Soluble concentrate for preventing decomposition of diethyl aminoethyl hexanoate

A technology that can dissolve diethyl aminoethyl hexanoate, is applied in the field of pesticides, and can solve the problems of unstable storage of diethyl aminoethyl hexanoate.

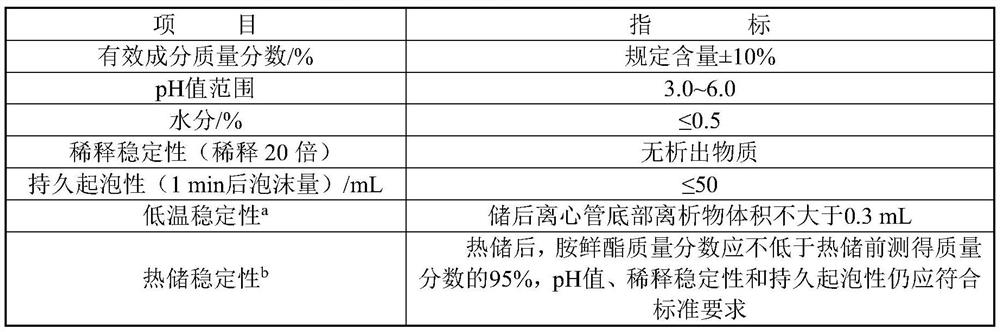

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2、1

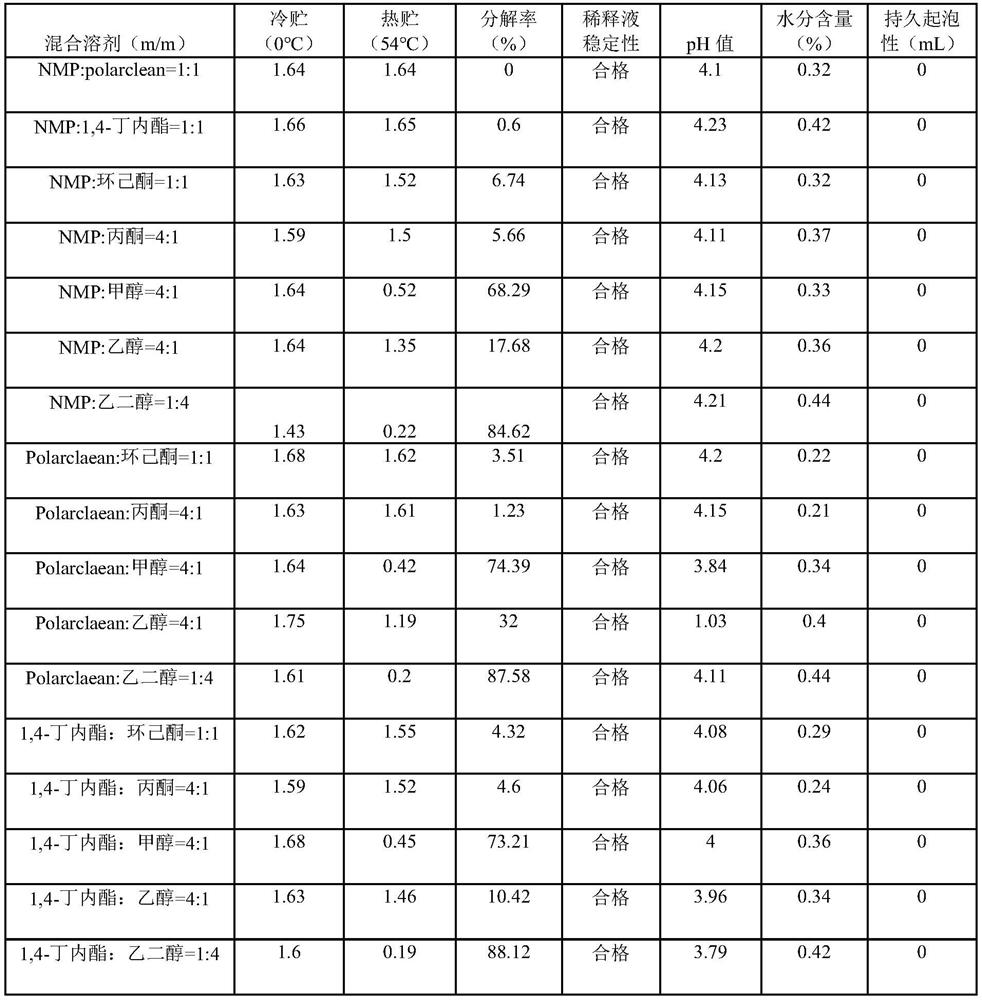

[0045] Embodiment 2, the formula screening of 1.6wt% diethyl diethyl ethyl hexanoate soluble agent

[0046] The solvent composition of the medicament is optimized according to different mass ratios in order to improve the stability of the pesticide product.

[0047] In this embodiment, the content of the diethyl diethyl ethyl ethyl alcohol is 1.6%, and the mixed solvent is supplemented to 100%.

[0048] The stability of diethyl hexanoate soluble agent when table 3 different mixed solvents

[0049]

[0050] The results in Table 3 show that the conventional solvents are likely to lead to an excessively high thermal storage decomposition rate of the diethyl aminoethyl hexanoate soluble solution. According to the 10% error range of the content, the combination of NMP, acetone, cyclopropanone and polarclean all meet the requirements of product quality, the combination of NMP, cyclohexanone, acetone and 1,4-butyrolactone meets the requirements of product quality, and the combina...

Embodiment 3

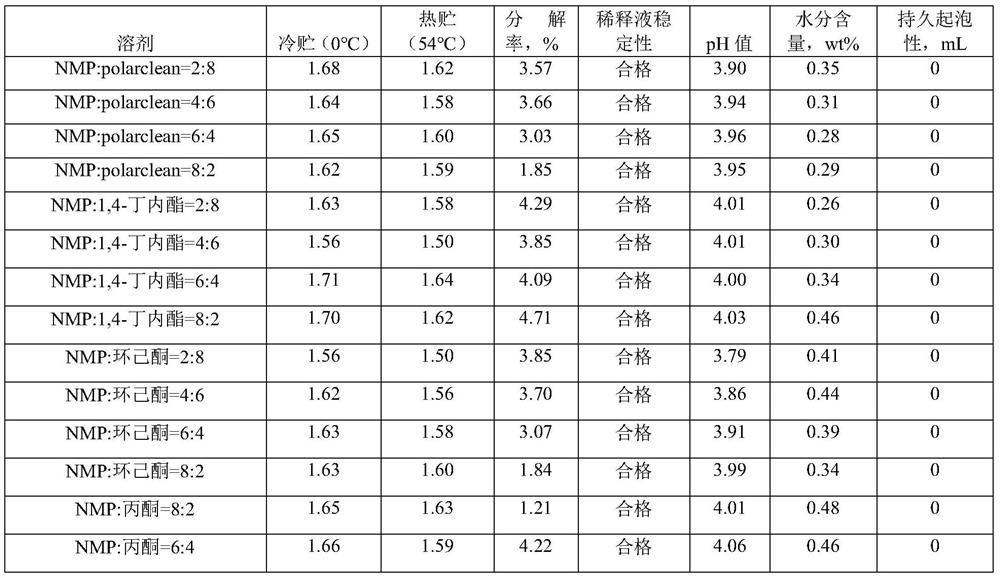

[0052] Based on the results of Example 2, the solvent content is further screened in order to improve the comprehensive performance of product quality.

[0053] In this embodiment, the content of the diethyl diethyl ethyl ethyl alcohol is 1.6%, and the mixed solvent is supplemented to 100%.

[0054] The stability of diethyl hexanoate soluble agent when table 4 different mixed solvents

[0055]

[0056] As can be seen from the experimental results in Table 4, adjusting the proportion of solvents will have a certain impact on the quality index of the product itself, but all meet the quality standards of the product. Under the above formula, the final effect of the product will not be affected by adjusting the ratio of each component.

Embodiment 4

[0058] Based on the above experimental results, this example investigates the effect of adding other auxiliary ingredients on the stability of diethyl hexanoate soluble solution.

[0059] In this embodiment, the content of the diethyl diethyl ethyl ethyl alcohol is 1.6%, and the mixed solvent is supplemented to 100%.

[0060] The stability of the diethyl aminoethyl hexanoate soluble agent of different formulas of table 5

[0061]

[0062] It can be shown from the above experimental results that the addition of auxiliary agents (emulsifiers) has no substantial impact on product performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com