Catalytic combustion adjuvant for coal

A technology of combustion-supporting agent and high-heating agent, applied in the field of catalytic combustion-supporting agent for coal, which can solve problems such as low thermal efficiency, high emission of air pollutants, insufficient coal combustion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

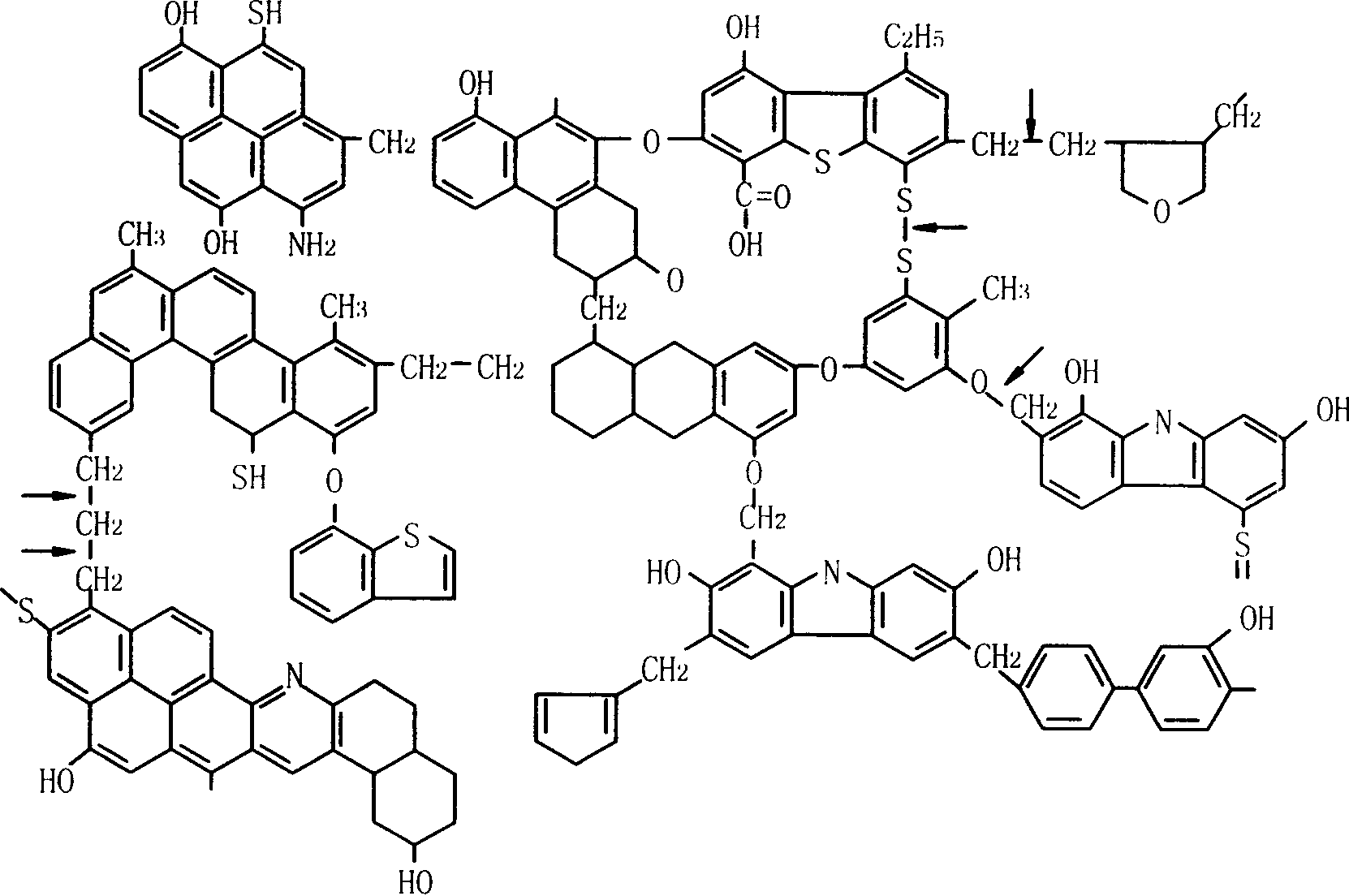

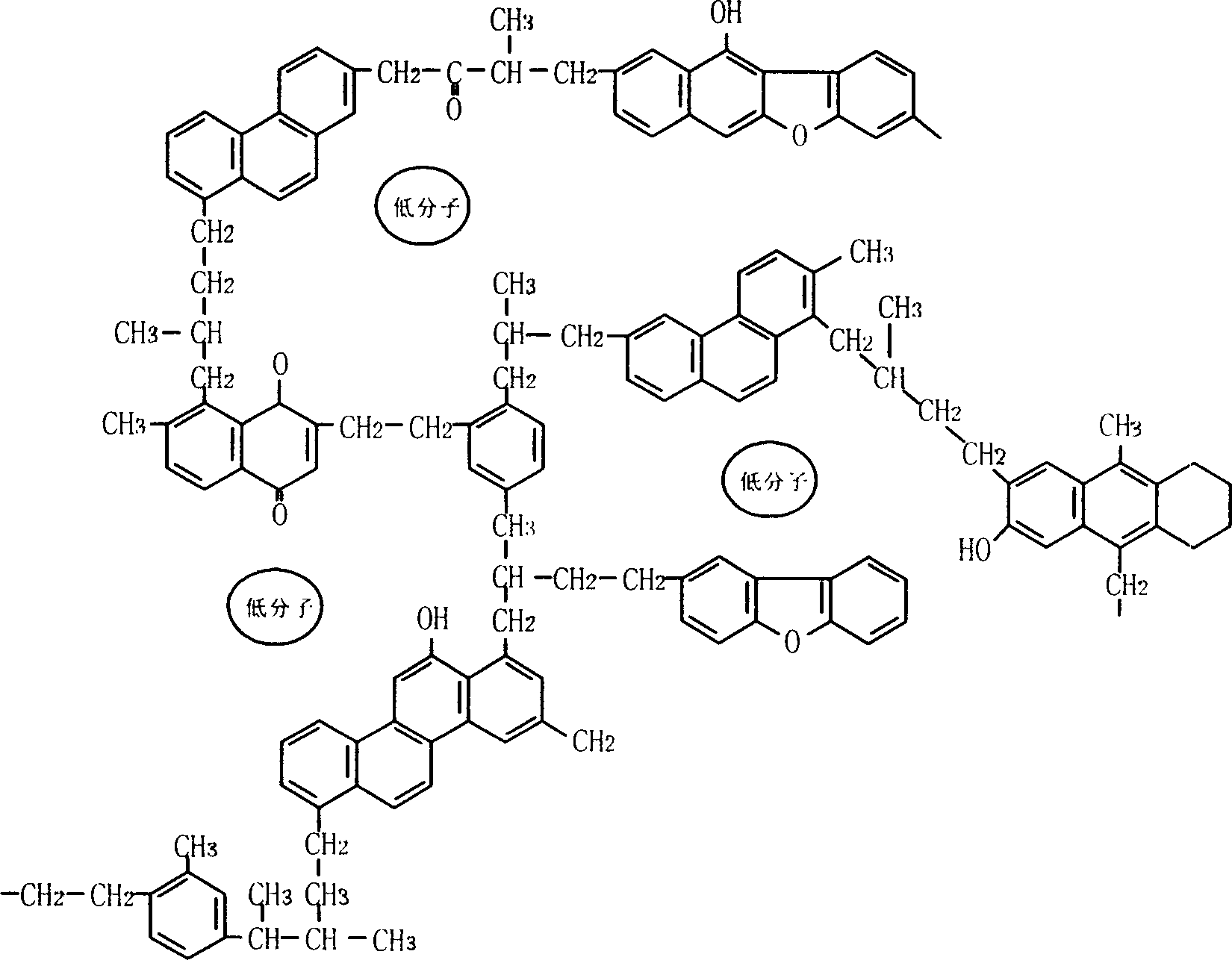

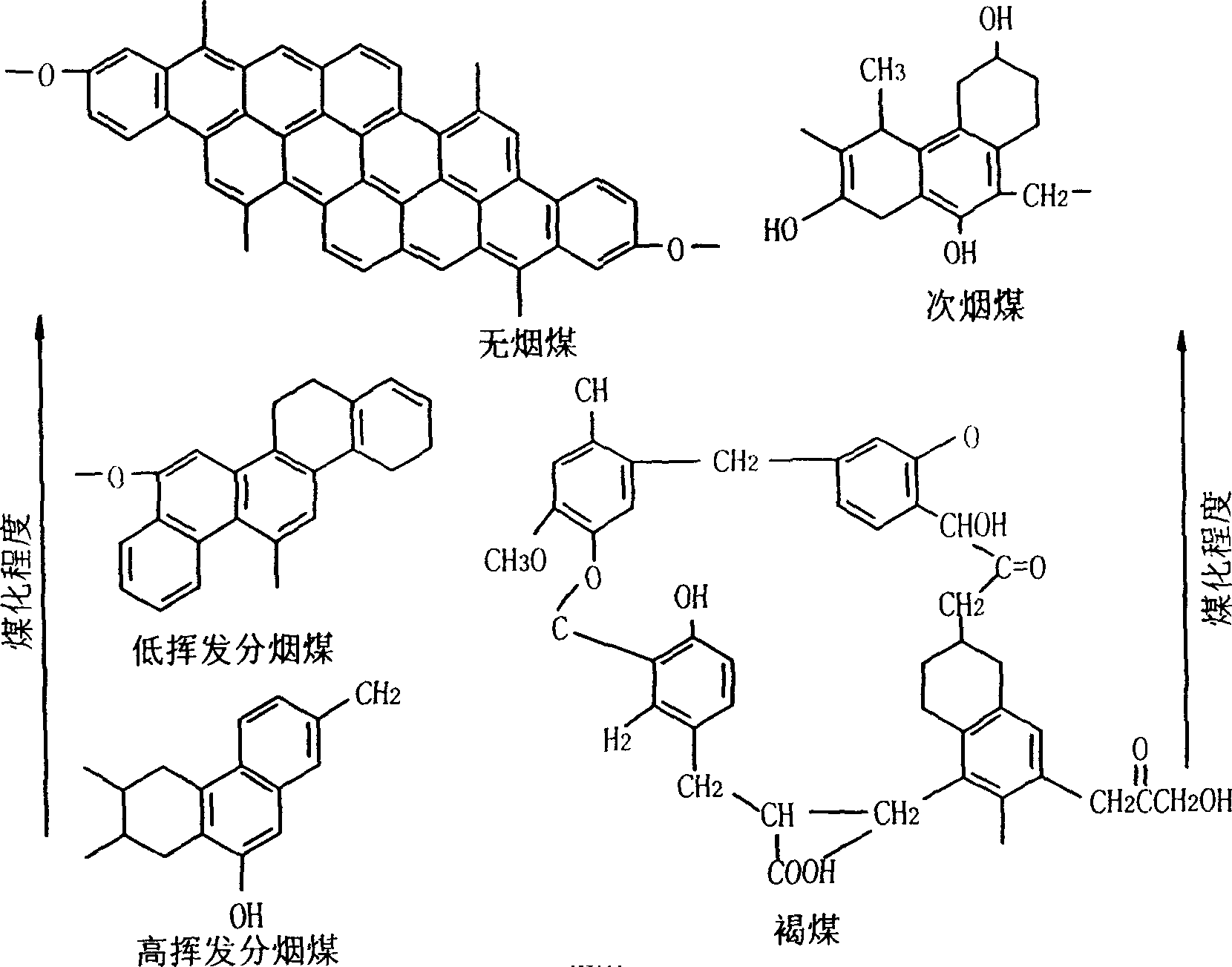

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: 10 parts of iron acetate (ferric iron), 8 parts of cobalt acetate, 16 parts of cerium acetate, 16 parts of lanthanum acetate, 5 parts of sodium benzoate, 3 parts of sucrose, 2 parts of sodium chloride, 40 parts of Dissolve in water evenly.

Embodiment 2

[0067] Embodiment 2: 6 parts of manganese naphthenate, 10 parts of cerium isooctanoate, 8 parts of cobalt naphthenate, 10 parts of iron isooctanoate, 16 parts of lanthanum isooctanoate, 6 parts of diisoamyl oxalate, 3 parts Ferrocene, 2 parts of diethyl aluminum, 1 part of tributyl phosphate, 3 parts of OP-3, 3 parts of pentaerythritol, 5 parts of diethylene glycol, and 27 parts of diesel are dissolved evenly.

Embodiment 3

[0068] Embodiment 3: 10 parts of " alkali slag " (sodium naphthenate), 3 parts of calcium lactate, 12 parts of zinc acetate, 16 parts of manganese acetate, 10 parts of cerium benzoate, 3 parts of cobalt hydroxyacid, 16 parts of Copper naphthenate, 5 parts of boron oxide, 3 parts of aluminum powder (pretreated with paraffin solution), 7 parts of ferric oxide, 8 parts of quicklime, 3 parts of bauxite, 4 parts of fine wood chips, after being crushed to less than 5mm, mix well . In application, it is added into coal mill powder together with coal in proportion to grind into fine coal powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com