Alcohol substitute in alcohol-free fountain solution and preparation method thereof

A substitute and dampening solution technology, applied in the field of alcohol substitutes for alcohol-free dampening solution, can solve the problems of difficult control of water-ink balance, excessive emulsification of ink, poor wetting performance, etc., achieve good water transfer performance, reduce surface Good tension and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

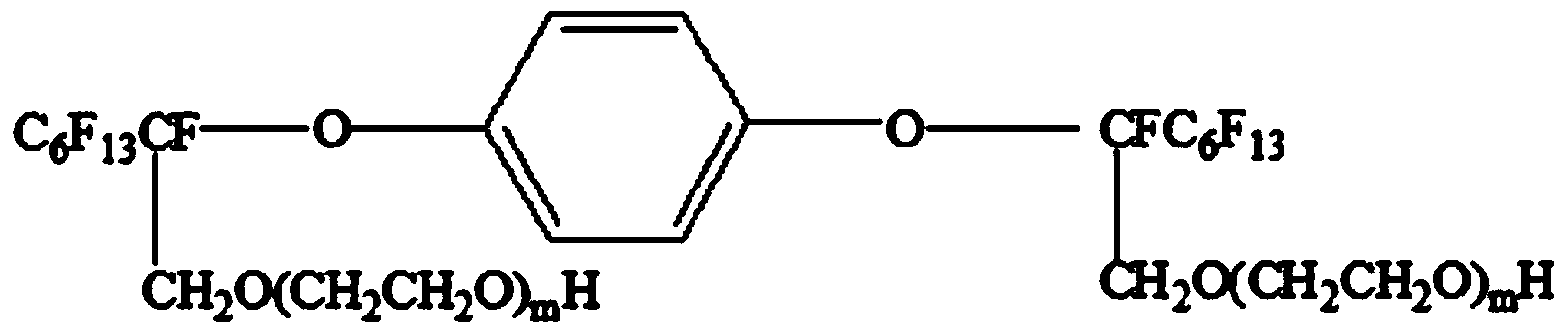

Method used

Image

Examples

Embodiment 1

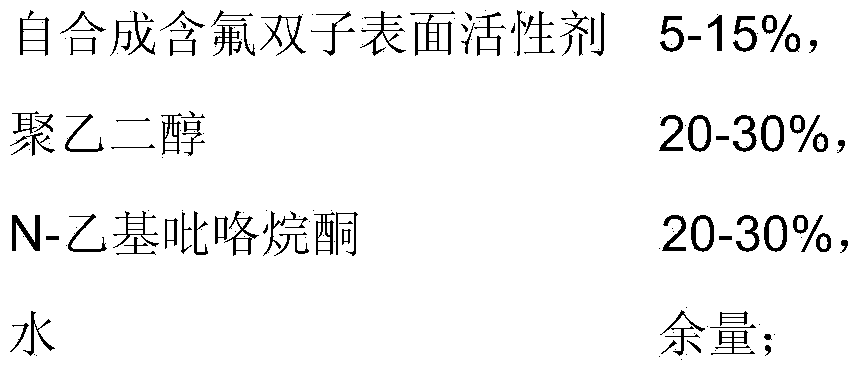

[0033] Alcohol substitute A in a kind of alcohol-free fountain solution, by weight percentage, is composed as follows:

[0034]

[0035] Weigh the above raw materials in proportion, first add water into the reaction kettle, raise the temperature to 70°C, then add polyethylene glycol-2000, stir and dissolve, then cool down to below 40°C, add N-ethylpyrrolidone (NEP), and dissolve completely Then add self-synthesized fluorine-containing gemini surfactant, and stir for 1 hour to prepare alcohol substitute A.

Embodiment 2

[0037] Alcohol substitute A in a kind of alcohol-free fountain solution, by weight percentage, is composed as follows:

[0038]

[0039] Weigh the above raw materials in proportion, first add water into the reaction kettle, raise the temperature to 70°C, then add polyethylene glycol-4000, stir and dissolve, then cool down to below 40°C, add N-ethylpyrrolidone (NEP), and dissolve completely Then add self-synthesized fluorine-containing gemini surfactant, and stir for 1 hour to prepare alcohol substitute A.

Embodiment 3

[0041] Alcohol substitute A in a kind of alcohol-free fountain solution, by weight percentage, is composed as follows:

[0042]

[0043] Weigh the above raw materials in proportion, first add water into the reaction kettle, raise the temperature to 70°C, then add polyethylene glycol-20000, stir and dissolve, then cool down to below 40°C, add N-ethylpyrrolidone (NEP), and dissolve completely Then add self-synthesized fluorine-containing gemini surfactant, and stir for 1 hour to prepare alcohol substitute A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Static surface tension | aaaaa | aaaaa |

| Static surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com