Fiber composite material for robotic electronic skin and preparation method thereof

A fiber composite material and electronic skin technology, which is applied in fiber type, fiber treatment, hollow filament manufacturing, etc., can solve the problems of low sensitivity, poor mechanical properties of pure liquid metal, weak tensile properties and electrical conductivity, etc. problems, to achieve the effect of excellent conductivity, broad application prospects, and good stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

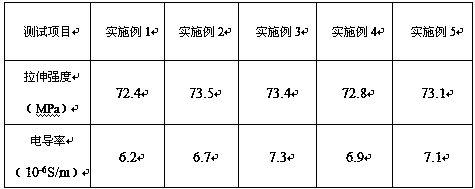

Examples

Embodiment 1

[0029] a. Add pyromellitic dianhydride and 4,4'-diphenyl ether diamine into N-methylpyrrolidone, and obtain polyamic acid solution through polycondensation reaction. The temperature of polycondensation reaction is 8°C, and the time is 4h. Wet spinning and thermal stretching, the temperature of thermal stretching is 290°C, and the stretching ratio is 2 times; hollow polyimide fibers are obtained; wherein, 12 parts by weight of pyromellitic dianhydride, 4,4' - 18 parts by weight of diphenyl ether diamine, 70 parts by weight of N-methylpyrrolidone;

[0030] b. Rinse the hollow polyimide fiber prepared in step a, and slowly immerse it in the tin-gallium liquid metal, in the tin-gallium liquid metal, 45 parts by weight of tin and 55 parts by weight of gallium; take it out after standing at 70°C for 25 minutes, And repeat the immersion and removal, the number of repetitions is 4 times; the tin-gallium liquid metal is filled with the hollow polyimide fiber;

[0031] c. Place the hol...

Embodiment 2

[0033] a. Add pyromellitic dianhydride and 4,4'-diphenyl ether diamine into N-methylpyrrolidone, and obtain polyamic acid solution through polycondensation reaction. The temperature of polycondensation reaction is 8°C, and the time is 3.5h. After wet spinning and thermal stretching, the temperature of thermal stretching is 295°C, and the draw ratio is 3 times; hollow polyimide fibers are obtained; wherein, 14 parts by weight of pyromellitic dianhydride, 4,4 19 parts by weight of '-diphenyl ether diamine, 67 parts by weight of N-methylpyrrolidone;

[0034] b. Rinse the hollow polyimide fiber prepared in step a, and slowly immerse it in the tin-gallium liquid metal, in the tin-gallium liquid metal, 50 parts by weight of tin and 50 parts by weight of gallium; take it out after standing at 80° C. for 27 minutes, And repeat the immersion and removal, the number of repetitions is 5 times; make the tin-gallium liquid metal fill the hollow polyimide fiber;

[0035] c. Place the hollo...

Embodiment 3

[0037] a. Add pyromellitic dianhydride and 4,4'-diphenyl ether diamine into N-methylpyrrolidone, and obtain polyamic acid solution through polycondensation reaction. The temperature of polycondensation reaction is 10°C, and the time is 3h. Wet spinning and thermal stretching, the temperature of thermal stretching is 300°C, and the stretching ratio is 3 times; hollow polyimide fibers are obtained; wherein, 15 parts by weight of pyromellitic dianhydride, 4,4' - 20 parts by weight of diphenyl ether diamine, 65 parts by weight of N-methylpyrrolidone;

[0038] b. Rinse the hollow polyimide fiber prepared in step a, and slowly immerse it in the tin-gallium liquid metal, in the tin-gallium liquid metal, 60 parts by weight of tin and 40 parts by weight of gallium; take it out after standing at 80° C. for 30 minutes, And repeat the immersion and removal, the number of repetitions is 5 times; make the tin-gallium liquid metal fill the hollow polyimide fiber;

[0039]c. Place the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com