Patents

Literature

100 results about "ETHYL PYRROLIDONE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-Temperature Crosslinked Polymer for Use in a Well

A method comprising the steps of: (A) forming a fluid comprising a crosslinked polymer, wherein the crosslinked polymer comprises: (i) a first monomeric unit of one or more N-vinyl lactams; and (ii) a crosslinker selected from the group consisting of: divinyl ether, diallyl ether, vinyl or allyl ethers of polyglycols or polyols, divinylbenzene, 1,3-divinylimidazolidin-2-one, divinyltetrahydropyrimidin-2(1H)-one, dienes, allyl amines, N-vinyl-3(E)-ethylidene pyrrolidone, ethylidene bis(N-vinylpyrrolidone), and any combination of any of the foregoing; and (B) introducing the fluid into a portion of a well. The crosslinked polymer may additionally comprise: a second monomeric unit selected from the group consisting of: acrylamide, N-substituted acrylamides, methacrylamide, N-substituted methacrylamides, acrylates, methacrylates, acrylic acid, methacrylic acid, N-vinylamides, N-allyl amides, vinyl alcohol, vinyl ethers, vinyl esters, allyl alcohol, allyl ethers, allyl esters, vinylpyridine, vinyl sulfonates, allyl sulfonates, vinylimidazole, allylimidazole, diallyldimethylammonium chloride, and any combination of any of the foregoing.

Owner:HALLIBURTON ENERGY SERVICES INC

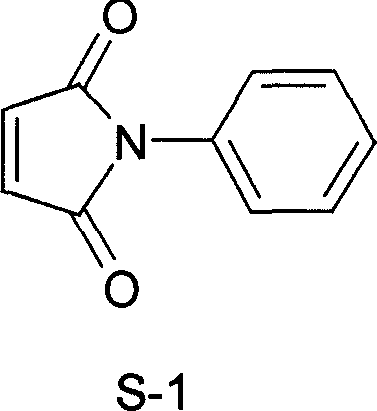

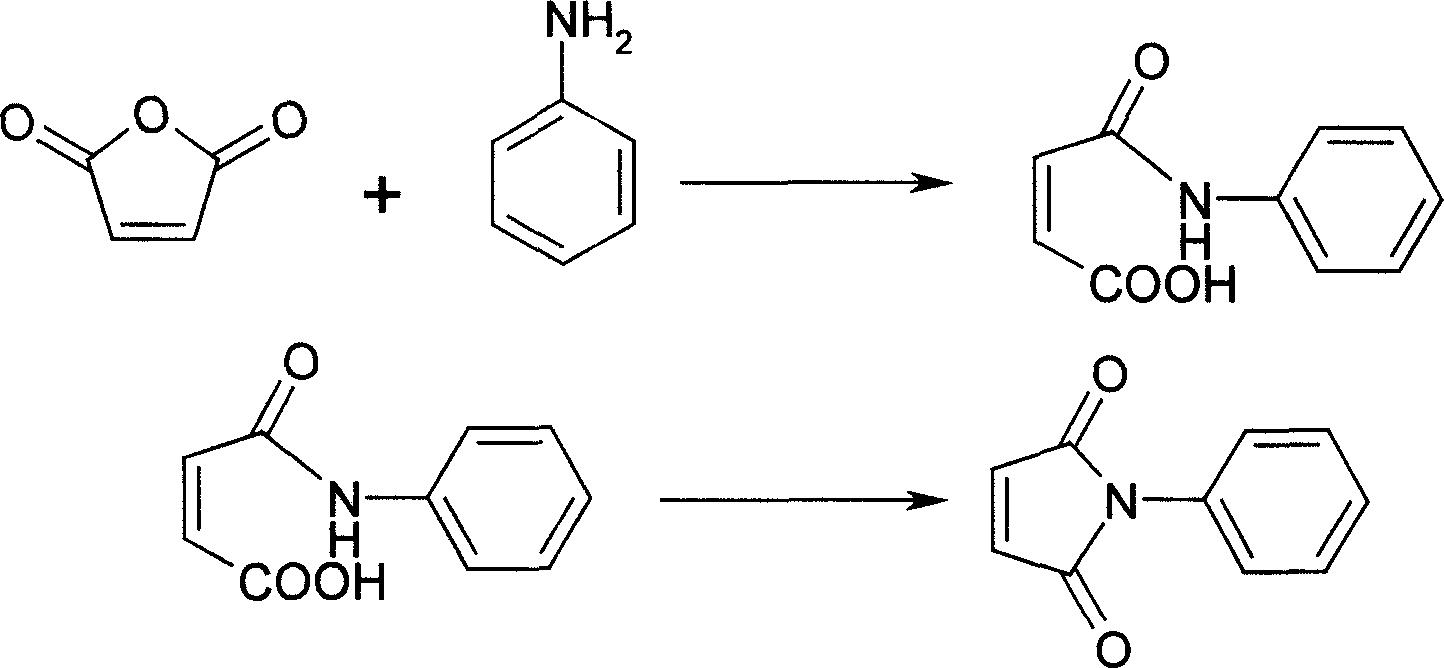

Process for preparing N-phenyl maleimide

The invention discloses a synthesizing method of N-phenyl maleimide, which comprises the following steps: 1) acylating the maleic anhydride and aniline in the solvent; 2) reacting N-phenyl maleamic acid with hydroquinone as inhibitor and p-toluenesulfonic acid and N-ethyl pyrrolidone as double catalyst; decompressing the liquid to remove solvent; obtaining the rought product; 3) recrystallizing to obtain the product.

Owner:ZHEJIANG UNIV

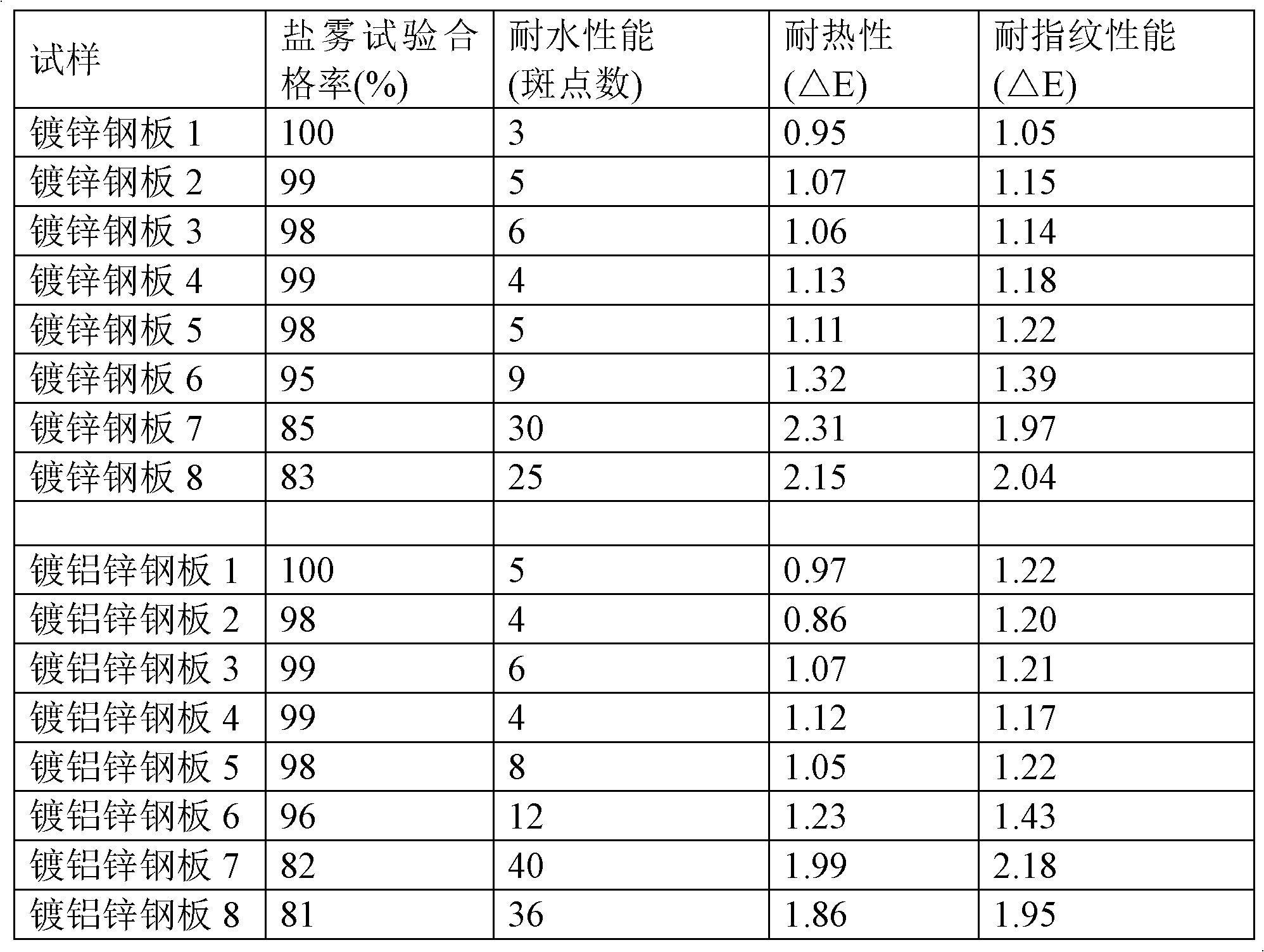

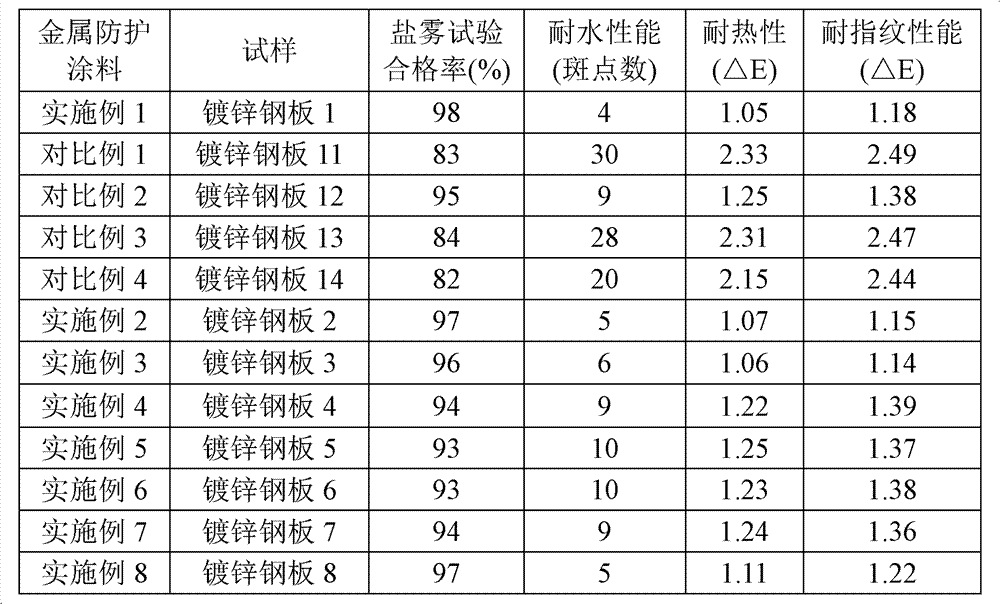

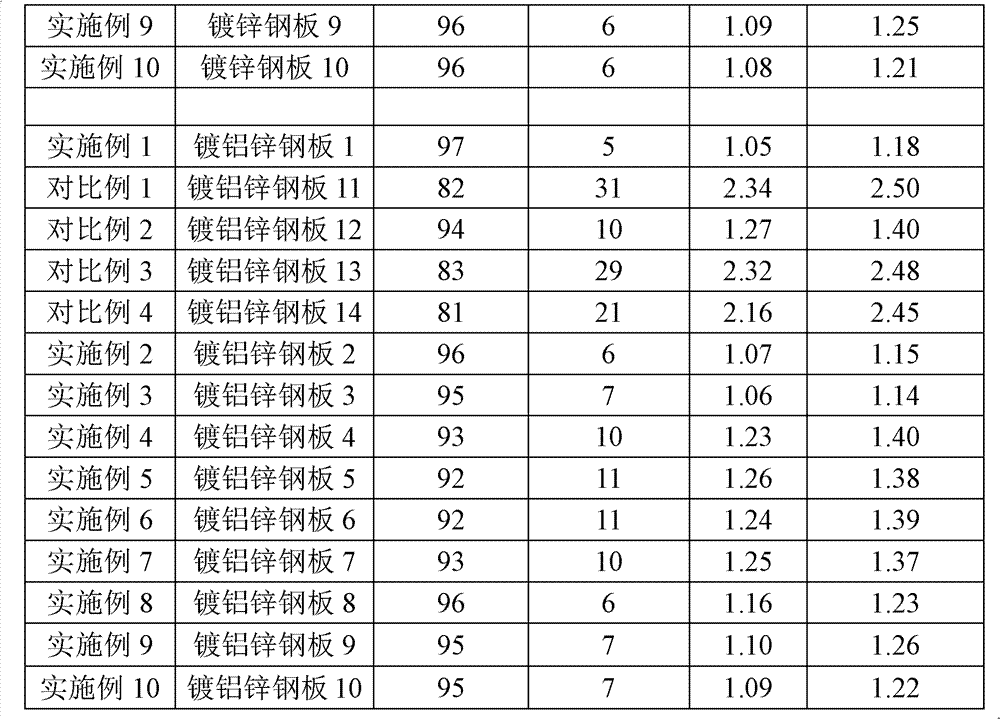

Metal protective coating and hot galvanizing metal material as well as hot-dip aluminium-zinc metal material

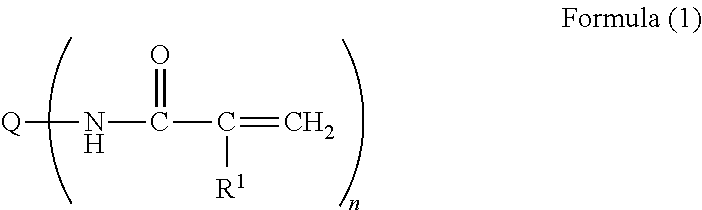

ActiveCN103013337AImprove corrosion resistanceImprove water resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsSilanesZinc metal

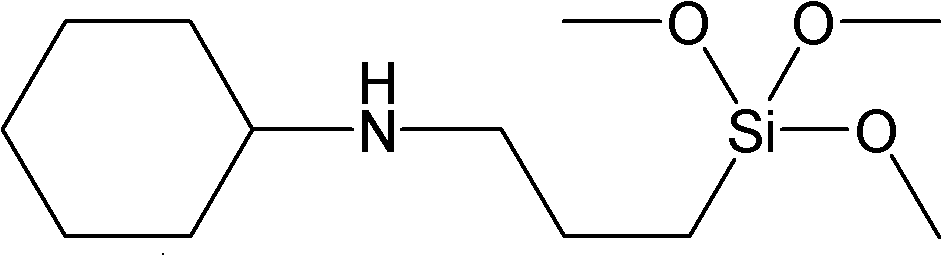

The invention provides metal protective coating. The metal protective coating is obtained by uniformly mixing raw material mixture, wherein the raw material mixture contains water soluble silicate, a promoter, a silane coupling agent, silicon oxide filler, water soluble film forming resin and water; the promoter is at least one of pyrrolidone, N-methyl pyrrolidone, and N-ethyl pyrrolidone; and the silane coupling agent contains first silane derivatives shown in formula (1) described in the specification, wherein R1, R2 and R3 are methoxyl or ethoxyl respectively, and n is an integral number ranging from 1 to 4. The invention also provides a hot galvanizing metal material and a hot-dip aluminium-zinc metal material. A protective film formed by the metal protective coating provided by the invention has excellent corrosion resistance, water resistance, heat resistance and fingerprint resistance. Formula (1) is described in the specification.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

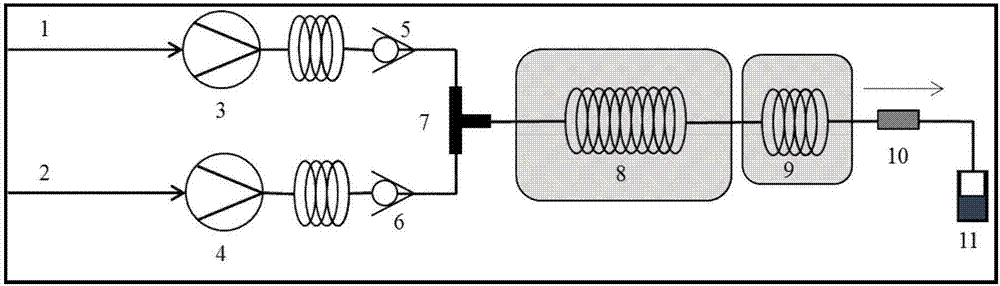

Continuous synthesis method for N-methyl pyrrolidone and N-ethyl pyrrolidone

ActiveCN107474003AShort synthesis reaction timeImprove efficiencyOrganic chemistrySynthesis methodsGlycol synthesis

The invention discloses a continuous synthesis method for N-methyl pyrrolidone and N-ethyl pyrrolidone. The method includes the steps that the reactions are carried out in a micro reactor, and the N-methyl pyrrolidone and the N-ethyl pyrrolidone are synthesized through continuously feeding a gamma-butyrolactone solution and a corresponding alkylamine solution to pass the micro reactor, wherein the micro reactor comprises a reaction section and a reaction inhibition section, synthesizing is carried out under the condition that the standing time of a reaction mixture in the reaction section is 1 minute to 30 minutes, ethylene glycol serves as a solvent in the gamma-butyrolactone solution and the corresponding alkylamine solution, the molar ratio of alkylamine to gamma-butyrolactone in the reaction mixture is 1.0 to 1.6, and the concentration of the gamma-butyrolactone solution is 0.5 mol / L to 2 mol / L. According to the method, the time of the synthesizing process of the N-methyl pyrrolidone and the N-ethyl pyrrolidone can be shortened to within 30 min from original several hours, and meanwhile the yield of products is 90% or above.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

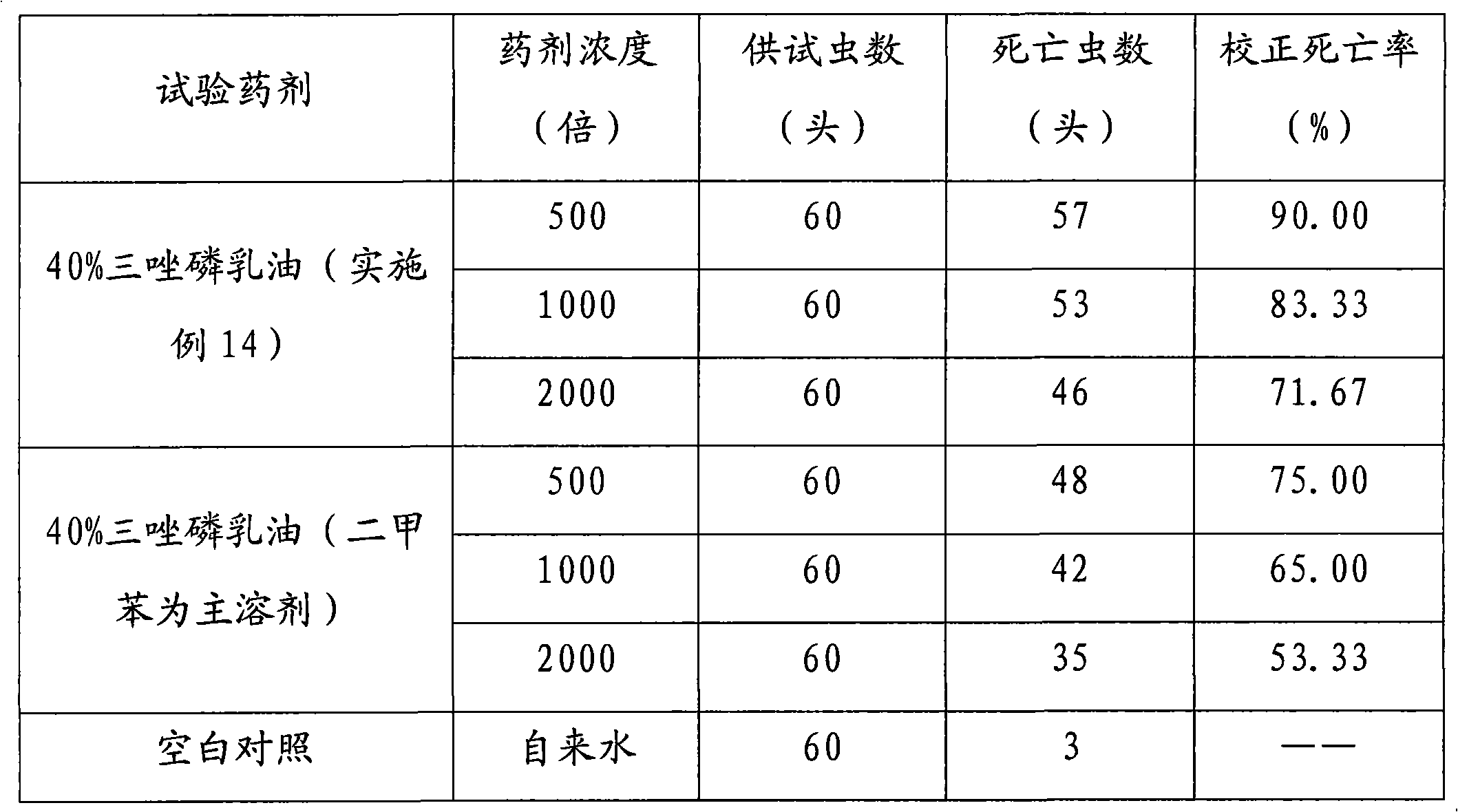

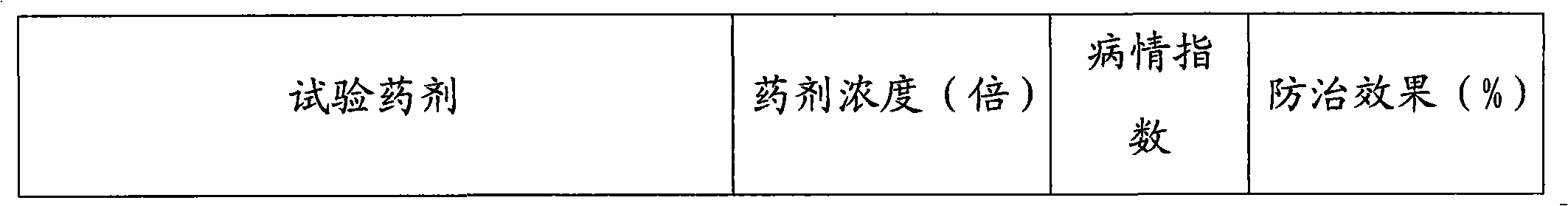

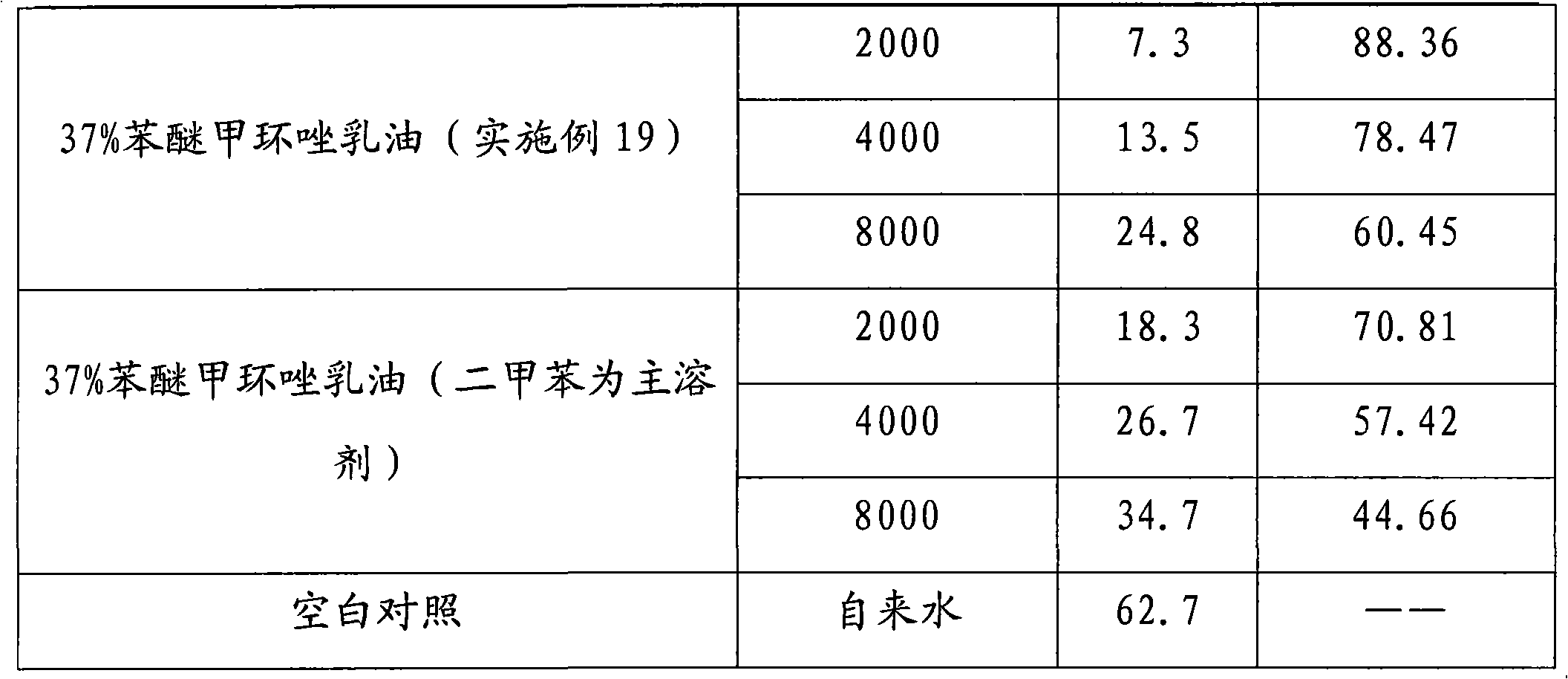

Pesticide adjuvant and applications thereof

InactiveCN101658163ASynergistic effect is obviousLow costBiocideAnimal repellantsAdditive ingredientMethyl salicylate

The invention relates to a pesticide adjuvant and applications thereof. The pesticide adjuvant is characterized by comprising the following ingredients by mass percentage: 90 to 100 percent of pine-stump light oil and 0 to 10 percent of cosolvent, wherein the cosolvent is at least one of n-butyl alcohol, isobutyl alcohol, N-methylpyrrolidone, N-hydroxyethylpyrrolidone and methyl salicylate. The pesticide adjuvant is applicable to various pesticides, and particularly applicable to missible oil, oiling agent, oil suspension solvent, suspension emulsion, micro-emulsion, aqueous emulsion and ultra-low volume concentrate, and also can be used as barrel pesticide mixing assistant agent; and the pesticide adjuvant is applicable to preparation of ingredients of pesticides such as insecticide, acaricide, bactericide, herbicide, plant growth regulator and the like. The pesticide adjuvant and the barrel-mixing agent have strong dissolving power, is environment-friendly, have synergy effect on agents, wide source and moderate use cost, and is the ideal choice substituting for triphenyl organic solvents.

Owner:SHENZHEN NOPOSION AGROCHEM

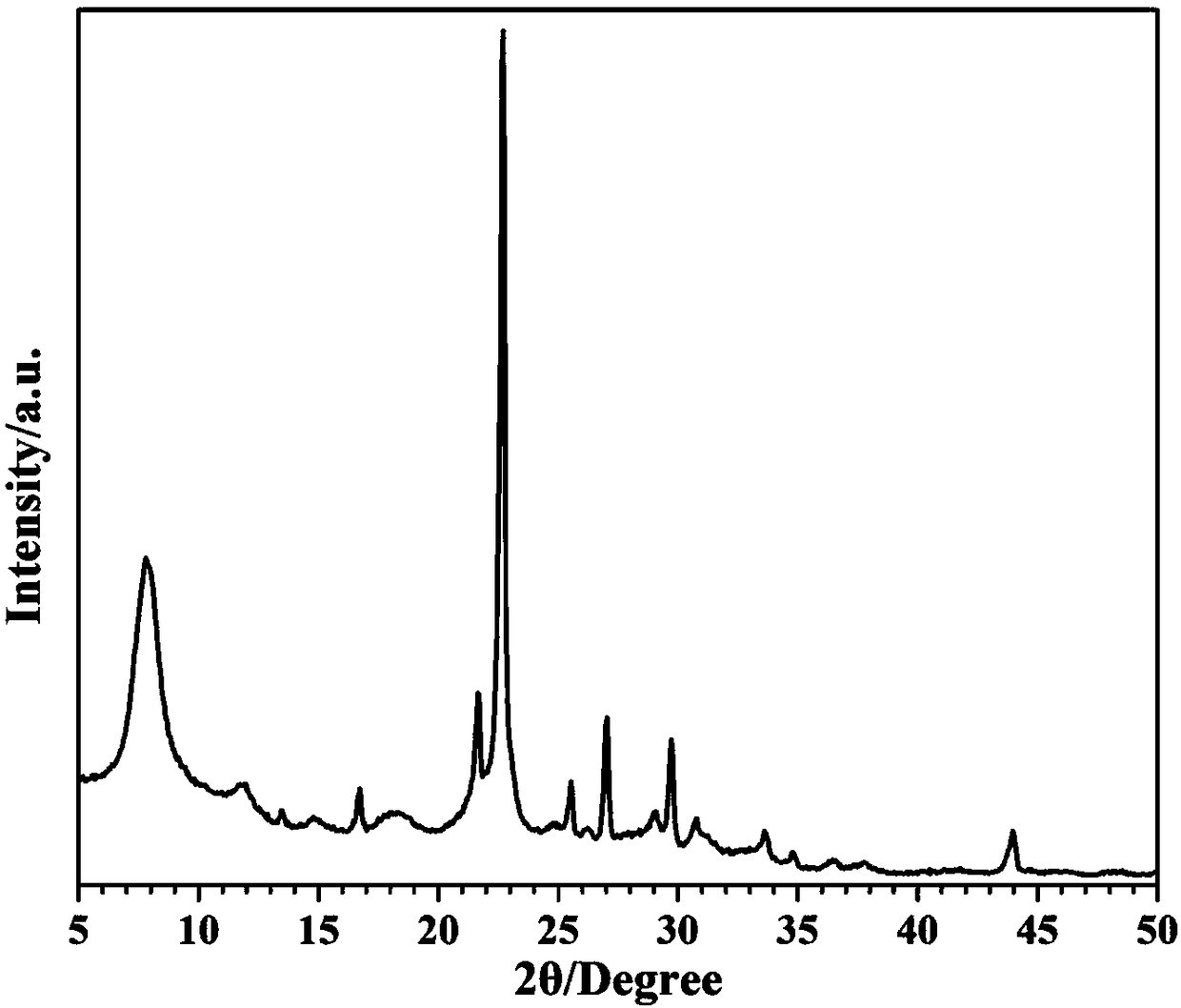

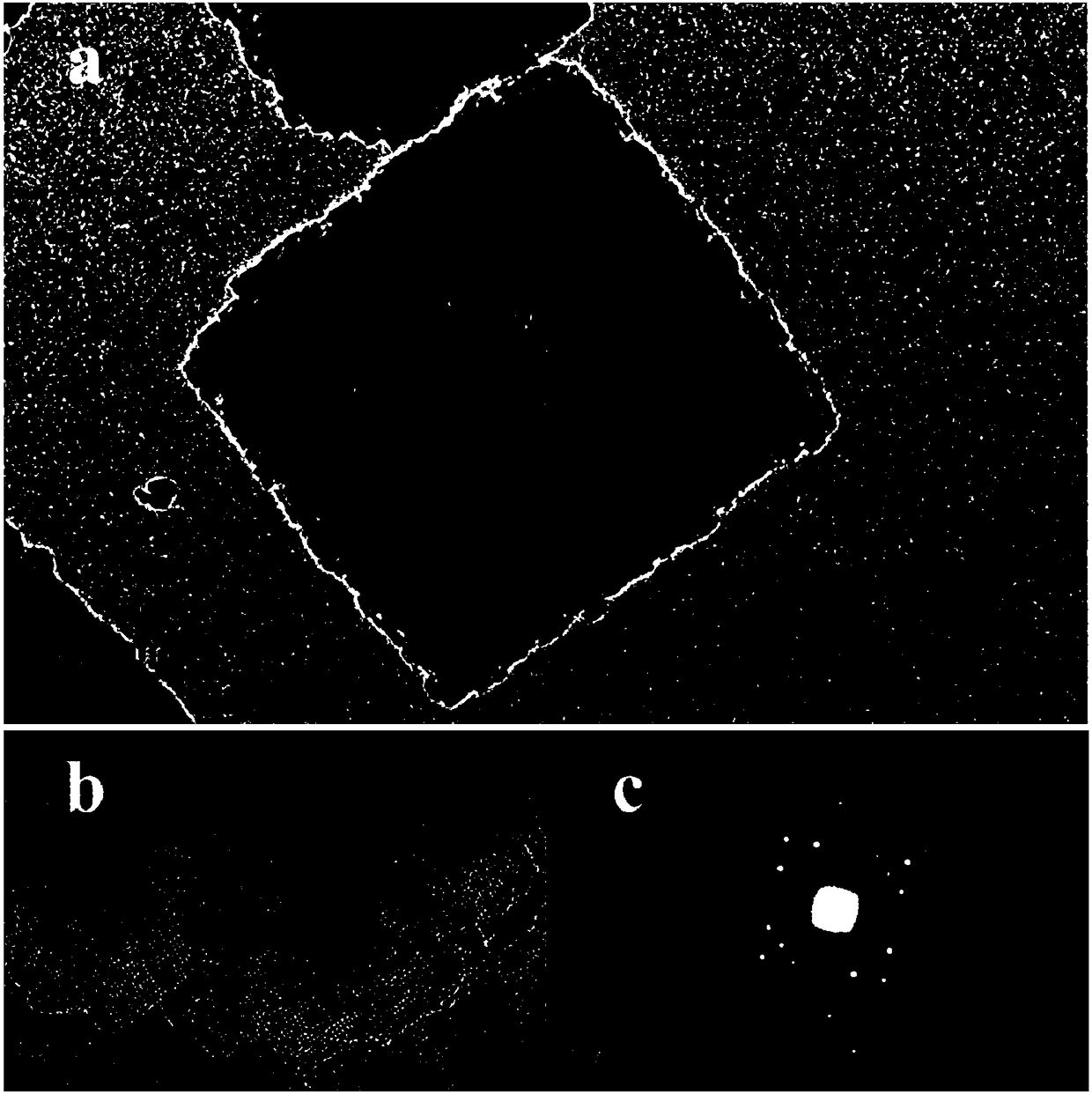

Preparation method of hollow single crystal Beta molecular sieve

InactiveCN108217675AHollow withHigh crystallinityNanotechnologyCrystalline aluminosilicate zeolitesMolecular sieveN-ethyl-2-pyrrolidone

The invention provides a preparation method of a hollow single crystal Beta molecular sieve. The method comprises the step that the hollow single crystal Beta molecular sieve is prepared by one-step hydrothermal crystallization of a gel formed by thoroughly mixing a silicon source, an aluminum source, an inorganic base, a microporous templating agent and an organic additive lactam R. A synthesizedproduct is formed by sequential stacking and connecting of primary nanoparticles, and the primary particle size is 10 to 30 nm; the preparation method of the hollow single crystal Beta molecular sieve takes inexpensive N-methyl-2-pyrrolidone or homolog thereof such as 2-pyrrolidone, N-ethyl-2-pyrrolidone, N-isopropyl-2-pyrrolidone as organic additives, the hollow single crystal Beta molecular sieve is synthesized by one-step method to replace a traditional two-step acid-base treatment method to obtain a hollow structure, the preparation method of the hollow single crystal Beta molecular sieveis an economical, efficient method for easily obtaining the hollow single crystal Beta molecular sieve.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

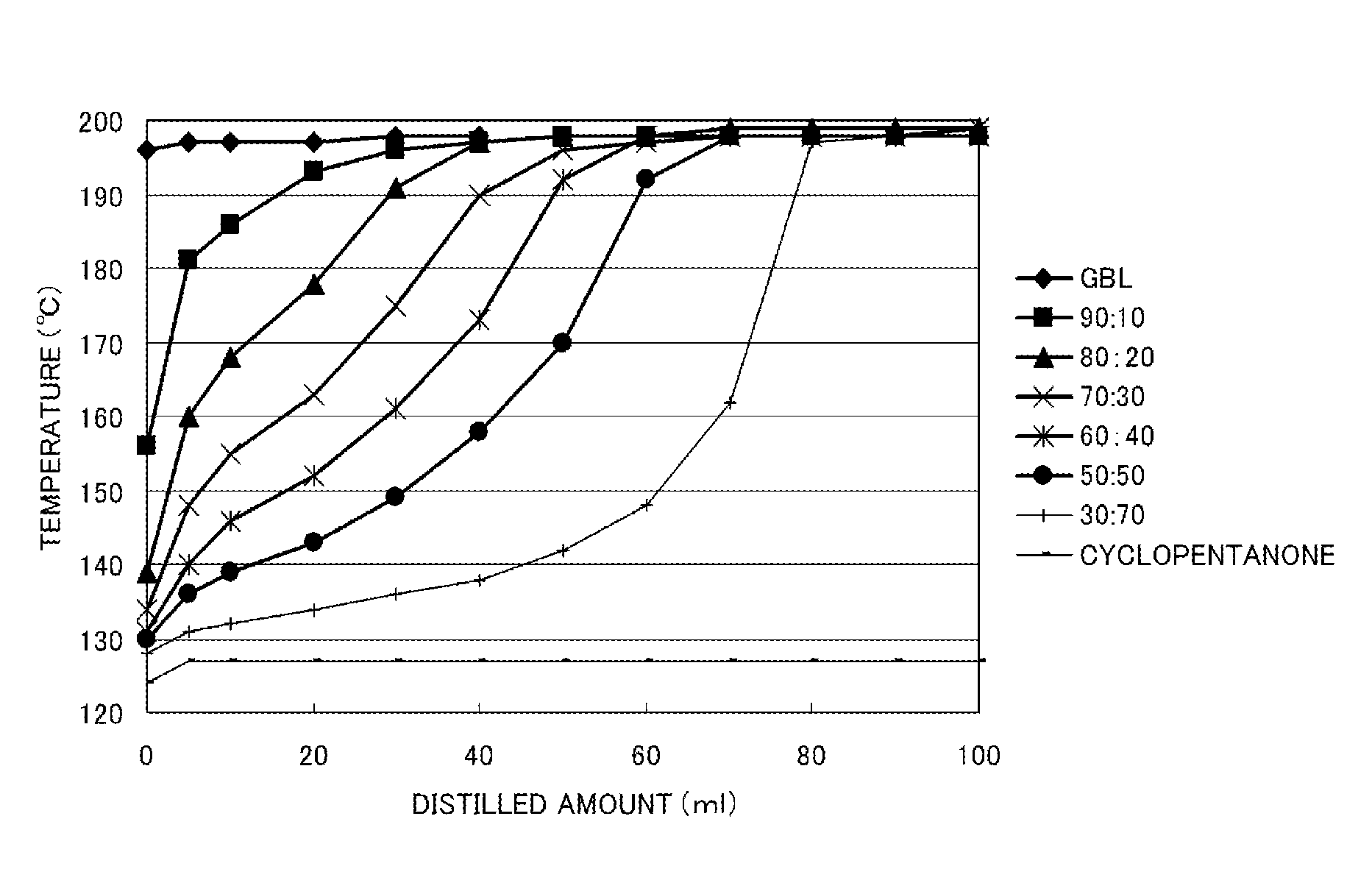

Polyamideimide-based film coating composition

ActiveUS8669305B2High molecular weightReduce coefficient of frictionSynthetic resin layered productsPaper coatingPolyamide-imideFilm-coated tablet

Disclosed is a polyamideimide-based film coating composition free from any restricted substance or a substance which might possibly be a restricted one such as N-methyl pyrrolidone and N-ethyl pyrrolidone and capable of replacing a conventional coating composition using a solvent such as N-methyl pyrrolidone. The polyamideimide-based film coating composition of the present invention is a polyamideimide-based film coating composition comprising a polyamideimide resin and a solvent, the polyamideimide resin being dissolved as a binder in the solvent, wherein the solvent contains γ-butyrolactone and cyclopentanone, and a volume of γ-butyrolactone is 50% by volume or more compared to a total volume of γ-butyrolactone and cyclopentanone.

Owner:VALEO JAPAN CO LTD

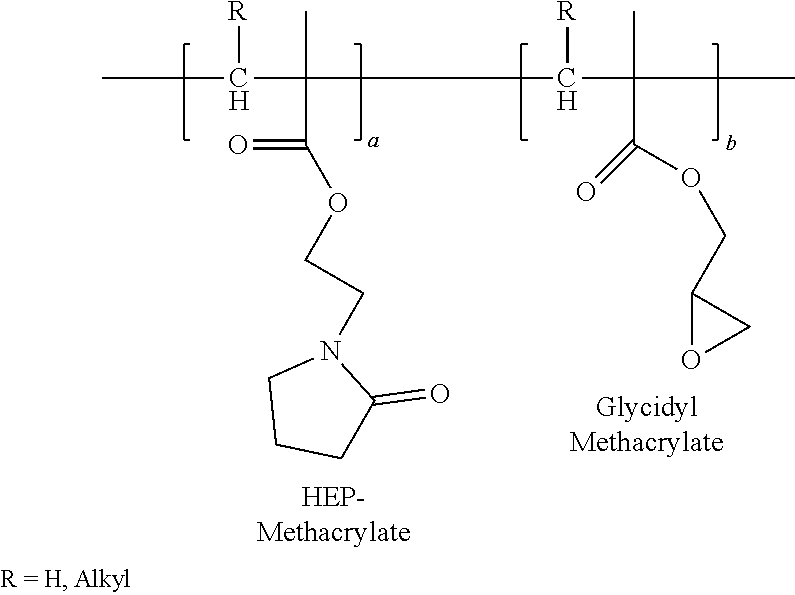

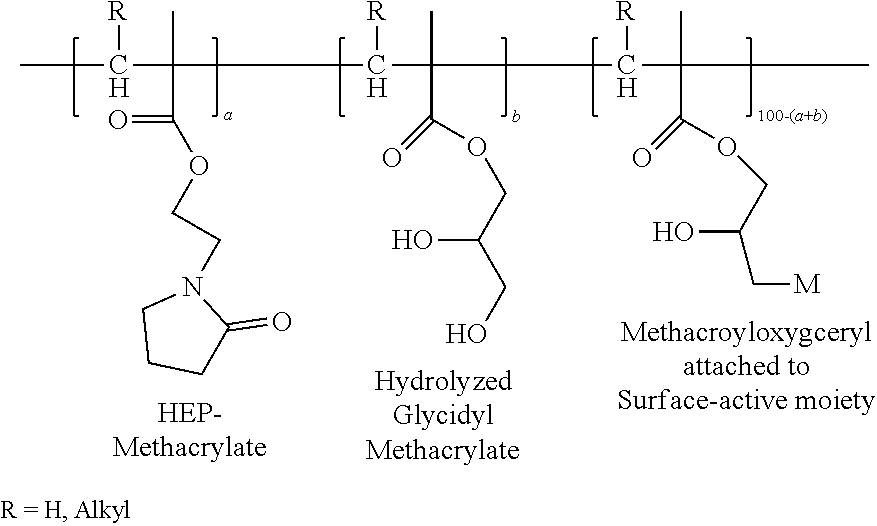

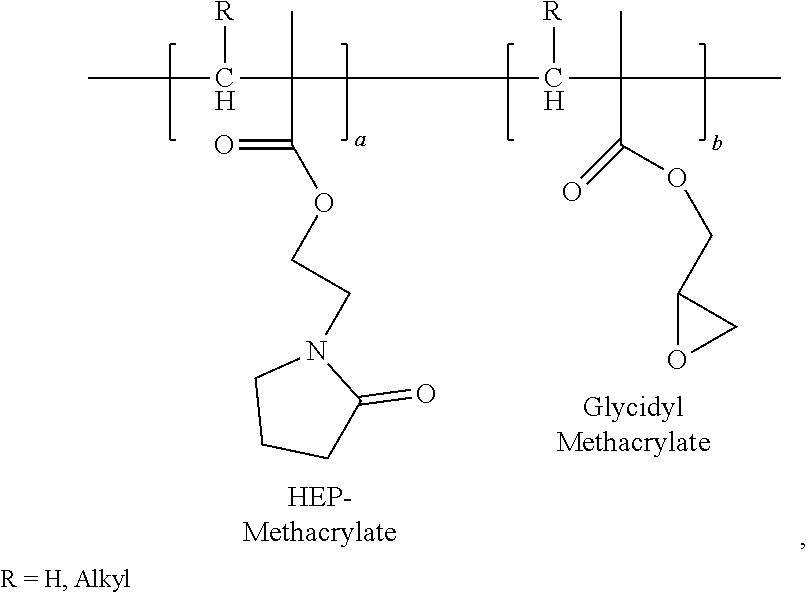

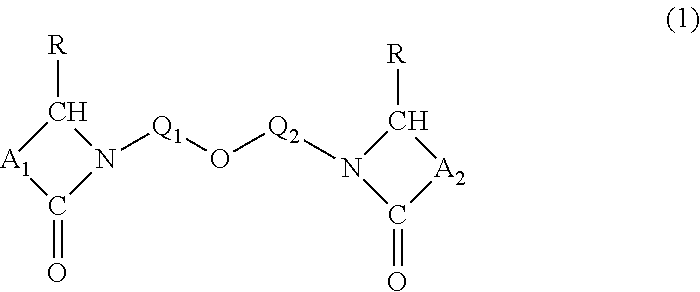

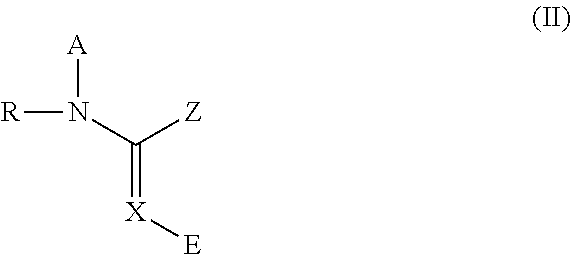

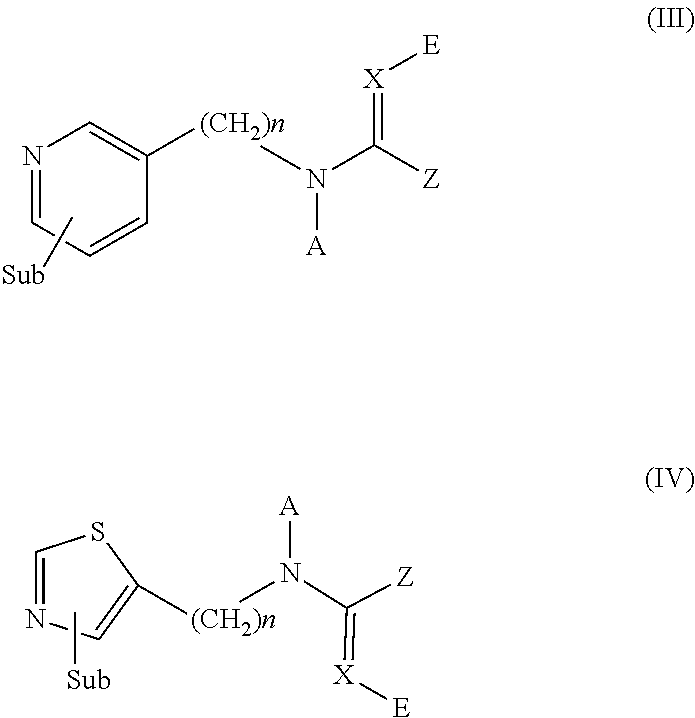

Hydroxyethylpyrrolidone ethacrylate/glycidyl ethacrylate copolymers

This application provides reactive, flexible, water-resistant hydroxyethylpyrrolidone methacrylate / glycidyl methacrylate copolymers having the structure:wherein a and b are integers, the sum of which less than 100, covalently linked to active agents that are useful in a wide variety of compositions. The present application also discloses hydroxyethylpyrrolidonemethacrylate / glycidyl methacrylate copolymer convently linked to one or more surface active moiety having a structure:wherein a, b, and c are integers, the sum of which equals 100, and M is a surface-active moiety.

Owner:ISP INVESTMENTS LLC

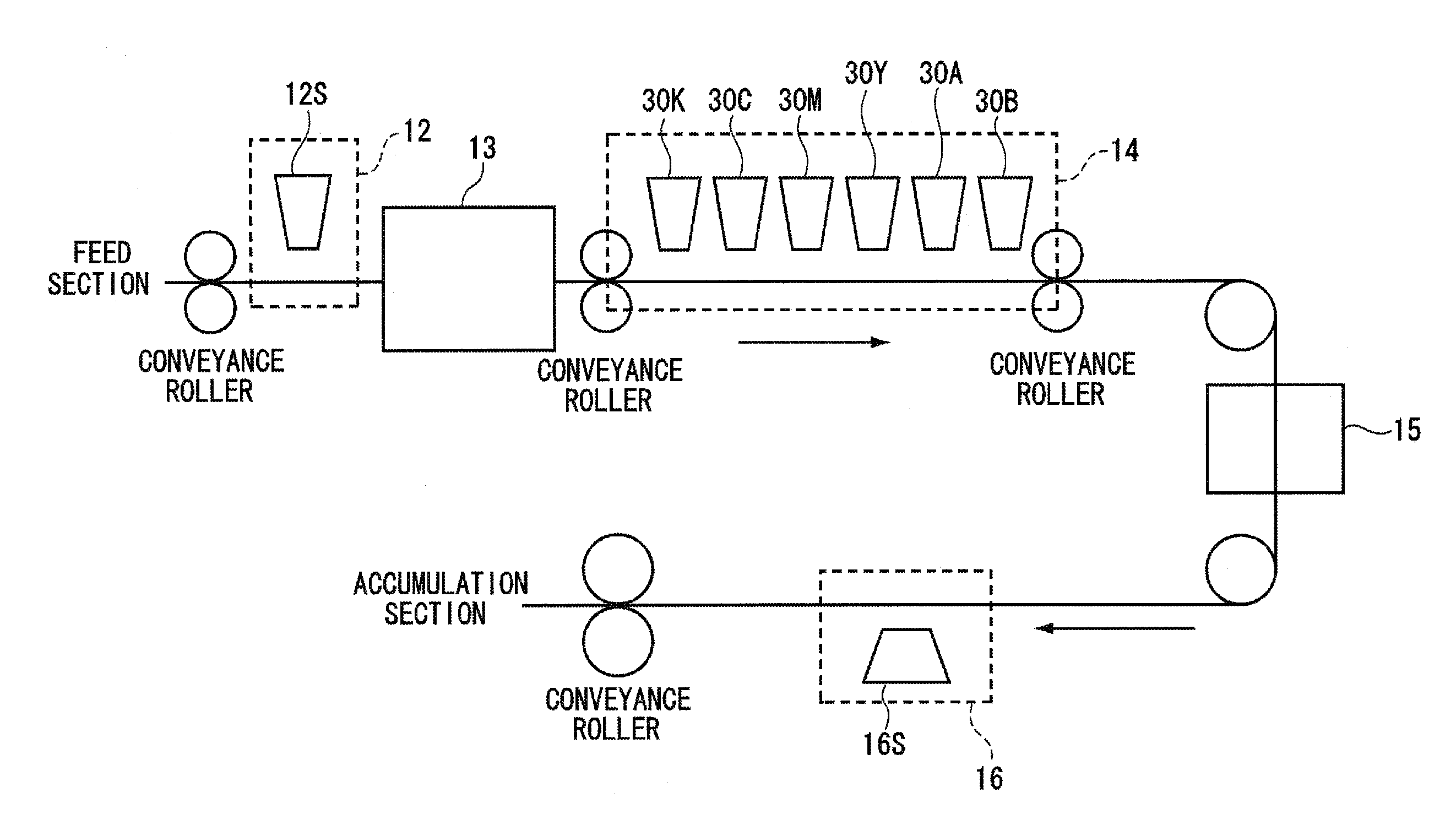

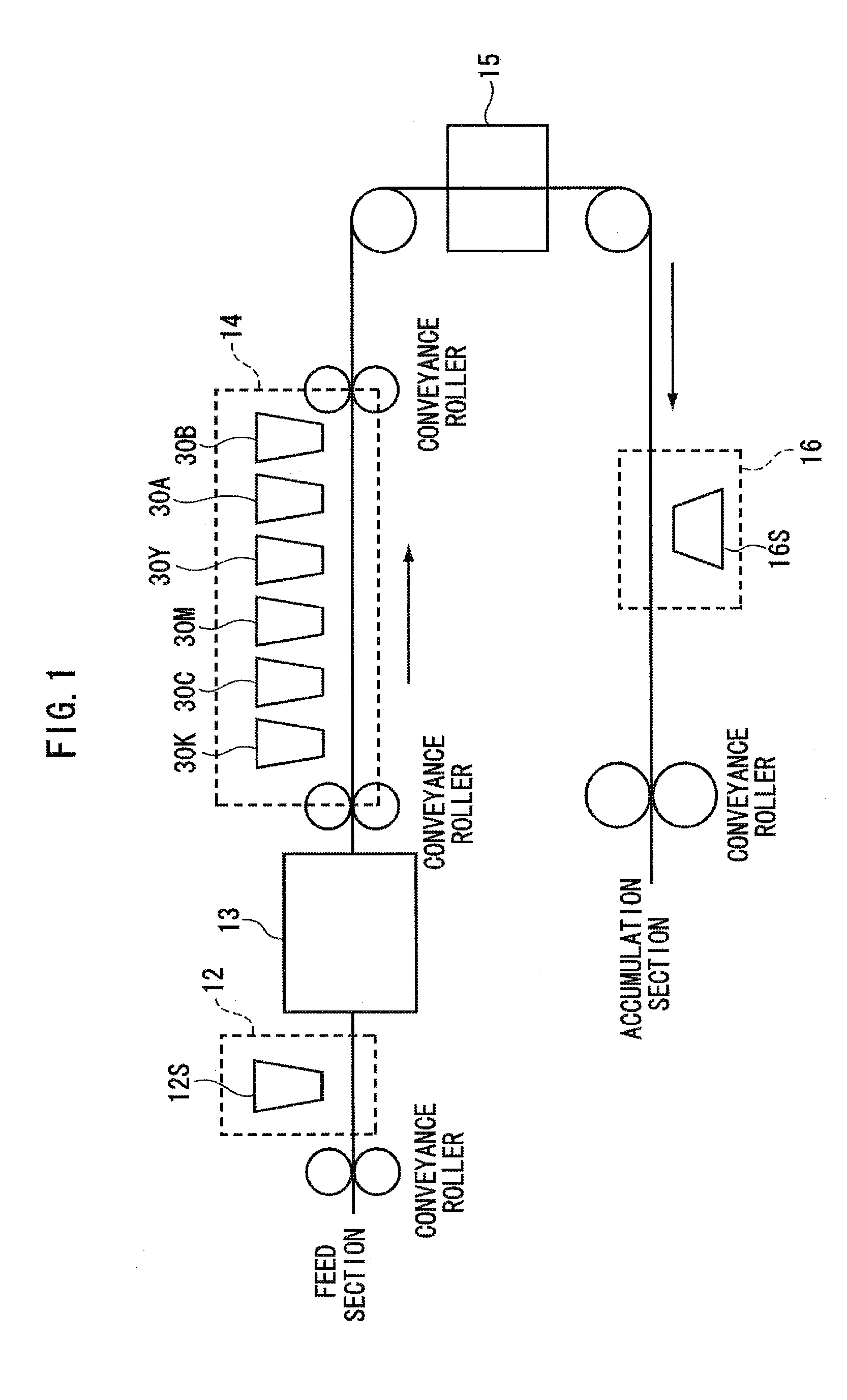

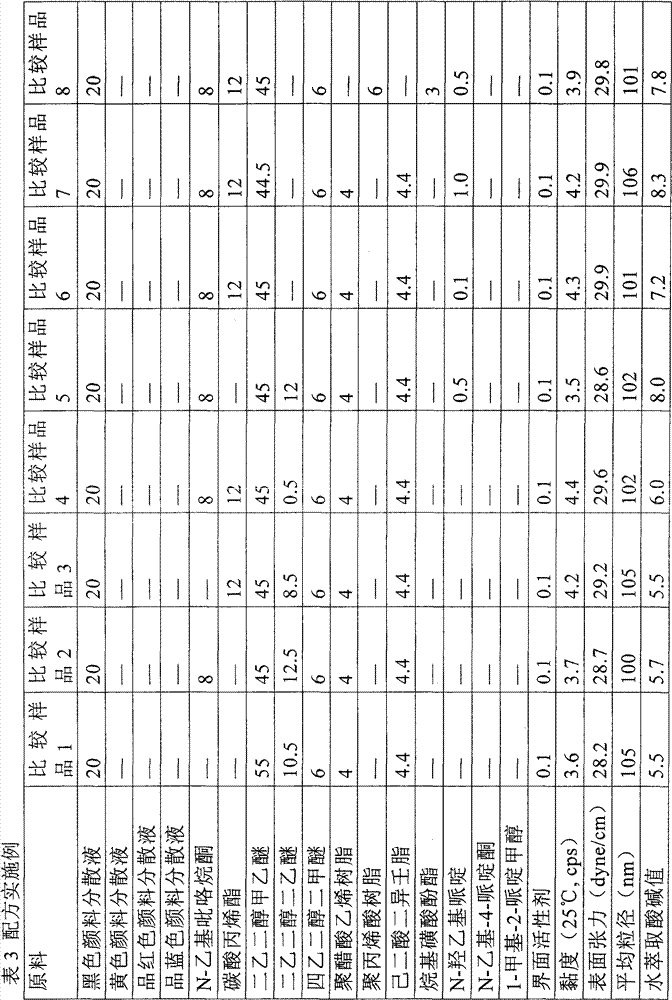

Ink composition, ink set, and image forming method

InactiveUS20130050331A1High temporal stabilityGood rubbing fastnessDuplicating/marking methodsInksSolubilityDouble bond

Disclosed is an ink composition including: (1) a pigment; (2) a polymerization initiator having a content of 2% by mass or more with respect to a total amount of the composition and having a solubility with respect to pure water at 25° C. of 5 to 8 g / l; (3) a compound A that is at least one selected from the group consisting of dimethylacrylamide, diethylacrylamide, N-isopropylacrylamide, dimethylacetamide, N-ethylpyrrolidone, 1-cyclohexyl-2-pyrrolidone, 1-(2-hydroxyethyl)-2-pyrrolidone, 1,3-dimethyl-2-imidazolidinone, tetramethylurea and gamma-valerolactone; (4) a polymerizable compound having two or more ethylenically unsaturated double bonds; and (5) water having a content of 50% by mass or more with respect to the total amount of the composition.

Owner:FUJIFILM CORP

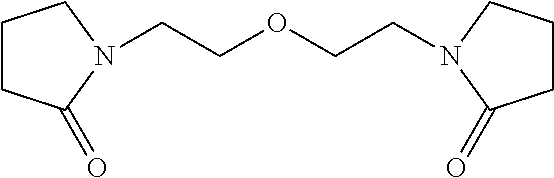

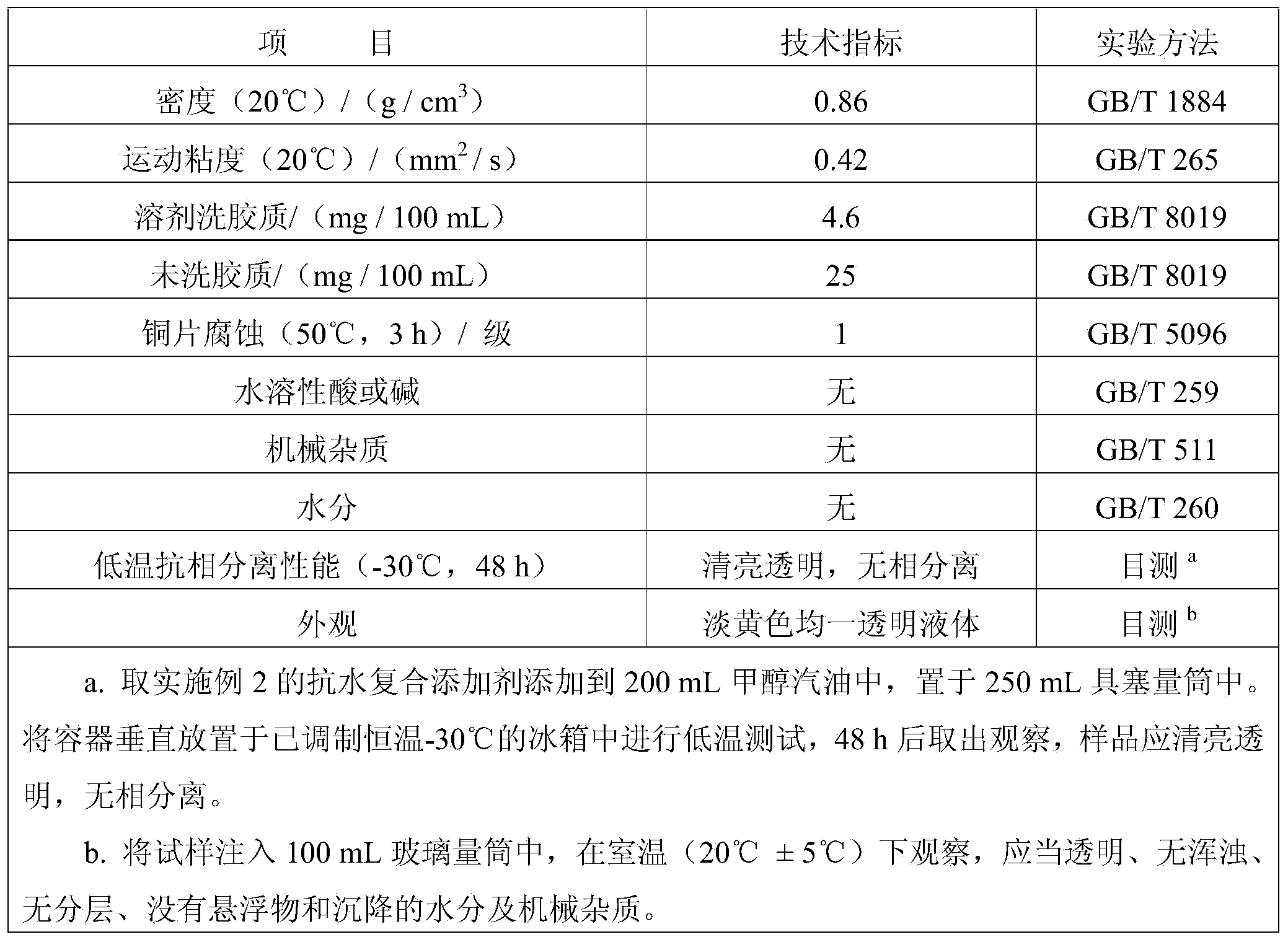

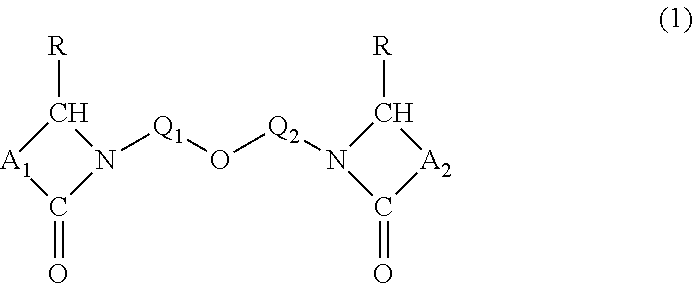

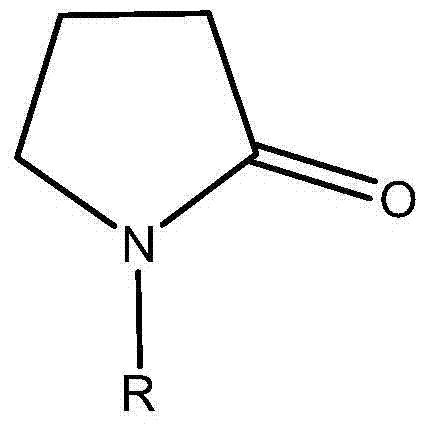

N-alkyl lactam ethers, and compositions and uses thereof

Described is a class of symmetrical and asymmetrical N-alkyl lactam ethers. One preferred ether is bis-N-ethyl pyrrolidone ether. Preferred compositions and uses of the ethers are in performance chemicals, personal care, and pharmaceutical fields, where they function a variety of roles, including as a solvent, solubilizer, freezing point depressor, diluent, extracting agent, cleaning agent, degreaser, absorbent and / or dispersion agent.

Owner:THE BANK OF NOVA SCOTIA

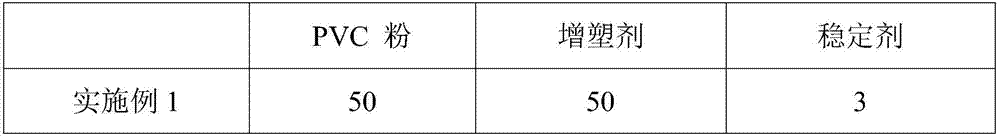

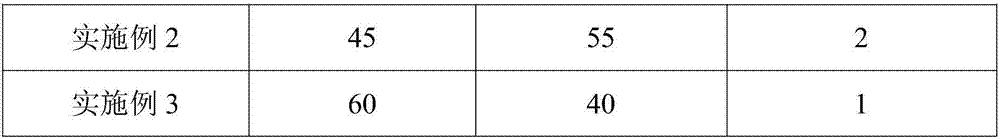

Reproductive-toxicity-free polyvinyl chloride vehicle interior decoration leather and preparation method thereof

InactiveCN107366166ANo reproductive toxicityReduce the smellPolyurea/polyurethane coatingsVehicle componentsSurface layerHeat resistance

The present invention discloses a reproductive-toxicity-free polyvinyl chloride vehicle interior decoration leather and a preparation method thereof, wherein the reproductive-toxicity-free polyvinyl chloride vehicle interior decoration leather comprises a polyvinyl chloride surface layer, a polyvinyl chloride foaming layer and an aqueous paint layer coated on the polyvinyl chloride surface layer. According to the present invention, the aqueous paint layer does not contain N-methylpyrrolidone and N-ethylpyrrolidone, and does not have reproductive toxicity under the premise of the meeting of the environmental protection requirements of low VOC and low odor, and the surface performance requirements of wear resistance, illumination resistance, heat resistance, fouling resistance and the like so as to avoid the harm to human body.

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

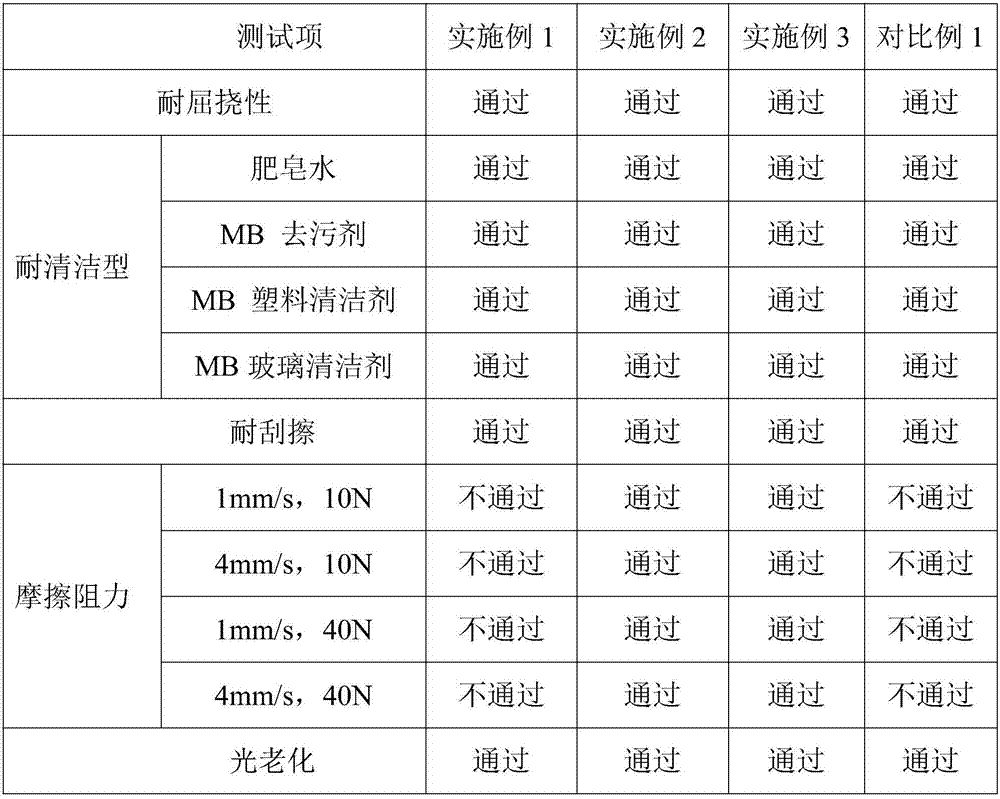

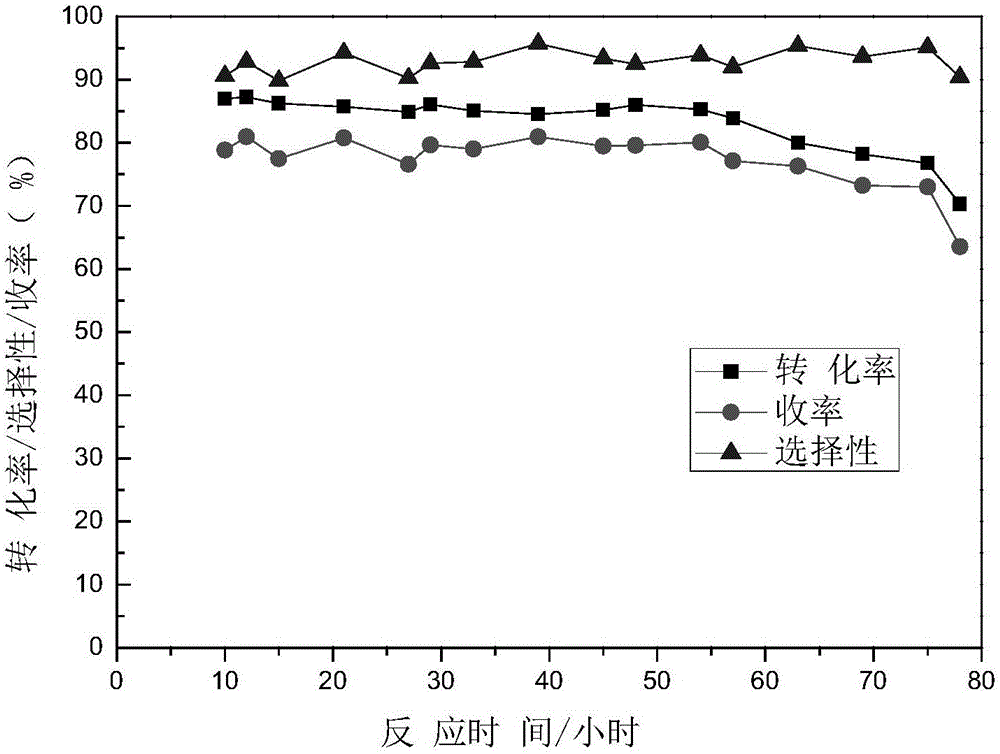

Method for preparing N-vinyl pyrrolidone in dehydration mode with N-hydroxyethyl pyrrolidone

The invention relates to a method for preparing N-vinyl pyrrolidone in a dehydration mode with N-hydroxyethyl pyrrolidone. The method includes the steps that gas with acidic components or alkaline components or liquid with alkaline components and N-hydroxyethyl pyrrolidone are mixed, the mixture passes through a dehydration-catalyst fixed bed reactor under the conditions that temperature ranges from 300 DEG C to 500 DEG C, pressure ranges from 0.01 MPa to 0.1 MPa, and the gas phase airspeed ranges from 10 h-<1> to 5,000 h-<1>, and the N-vinyl pyrrolidone product is obtained. The preparing method is obviously better than the prior art in the conversion rate respect, the selectivity respect and the service life respect.

Owner:XIAN ORIGIN CHEM TECH

Process for producing silylated pullulan and cosmetic preparation

InactiveUS20100048886A1Simpler and easy and efficient processInsufficient water resistanceCosmetic preparationsSugar derivativesPullulanN-ethyl-2-pyrrolidone

The present invention provides a process for producing silylated pullulan, which features reacting pullulan with N,O-bistrimethylsilylacetamide by using, as a reaction medium, only one of N-methyl-2-pyrrolidone and N-ethyl-2-pyrrolidone or a mixed solvent of both of them. Compared with conventional processes, the process according to the present invention can produce high-purity silylated pullulan simply, easily and efficiency.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

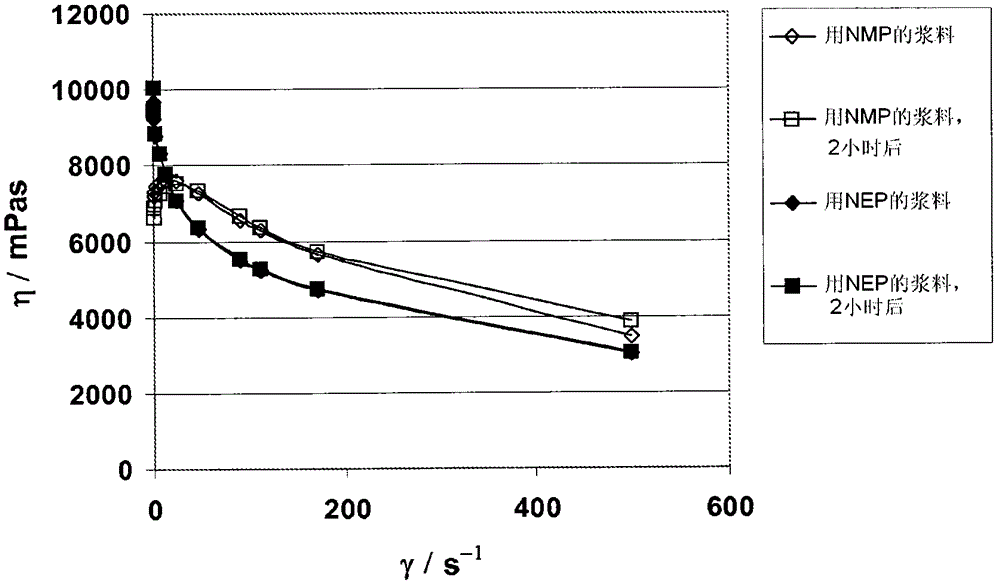

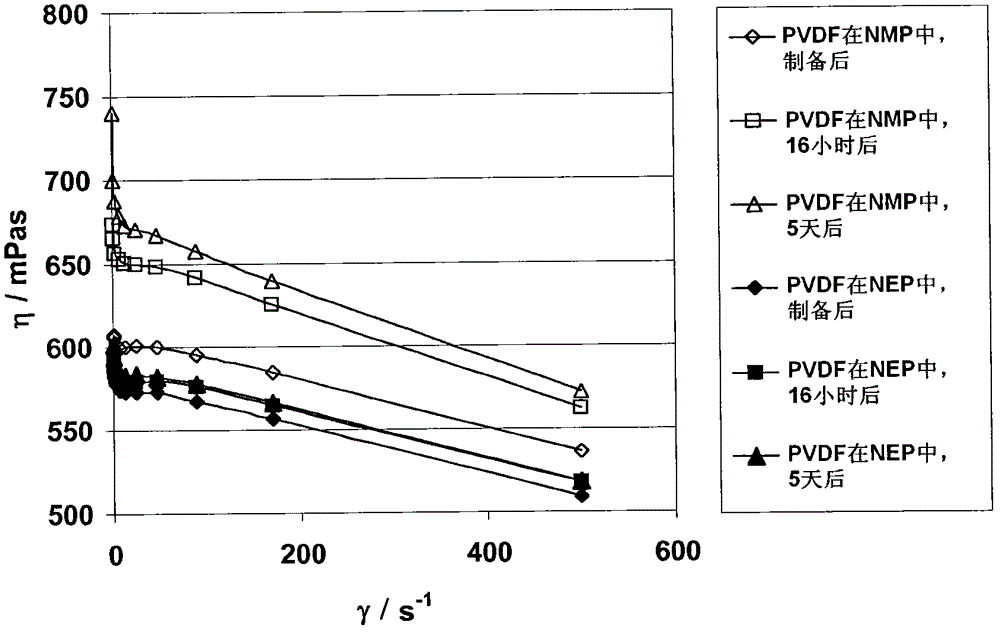

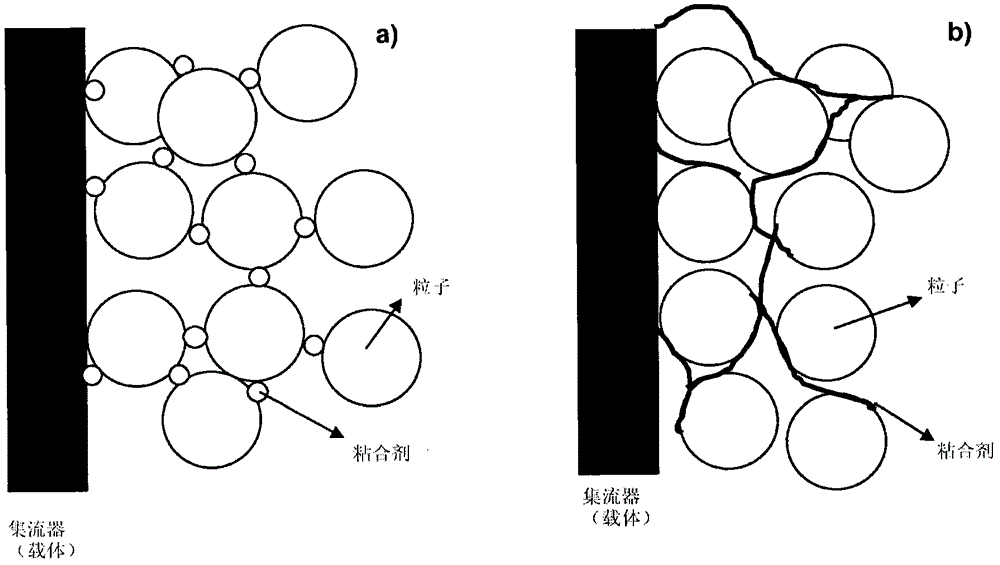

Use of n-ethyl pyrrolidone in the production of electrodes for double-layer capacitors

InactiveCN102754173AHigh solid contentHybrid capacitor electrodesDouble layer capacitorsEngineeringElectric double-layer capacitor

The invention relates to the use of N-ethyl pyrrolidone in the production of electrodes for double-layer capacitors.

Owner:EVONIK LITARION

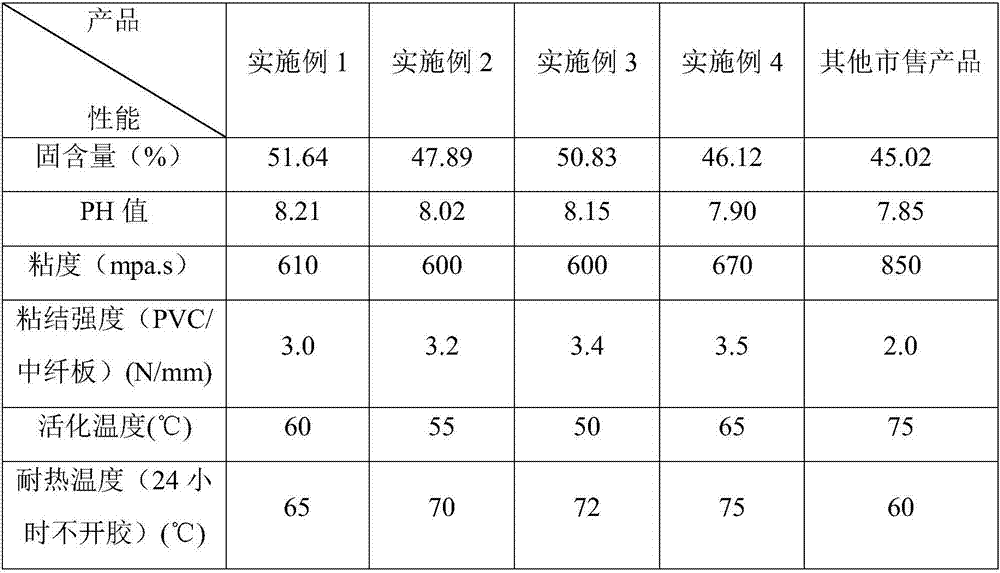

Water-based anionic polyurethane emulsion as well as preparation method and application

InactiveCN107353387AImprove heat resistanceGood weather resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedN dimethylformamide

The invention discloses a water-based anionic polyurethane emulsion as well as a preparation method and an application and belongs to the field of fine polymer materials. The water-based anionic polyurethane emulsion is prepared from raw material components in parts by weight as follows: 10 parts of pentaerythritol, 39.5-79 parts of dimethylolpropionic acid A, 40-90 parts of N,N-dimethylformamide, 0.005-0.09 parts of p-toluenesulfonic acid, 200-350 parts of polyhydric alcohols, 35-80 parts of isocyanate, 0.03-0.05 parts of a catalyst, 5-10 parts of a micromolecular chain extender, 10-18 parts of dimethylolpropionic acid B, 50-80 parts of N-hydroxyethyl pyrrolidone, 6.7-13.5 parts of a neutralizer and 270-480 parts of deionized water. The solid content of the water-based anionic polyurethane emulsion is 40%-50%, and water-based vacuum plastic suction adhesive has excellent heat resistance, weather resistance, low-temperature viscosity stability, adhesive strength and the like when the emulsion is used for the water-based vacuum plastic suction adhesive.

Owner:SHANDONG TIANQING TECH DEV

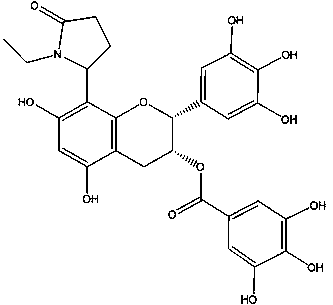

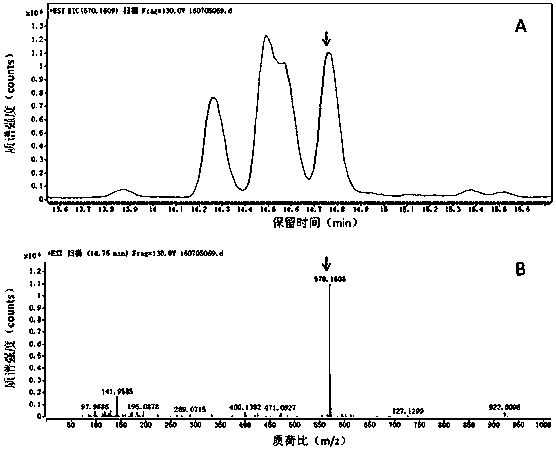

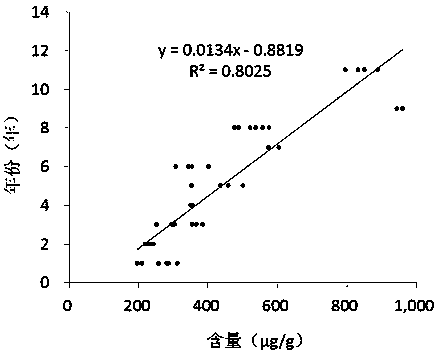

White tea manufacturing time determination method based on year white tea characteristic compound

ActiveCN108254482AThe result is objectiveLower requirementComponent separationTechnical supportChemistry

The invention relates to a white tea manufacturing time determination method based on year white tea characteristic compound, which belongs to the technical field of tealeaves determination. The method comprises the following steps: establishing a linear equation of the content of 8-CN-ethyl-2-pyrrolidone-substituted epigallocatechin gallate in white tea and white tea manufacturing time, and substituting a determined quantitative result of the 8-CN-vinyl-2-pyrrolidone-substituted epigallocatechin gallate in an unknown white tea sample into the linear equation, thus obtaining a predicted valueof the manufacturing time of the white tea sample. The method provides effective technical support to the determination of the manufacturing time of the market available white tea. The method has theadvantages of simplicity in operation, data quantification, objective result and high determination accuracy.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

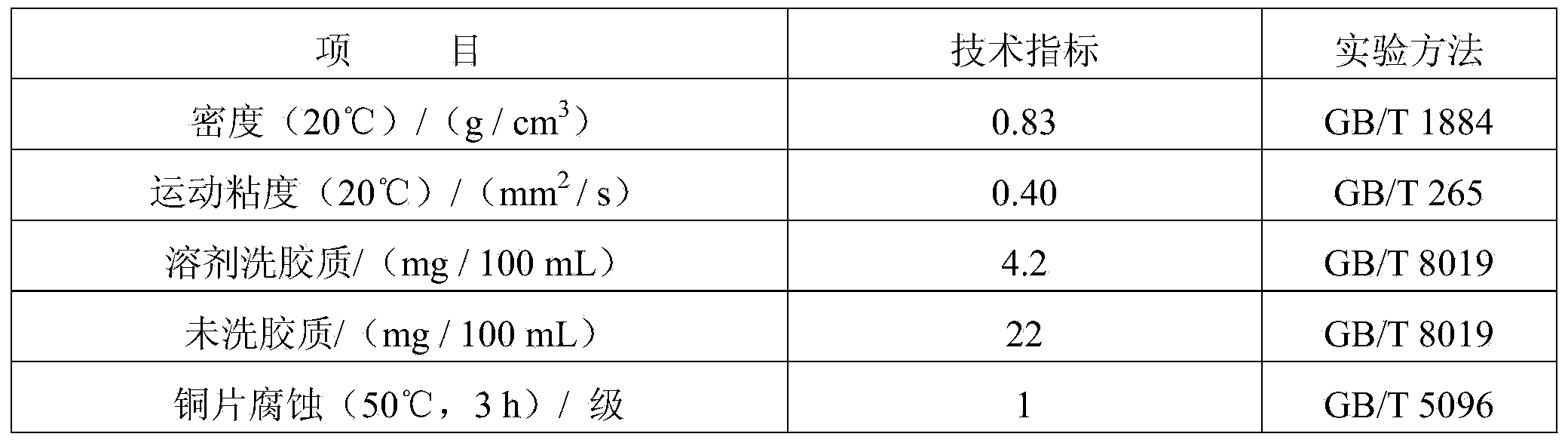

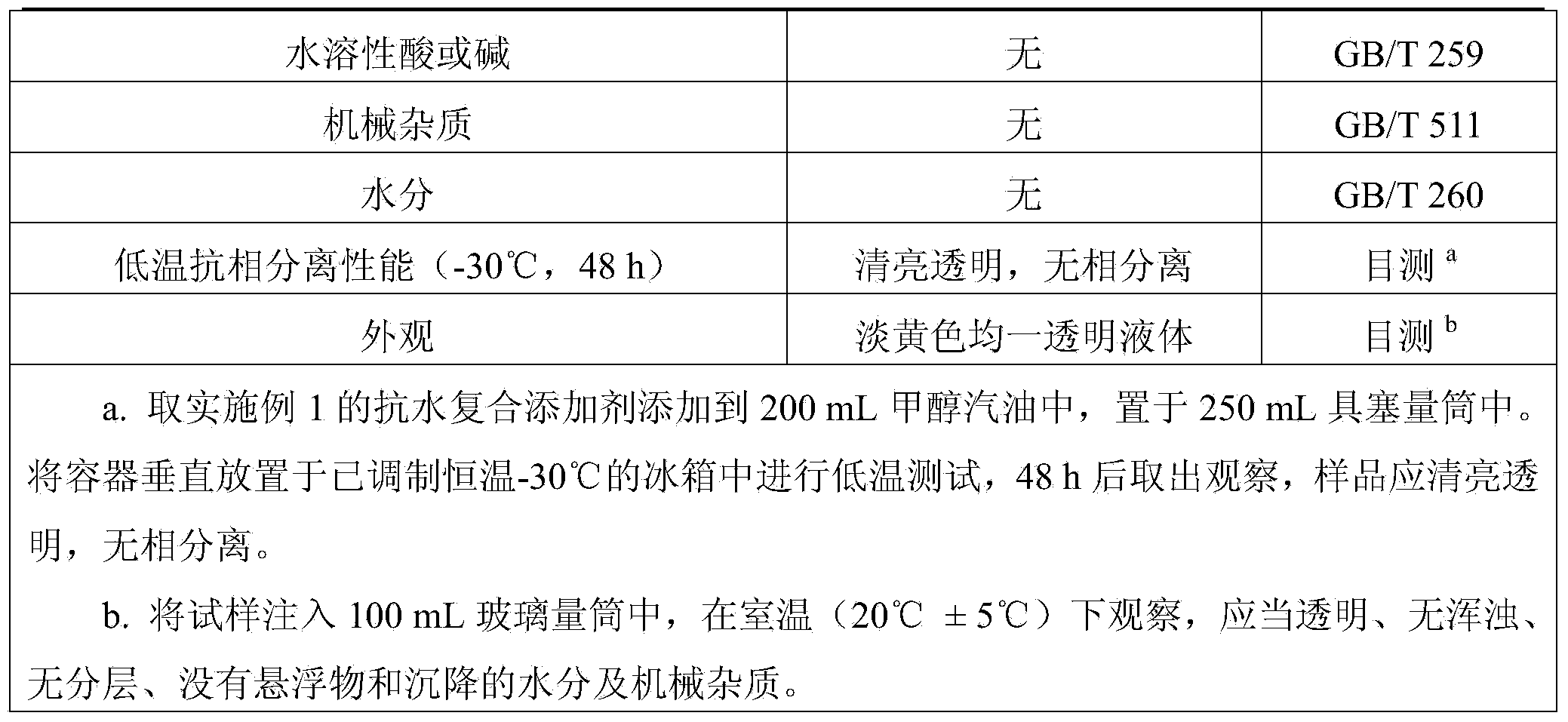

Water-resistant composite additive for vehicular fuel oil

InactiveCN104164260ADestruction of oxidation conditionsDestroy anti-oxidant and anti-corrosionLiquid carbonaceous fuelsImidazolidineTert butyl phenol

The invention provides a water-resistant composite additive for vehicular fuel oil. The water-resistant composite additive is prepared from the following components in percentage by weight: 40-70% of mutual solvent, 20-40% of oxidization-corrosion inhibitor, 2-6% of bactericide and 8-14% of auxiliaries; the mutual solvent comprises the following components in percentage by weight: 10-30% of methyl tert-butyl ether, 10-15% of tert-butyl acetate, 15-20% of dimethyl carbonate, 40-50% of a mixture of C3-C6 higher alcohols, and 5% of N-ethylpyrrolidine; the oxidization-corrosion inhibitor comprises the following components in percentage by weight: 30-50% of 2,6-tert-butyl phenol, 10-15% of Bis(1-methylpropyl)-1,4-phenylenediamine, 20-30% of T1201, 15-20% of methyl benzotriazole and 5% of a mixture of ethoxylated alkylphenol and oil-soluble imidazolidine according to the weight ratio of 6:4; the bactericide comprises the following components in percentage by weight: 40-60% of dioxolakylborane-containing solution, 15-30% of N-benzylideneaniline, 10-15% of polyethylene glycol borate, and 15% of 2-methyl-4-Isothiazolin-3-one; and the auxiliaries comprise the following components toluene, aviation kerosene, dioctyl sebacate and cyclohexane according to the weight ratio of 3:2:1:4. The water-resistant composite additive can effectively solve the problems that the vehicular fuel oil causes phase separation, serious corrosion and wear to an engine, and the like when absorbing water during production and storage and transportation.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Method for synthesizing di-alkyl chlorosilane

InactiveCN104892659AHigh yieldSimple Reaction ProcessGroup 4/14 element organic compoundsAluminium chlorideReaction temperature

The invention discloses a method for synthesizing di-alkyl chlorosilane. The method includes the following steps: adding a reducing agent A into a container containing a solvent B and a reflux condenser, wherein the mass ratio of the reducing agent A to the solvent B is (1:10)-(1:90), stirring for 10-20 minutes, adding an equimolar amount of a raw material C within 16-20 minutes of stirring for reaction at 55-90 DEG C, stirring and reacting for 2-3 hours, wherein the structural formula of the raw material C is (Rf) 2SiCl2, and Rf is methyl, ethyl, propyl or butyl; increasing the reaction temperature to 120-130 DEG C, stirring for 40-60 minutes and stopping the reaction; filtering and distilling the mixture after reaction. The solvent B is one or more of methyl pyrrolidone, ethyl pyrrolidone, and N,N-dimethyl imidazolidinone, the reducing agent A is one or more of aluminum hydride / aluminum chloride, lithium aluminum hydride / chloride aluminum, sodium hydride / aluminum chloride and aluminum hydride / lithium aluminum hydride. The reaction process and post-treatment are simple, the synthetic yield is high, and the raw material cost is low.

Owner:CHANGSHU 3F ZHONGHAO NEW CHEM MATERIALS +1

N-alkyl lactam ethers, and compositions and uses thereof

Described is a class of symmetrical and asymmetrical N-alkyl lactam ethers. One preferred ether is bis-N-ethyl pyrrolidone ether. Preferred compositions and uses of the ethers are in performance chemicals, personal care, and pharmaceutical fields, where they function a variety of roles, including as a solvent, solubilizer, freezing point depressor, diluent, extracting agent, cleaning agent, degreaser, absorbent and / or dispersion agent.

Owner:ISP INVESTMENTS LLC

Crosslinked polyvinylpyrrolidone (PVPP) copolymer of vinyl pyrrolidone (VP) and monomer derived from 1-vinyl-3-(E)-ethylidene pyrrolidone (EVP)

What is described herein is a crosslinked polyvinylpyrrolidone (PVPP) copolymer of vinyl pyrrolidone (VP) and monomer derived from 1-vinyl-3-(E)-ethylidene pyrrolidone (EVP).

Owner:ISP CAPITAL

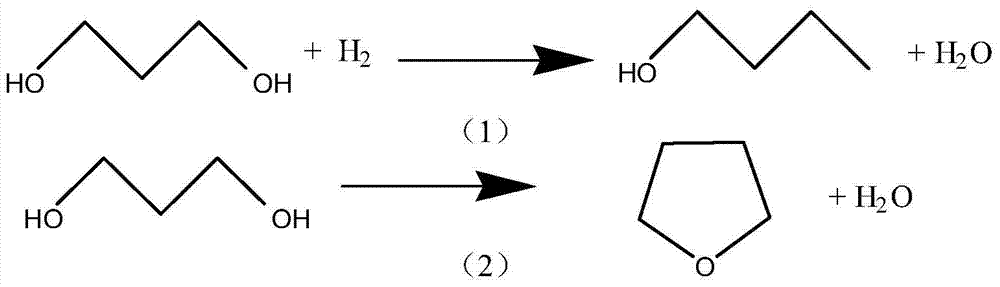

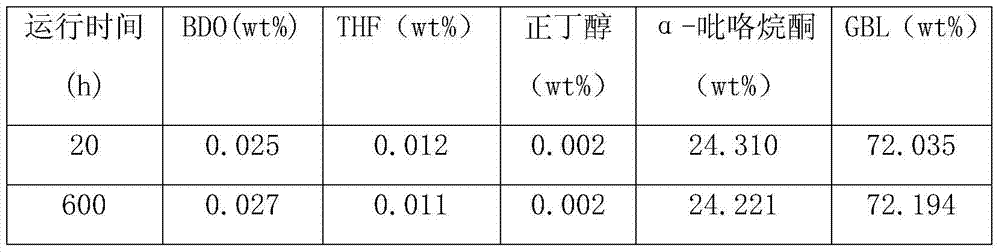

A kind of production method of pyrrolidone products

The invention discloses a production method of pyrrolidone products. The method includes the steps that 1,4-butanediol serves as the raw material for conducting a one-step reaction, pyrrolidone is directly produced, 1,4-butanediol is converted into the pyrrolidone series products in a reaction unit through a dehydrogenation-amination reaction in the modes of a stagewise reactor and composite catalysts, such as, alpha-pyrrolidone or N-methyl pyrrolidone or N-ethyl pyrrolidone. According to the production method, the 1,4-butanediol is dehydrogenized into gamma-butyrolactone, gamma-butyrolactone is converted into pyrrolidone in an amination mode, the gamma-butyrolactone and the pyrrolidone are coupled into the same reactor, the separation and refining steps in a traditional process are omitted, energy consumption is saved, heat emitted by amination is fully utilized, the production method is easy to conduct, the yield is raised compared with a traditional process, and the production method is more environmentally friendly.

Owner:MAIQI CHEM CO LTD

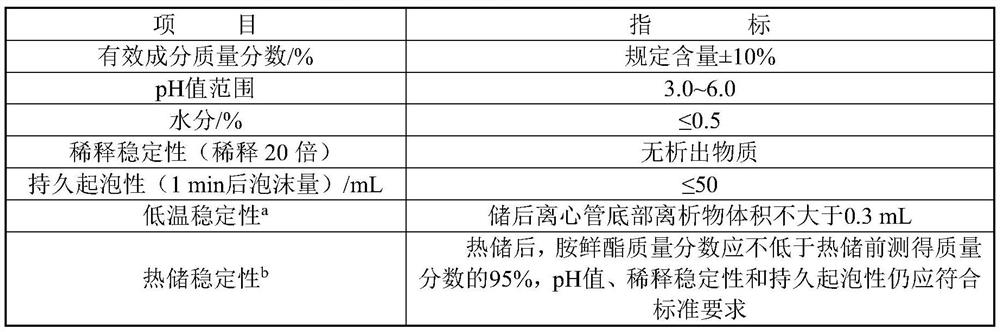

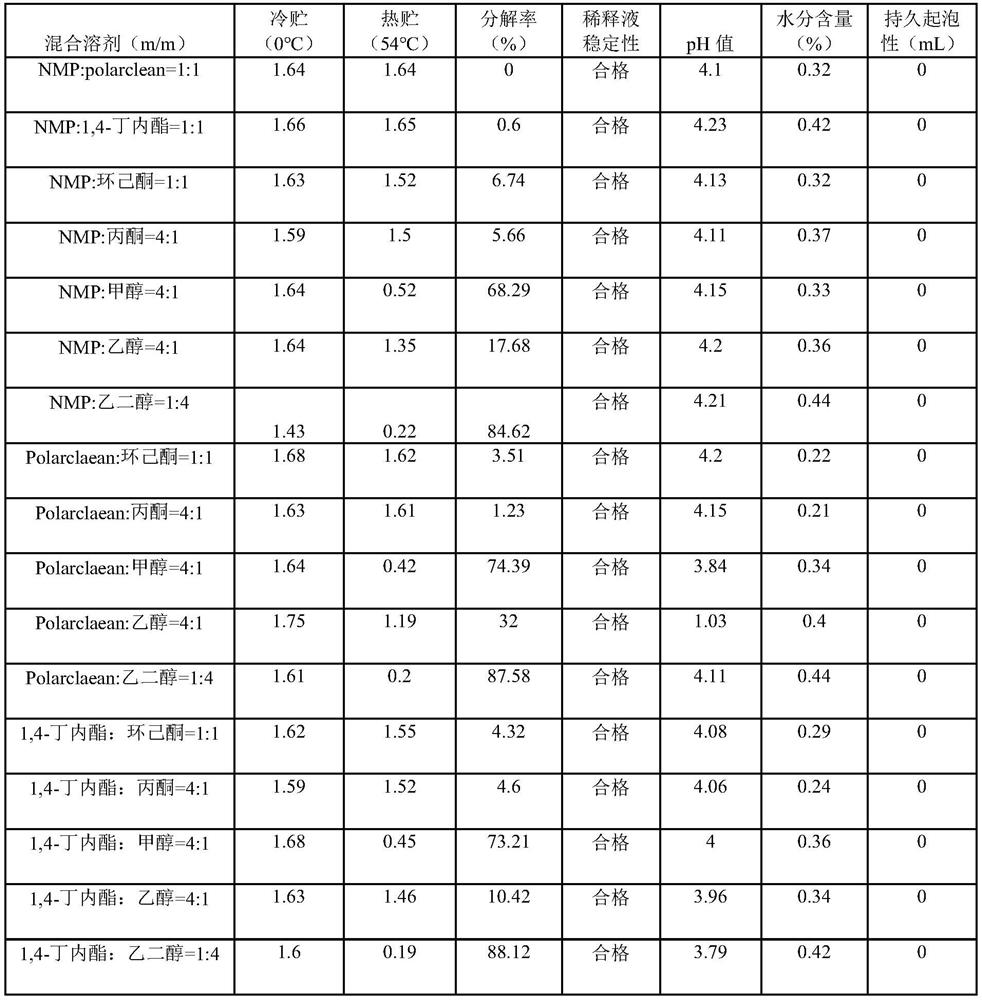

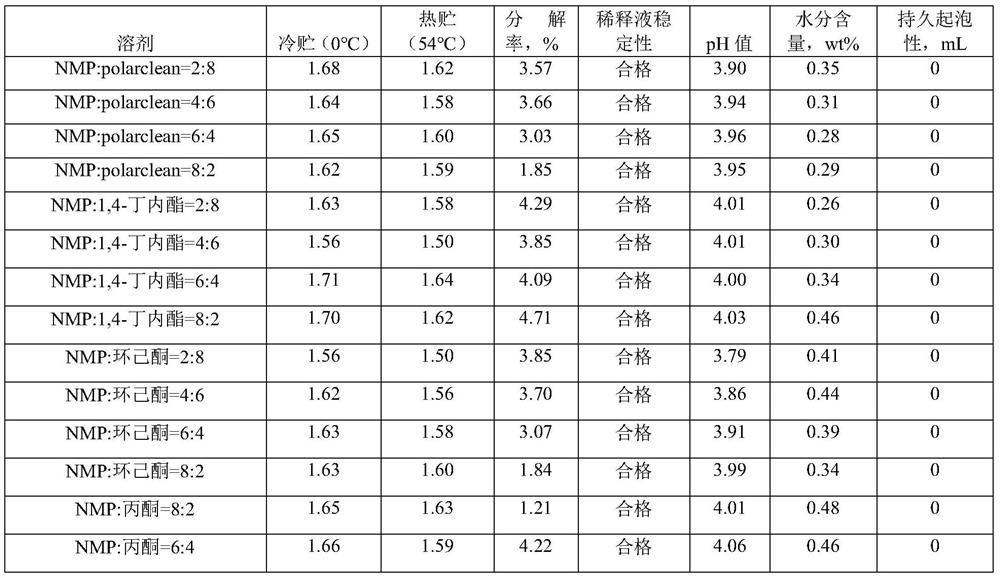

Soluble concentrate for preventing decomposition of diethyl aminoethyl hexanoate

The invention discloses a soluble concentrate for preventing decomposition of diethyl aminoethyl hexanoate. The soluble concentrate for preventing the decomposition of the diethyl aminoethyl hexanoate comprises an effective component and an auxiliary agent. The effective component is diethyl aminoethyl hexanoate or diethyl aminoethyl hexanoate organic acid salt; the auxiliary agent is at least one of the following solvents a) to c): the solvent a) is NMP (N-Methyl Pyrrolidone), N-ethyl-2-pyrrolidone, 2-pyrrolidone, 1-butylpyrrolidin-2-one, N-isobutyl pyrrolidone, N-tert-butyl pyrrolidone or 1-amylpyrrolidin-2-one; the solvent b) is polarclean; and the solvent c) is 1,4-butyrolactone. The diethyl aminoethyl hexanoate soluble concentrate disclosed by the invention is sealed by an ampoule bottle and is thermally stored at 54 DEG C for 14 days, and the thermal storage decomposition rate is less than 5% compared with that of a normal-temperature sample. The quality standard of the diethyl aminoethyl hexanoate soluble concentrate is met.

Owner:鹤壁全丰生物科技有限公司

Industrial production method of N-ethyl pyrrolidone

ActiveCN110183370AHigh puritySolve temperature problemsOrganic chemistryHeterogenous catalyst chemical elementsComing outReaction temperature

The invention provides an industrial production method of N-ethyl pyrrolidone, and belongs to the technical field of preparation of fine chemical engineering products. The method comprises the following steps: step 1, gamma-butyrolactone is added into a stirring vessel, row tubes are welded on a stirrer, the row tubes are filled with catalysts, and solvent flows out of holes on the row tubes to befully mixed with gamma-butyrolactone; step 2, materials flowing out of the stirring vessel are fully mixed with monoethyl amine and are then fed into a tubular reactor, a feeder is provided with atomizing nozzles, the solvent is fully mixed with the materials coming out of an upper reaction section after being atomized, and a mixture is collected and uniformly enter the row tubes of a lower reaction section after passing through a distributor; step 3, products flowing out of the tubular reactor are fed into the jacket of the stirring vessel, heat transfer is carried out on the products and materials in the step 1, and then the products flow out from the outlet of the jacket and enter a refining stage. The industrial production method provided by the invention overcomes the deficiencies, such as high reaction temperature, high reaction pressure, high requirements on equipment and low environmental protection benefit, existing in existing production of N-ethyl pyrrolidone.

Owner:MAIQI CHEM CO LTD

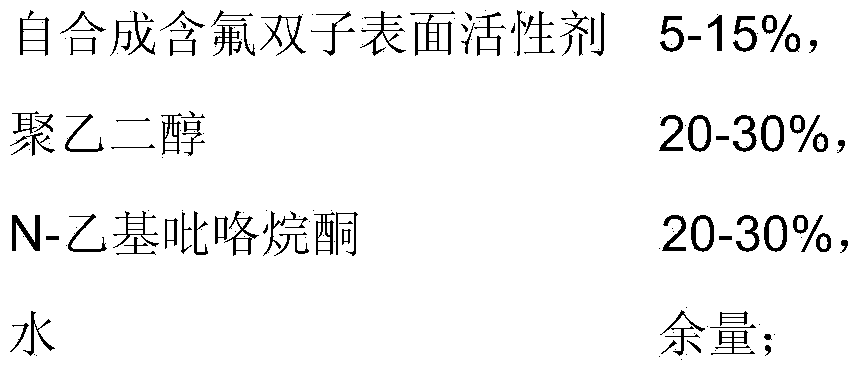

Alcohol substitute in alcohol-free fountain solution and preparation method thereof

The invention relates to a constituent of fountain solution for a lithographic printer, and particularly discloses alcohol substitute A for alcohol-free fountain solution. The alcohol substitute A comprises the following constituents in percent by weight: 5 to 15 percent of self-synthesis fluorine-containing dimeric surfactant, 20 to 30 percent of polyethylene glycol, 20 to 30 percent of N-ethyl-pyrrolidone (NEP), and the balance of water, wherein the chemical formula of the self-synthesis fluorine-containing dimeric surfactant is shown in the description, and m is any integer from 6 to 8. The alcohol substitute A is applied to the alcohol-free fountain solution, can effectively reduce the surface tension, has good wettability, has good water feeding property when being used for the existing equipment, has good compatibility with printing ink, and rapidly realizes ink-water balance. When the alcohol-free fountain solution produced by adding the alcohol substitute A into the exiting fountain solution is used for lithography, ethyl alcohol or isopropyl alcohol can be free of being added, the cost is reduced, the quality is improved, and the alcohol substitute A is safer and more environmentally friendly, and can be beneficial to green printing.

Owner:JIANGMEN CHENGXIN PRECISION CHEM FACTORY

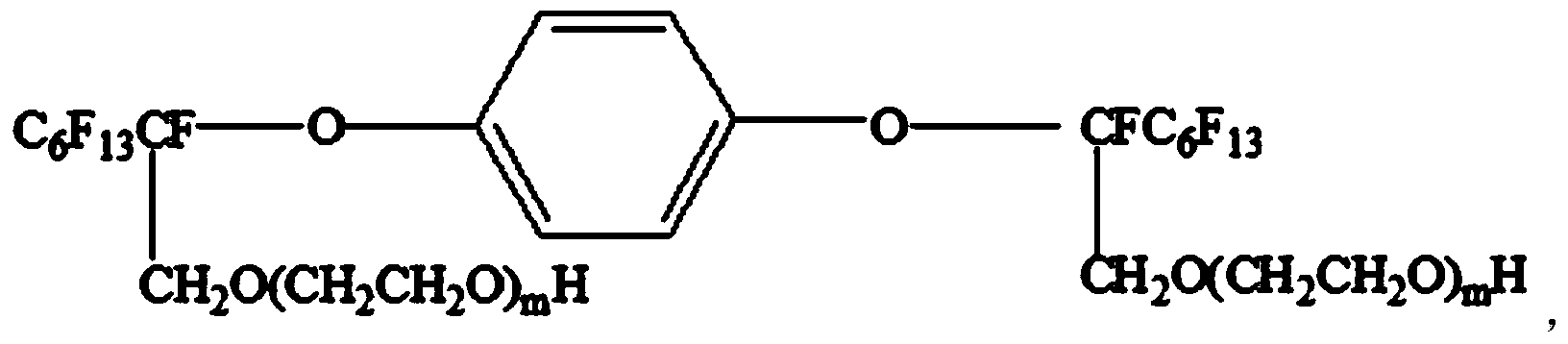

Percutaneous absorption preparation

ActiveCN104208042AReduce absorptionGood effectAntibacterial agentsOrganic active ingredientsActive componentTobramycin

Owner:嘉善县魏塘资产管理有限公司

Metal protective paint and application thereof, and hot-dip metal material

InactiveCN103360812AImprove corrosion resistanceImprove water resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsMetallic materialsSilicon oxide

The invention provides a metal protective paint which is prepared by uniformly mixing a raw material mixture, wherein the raw material mixture contains water-soluble silicate, silicon oxide filler, accelerator, water-soluble film-forming resin, C6H11NHCH2CH2CH2Si(OCH3)3 and water; and the accelerator is at least one of pyrrolidone, N-methylpyrrolidone and N-ethylpyrrolidone. The invention also discloses application of the metal protective paint in preparation of metal materials. The invention also provides a hot-dip metal material which comprises a hot-dip metal substrate and a coating attached to the hot-dip metal substrate, wherein the coating is the cured product of the metal protective paint. The protective film formed by the metal protective paint provided by the invention has very excellent corrosion resistance, water resistance, heat resistance and fingerprint resistance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

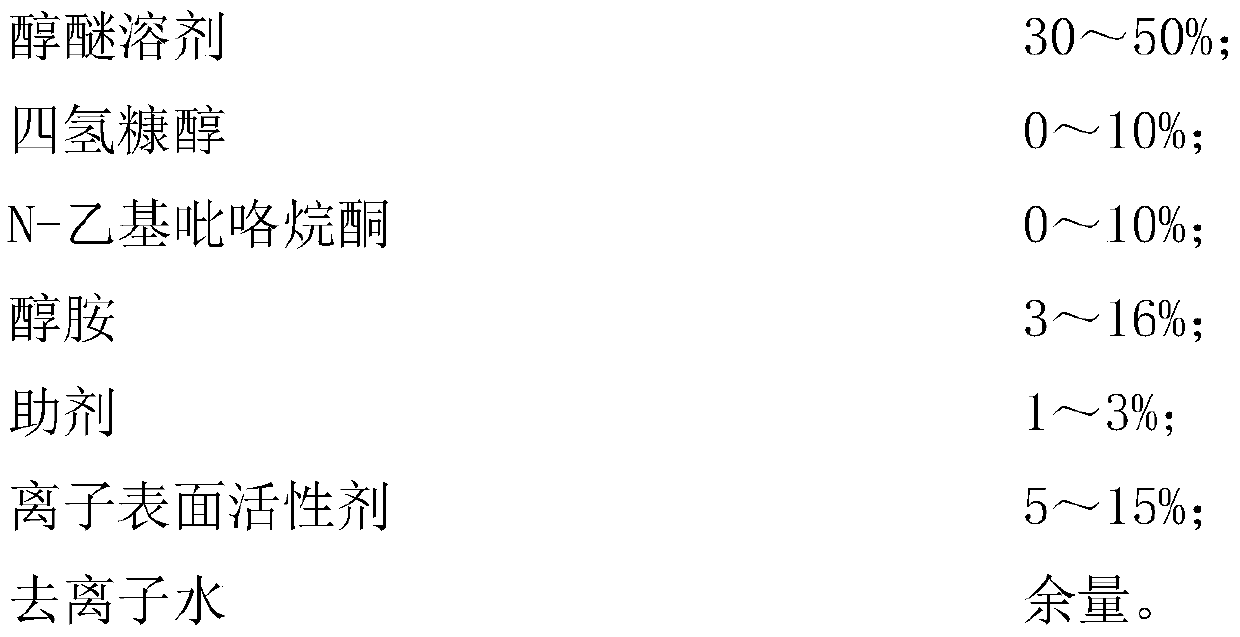

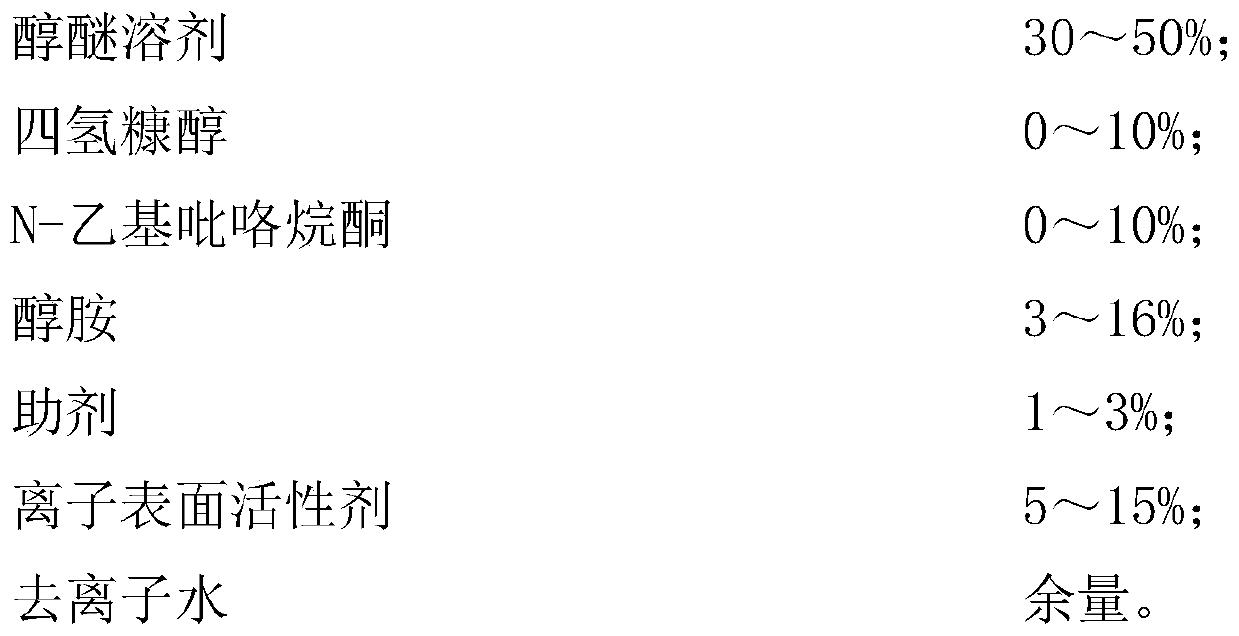

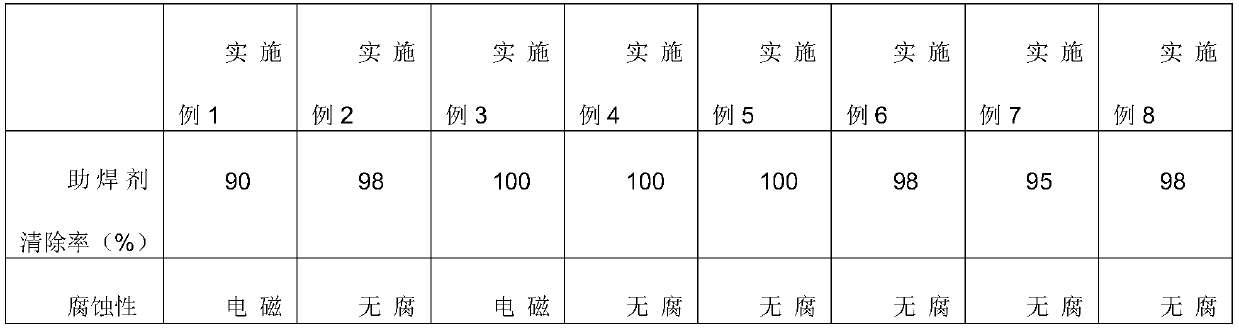

Water-based flexible circuit board cleaning agent and preparation method thereof

InactiveCN110669592AImprove cleaning efficiencyLow VOC contentOrganic detergent compounding agentsAnionic surface-active compoundsHalohydrocarbonFlexible circuits

The invention discloses a water-based flexible circuit board cleaning agent, which comprises the following components: 30-50% of alcohol ether solvent; 0-10% tetrahydrofurfuryl alcohol; 0-10% of N-ethyl pyrrolidone; 3-16% of alcohol amine; 1-3% of an auxiliary agent; 5-15% of an ionic surfactant and the balance of deionized water. The water-based flexible circuit board cleaning agent prepared by the invention is a weakly alkaline concentrated cleaning agent, does not contain any fluorocarbon solvent and halogenated hydrocarbon solvent in the formula, has low VOC volatile organic matter content, small odor, low toxicity, convenient use and safe operation. Through the ultrasonic cleaning method, the cleaning efficiency of a flexible circuit board can be obviously improved, and the reliability is improved.

Owner:ITW SPECIALTY MATERIALS (SUZHOU) CO LTD

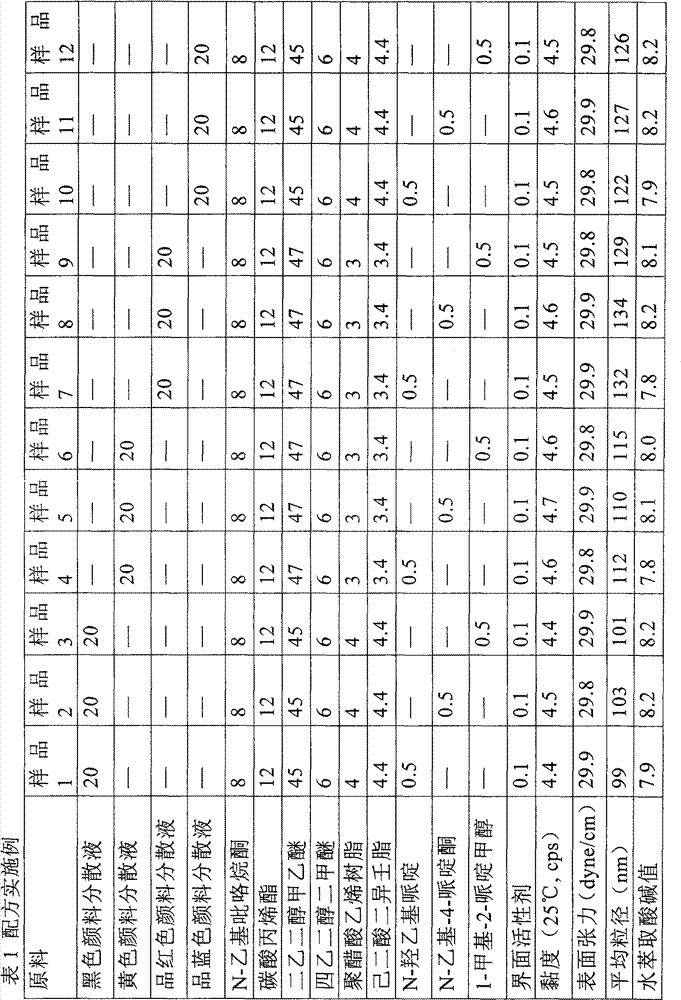

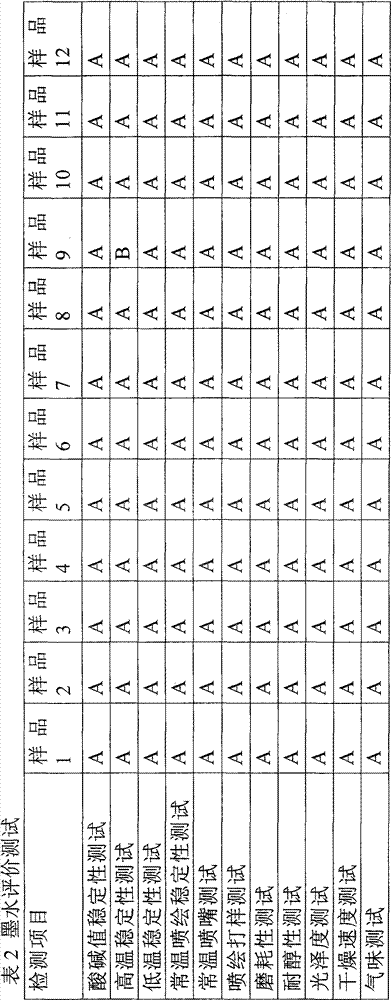

Low odor environment-friendly type nano pigment inkjet ink composition

A low odor environment-friendly type nano pigment inkjet ink composition has excellent storage stability, inkjet stability and printing quality. A spray nozzle orifice is not easy to be blocked, printed images are high in gloss, resistant to scraping and resistant to weather. A low toxicity and low odor material is used. The ink has a high flash point and is safe for human health and environment, and meets the needs of environmental protection and maintaining print quality. The ink composition comprises 1-10% of N-ethyl pyrrolidone, 1-20% of propylene carbonate, 50-80% of ether alcohol solvents, pigments, a dispersant, resin, a plasticizer, a surface active agent and a cyclic tertiary amine compound as an acid adjusting agent.

Owner:JETBEST CORP

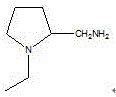

Process for producing 1-ethyl-2-aminomethylpyrrolidine

InactiveCN106631955AReduce decompositionReduce side effectsOrganic chemistryChemical recyclingOrganic solventDecomposition

The invention relates to a process for producing 1-ethyl-2-aminomethylpyrrolidine. An intermediate 1-ethyl-2-nitro-methylene pyrrolidine is taken as a raw material, and 1-ethyl-2-aminomethylpyrrolidine is obtained through catalytic reduction under the action of solvents and a catalyst; and the solvents are an organic solvent and carbon dioxide. The process for producing 1-ethyl-2-aminomethylpyrrolidine has the advantages that the organic solvent and carbon dioxide are adopted as the solvents, 1-ethyl-2-aminomethylpyrrolidine is synthesized by catalytic reduction in the presence of carbon dioxide, side reaction is reduced, the decomposition of 1-ethyl-2-aminomethylpyrrolidine into 1-ethyl-2-pyrrolidinone is reduced, and the product yield and GC content are greatly improved.

Owner:JIANGSU KANGHENG CHEM

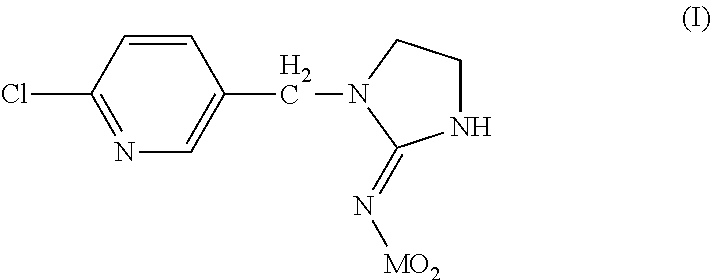

Dermal compositions

ActiveUS20160174556A1Less NMPExcellent long-term storage stabilityBiocidePharmaceutical delivery mechanismImidaclopridPyrethrin I

Disclosed herein are veterinary compositions including imidacloprid or an analogue thereof; a pyrethroid; a solvent selected from the group consisting of N-methyl pyrrolidone, N-ethyl pyrrolidone and mixtures thereof; and dimethyl sulfoxide. The veterinary compositions of the invention are useful in methods of controlling parasites on or within warm-blooded domesticated animals.

Owner:NEOGEN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com