Water-based flexible circuit board cleaning agent and preparation method thereof

A technology for flexible circuit boards and cleaning agents, applied in the preparation of detergent mixture compositions, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of shortening the life of cleaning agents and affecting production efficiency, and achieve cleaning power Excellent, long service life, low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

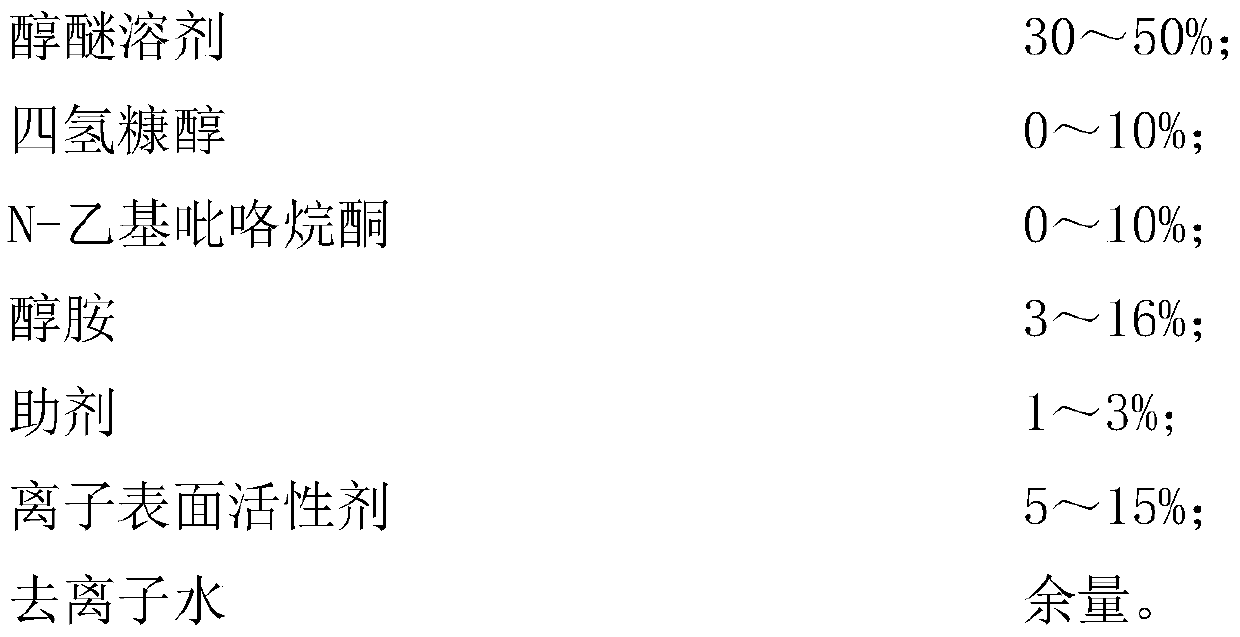

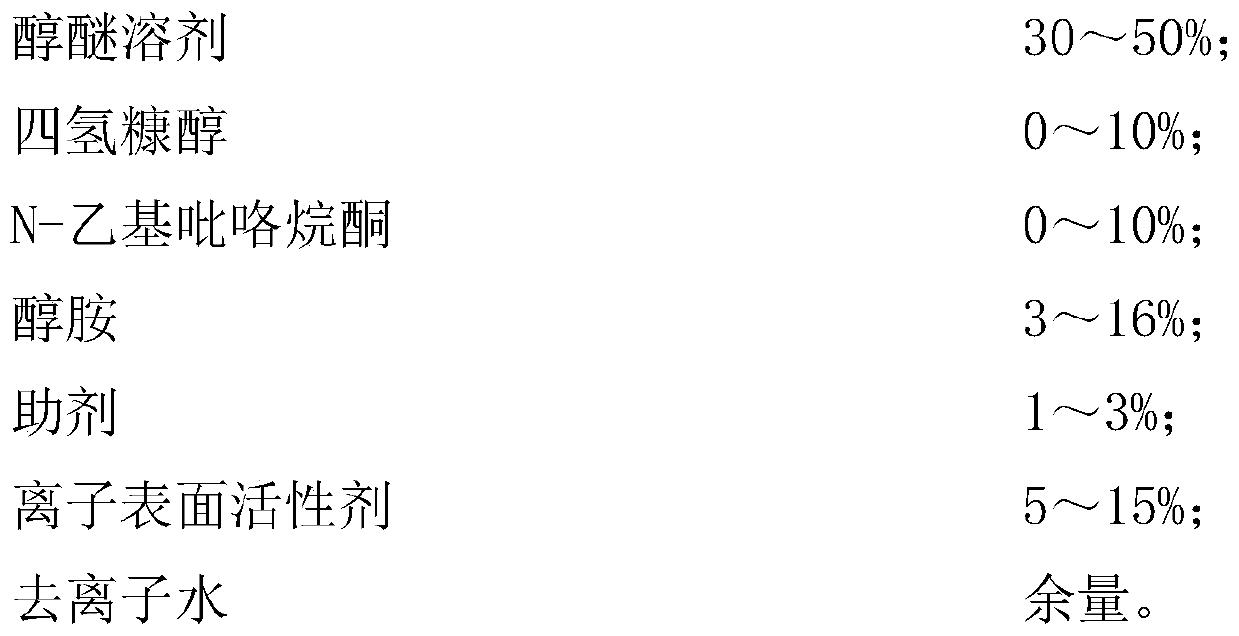

Method used

Image

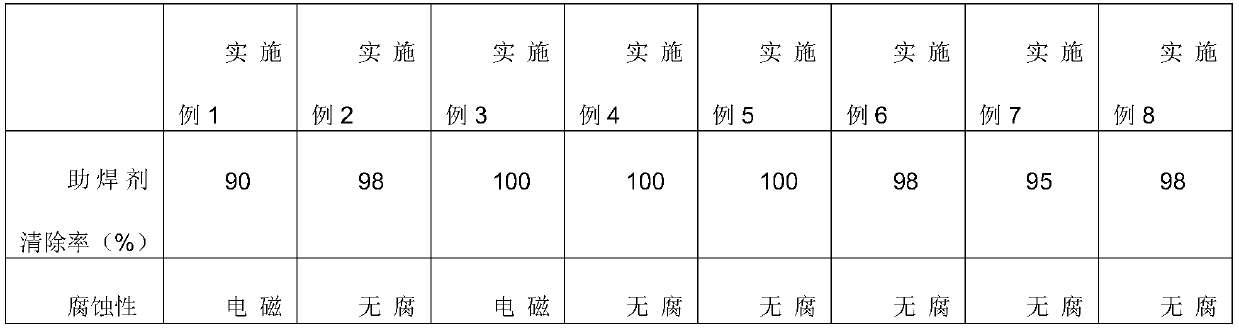

Examples

Embodiment 1

[0023] The components of the water-based flexible circuit board cleaning agent, in parts by weight, include 30 parts of alcohol ether solvent, 20 parts of N-ethyl-2-pyrrolidone, 5 parts of ionic surfactant, 1.5 parts of auxiliary agent, 3 parts of alcohol amine Parts, wherein the components in alcohol ether solvents, by weight parts, include: 1 part of dipropylene glycol monomethyl ether, 1 part of dipropylene glycol propyl ether; the components in alcohol amines, by weight parts, include 2- Amino-2-methyl-1-propanol is 1 part, monoisopropanolamine is 0.5 part; ionic surfactant components, by weight, include 1 part of sodium lauryl sulfate, hexadecyl 1.5 parts of sulfophenoxybenzenesulfonic acid disodium salt; the components of the additives, in parts by weight, include 1 part of benzotriazole and 1 part of sodium gluconate.

[0024] The preparation method is as follows: under the condition of rotating speed of 500r / m, add alcohol ether solvent and N-ethyl-2-pyrrolidone into t...

Embodiment 2

[0026] The components of the water-based flexible circuit board cleaning agent, in parts by weight, include 40 parts of alcohol ether solvent, 10 parts of N-ethyl-2-pyrrolidone, 10 parts of ionic surfactant, 1.5 parts of auxiliary agent, 5 parts of alcohol amine Parts, wherein the components in alcohol ether solvents, by weight parts, include: 1 part of dipropylene glycol monomethyl ether, 1 part of dipropylene glycol propyl ether; the components in alcohol amines, by weight parts, include 2- 1 part of amino-2-methyl-1-propanol, 0.2 part of N,N-dimethylcyclohexylamine; ionic surfactant component, by weight, including 1 part of sodium lauryl sulfate 1.5 parts of cetyl sulfophenoxybenzene sulfonic acid disodium salt; the components of the auxiliary agent, in parts by weight, include 1 part of benzotriazole and 1 part of sodium gluconate.

[0027] The preparation method is as follows: under the condition of rotating speed of 500r / m, add alcohol ether solvent and N-ethyl-2-pyrroli...

Embodiment 3

[0029] The components of the water-based flexible circuit board cleaning agent, in parts by weight, include 30 parts of alcohol ether solvents, 20 parts of tetrahydrofurfuryl alcohol, 5 parts of ionic surfactants, 1.5 parts of additives, and 3 parts of alcohol amines, of which alcohol ether The components in the solvent, by weight, include: 1 part of dipropylene glycol monomethyl ether, and 1 part of dipropylene glycol propyl ether; the components in the alcohol amine, by weight, include 2-amino-2-methyl Base-1-propanol is 1 part, monoisopropanolamine is 0.5 part; ionic surfactant components, by weight, include 1 part of sodium lauryl sulfate, hexadecylsulfophenoxy 1.5 parts of disodium benzenesulfonic acid; the components of the auxiliary agent, in parts by weight, include 1 part of benzotriazole and 1 part of sodium gluconate.

[0030] The preparation method is as follows: under the condition of rotating speed of 500r / m, add alcohol ether solvent and tetrahydrofurfuryl alcoh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com