Self-lubricating polyamidoimide enamelled wire paint and preparation method thereof

A polyamide-imide and enameled wire enamel technology, applied in the coating and other directions, can solve the problems of the insulation layer being susceptible to mechanical damage, the performance of the enameled wire, and the insulation performance of the enameled wire, etc., to improve the winding performance and winding performance, lubrication Good effect, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

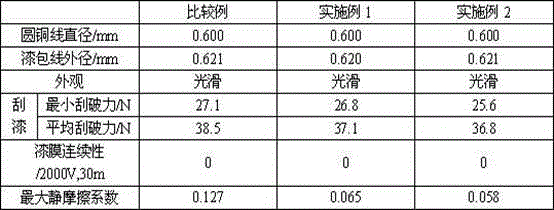

Examples

Embodiment 1

[0016] The preparation method of the self-lubricating polyamide-imide wire enamel of the present embodiment may further comprise the steps:

[0017] (1) The preparation method of polyamide-imide resin: take 10 parts of dimethylacetamide, 2 parts of 4,4'-diaminodiphenyl ether, and 2 parts of pyromellitic dianhydride, and add dimethyl Acetamide, 4,4'-diaminodiphenyl ether, after dissolving, add pyromellitic dianhydride in 8 batches, stir and react until transparent;

[0018] (2) Preparation method of wax slurry: Take 10 parts of palm wax and 90 parts of xylene according to the weight ratio, add xylene and wax under stirring, gradually raise the temperature from room temperature to 120 ° C over 5 hours, keep it warm for 2 hours, and cool to room temperature;

[0019] (3) Preparation method of wire enamel: Take 100 parts of the above polyamide-imide resin and 10 parts of wax slurry, stir and mix evenly, heat to 180°C, keep it warm for 20 hours, and then cool to room temperature t...

Embodiment 2

[0021] The preparation method of the self-lubricating polyamide-imide wire enamel of the present embodiment may further comprise the steps:

[0022] (1) The preparation method of polyamide-imide resin: take 10 parts of dimethylacetamide, 2 parts of 4,4'-diaminodiphenyl ether, and 2 parts of pyromellitic dianhydride, and add dimethyl Acetamide, 4,4'-diaminodiphenyl ether, after dissolving, add pyromellitic dianhydride in 8 batches, stir and react until transparent;

[0023] (2) Preparation method of wax slurry: Take 20 parts of oxidized polyethylene wax and 80 parts of xylene according to the weight ratio, add xylene and wax under stirring, gradually raise the temperature from room temperature to 120 ° C over 4 hours, and keep it warm for 3 hours , cooled to room temperature;

[0024] (3) Preparation method of wire enamel: Take 100 parts of the above polyamide-imide resin and 10 parts of wax slurry, stir and mix evenly, heat to 160°C, keep it warm for 20 hours, and then cool t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com