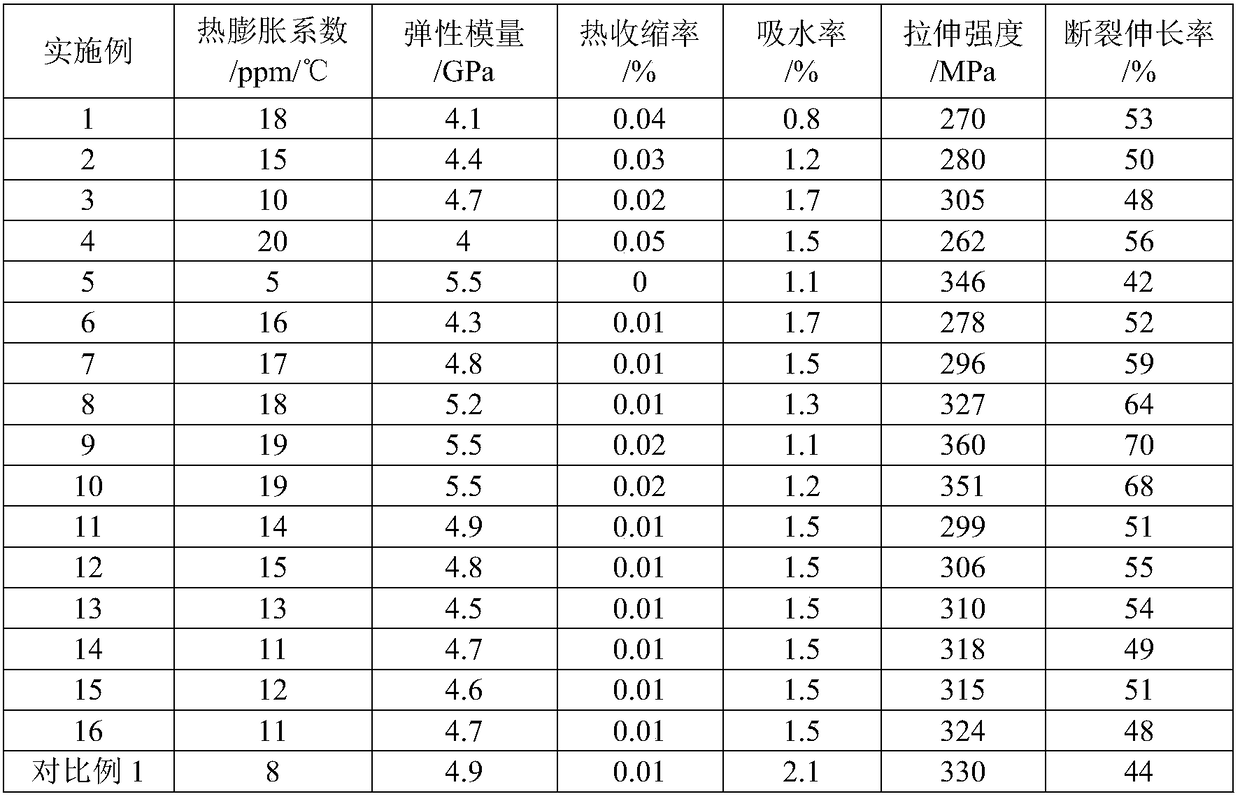

Stable dimension type polyimide film and preparation method thereof

The invention discloses a dimension stable polyimide film, which contains the following components: component A: copolymer of biphenyl tetracarboxylic acid dianhydride, pyromellitic dianhydride and p-phenylenediamine in dimethyl acetamide solvent; component B: copolymer of pyromellitic dianhydride and p-phenylenediamine in dimethyl acetamide solvent; copolymer of pyromellitic dianhydride and p-phenylenediamine, 4, 4'-diaminodiphenyl ether in dimethyl acetamide solvent; wherein, the weight percent of the component A is 20 to 50 percent; the weight percent of the component B is 5 to 20 percent; the weight percent of the component C is 30 to 60 percent; the invention also discloses a preparation method of the dimension stable polyimide film. The dimension stable polyimide film of the invention has high tensile elastic modulus, low thermal expansion coefficient, low shrinkage rate and good dimensional stability, and is mainly used as a substrate of flexible circuit FPC and achieves high performance of FPC.

Owner:无锡高拓新材料股份有限公司

Catalyst and preparation method thereof

InactiveCN102319580AHigh selectivityHigh yieldPhysical/chemical process catalystsOrganic chemistryGas phaseToluene

The invention discloses a catalyst for catalyzing in preparation of pyromellitic acid dianhydride from durene. In the catalyst, V2O5-TiO2-P2O5-Sb2O3-MoO3 is taken as a composition system; a major catalyst consists of V2O5 and TiO2 in the ratio of (0.18-0.20):(0.82-0.80); a catalyst accelerator consists of P2O5, Sb2O3 and MoO3; and when the weight of the major catalyst is set as 1, P2O5 accounts for 0.017-0.019, Sb2O3 accounts for 0.036-0.038, and MoO3 accounts for 0.002-0.004. The invention further discloses a preparation method of the catalyst. The catalyst has the characteristics of high selectivity and high yield, and is suitable to be applied to gas-phase oxidation of durene.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Preparation method for graphene-polyimide composite film

ActiveCN103665866AImprove thermal conductivityHigh dielectric constantDiaminodiphenyl etherComposite film

The invention discloses a preparation method for a graphene-polyimide composite film. The preparation method comprises the following steps: adopting graphene and polyamide acid prepared through enabling 4, 4-diaminodiphenyl ether and pyromellitic acid dianhydride to be subjected to polycondensation in a solvent; adding dispersed graphene suspension liquid into the polyamide acid prepared through polycondensation reaction, dispersing circularly for 10-16 hours, adjusting the molar ratio of amine to anhydride in the polyamide acid to (1:0.98)-(1:0.995), and enabling the viscosity to reach 60000 CP-90000 CP, wherein the graphene is 1-15% of the solid content of the polyamide acid; then, defoaming and casting for forming the film; finally, performing imidization, rolling and slitting. According to the graphene-polyimide composite film prepared by the preparation method, the tensile strength is not less than 100 Mpa, the heat-conducting property is not less than 5w / m.k, and the elongation at break is not less than 15%.

Owner:NINGBO JINSHAN NEW MATERIAL

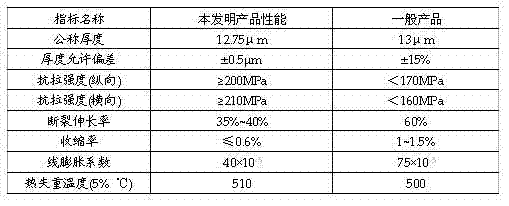

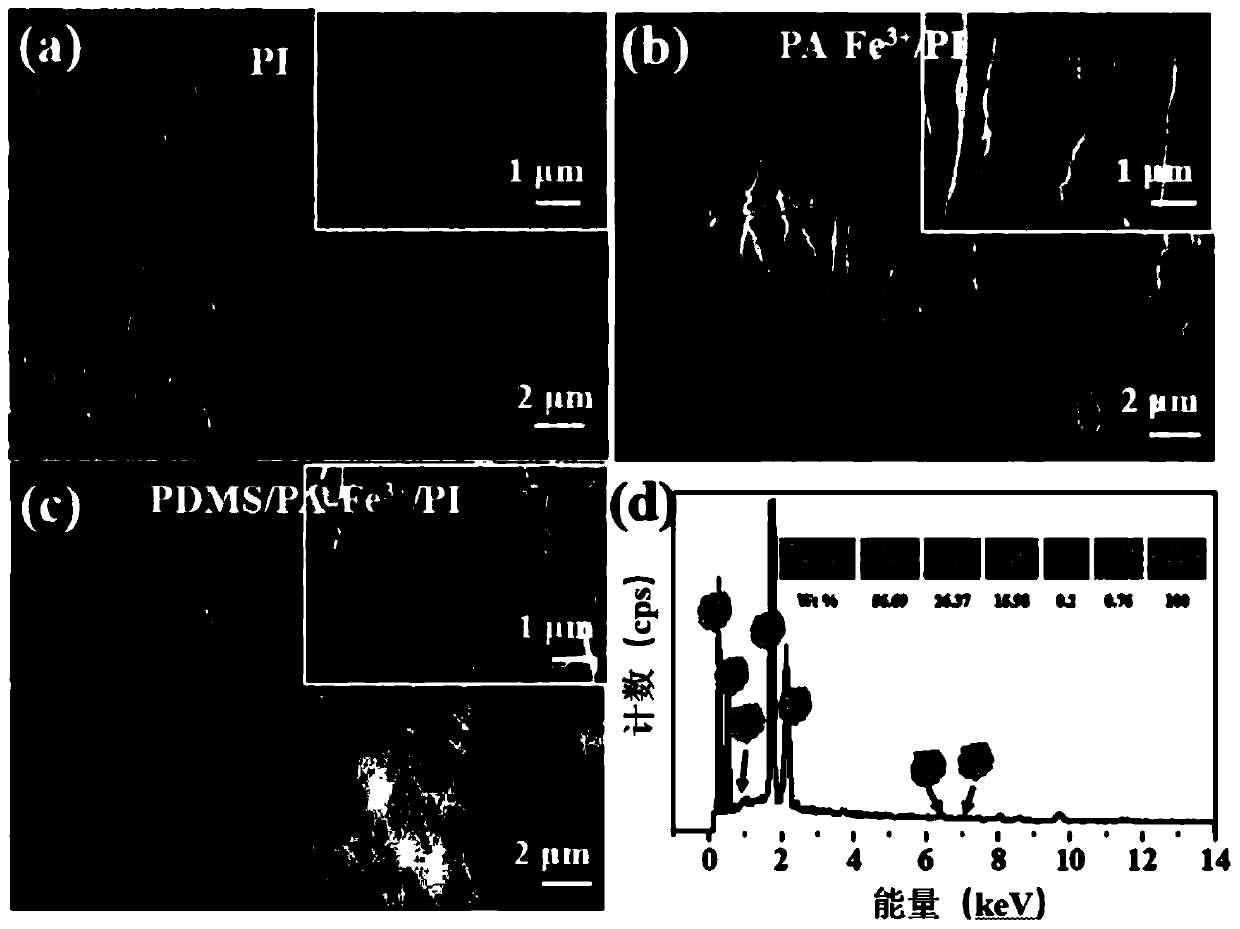

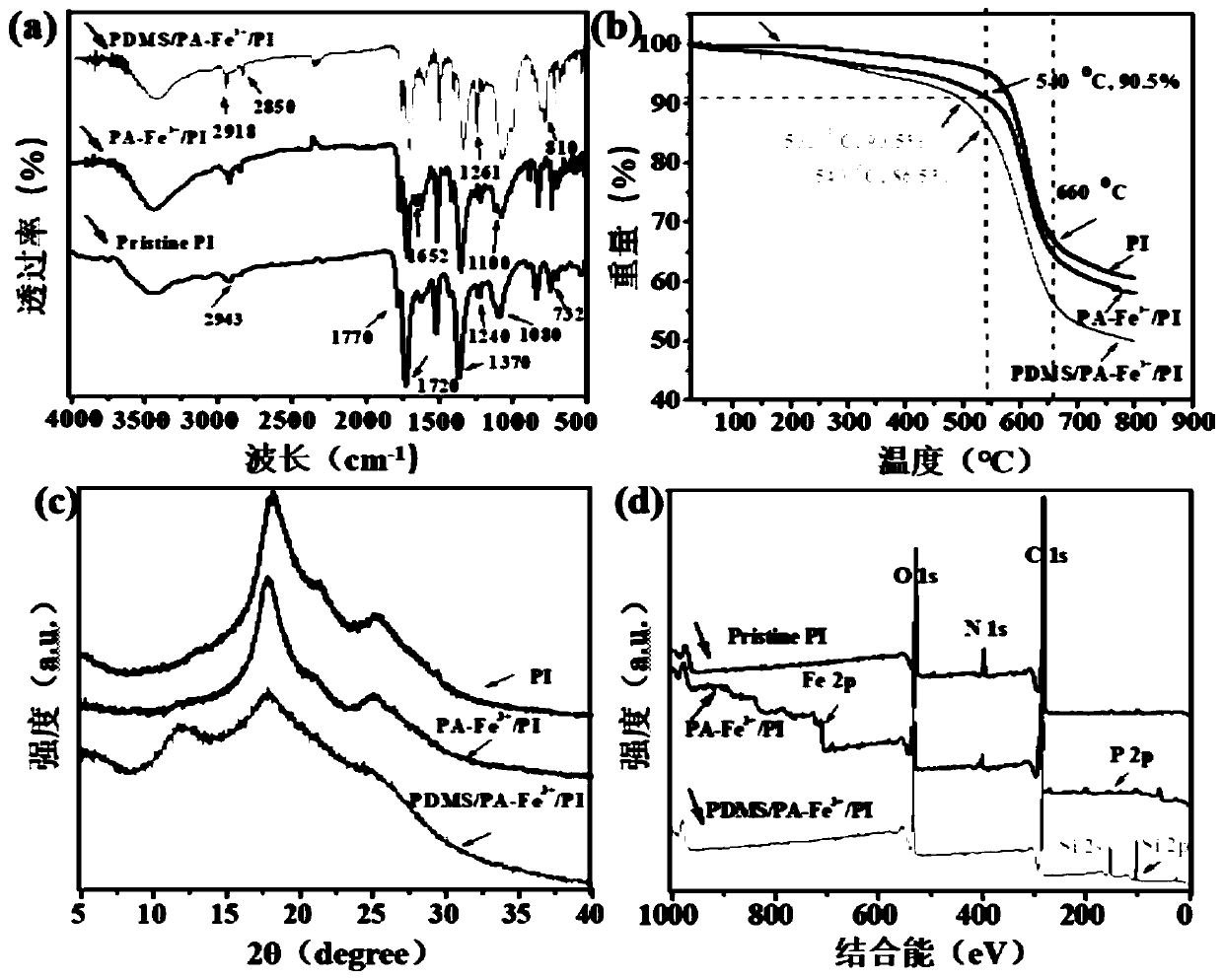

Superhydrophobic nanofiber membrane and preparation method thereof

ActiveCN109731479ASuperhydrophobic and superoleophilic wettabilityEasy to separateSemi-permeable membranesFibre typesN dimethylformamidePhytic acid

The invention discloses a superhydrophobic nanofiber membrane and a preparation method thereof. The superhydrophobic nanofiber membrane comprise the steps of dissolving monomer biphenyl tetracarboxylic dianhydride and p-phenylenediamine in N, N-dimethylformamide, reacting at low temperature to synthesize PAA, preparing a PAA nanofiber membrane from PAA through electrostatic spinning, and then imidizing to obtain a PI membrane; and carrying out layer-by-layer self-assembly by using ferric chloride and phytic acid and carrying out dip-coating modification by using a PDMS solution to obtain the superhydrophobic nanofiber membrane. According to the invention, a layer-by-layer self-assembly structure is utilized, a silane coupling agent is introduced on the basis, and the layer-by-layer self-assembly structure and the silane coupling agent are combined to obtain an oil-water separation membrane with super-hydrophobic and super-oleophilic wettability. A nano structure with a rough surface has improved oil-water separation performance, the separation efficiency of the membrane can reach 99% or above, and by verification, the membrane can be recycled.

Owner:NANJING FORESTRY UNIV

Preparation of pyromellitic dianhydride modified banana peel adsorbent

InactiveCN104289188AGood physical and chemical stabilityGood mechanical strengthOther chemical processesWater contaminantsDimethyl formamideIon

The invention discloses a preparation method and an application of a pyromellitic dianhydride modified banana peel adsorbent, and is characterized in that the preparation method comprises the steps: washing cleanly banana peels, drying, then smashing, and thus obtaining preprocessed banana peels; then, according to the mass percentage concentration, adding 78-92% of N,N-dimethylformamide and 1.0-5% of pyromellitic dianhydride into a reactor, completely dissolving, and then adding 5-18% of the alkalized banana peels, wherein the sum of the percentages of the components is 100%; and at the constant temperature of 70+ / -3 DEG C, carrying out a reflux reaction for 3-6 h, carrying out suction filtration, washing to be neutral, drying, and thus obtaining the pyromellitic dianhydride modified banana peel adsorbent. The adsorbent can directly adsorb lead ions in a water body, is high in adsorption efficiency, has good physicochemical and mechanical stability, can be used in a relatively wide pH range, and can be renewable and be used repeatedly; the banana peels are natural biomacromolecules, are biodegradable, belong to agricultural waste reuse, and is easy to obtain and cheap; and the adsorbent is a natural green adsorbent.

Owner:UNIV OF JINAN

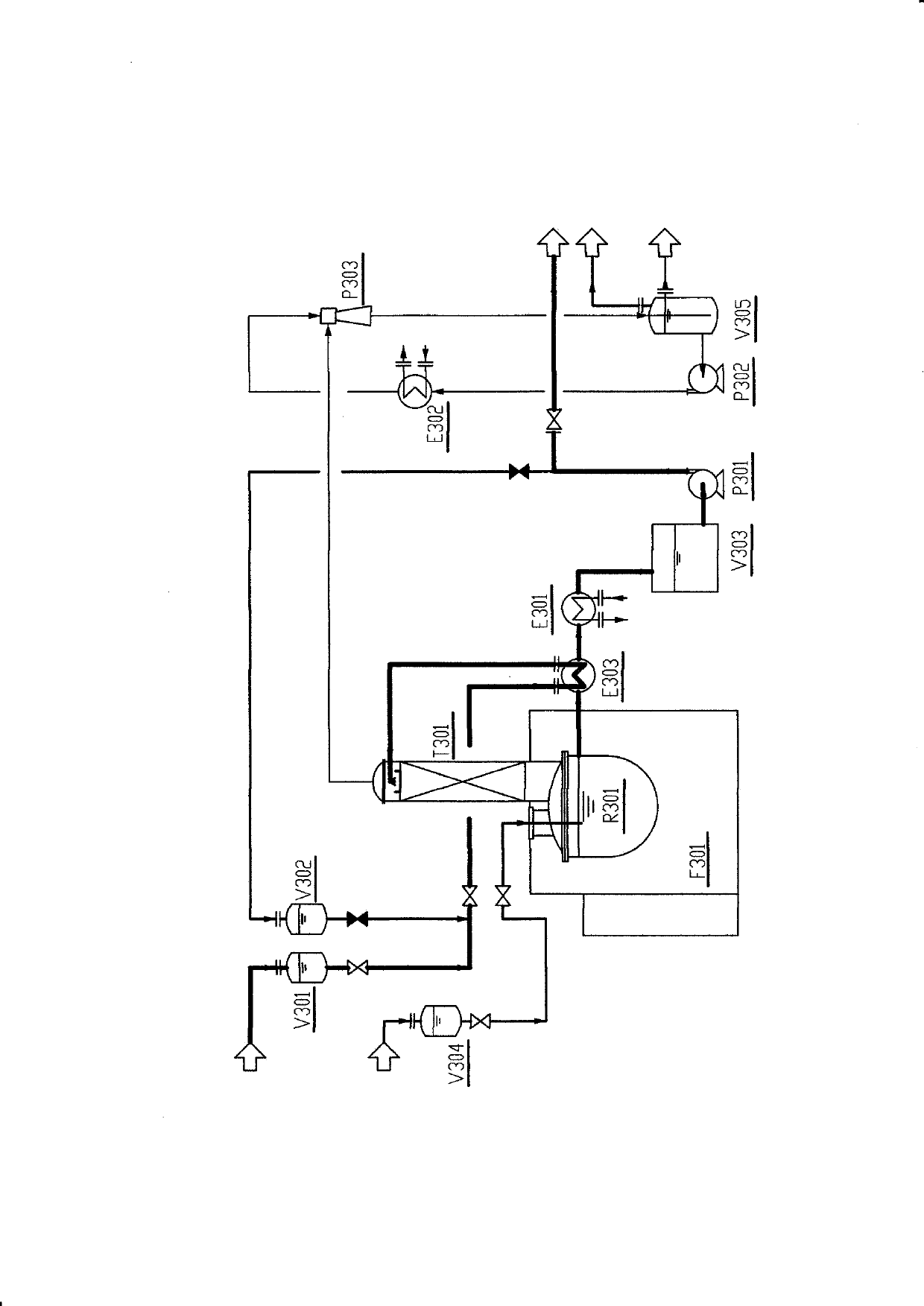

Device and method for recovering sulfuric acid from waste sulfuric acid generated in process of producing perylene series pigment

The invention relates to a device and method for recovering sulfuric acid in waste sulfuric acid generated in the process of producing a perylene-3,4,9,10-tetracarboxylic dianhydride pigment, mainly solving the problem that the waste sulfuric acid generated when perylene series pigments are produced can not be recovered. The device comprises a concentrating pan, a fractionating tower, a dilute sulfuric acid preheater, a concentrated sulfuric acid cooler, a concentrated sulfuric acid buffer tank, a concentrated sulfuric acid head tank, a waste sulfuric acid head tank, a medicament head tank and the like. The method is characterized in that concentrated sulfuric acid in the concentrated sulfuric acid buffer tank is circularly preheated in the concentrated sulfuric acid head tank, the preheater, the fractionating tower, the concentrating pan and the concentrated sulfuric acid cooler; the sulfuric acid enters the fractionating tower after being evaporated, and the waste sulfuric acid in the concentrating pan is sent to the waste sulfuric acid head tank and then enters the preheater; the waste sulfuric acid enters the fractionating tower; the waste sulfuric acid enters the concentrating pan after being concentrated, and a medicament is added to the concentrating pan; and the hot sulfuric acid enters the cooler after being cooled and then enters the concentrated sulfuric acid buffer tank, and part of the sulfuric acid is sent to the head tanks and part of the sulfuric acid is sent to a product storage tank by a pump. The device and the method have the advantage that the sulfuric acid in the waste sulfuric acid can be effectively recovered.

Owner:辽阳环亚废酸再生科技有限公司

Solid superstrong acid catalyst of esterification of preparation thereof

InactiveCN1680028AReduce dosageHigh catalytic activityPhysical/chemical process catalystsOrganic compound preparationAluminium nitrateIsooctyl alcohol

An ultra-strong solid acid catalyst used for esterifying reaction to synthesize tetraisooctyl sym-phenyltetraformate (TOPM) from sym-phenyl tetraformic dianhydride and isooctanol is prepared from titanium sulfate, aluminium nitrate, sulfuric acid and RE salt. Its formula is SO4 / Ti-Al-M-O, where M is chosen from Re, Tm and La. Its advantages are high activity and selectivity, long service life and low reaction temp.

Owner:NANJING TECH UNIV

Method for preparing nano-silica-containing polyimide hybrid material

The invention provides a method for preparing nano-silica-containing polyimide hybrid material. The preparation method comprises the following steps: ultrasonically mixing nano-silica, coupling agents and toluene in a reaction kettle filled with nitrogen; stirring the mixture at a certain temperature to cool the mixture to room temperature; adding paraformaldehyde and the phenol to the sol so as to obtain transparent modified silica sol; adding diamine monomer PAPB and ODA to N,N-dimethylacetamide under nitrogen protection and stirring to completely dissolve the obtained product; adding an equimolar amount of pyromellitic dianhydride equally divided to the solution in two steps so as to obtain polyamide acid solution; adding the obtained modified silica sol to the obtained polyamide acid solution so as to obtain mixed glue solution; and placing the obtained glue solution at a certain temperature for vacuum drying so as to obtain the nano-silica-containing polyimide hybrid material. Compared with non-hybrid polyimide, the composite material synthesized by the method has better mechanical properties, thermal stability and lower coefficient of thermal expansion.

Owner:DONGGUAN UNIV OF TECH

Corona-resistant polyimide film and process for preparing same

InactiveCN102732032AStrengthen the function of corona resistanceImprove performanceImidePolymer science

The invention provides a process for stably producing a corona-resistant polyimide film in the actual environment, comprising the following steps: preparing a component A and a component B, wherein the component A is a stable and uniform corona-resistant slurry, and the component B is a polyamic acid solution with low molecular weight; adding the component A into the component B; stirring mechanically at strong force so that nano fillings in a mixing system are distributed uniformly and stable; adding pyromellitic dianhydrider by adopting the in situ polymerization process for continuous reaction to prepare a corona-resistant polyimide solution with high molecular weight; preparing the corona-resistant polyimide solution with high molecular weight into a film at 130-175 DEG C by adopting the corresponding sobbering process according to the characteristics of the corona-resistant polyimide solution with high molecular weight; and preparing the film into the corona-resistant polyimide film at 380-450 DEG C by adopting the imidization process.

Owner:周天兴 +1

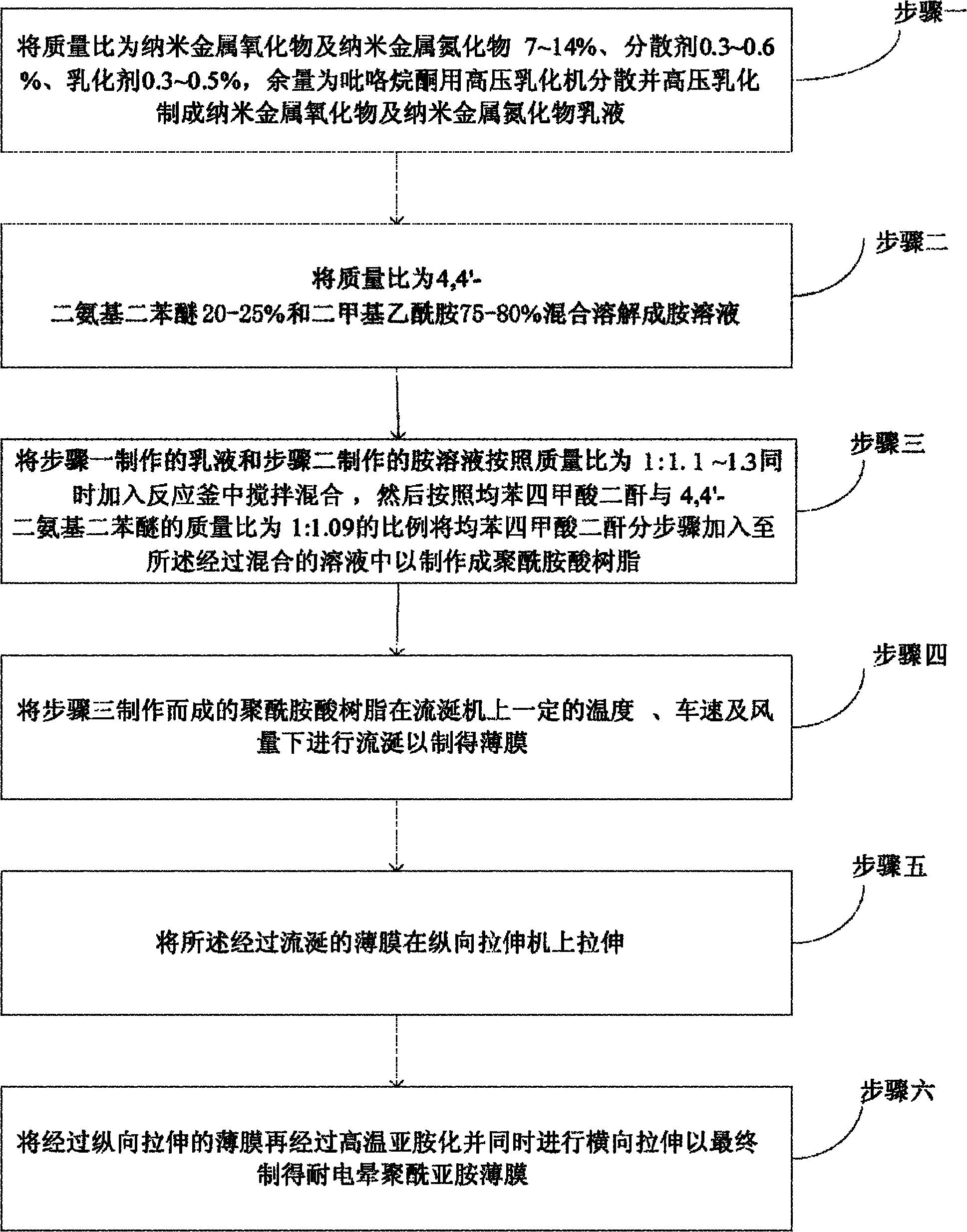

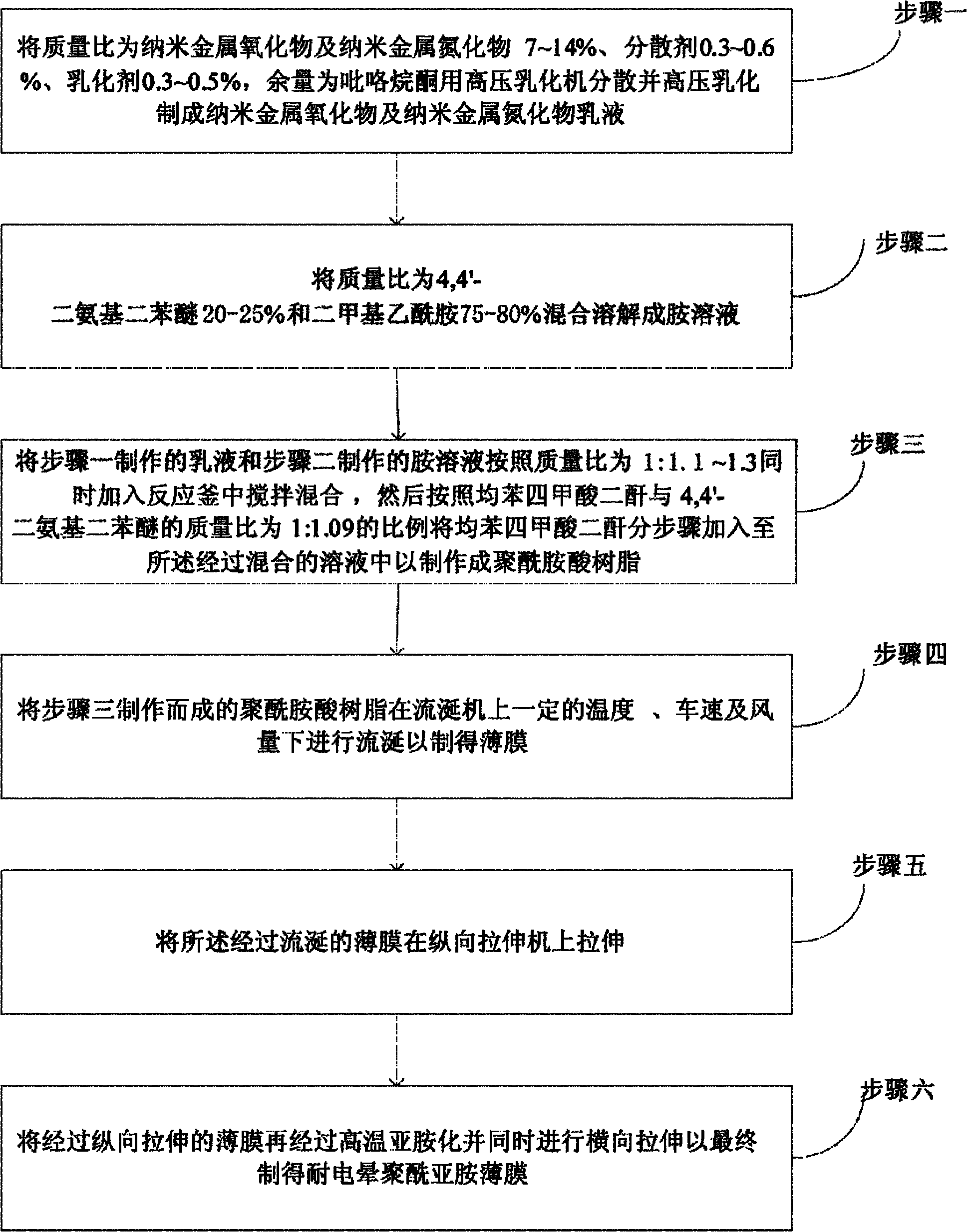

Corona-resistance polyimide film and manufacturing method thereof

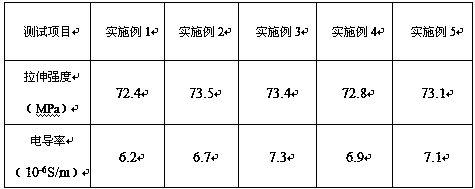

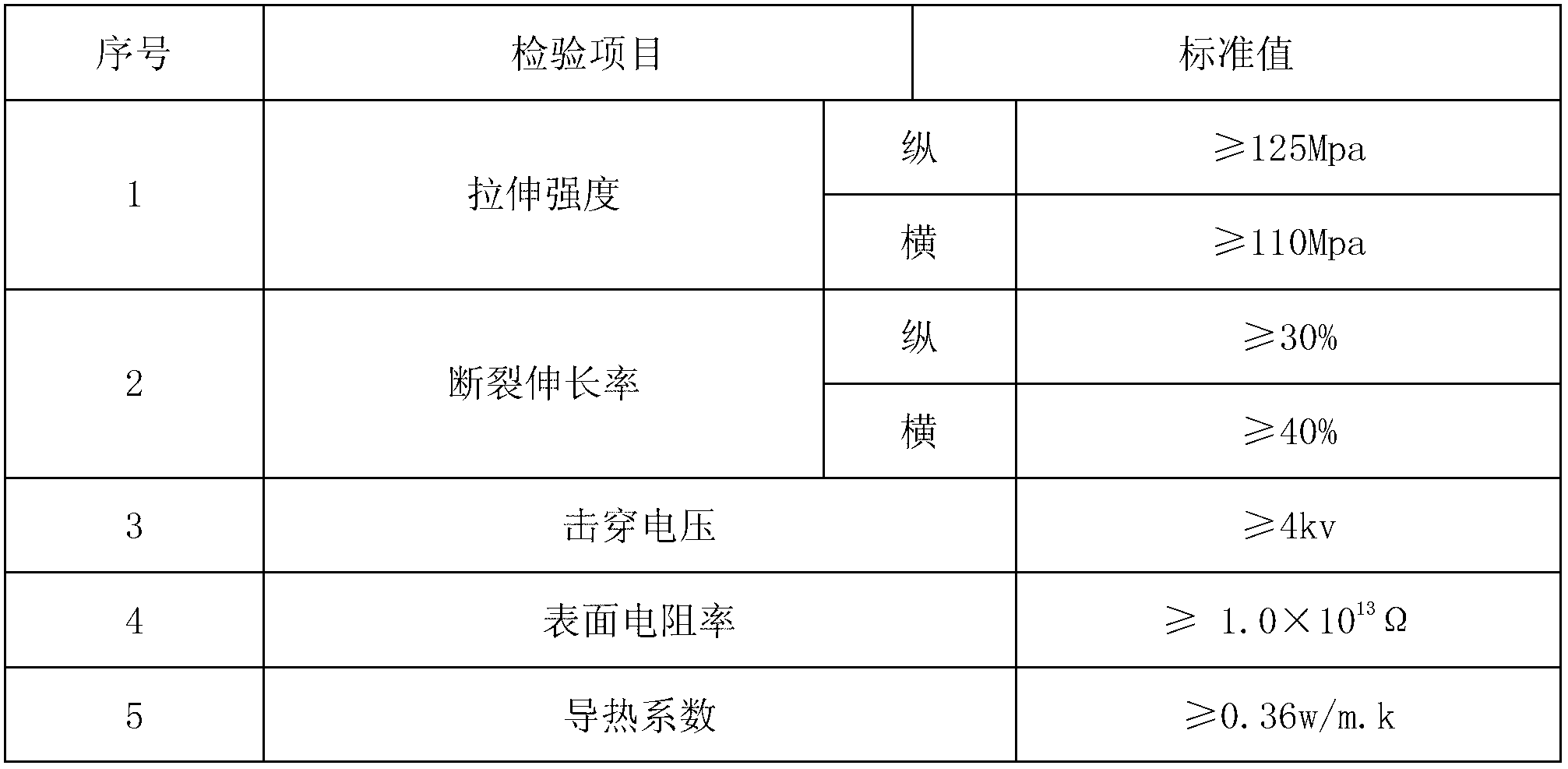

The invention discloses a corona-resistance polyimide film, which comprises emulsion, amine solution and pyromellitic dianhydride, wherein the emulsion comprises 7 to 14 mass percent of nano metal oxide and nano metal nitride, 0.3 to 0.6 mass percent of dispersant, 0.3 to 0.5 mass percent of emulsifier and the balance of pyrrolidone; the amine solution comprises 20 to 25 mass percent of 4,4'-diamino-diphenyl ether and 75 to 80 mass percent of dimethylacetylamide, and the mass ratio of the emulsion to the amine solution is 1:(1.1-1.3); and the mass ratio of the pyromellitic dianhydride to the 4,4'-diamino-diphenyl ether is 1:(1.09). The invention also discloses the manufacturing method of the corona-resistance polyimide film. In the invention, the nano metal oxide and nitride are fully dispersed in polyamic acid resin by adding the emulsifier and dispersant and by a high-pressure emulsification technique, and the content of the nano metal oxide and nitride in the polyamic acid resin is high. Therefore, the produced film has high corona resistance and small astigmatic aberration, and at the same time, the film has high mechanical performance, electrical performance and the like.

Owner:TIANJIN TIANYUAN ELECTRONICS MATERIAL

Fiber composite material for robotic electronic skin and preparation method thereof

InactiveCN109338716AImprove conductivityEasy to stretchHollow filament manufactureFibre typesLiquid metalFlexible electronics

The invention discloses a fiber composite material for robotic electronic skin and a preparation method thereof. The fiber composite material is prepared according to the following steps: a, adding pyromellitic dianhydride and 4,4'-diphenyl ether diamine into N-methylpyrrolidone, performing a polycondensation reaction, and then performing wet spinning and hot stretching to obtain hollow polyimidefiber; b, filling the hollow polyimide fiber with tin-gallium liquid metal; c, curing the tin-gallium liquid metal in a room-temperature environment to obtain the fiber composite material for the electronic skin. The preparation method has the beneficial effects as follows: the hollow fiber material is used and filled with the liquid metal, and the tin-gallium liquid metal has excellent electricalconductivity as well as good stretchability in a solid state, the obtained fiber composite material has high stretchability and high electrical conductivity and has a broad application prospect in the fields of flexible wearable devices, the flexible electronic skin, intelligent robots and the like.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Polyimide resin synthesis method

InactiveCN102936341AExtended service lifeExcellent electrical performanceDiaminodiphenyl etherPowder mixture

The present invention discloses a polyimide resin synthesis method. The polyimide resin comprises a thermally conductive nanometer powder mixture and a resin solid, wherein the resin solid is polyamic acid, and the thermally conductive nanometer powder mixture is a mixture of three thermally conductive nanometer powders such as Al2O3, NB and AlN, and is 10-30% of the total amount of the resin solid. During synthesis, pyromellitic dianhydride reacts with 4,4'-diaminodiphenyl ether to obtain polyamic acid, the grinded thermally conductive nanometer powder mixture is added to the polyamic acid according to a certain proportion, then pyromellitic dianhydride is added to control a viscosity of the final reaction product to reach 85000-95000 CP, and deaeration slobbering film formation is performed to obtain the finished product. According to the polyimide resin synthesized by the method, a thermal conductivity coefficient can be more than three times the thermal conductivity coefficient of the ordinary polyimide film, excellent electrical property, excellent thermal property and excellent mechanical property are provided, and a storage life of the electronic component can be substantially improved.

Owner:宁波今山电子材料有限公司

Dimensionally stable oxazolyl polyimide film and preparation method thereof

The invention discloses a dimensionally stable oxazolyl polyimide film and a preparation method thereof. The dimensionally stable oxazolyl polyimide film is prepared by the steps of carrying out polymerization reaction on aromatic diamine and aromatic dianhydride in a polar aprotic solvent, and carrying out salivation and thermal imidization on an obtained polyamide acid resin solution, wherein aromatic diamine contains the following components in percentage by weight: 10%-30% of p-phenylenediamine, 5%-40% of 2-(4-aminophenyl)-5-amino benzoxazole and the balance of 4,4',-diaminodiphenyl ether,and aromatic dianhydride contains the following components in percentage by weight: 3,3',4,4'-biphenyl tetracarboxylic dianhydride and the balance of pyromellitic acid dianhydride. The dimensionallystable oxazolyl polyimide film prepared from the raw material in parts by weight has excellent dimensional stability, and meanwhile, the water absorption rate of the film is less than 2%.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

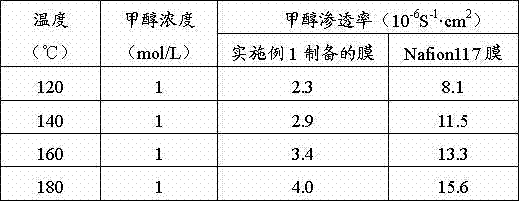

Preparation method of phosphotungstic acid-polyimide composite proton exchange membrane

InactiveCN102863637AGood dispersionAvoid the problem of poor compatibility and easy phase separationFinal product manufactureSolid electrolyte fuel cellsO-Phosphoric AcidPolyamide

The invention discloses a preparation method of a phosphotungstic acid-polyimide composite proton exchange membrane. Diphenyl ether diamine and benzenetetracarboxylic anhydride with equal molar weight are added in dimethyl sulfoxide solvent to synthesize polyamide acid solution, deionized water, sodium tungstate and concentrated phosphoric acid are then added for heating and stirring to form a solution, the solution is poured on a glass plate, the glass plate is flatly placed in an oven in a stepped temperature rise mode for imidization, and the phosphotungstic acid-polyimide composite proton exchange membrane is obtained. The preparation method is simple in method, the cost of prepared membrane is low, and the membrane is even in distribution, and conductivity and alcohol blocking performance are obviously improved. Compared with a Nafion membrane, the phosphotungstic acid-polyimide composite proton exchange membrane prepared by the method obviously improves proton conduction performance at high temperature (lower than 100 DEG C), carbinol permeability is reduced, swelling degree is reduced, cost is lowered, and the preparation method brings convenience to mass production.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for preparing loofah sponge immobilized ionic liquid adsorbent

InactiveCN103933950AGood physical and chemical stabilityHigh mechanical strengthOther chemical processesWater/sewage treatment by sorptionFiltrationSorbent

The invention discloses a method for preparing a loofah sponge immobilized ionic liquid adsorbent and application techniques of the adsorbent. The method is characterized by comprising the following steps: removing peels and kernels of a mature loofah fruit, washing by water to remove soil and impurities, drying, smashing, treating the smashed loofah sponge by sodium hydroxide and hydrogen peroxide, drying to obtain an oxidized loofah sponge, adding 62%-72% of epoxy chloropropane and 15%-28% of oxidized loofah sponge in percentage by mass into a reactor, stirring and reacting at the constant temperature of 70-80 DEG C for 40-60 minutes, cooling, adding 4%-10% of pyromellitic dianhydride and 2%-6% of N-ethyl-3methylpyridine bromate ionic liquid, stirring and reacting for 48-60 hours at the constant temperature of 33-37 DEG C, cooling, carrying out suction filtration, washing by deionized water till filtrate is neutral, washing by a little ethyl alcohol and drying in a vacuum drying oven at the temperature of 50 DEG C to obtain the loofah sponge immobilized ionic liquid adsorbent. The adsorbent has the advantages of very high arsenic adsorption capacity, excellent physicochemical and mechanical properties, strong regeneration capacity, high frequency of repeated use, low cost and environmental protection.

Owner:UNIV OF JINAN

Heat conduction graphite flake and manufacturing process thereof

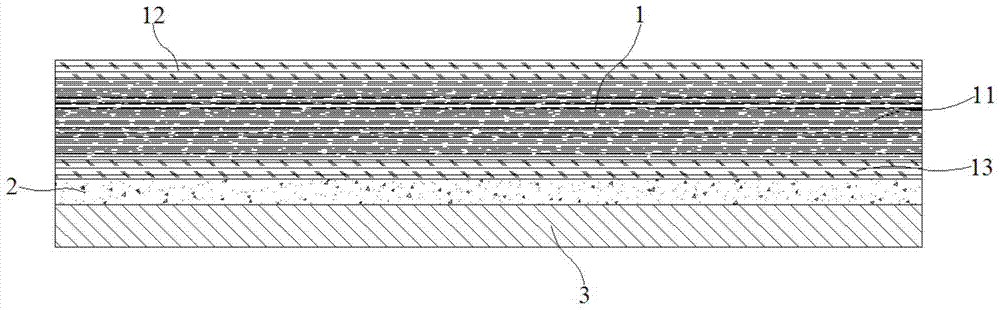

ActiveCN103787323AImprove biaxial tensile propertiesHigh thermal conductivityCarbon compoundsRadiationPolydimethylsiloxane

The invention discloses a heat conduction graphite flake, and a manufacturing process thereof. The heat conduction graphite flake comprises a polyimide film, a first coating layer and a second coating layer, wherein the first coating layer and the second coating layer are respectively arranged on the upper surface and the lower surface of the polyimide film; the first coating layer and the second coating layer are formed by sintering a graphite modifier; the graphite modifier comprises the following components in parts by weight: 20-25 parts of benzophenonetetracarboxylic dianhydride, 14-16 parts of pyromellitic dianhydride, 22-26 parts of diaminodiphenyl methane, 25-35 parts of dimethylformamide, 1.8-2.5 parts of ethylene glycol, and 2.5-3 parts of polydimethylsiloxane. According to the heat conduction graphite flake, the heat conduction performance can be improved in the vertical direction and the horizontal direction, local overheat is avoided, the uniform heat conduction performance is achieved, and the stability and reliability of radiation performance of products are improved.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

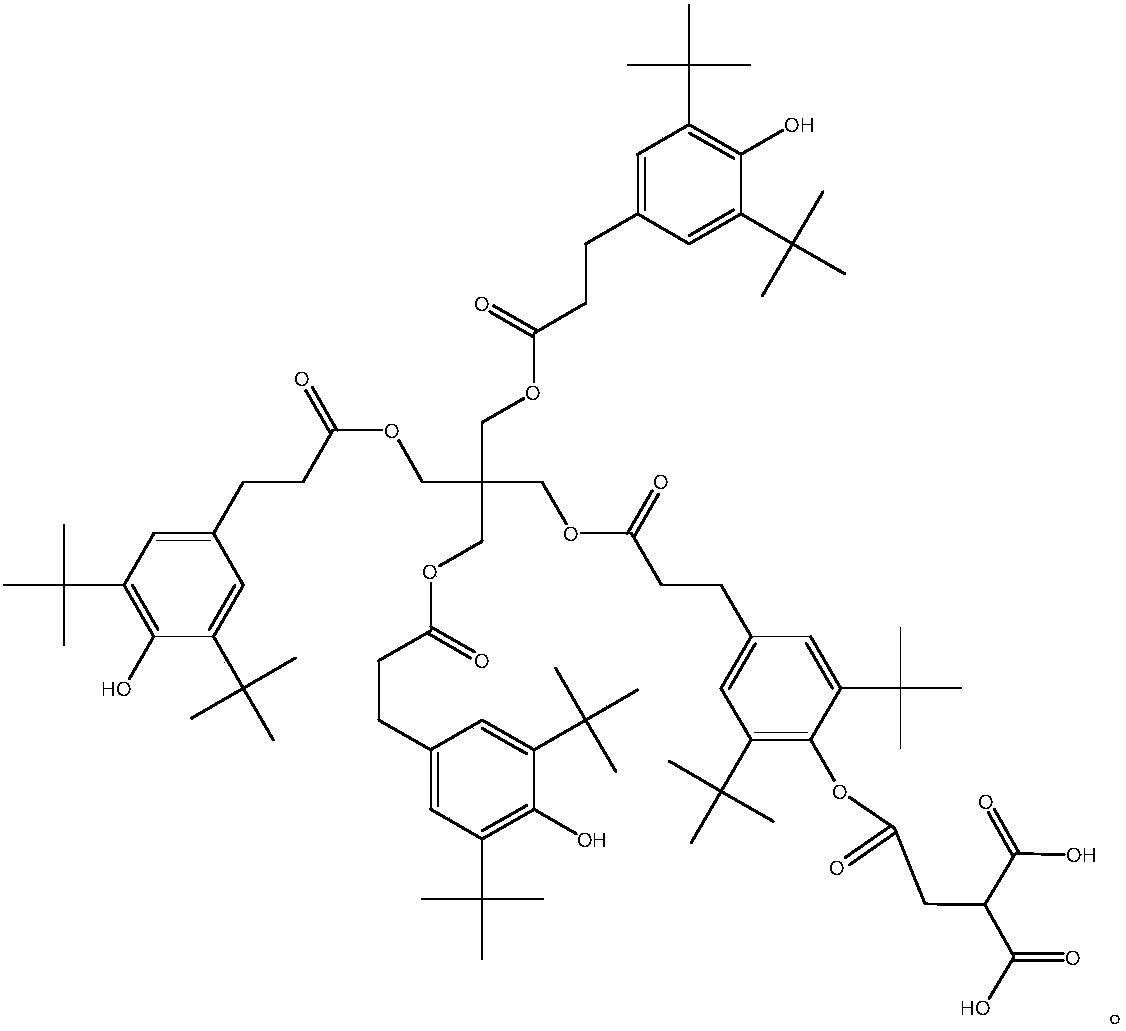

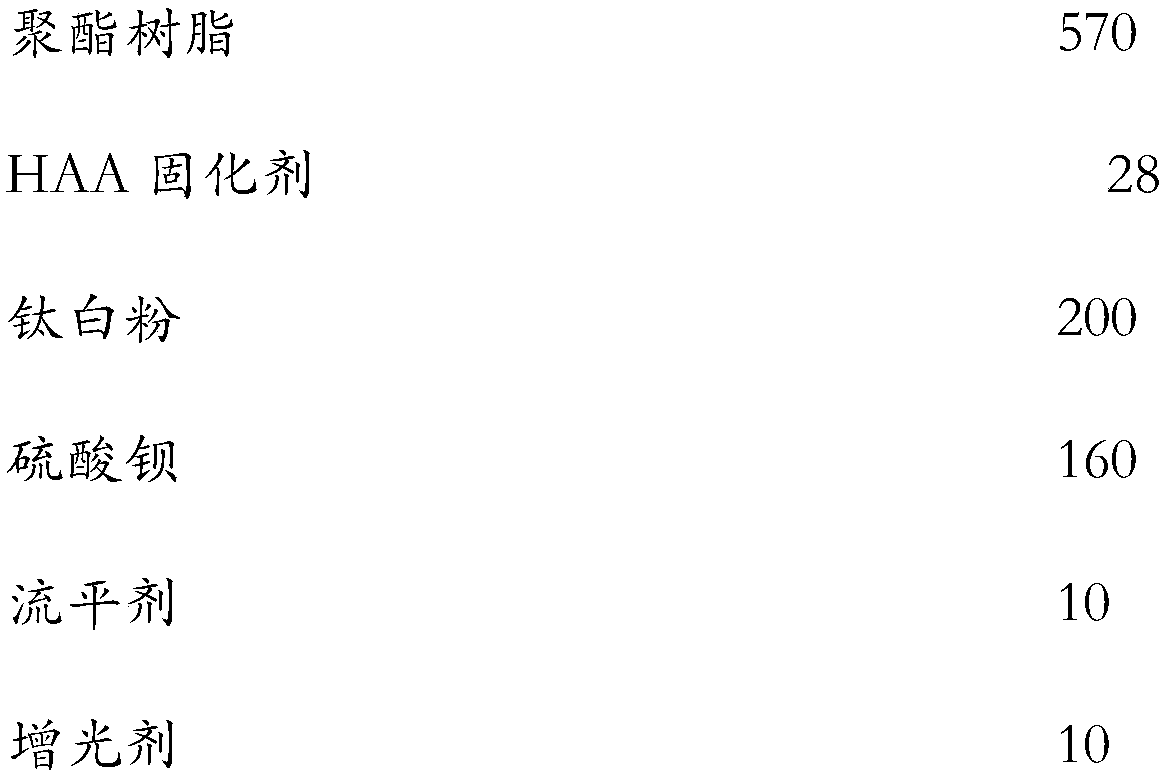

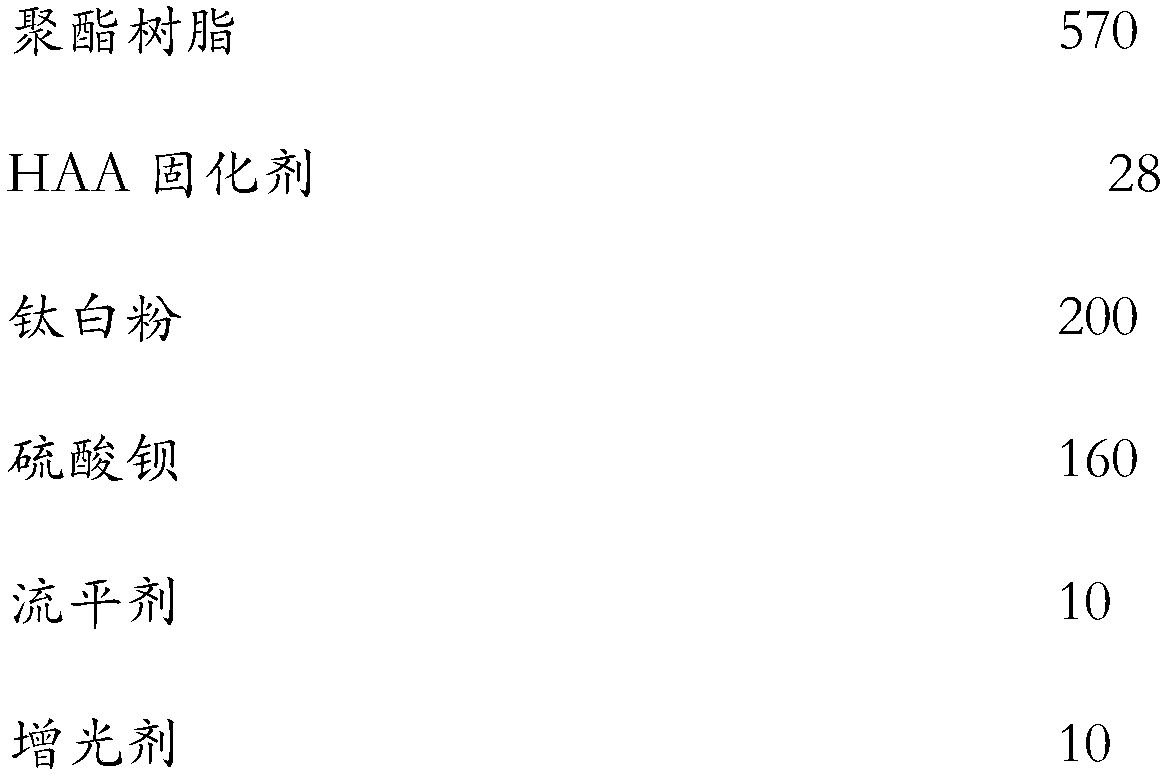

Polyester resin for anti-yellowing HAA (N,N,N',N'-tetra(Beta-hydroxyethyl)adipamide) system powder paint, preparation method and application

ActiveCN109054008AImprove high temperature resistanceImprove anti-yellowing effectPowdery paintsPolyester coatingsDiphenic acidPyromellitic dianhydride

The invention belongs to the technical field of resin production, and particularly relates to a polyester resin for an anti-yellowing HAA (N,N,N',N'-tetra(Beta-hydroxyethyl)adipamide) system and further relates to a preparation method and application of the polyester resin. The anti-yellowing HAA system provided by the invention is polymerized by using pyromellitic dianhydride, 1,6-hexanediamine,isophthalic acid, phloroglucinol formic acid, ethanetricarboxylic acid monoester, 2,5-dihydroxy hexane, neopentyl glycol and 2,2'-diphenic acid. Because a polyimide chain is carried in the molecular chain of the polyester resin obtained by the materials and a specific process, the high temperature-resistant and anti-yellowing properties are excellent; moreover, because the materials containing phenolic hydroxyl groups, such as phloroglucinol formic acid and ethanetricarboxylic acid monoester, are used for participating in reaction and the phenolic functional group with high anti-yellowing capability is contained in the polyester chain, the polyester product has excellent high temperature-resistant and anti-yellowing properties, and is ultimately used in the powder paint of the HAA system,so that a coated panel with excellent anti-yellowing property can be obtained.

Owner:HUANGSHAN HUIZHOU KANGJIA CHEM CO LTD

Polyimide film, copper-clad laminate, and circuit substrate

PendingCN109789689ALow moisture absorptionLow Dielectric TangentSynthetic resin layered productsElectrical equipmentPolymer scienceBPDA

Provided is a polyimide film having a non-thermoplastic polyimide layer, wherein: the non-thermoplastic polyimide constituting the non-thermoplastic polyimide layer preferably contains at least one ofa biphenyl-tetracarboxylic dianhydride (BPDA) residue derived from 3,3',4,4'-BPDA and a phenylenebis(trimellitic monoester) dianhydride (TAHQ) residue derived from 1,4-TAHQ, as well as at least one of a pyromellitic dianhydride (PMDA) residue derived from PMDA and a napthalenetetracarboxylic dianhydride (NTCDA) residue derived from 2,3,6,7-NTCDA, the total amount of these residues being at least80 mol parts with respect to 100 mol parts of a tetracarboxylic acid residue; and the dielectric loss tangent (Df) is preferably 0.004 or less.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

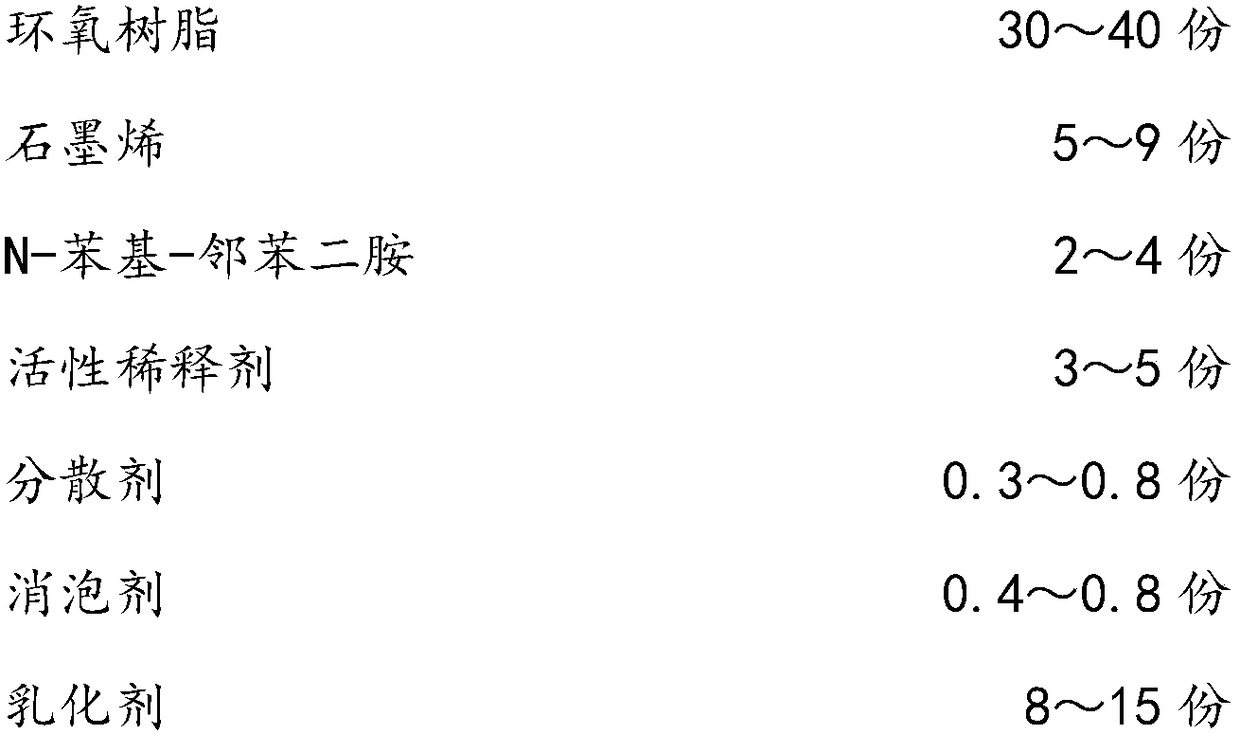

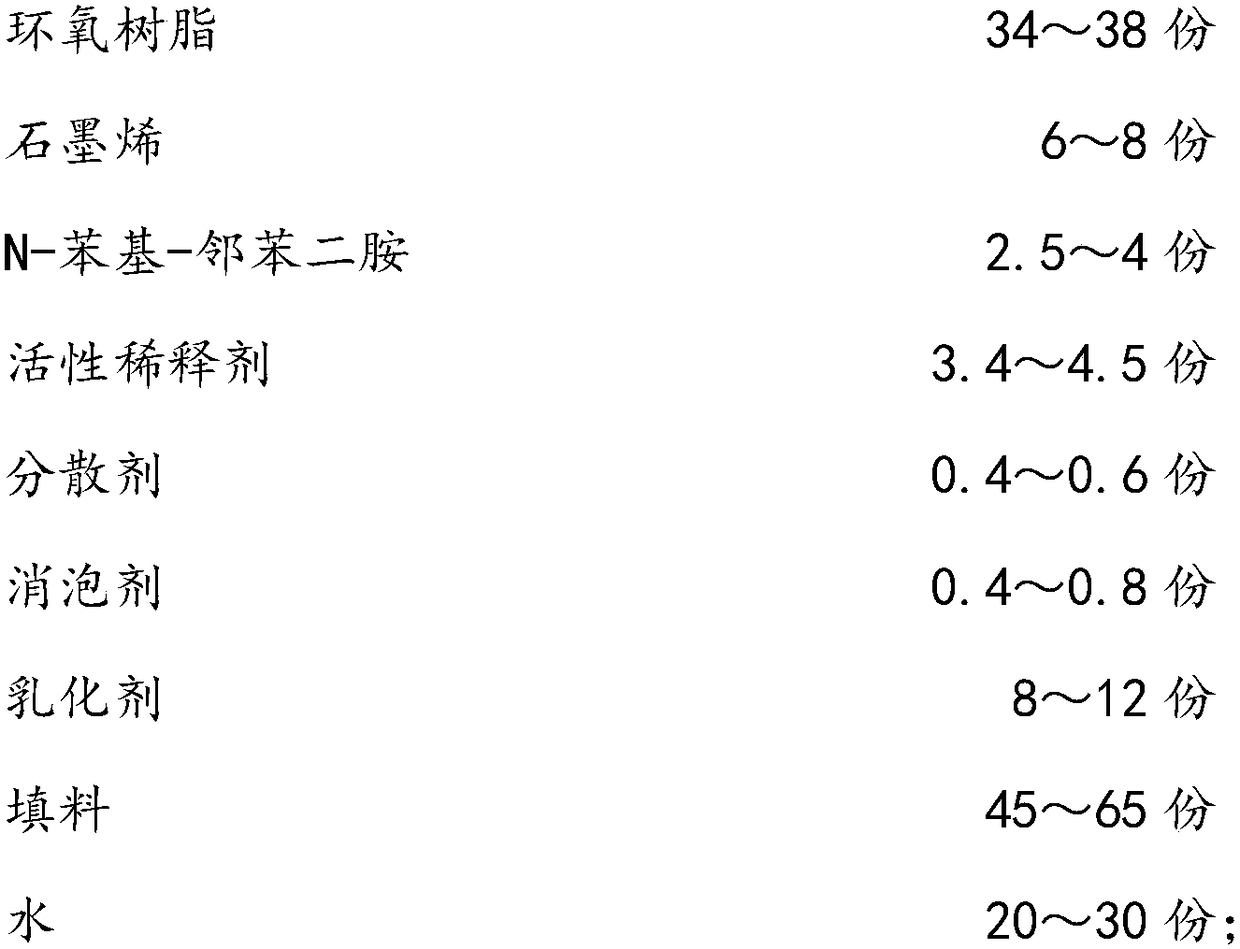

Anti-static graphene floor paint and preparation method thereof

InactiveCN108300161ASolving the Spontaneous Reunion ProblemAvoid loss of electrical conductivityEpoxy resin coatingsElectrically-conductive paintsDiethylenetriamineStatic performance

The invention provides anti-static graphene floor paint and a preparation method thereof. The anti-static graphene floor paint contains a component A and a component B, wherein the component A is prepared from constituents by weight as follows: 30-40 parts of epoxy resin, 2-5 parts of graphene, 2-4 parts of N-phenyl-o-phenylenediamine, 3-5 parts of a reactive diluent, 0.3-0.8 parts of a dispersingagent, 0.4-0.8 parts of a defoaming agent, 8-15 parts of an emulsifier, 40-70 parts of filler and 15-30 parts of water; the component B is prepared from constituents by weight as follows: 8-11 partsof pyromellitic dianhydride, 8-12 parts of amino modified graphene and 6-9 parts of an acrylonitrile-diethylenetriamine compound; a weight ratio of the component A to the component B is 5.5-7:1. The invention further provides the preparation method of the anti-static graphene floor paint. According to the prepared anti-static graphene floor paint, the problem of conductivity reduction due to bedding void caused by graphene layering is solved, and anti-static performance of the floor paint is greatly enhanced.

Owner:厦门中凯新材石墨烯科技有限公司

Highly adhesive polyimide film and method for producing same

ActiveCN101018817AGood adhesionReduce tightnessPrinted circuit manufactureCoatingsBenzophenonePropane

Owner:KANEKA CORP

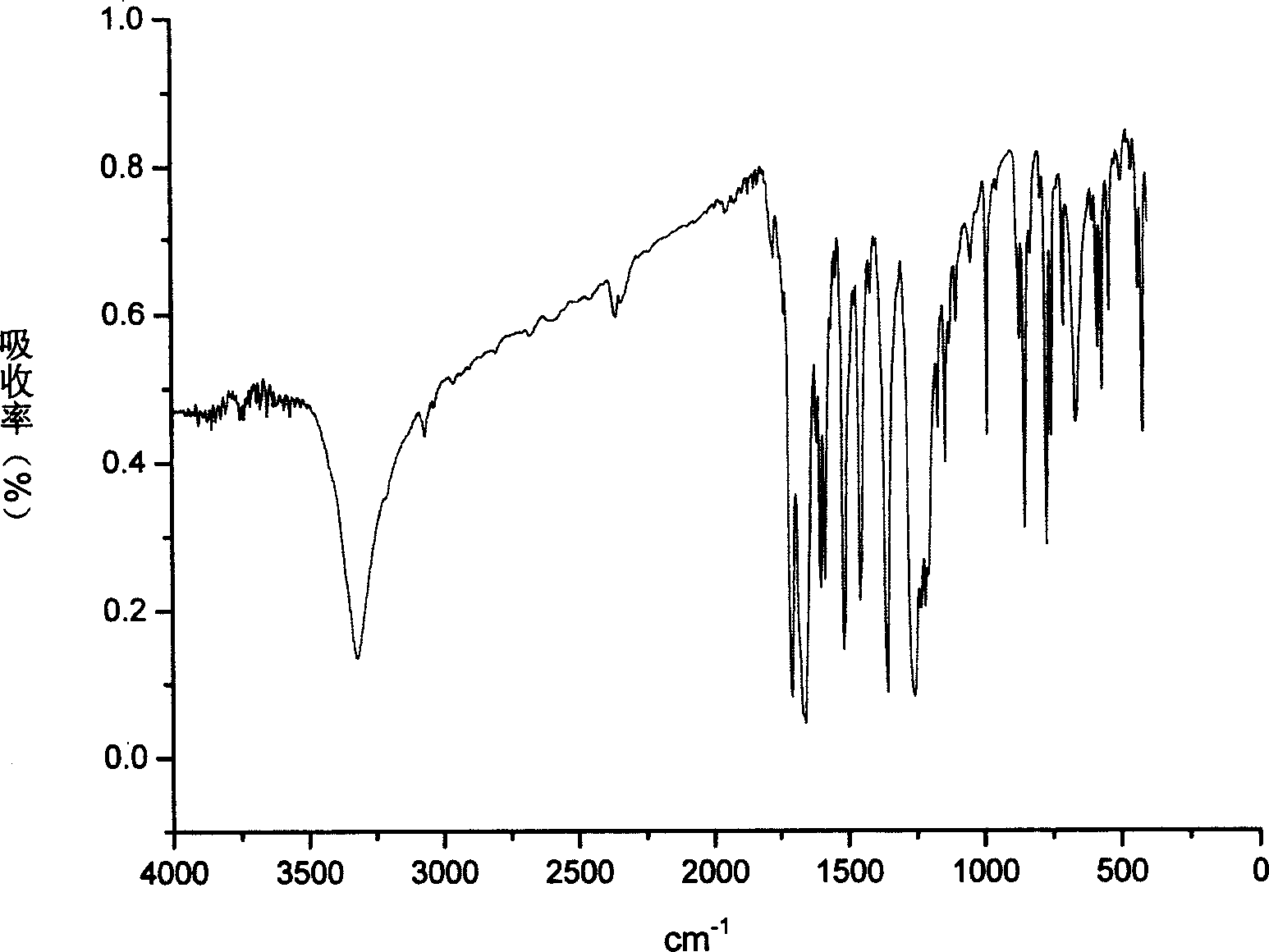

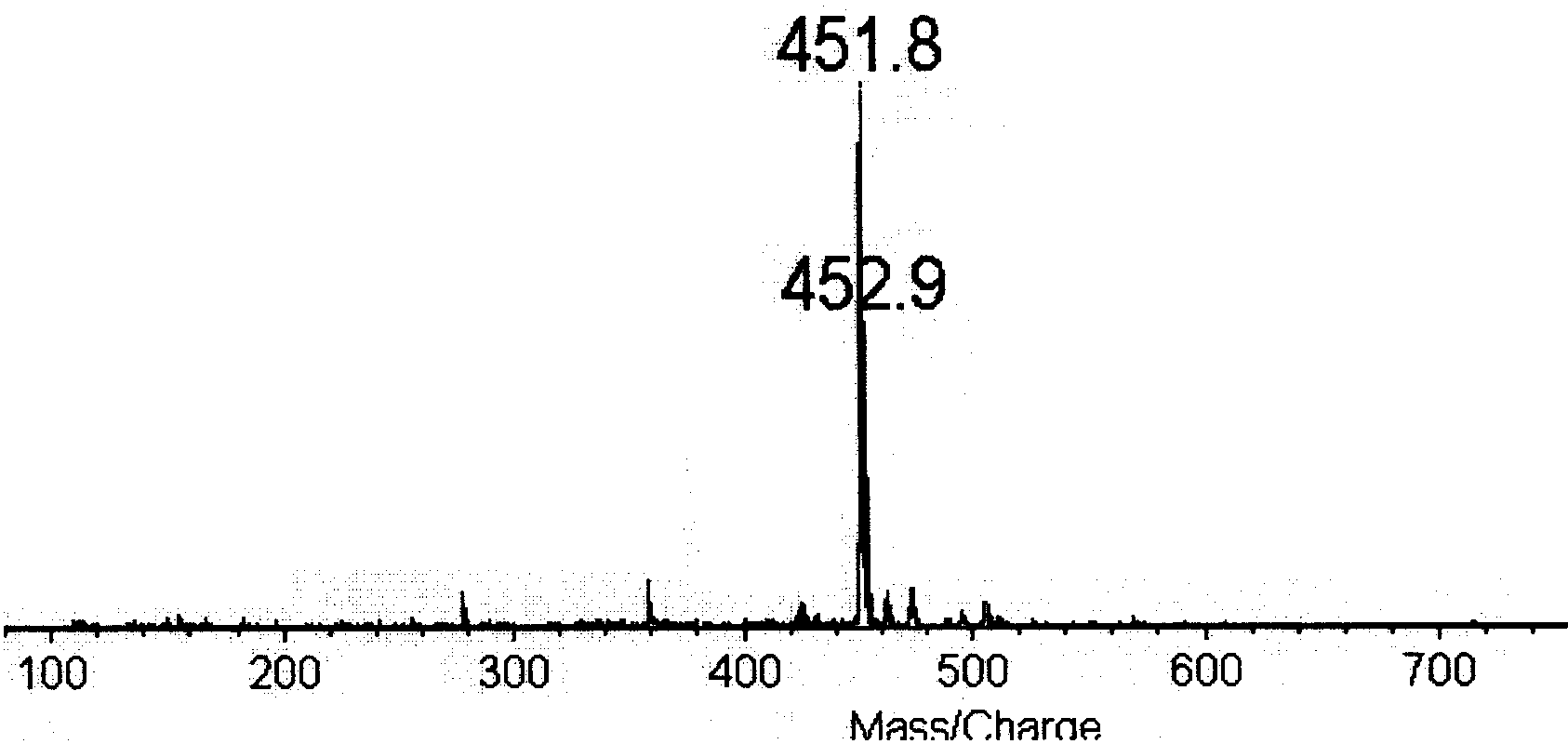

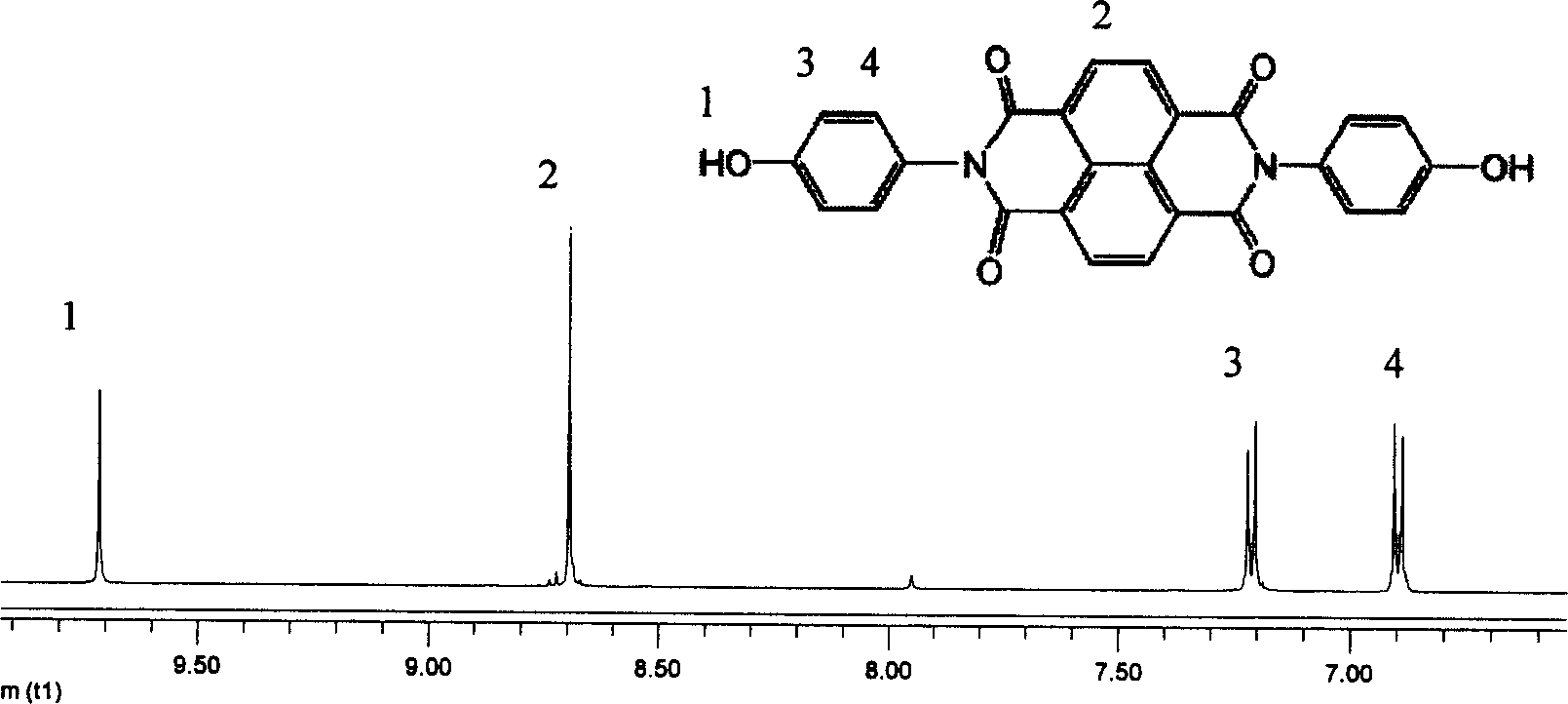

Bisphenols monomer with imide structure and its synthesis

Bisphenol monomer with acid imide structure and its synthesis are disclosed. It is carried out by taking 1,2,4,5-benzenetetracarboxylic acid dianhydride or naphthyl-1,4,5,8-dianhydride or p-aminophenol as material, taking DMF as reacting solvent, agitating for 2-3 hrs at room temperature, clarifying the system into solution, adding methylbenzene or dimethyl benzene with volume ratio 1 / 3-1 / 2 of solvent, continuous heating and agitating under nitrogen protecting, back-flowing with water for 3-4 hrs at 110-120deg.C, the light liquid changing into suspensoid, evaporating out methylbenzene, back-flowing for 4-5 hrs at 140-150deg.C, lowering temperature, discharging, washing for 3-4 times by alcohol, removing organic solvent in mixed system, boiling for 3-4 times by water, drying the solid products in oven at 80-100deg.C, and obtaining powdered solid pure products. It achieves high productivity.

Owner:JILIN UNIV

Corona-resistant PI (polyimide) film and preparation method thereof

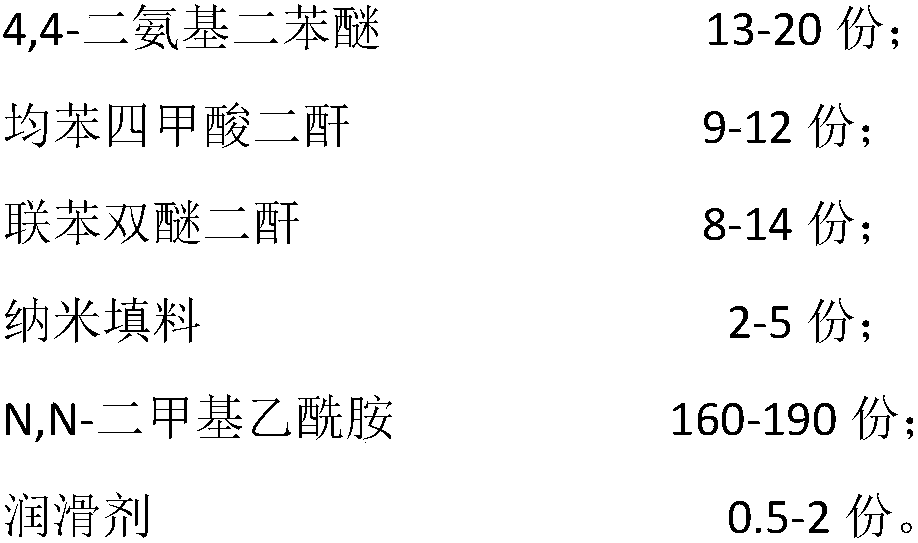

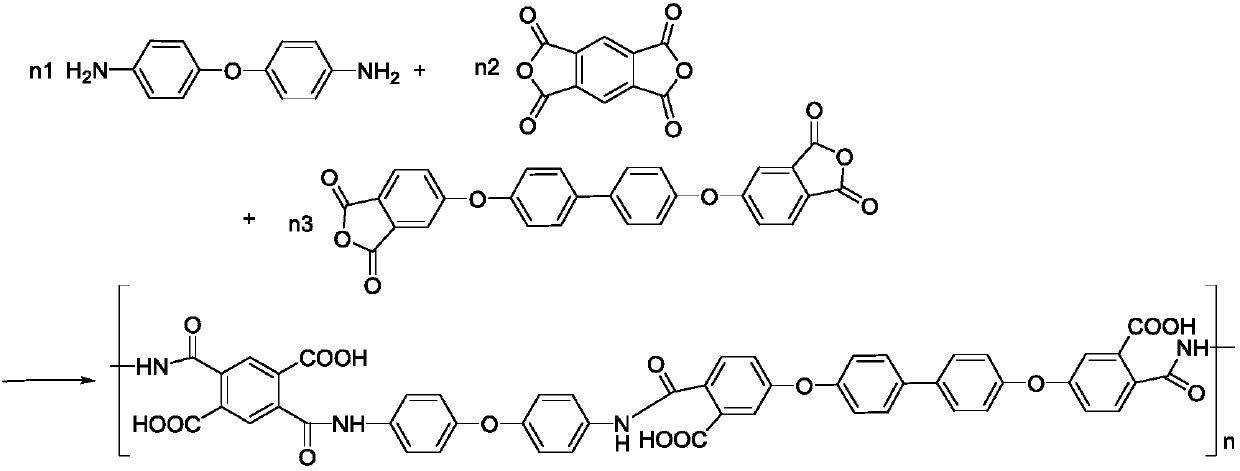

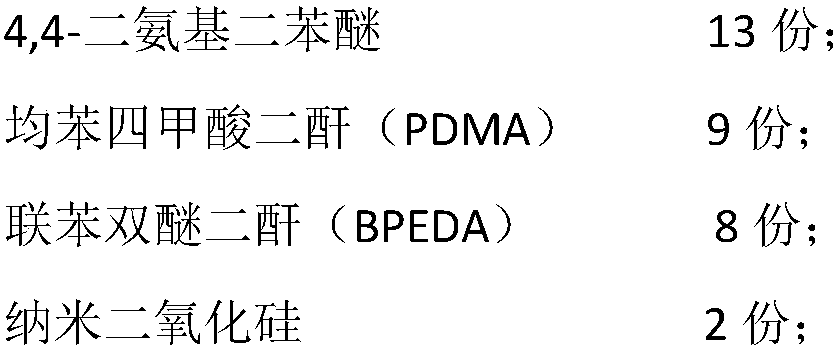

InactiveCN107652679ALower glass transition temperatureHigh strengthDiaminodiphenyl etherThermal expansion

The invention discloses a corona-resistant PI (polyimide) film, which comprises the following components in parts by weight: 13-20 parts of 4,4'-diaminodiphenyl ether, 9-12 parts of pyromellitic dianhydride, 8-14 parts of biphenylether dianhydride; 2-5 parts of a nano filler; 160-190 parts of N, N-dimethylacetamide and 0.5-2 parts of a lubricant. The polyimide film prepared by the method has the advantages of strength, rigidity and dimensional stability; the film is produced through a casting nozzle and a casting machine has good uniformity, and the surface is clean and flat; by a biaxial stretching and heat treatment process, the longitudinal modulus and the transverse modulus of the polyimide film can be further improved, and thermal expansion coefficient and thermal shrinkage can be reduced.

Owner:ANHUI GUOFENG PLASTIC

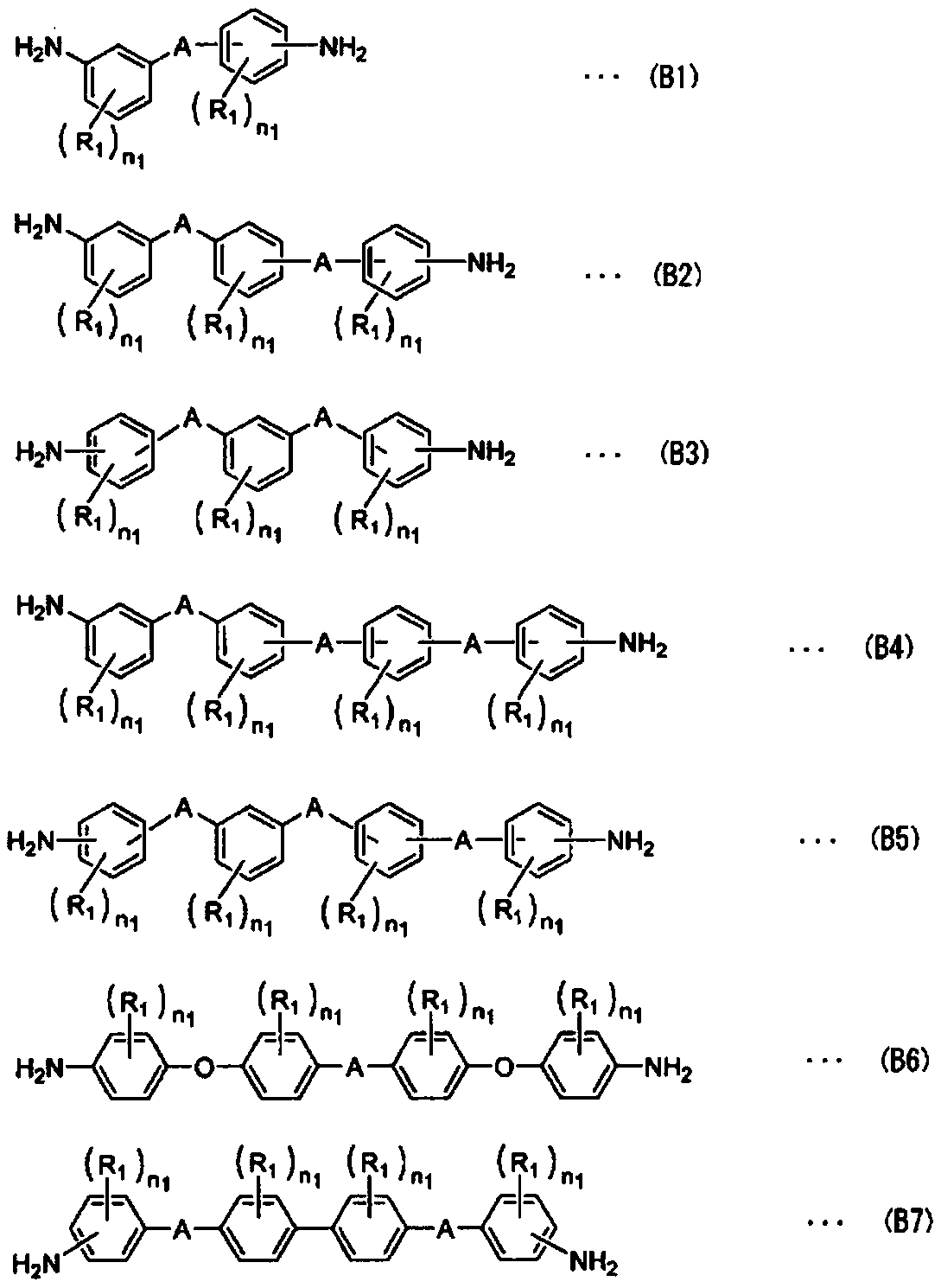

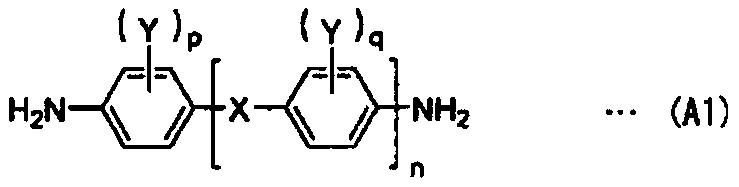

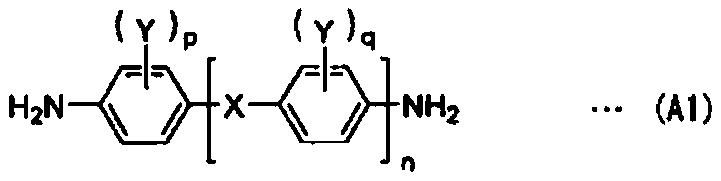

Polyamide acid, thermoplastic polyimide, resin film, metal-clad laminate and circuit board

ActiveUS20190100624A1Improve adhesionStrong adhesionPlastic/resin/waxes insulatorsPrinted circuit aspectsPolyamideThermoplastic polyimide

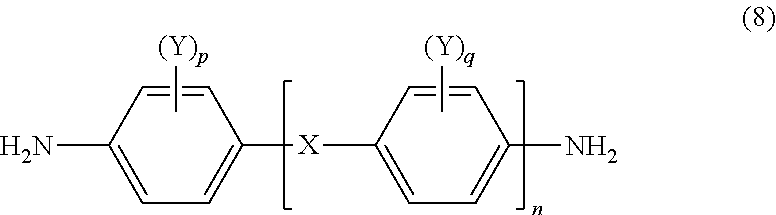

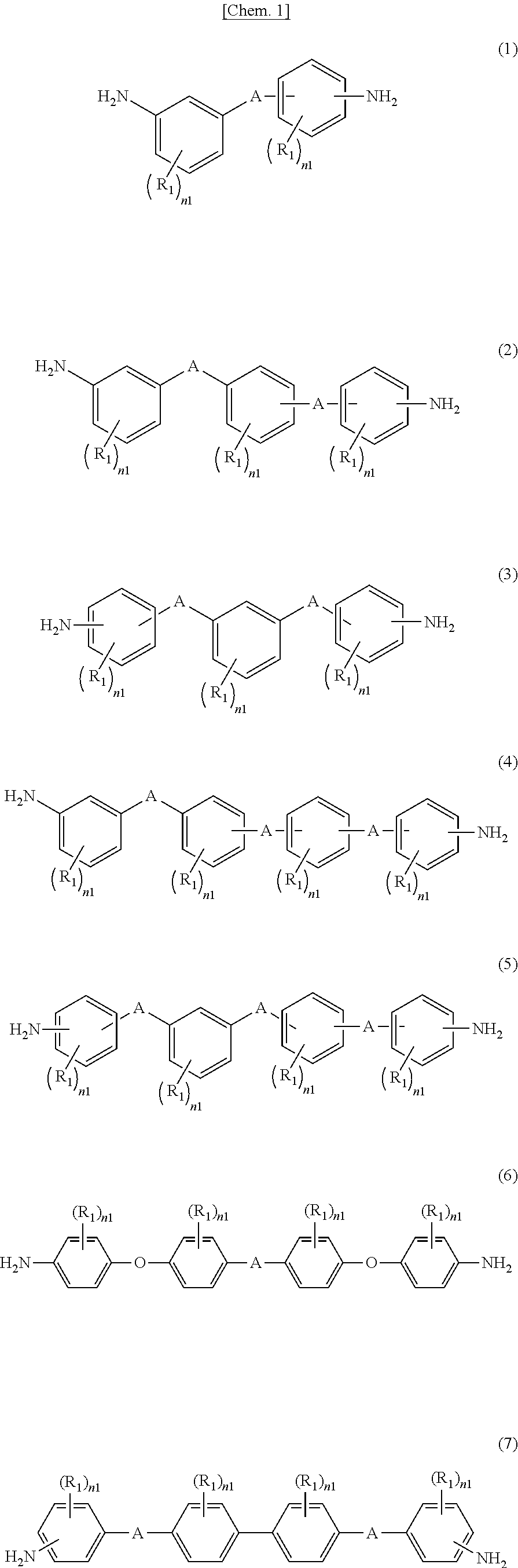

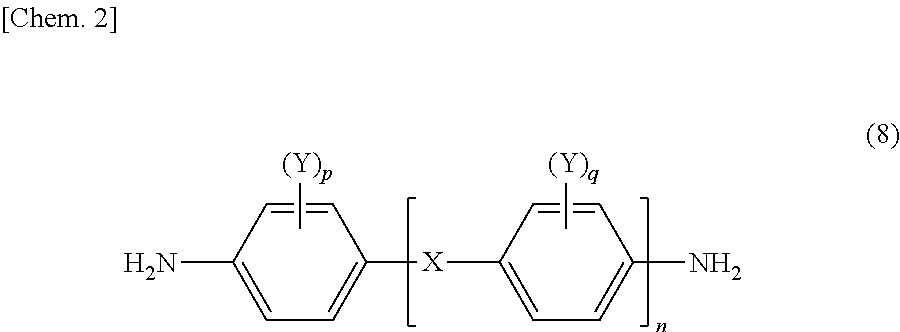

A polyamide acid which contains at least one diamine compound selected from among diamine compounds represented by general formula (8) within the range of 3-60 parts by mole in total per 100 parts by mole of all diamine components, while containing a biphenyl tetracarboxylic acid dianhydride within the range of 40-100 parts by mole and a pyromellitic acid dianhydride within the range of 0-60 parts by mole per 100 parts by mole of all acid anhydride components; and a thermoplastic polyimide which is obtained curing this polyamide acid.(In formula (8), linking group X represents a single bond or a divalent group selected from among —CONH—; each Y independently represents a hydrogen atom, a monovalent hydrocarbon group having 1-3 carbon atoms or an alkoxy group; n represents an integer of 0-2; and each of p and q independently represents an integer of 0-4.)

Owner:NIPPON STEEL CHEMICAL CO LTD

Heat conduction graphite paster for adhesive tape and preparing method of heat conduction graphite paster

ActiveCN103796493AAvoid local overheatingAchieve uniformityLamination ancillary operationsSynthetic resin layered productsAdhesiveDimethyl siloxane

The invention discloses a heat conduction graphite paster for adhesive tape and a preparing method of the heat conduction graphite paster. The surface of the heat conduction graphite paster is coated with a heat conduction adhesive layer, the heat conduction graphite paster is composed of a polyimide film, a first coating layer and a second coating layer, and the first coating layer and the second coating layer are located on the upper surface and the lower surface of the polyimide film respectively. The first coating layer and the second coating layer respectively comprise, by weight, 20-25 parts of benzophenone tetracid dianhydride, 12-18 parts of pyromellitic acid dianhydride, 20-28 parts of diaminodiphenylmethane, 20-25 parts of dimethyl formamide, 8-10 parts of N-methyl pyrrolidone, 1.5-2.5 parts of ethylene glycol, 2-3 parts of dimethyl silicone polymer and 0.8-1.5 parts of phthalic acid dibutyl ester. According to the heat conduction graphite paster, local overheating is avoided, the evenness of the heat conduction performance is achieved, the stability and reliability of the heat dissipation performance of the heat conduction graphite paster are improved, and the cost of the heat conduction graphite paster is reduced.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

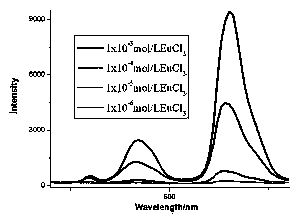

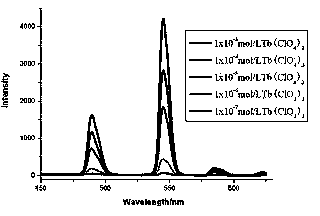

Preparation method of lanthanide ion loaded metal-organic framework material capable of realizing lighting adjustability and sensing property

InactiveCN103436255ADoping operation is convenientDoping operation is stableFluorescence/phosphorescenceLuminescent compositionsPyromellitic acid dianhydrideFormic acid

The invention discloses a preparation method of a lanthanide ion loaded metal-organic framework material capable of realizing lighting adjustability and sensing property. The preparation method comprises the following steps: with Zn(NO3)2.6H2O, (NH4)6Mo7O24.4H2O and pyromellitic dianhydride as raw materials, complexing all the raw materials to obtain a complex; soaking the complex into an EuCl3 or Tb(ClO4)3 solution to respectively obtain a lanthanide doped complex; and soaking the doped complex into an MClx solution to respectively obtain complexes M-Eu@[NH4]2[ZnL].6H2O and M-Tb@[NH4]2[ZnL].6H2O. According to the invention, a novel lanthanide MOFs molecule with lighting adjustability and sensing property can be obtained through simple soaking; and the lanthanide doping operation is convenient, stable, efficient, strong in repeatability and favorable in control effect on the lighting adjustability and sensing property of MOFs.

Owner:EAST CHINA UNIV OF TECH

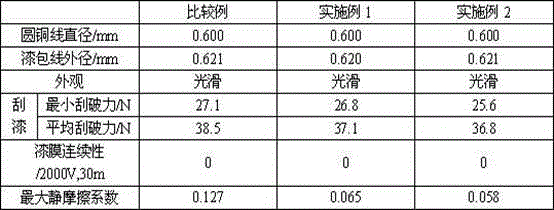

Self-lubricating polyamidoimide enamelled wire paint and preparation method thereof

InactiveCN104449341AReduce the maximum static friction coefficientSimple preparation processCoatingsStatic friction coefficientWax

The invention relates to a self-lubricating polyamidoimide enamelled wire paint preparation method, which comprises the following steps: 1)preparation method of polyamidoimide resin: employing dimethyl acetamide, 4,4'-diaminodiphenyl ether, dissolving and then adding pyromellitic dianhydride by eight batches, stirring and reacting until the color is transparent; 2)preparation method of wax slurry: adding xylene and wax under stirring, gradually heating from room temperature to 100-120 DEG C in 3-5 hours, insulating for 2-3 hours, cooling to room temperature; and 3)preparation method of the enamelled wire paint: taking polyamidoimide resin and wax slurry, stirring and uniformly mixing, heating to 160-180 DEG C, insulating for 10-20 hours, and cooling to room temperature to obtain the self-lubricating polyamidoimide enamelled wire. According to the invention, wax slurry with good lubricity is introduced in the polyamidoimide enamelled wire, maximum static friction coefficient of the enamelled wire is reduced, and the maximum static friction coefficient of the enamelled wire is about 0.060.

Owner:DANYANG STAR CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com