Low odor environment-friendly type nano pigment inkjet ink composition

An inkjet ink and nano-pigment technology, applied in one field, can solve the problems of heavy solvent odor, high ink threshold, high toxicity and corrosiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

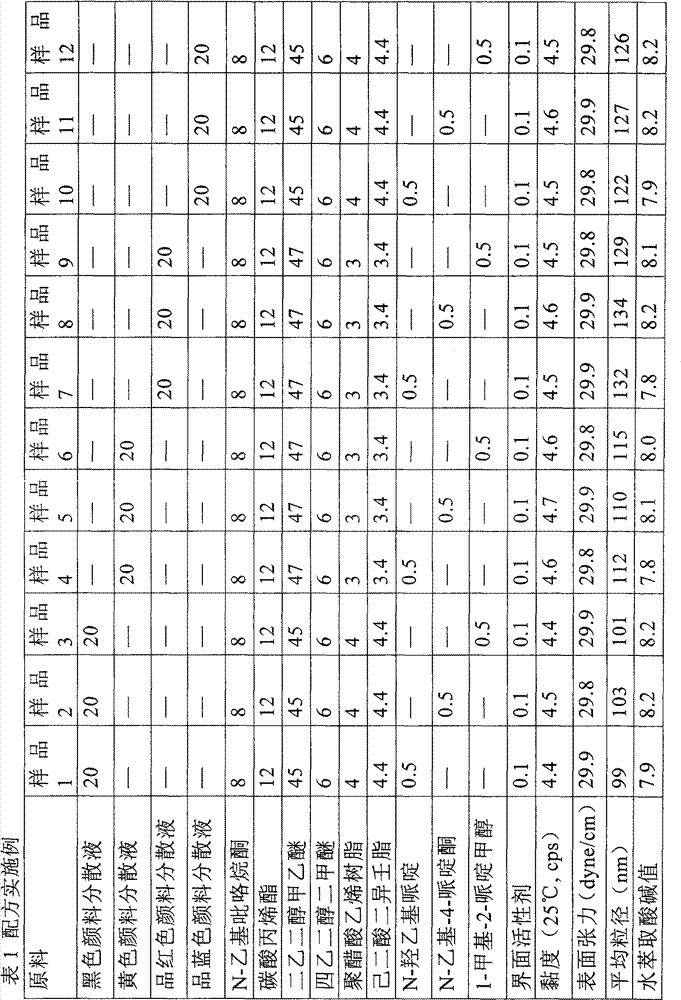

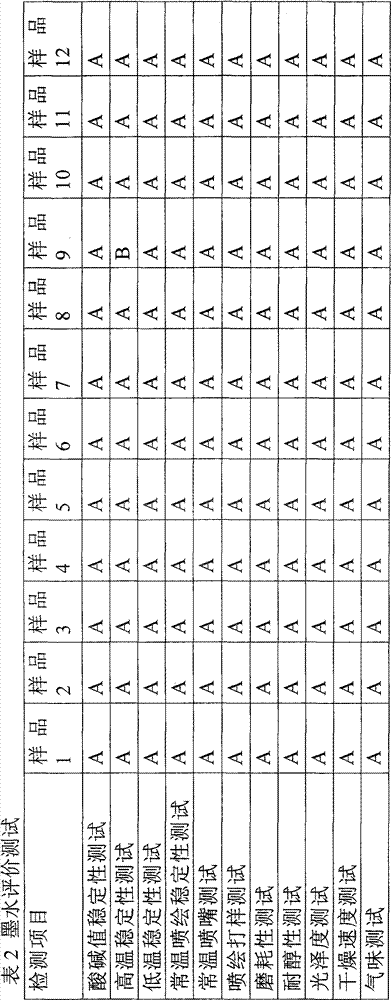

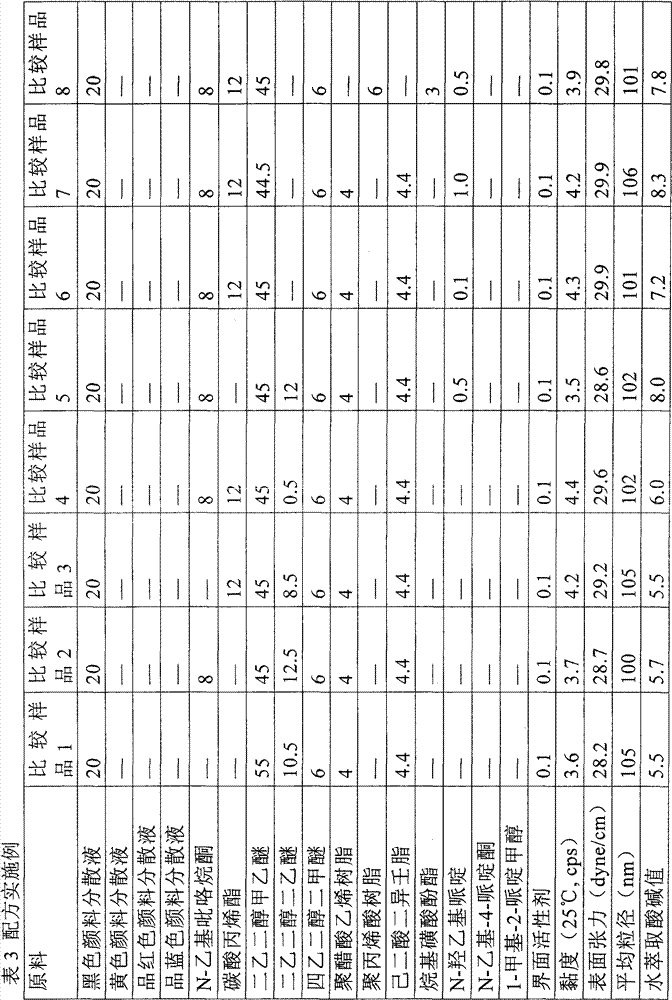

[0020] For a further understanding of the present invention, please refer to the following examples. The following examples are only preferred examples of the present invention, and cannot be used to limit the scope of the claims of the present invention.

[0021] (Preparation of Nano Pigment Dispersion Liquid)

[0022] In 68 parts by weight of diethylene glycol diethyl ether, add 20 parts by weight of carbon black (Mitsubishi Chemical, MA-100R) and 12 parts by weight of dispersant (Evonik, Germany, TEGO Dispers-652), and stir the disperser at a high speed , the rotation speed was set at 500 rpm, and after stirring for 1 hour, 50% volume zirconium beads (2.0 mm) were added to the bead mill for pre-dispersion. The obtained coarsely ground pigment dispersion had an average particle diameter of 1 μm or less. The coarsely ground pigment dispersion was transported to a nano grinder for dispersion, and a black pigment dispersion was obtained through particle size analysis and filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com