Reproductive-toxicity-free polyvinyl chloride vehicle interior decoration leather and preparation method thereof

A polyvinyl chloride, reproductive toxicity technology, applied in the field of leather, can solve the problems of adverse effects on the human body, and achieve the effect of being suitable for large-scale production, high production efficiency, and firm adhesive layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

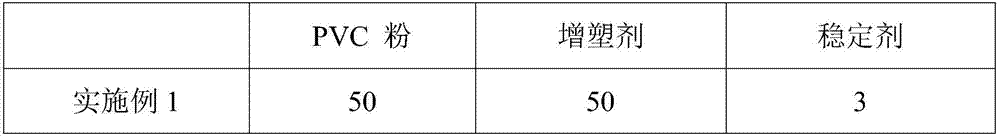

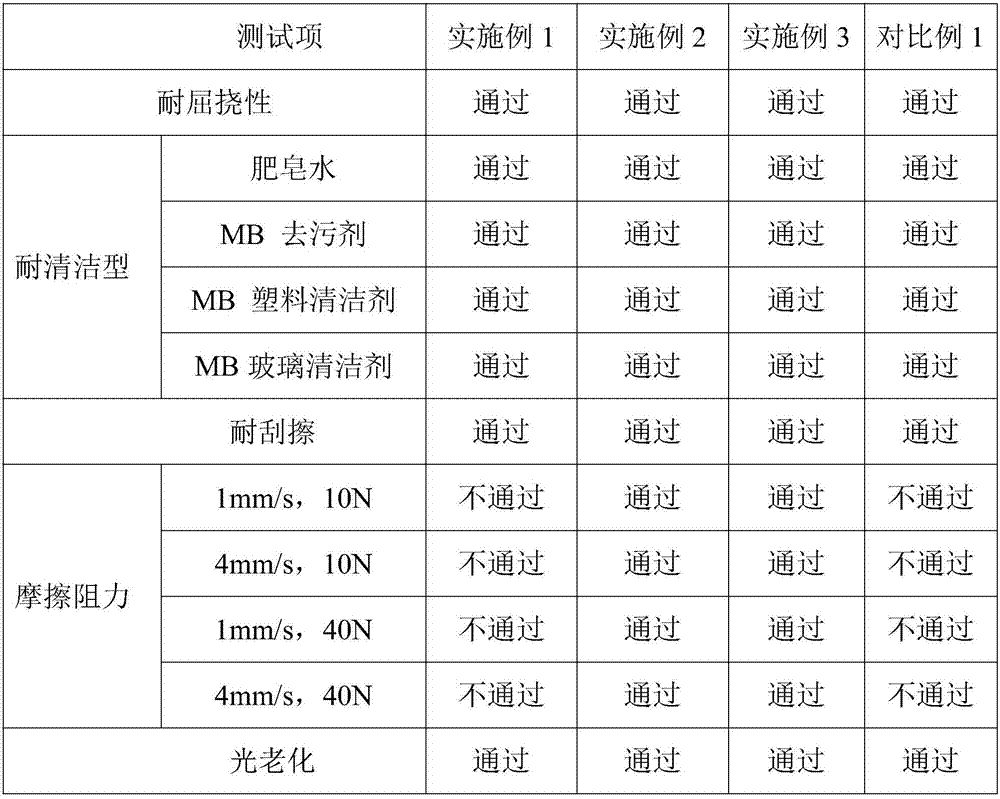

Embodiment 1

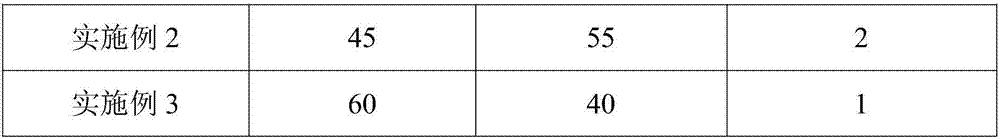

[0027] Weigh the PVC layer components according to the parts by weight of Example 1 in Table 1 below, stir for 30 minutes, vacuumize for 5 minutes, and vacuum stir for 10 minutes to obtain PVC slurry, coat a layer on the release paper, and then heat it under the condition of 190 ° C Plasticize for 2.5 minutes and 200°C for 3 minutes, apply glue and stick it to the base cloth, dry at 200°C for 5 minutes, cool and form, tear off the release paper to obtain the PVC skin.

[0028] Weigh the components of the water paint layer according to the parts by weight of Example 1 in Table 2 below, and stir well to form the raw material of the water paint layer, which is evenly printed on the surface of the PVC layer, with a printing speed of 30m / min, a printing thickness of 18μm, and a temperature of 120°C. Dry to cure.

[0029] Embossing equipment is used to emboss patterns on PVC with a paint layer, and the embossing temperature is 220 ° C to obtain polyvinyl chloride automotive interior...

Embodiment 2

[0031] Weigh the PVC layer components according to the parts by weight of Example 2 in Table 1 below, stir for 60 minutes, vacuumize for 10 minutes, and vacuum stir for 5 minutes to obtain PVC slurry, coat one layer on the release paper, and then heat at 210 ° C Plasticize for 1min, plasticize for 1min at 210°C, apply glue and stick to the base cloth, dry at 200°C for 3min, cool and form, tear off the release paper to obtain the PVC skin.

[0032] Weigh the components of the water paint layer according to the weight parts of Example 2 in Table 2 below, and stir well to form a water paint layer raw material, which is evenly printed on the surface of the PVC layer, with a printing speed of 17m / min, a printing thickness of 10μm, and 80°C Dry to cure.

[0033] Embossing equipment is used to emboss patterns on PVC with a paint layer, and the embossing temperature is 160°C to obtain polyvinyl chloride automotive interior leather without reproductive toxicity.

Embodiment 3

[0035] Weigh the PVC layer components according to the parts by weight of Example 3 in Table 1 below, stir for 30 minutes, vacuumize for 8 minutes, and vacuum stir for 6 minutes to obtain PVC slurry, coat a layer on the release paper, and then heat at 200 ° C Plasticize for 2.5 minutes, plasticize at 210°C for 3 minutes, apply glue and stick to the base cloth, dry at 210°C for 5 minutes, cool and form, tear off the release paper to obtain the PVC skin.

[0036] Weigh the components of the water paint layer according to the parts by weight of Example 3 in Table 2 below, and stir well to form the raw material of the water paint layer, which is evenly printed on the surface of the PVC layer, the printing speed is 20m / min, the printing thickness is 12μm, and 100°C Dry to cure.

[0037] Embossing equipment is used to emboss patterns on PVC with a paint layer, and the embossing temperature is 190°C to obtain polyvinyl chloride automotive interior leather without reproductive toxicit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com