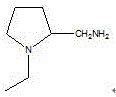

Process for producing 1-ethyl-2-aminomethylpyrrolidine

A technology of aminomethylpyrrolidine and nitromethylenepyrrolidine is applied in the field of 1-ethyl-2-aminomethyl, and can solve the problem of high reaction pressure, high reaction pressure of 1-ethyl-2-aminomethylpyrrolidine, Recycling solvent wastes energy and low reaction yield, and achieves the effect of reducing side reactions, easier recovery, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 78g (0.5mol) of 1-ethyl-2-nitromethylenepyrrolidine and 300ml of methanol into a 1000ml autoclave, then add catalyst nickel (8g), fill it with nitrogen to a pressure of 5kg, and re-exhaust After three times, add hydrogen at a hydrogen pressure of 35 kg and a temperature of about 80°C until the hydrogen pressure does not decrease. The reaction time is about 4 hours. 49 grams of colorless liquid, yield 77%, GC content ≥ 98.5%.

Embodiment 2

[0025] Add 78g (0.5mol) of 1-ethyl-2-nitromethylenepyrrolidine and 300ml of methanol into a 1000ml autoclave, then add catalyst nickel (8g), fill it with carbon dioxide to a pressure of 5kg, and exhaust the gas After three times, press the carbon dioxide pressure to 10 kg, then add hydrogen at a hydrogen pressure of 35 kg and a temperature of 80°C until the hydrogen pressure does not decrease. The reaction time is about 4 hours. , and then rectify after recovering methanol to obtain 53 grams of colorless liquid, with a yield of 83% and a GC content of ≥99%.

[0026] The following table 1 is a comparison table of the production process of 1-ethyl-2-aminomethylpyrrolidine in Examples 1 to 2 to produce 1-ethyl-2-aminomethylpyrrolidine:

[0027] Example 1 Example 2 stamping nitrogen stamping partial pressure of carbon dioxide Raw material quantity 78g 78g Yield 49g 53g yield 77% 83% GC content ≥98.5% ≥99%

[0028] As can be se...

Embodiment 3

[0030] With reference to Example 2, the catalyst nickel was replaced with 5% palladium carbon (2 grams) as a catalyst, and the other reaction conditions were unchanged. After the treatment, 55 grams of a colorless liquid were obtained, with a yield of 86% and a GC content ≥ 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com