Synthesis method of novel self-lubricating polyamide-imide insulating resin

A polyamide-imide and insulating resin technology is applied in the field of enameled wire enamel manufacturing to achieve the effects of improving winding performance and winding performance, improving production efficiency, good self-lubricating performance and flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

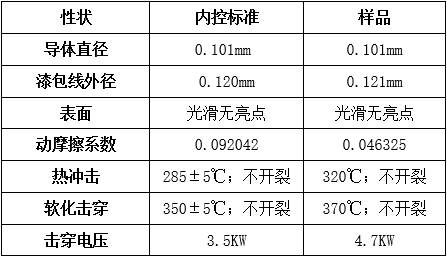

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below according to the embodiments. In the description of this specification, the content of an embodiment means that the specific technical features described in conjunction with it are included in at least one embodiment of the present invention. In this specification, schematic representations of the above terms do not necessarily refer to the same embodiment or example. Moreover, the described specific technical features may be combined in any one or more implementations or examples in a proper manner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com