Bag filling apparatus and method

An equipment, bagging technology, applied in packaging, transport packaging, transportation and packaging, etc., can solve the problem of not being fully emphasized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Detailed description of the preferred embodiment

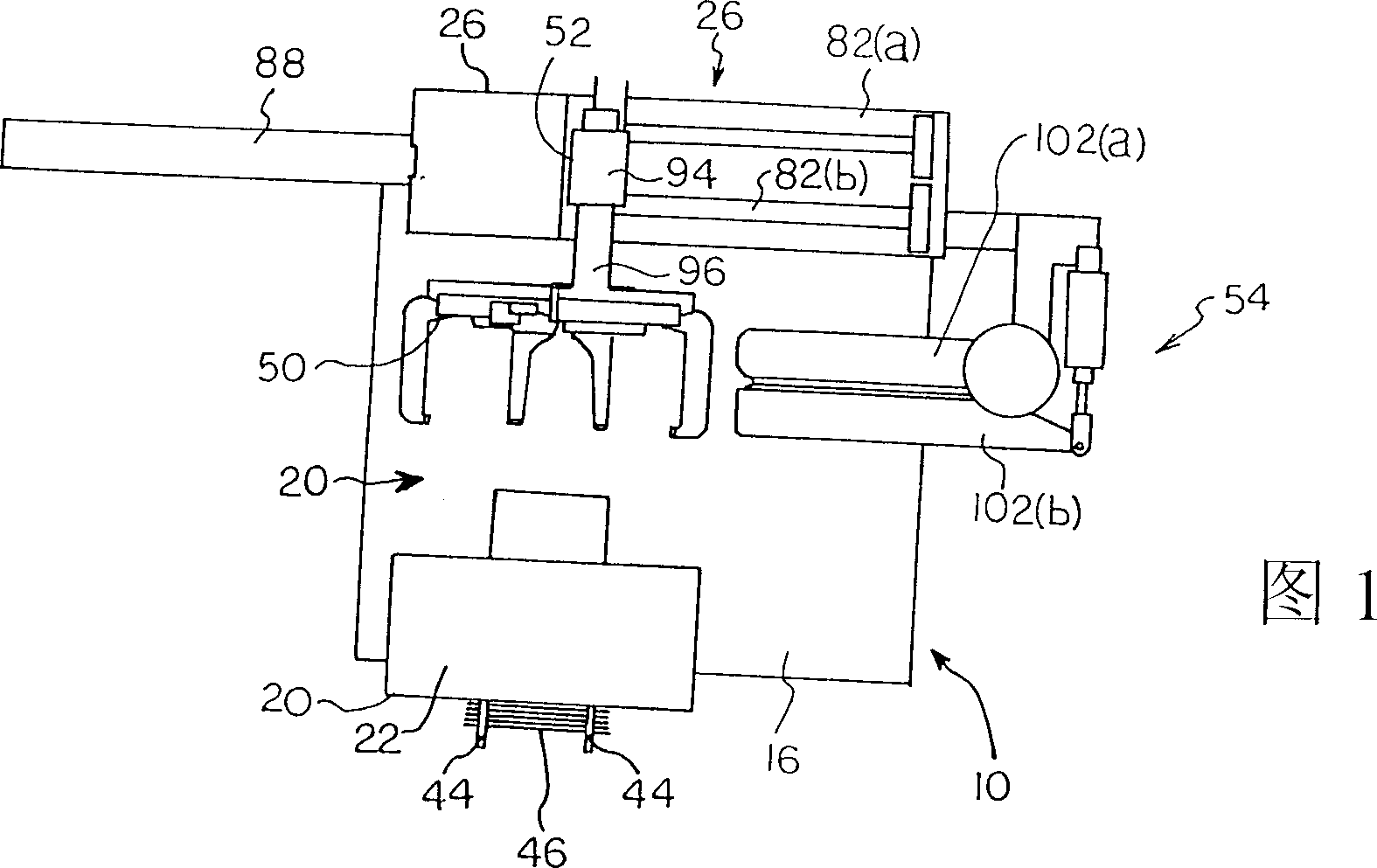

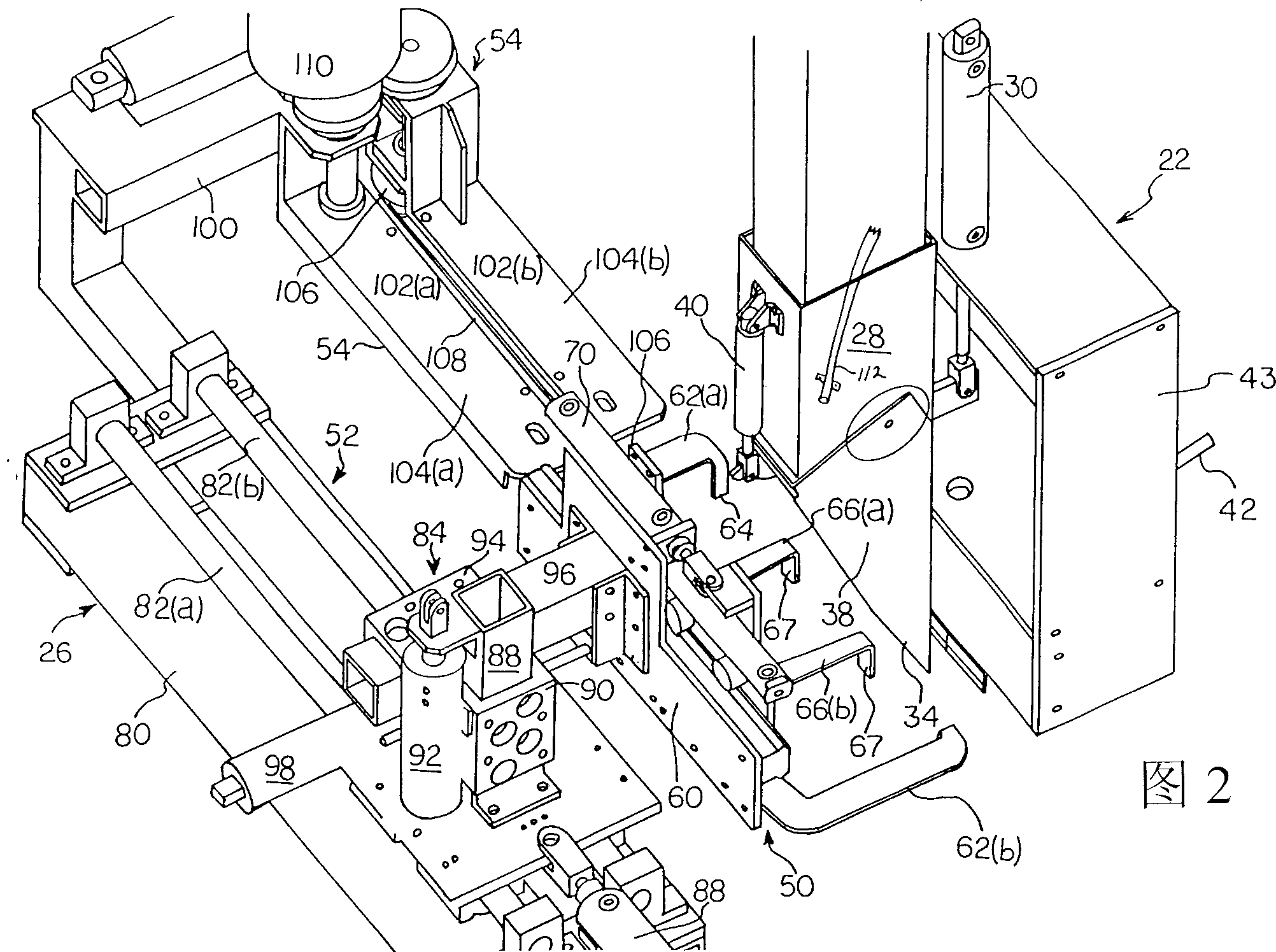

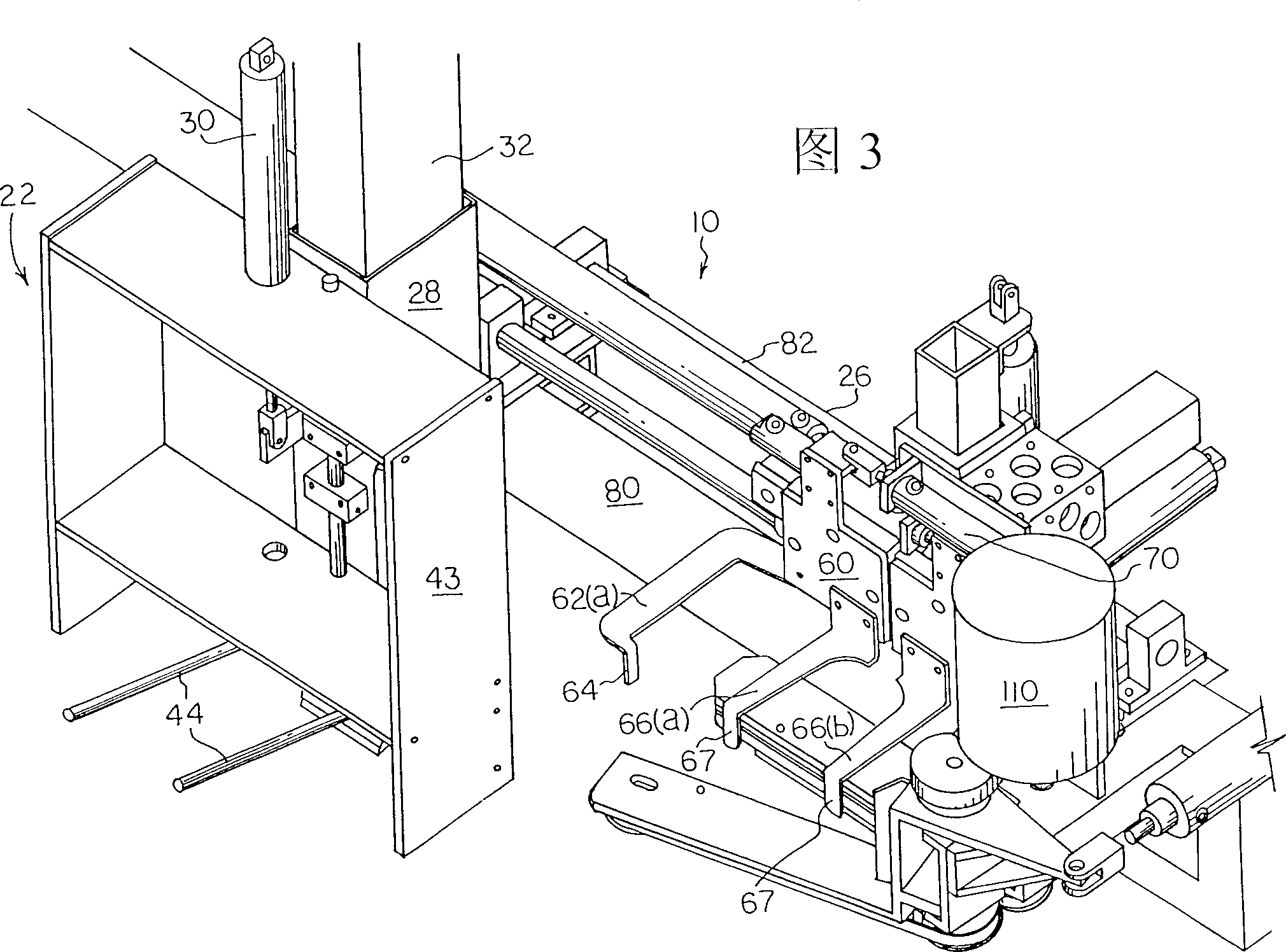

[0040] Referring to the drawings, the apparatus indicated generally at 10 is supported on a frame 16 . The apparatus includes a bagging station 20 having a bag gate station 22 associated therewith, and a bag transfer station 26 . The bagging station includes a vertically reciprocating hopper 28 driven by a pneumatic cylinder 30 for reciprocating vertical movement. Supply conduit 32 loads grain or other loose, bulk cargo (not shown) into hopper 28 . The flow of goods from the hopper 28 is controlled by an expandable jaw structure 34 defining the lower portion of the hopper 28 and comprising a fixed jaw member 36 and a movable jaw member 38 rotatable about a horizontal axis. By means of a pneumatic cylinder 40 mounted on the hopper 28, the movable jaw member 38 is driven to reciprocate, separate and converge with the fixed jaw member 36. In the closed position shown in FIG. 2 , the corresponding jaw structure 34 is clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com