Patents

Literature

49results about How to "Reduce NOx content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

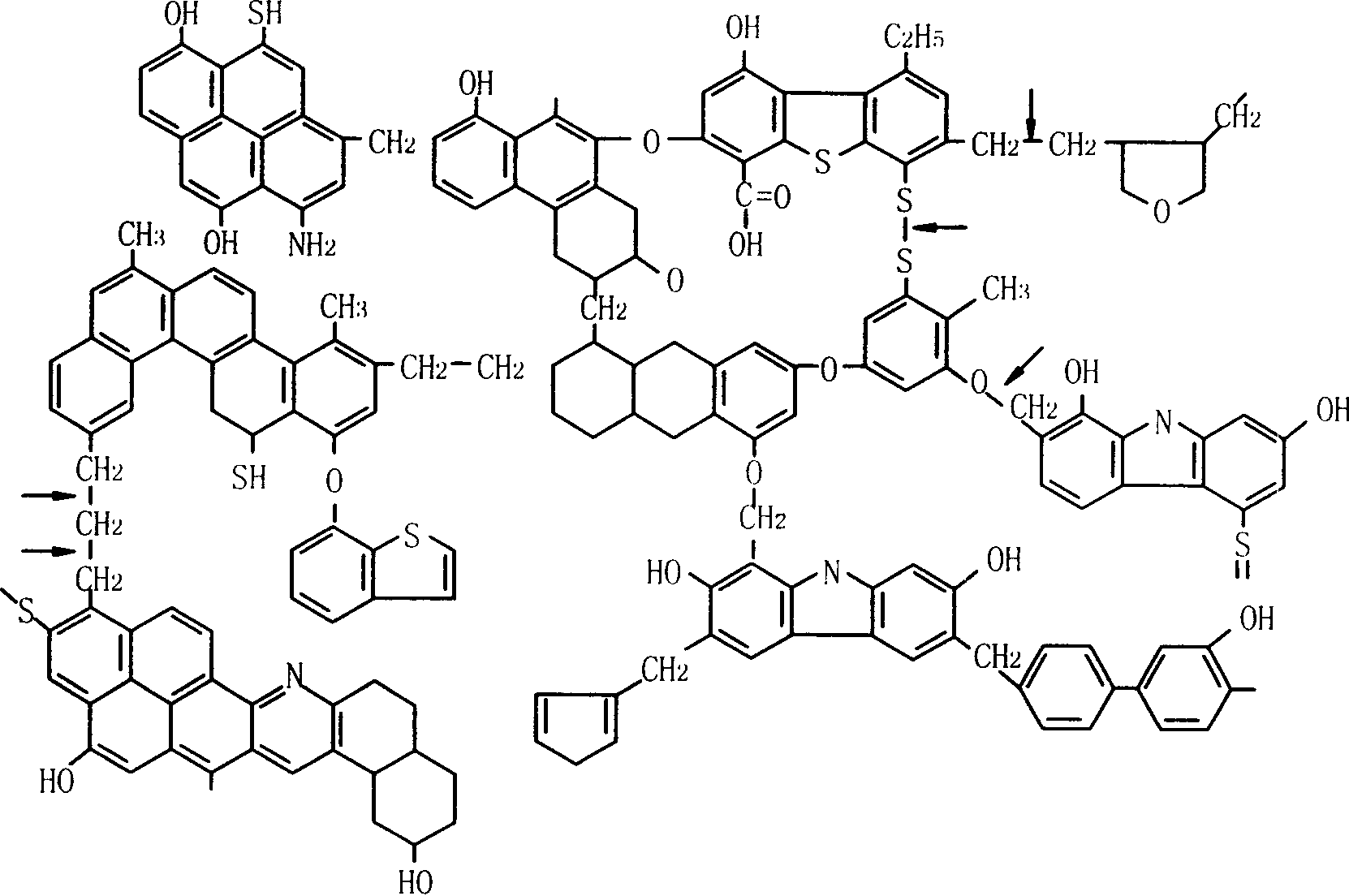

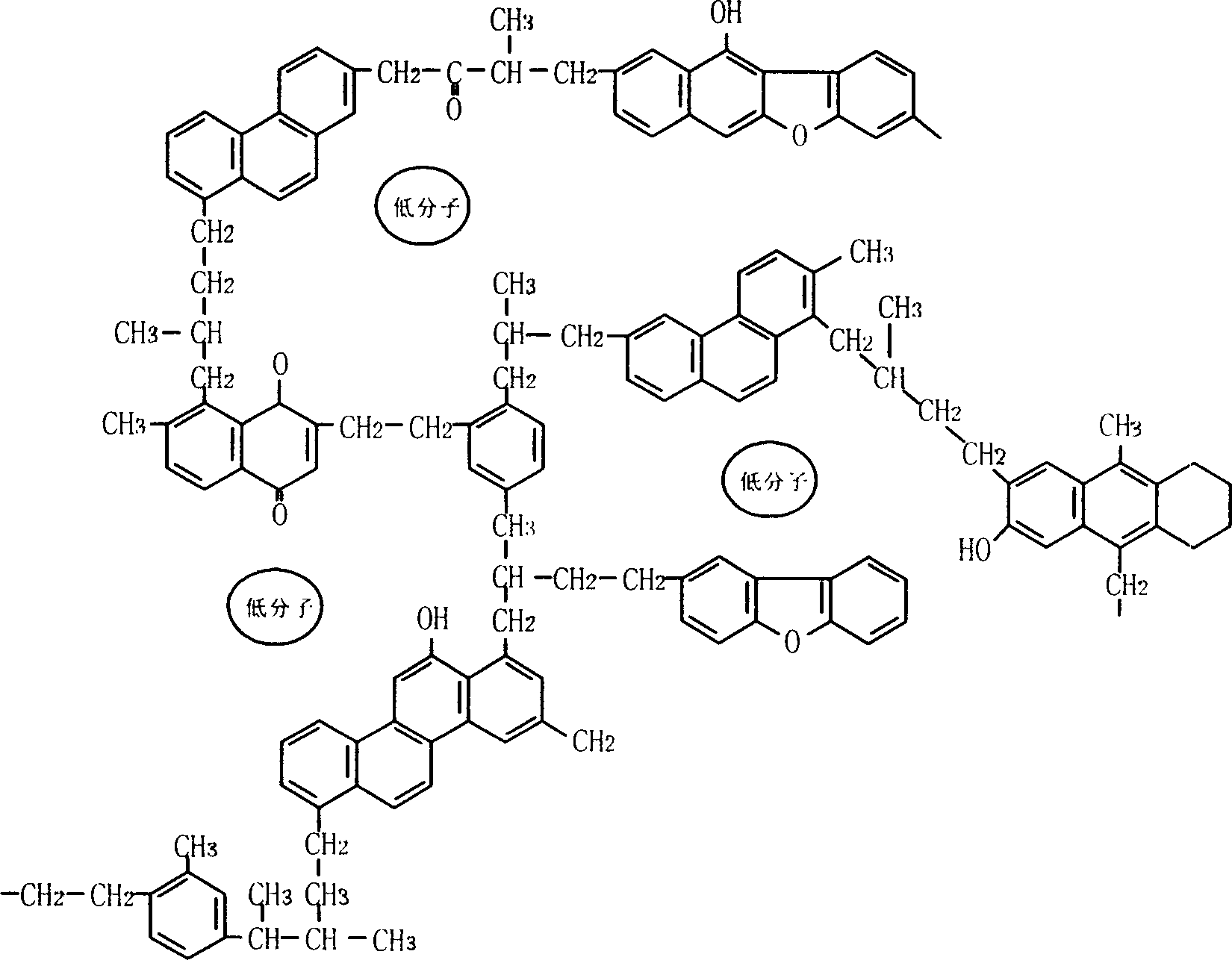

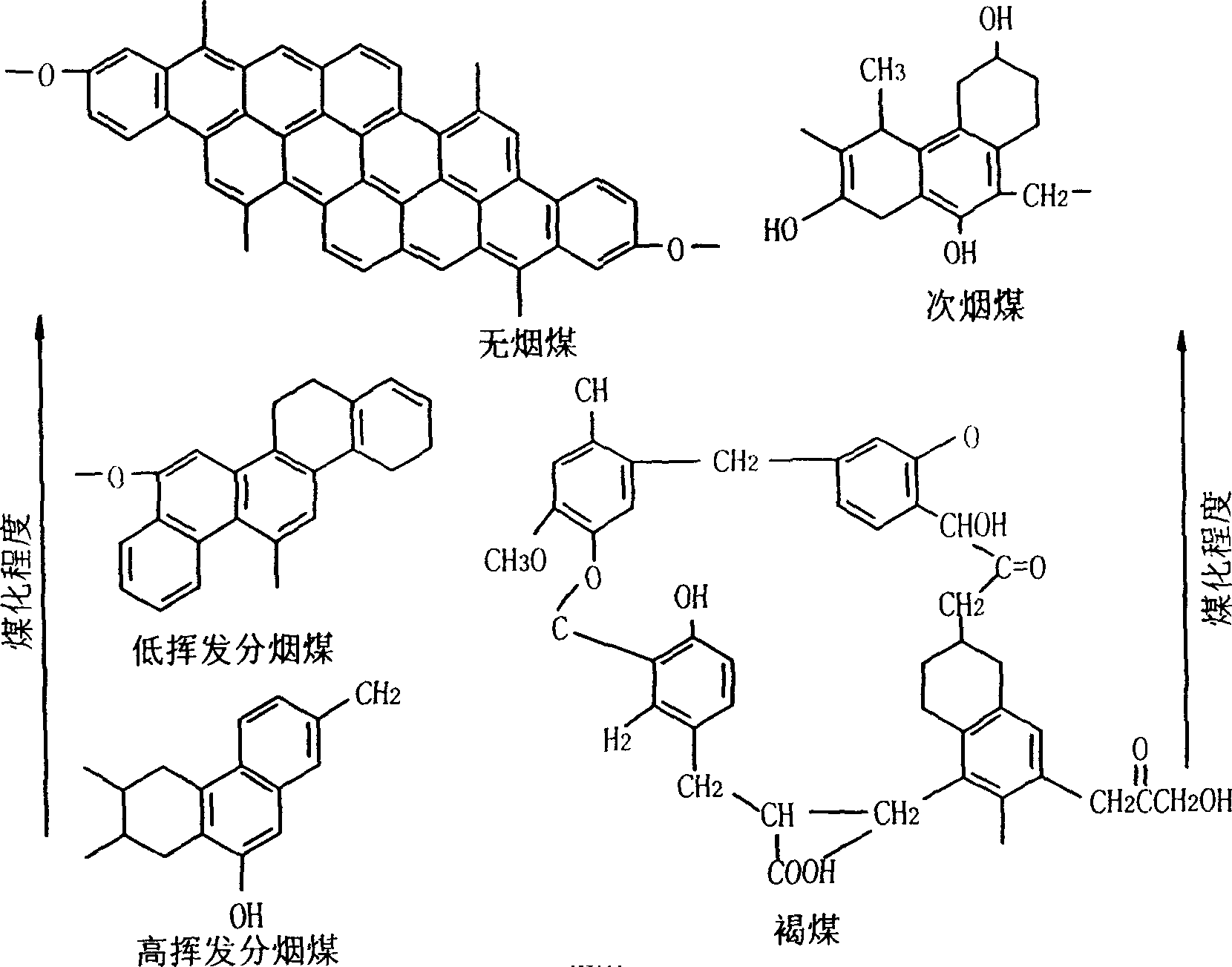

Catalytic combustion adjuvant for coal

A catalytic combustion improver of coal for increasing combustion efficiency and decreasing the exhaust of SO2, CO and NOx is composed of the primary raw materials chosen from 17 salts of organic acid, including acetate, oxalate, succinate, etc, the organic compound prepared by reaction between 17 organic acids and ore, metal, metallic oxide, or compound, chloride, etc, and the secondary raw materials chosen from high-caloricity agent, surface coating agent, solvent, assistant, emulsifying disperser, sulfur fixating agent and filler.

Owner:尹小林

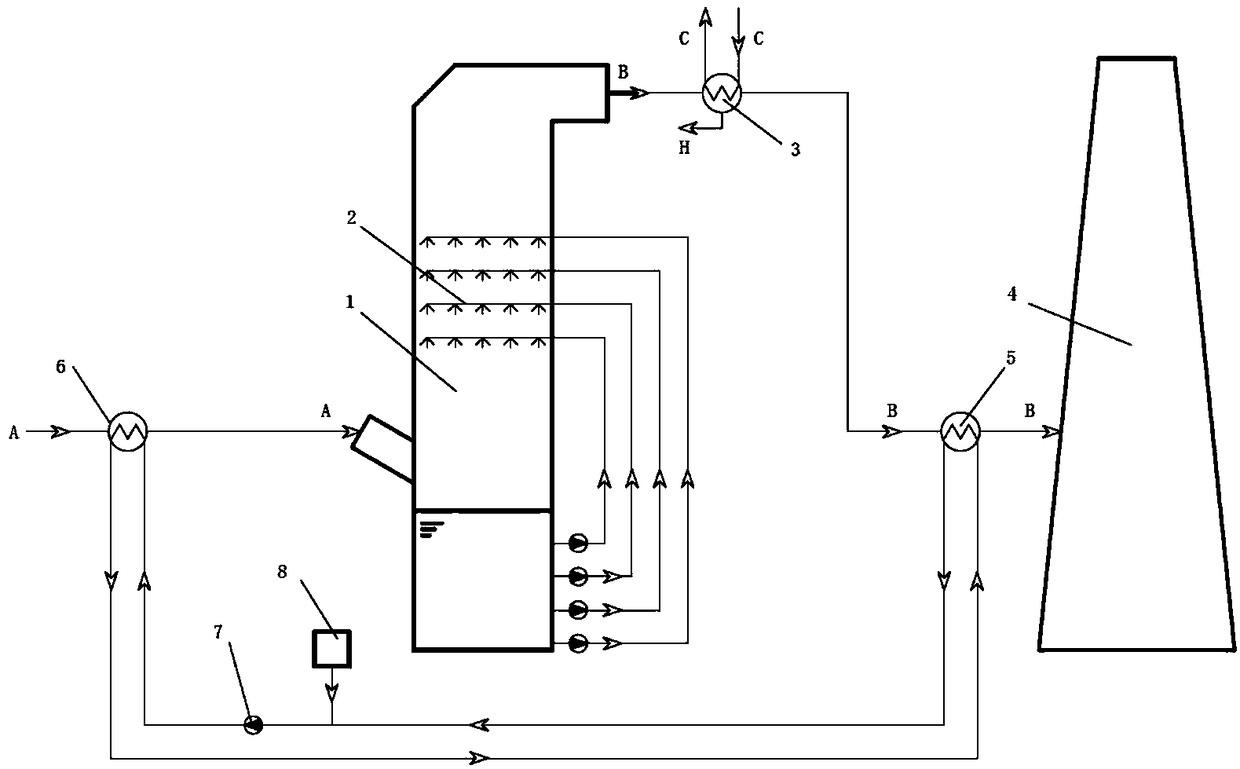

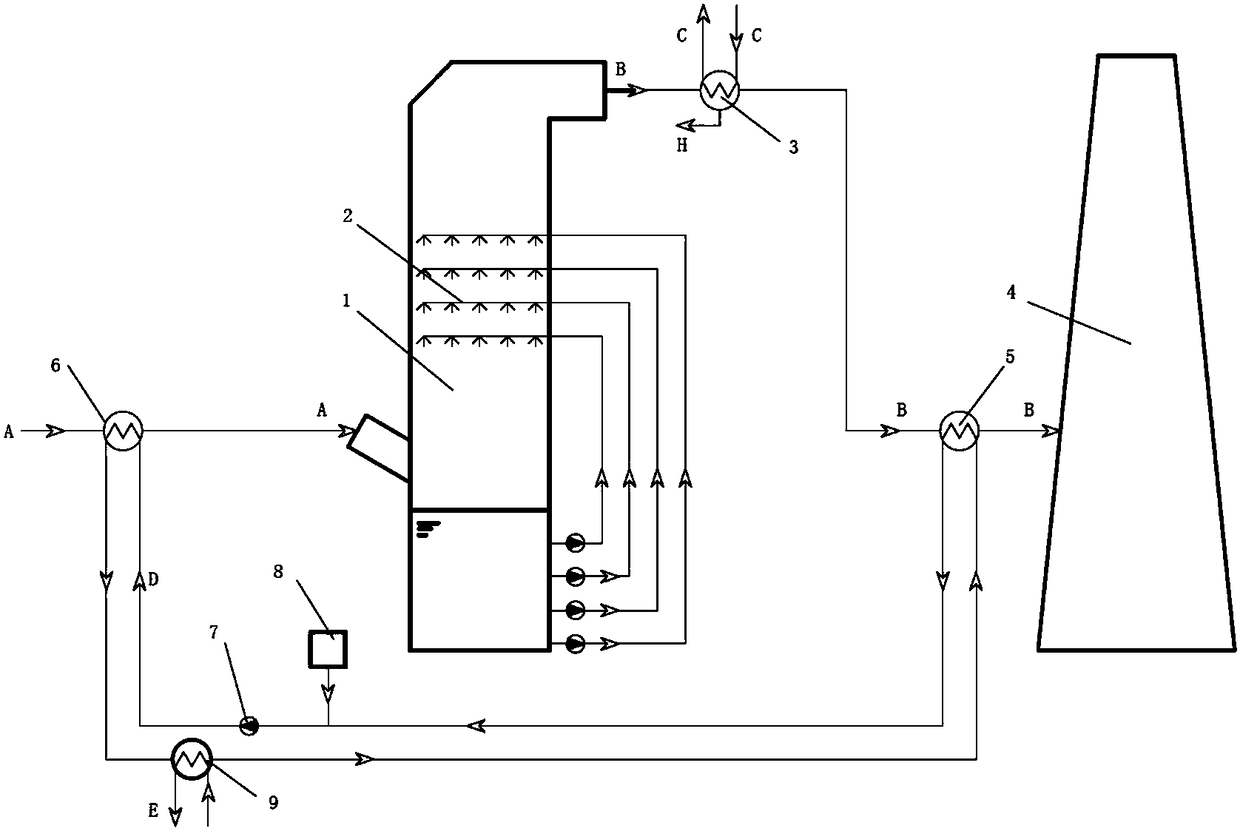

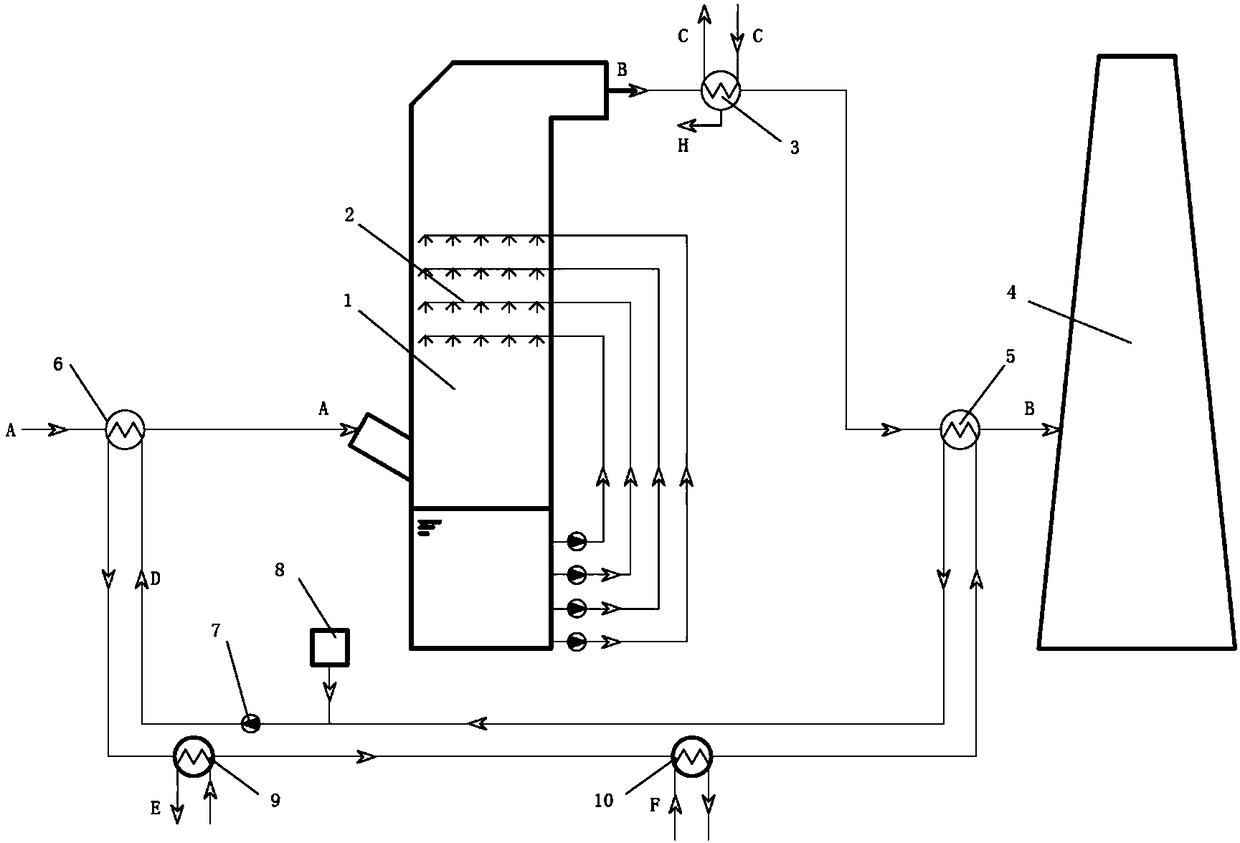

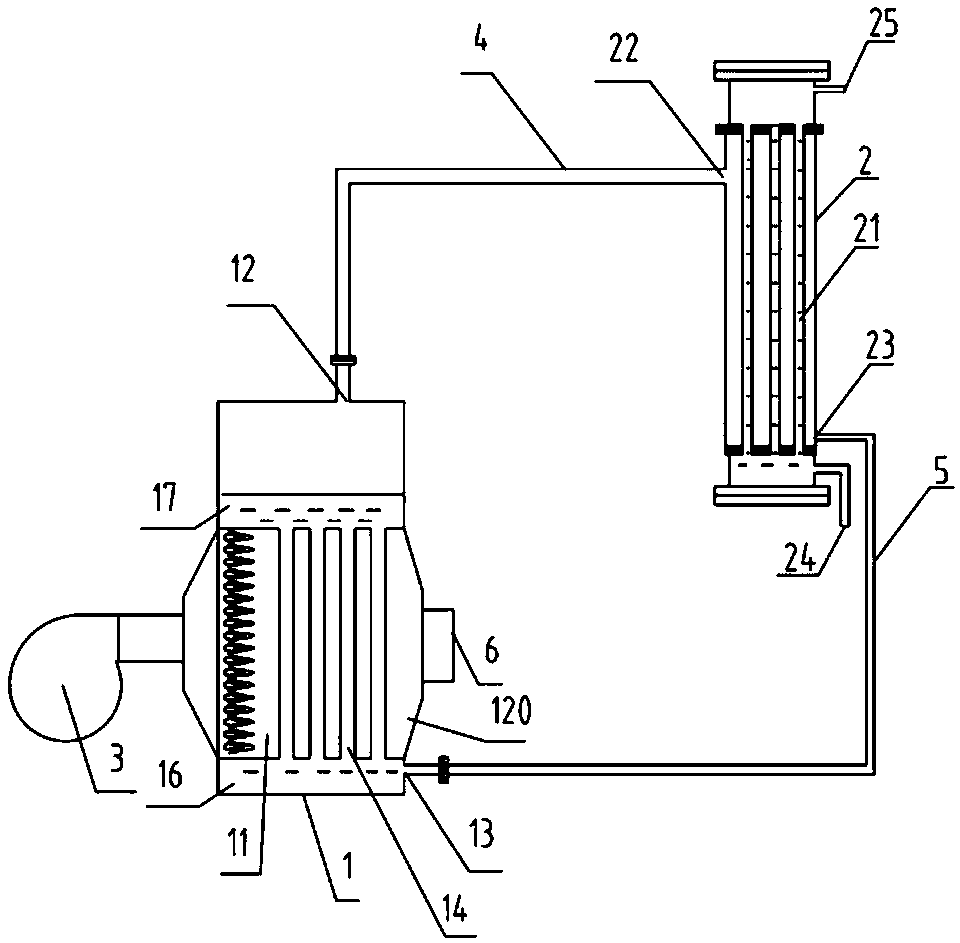

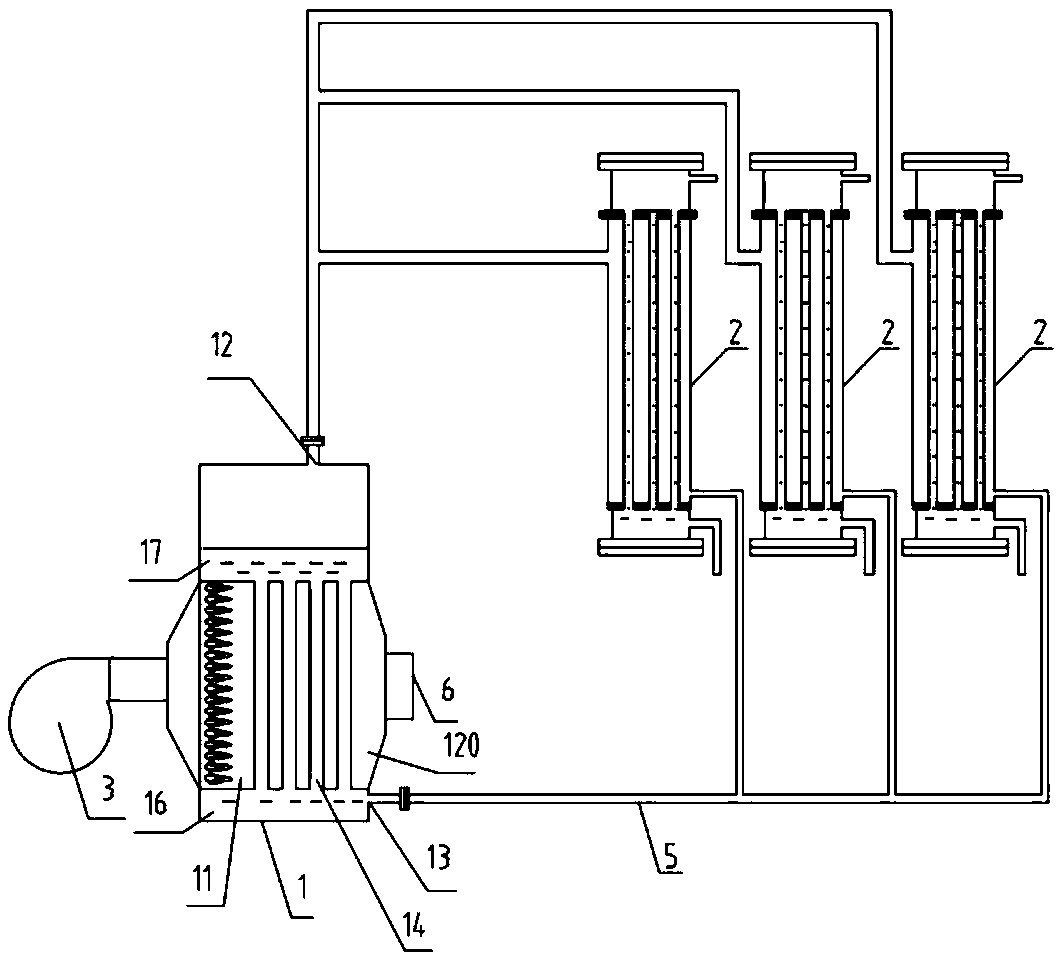

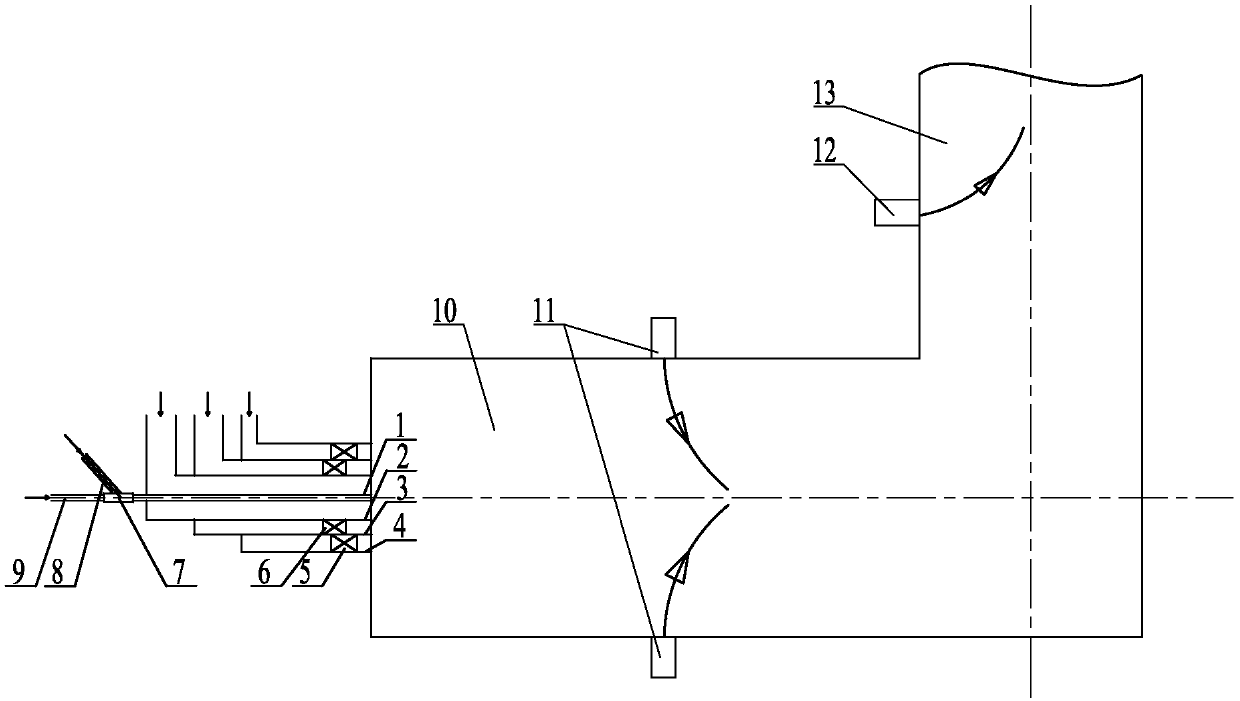

Outside-tower condensed heat-medium smoke plume elimination system for flue gas

PendingCN108126482AReduce heat loadReduce overall form factorGas treatmentDispersed particle separationWater vaporAtmospheric air

The invention discloses an outside-tower condensed heat-medium smoke plume elimination system for flue gas, and relates to a smoke plume elimination system for desulfurized flue gas. The outside-towercondensed heat-medium smoke plume elimination system comprises a desulfurizing tower, a heat medium water closed cycle and a plate type flue gas condenser, wherein the heat medium water closed circleconsists of a temperature lowering section heat exchanger and a temperature raising section heat exchanger. Raw flue gas is cooled by heat medium water through the temperature lowering section heat exchanger and then enters the desulfurizing tower; desulfurized flue gas is cooled and dehumidified through the flue gas condenser, then enters the temperature raising section heat exchanger, and is discharged into the atmosphere through a chimney after being heated by the heat medium water; through the condensation, on purified flue gas, of the flue gas condenser, the reduction of the moisture content of the flue gas and the reduction of the smoke plume elimination heat load of the flue gas are realized; the purified flue gas is heated by utilizing the heat of the raw flue gas; the degree of superheat of the dehumidified flue gas is further improved; the elimination of a smoke plume and the abatement of the emissions of mill dust and water vapor are realized; as the flue gas condenser is arranged outside the system, condensed fluid separated out by the water vapor in the flue gas is discharged outside the system, and the influence cannot be generated to the water balance in the desulfurizing tower.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

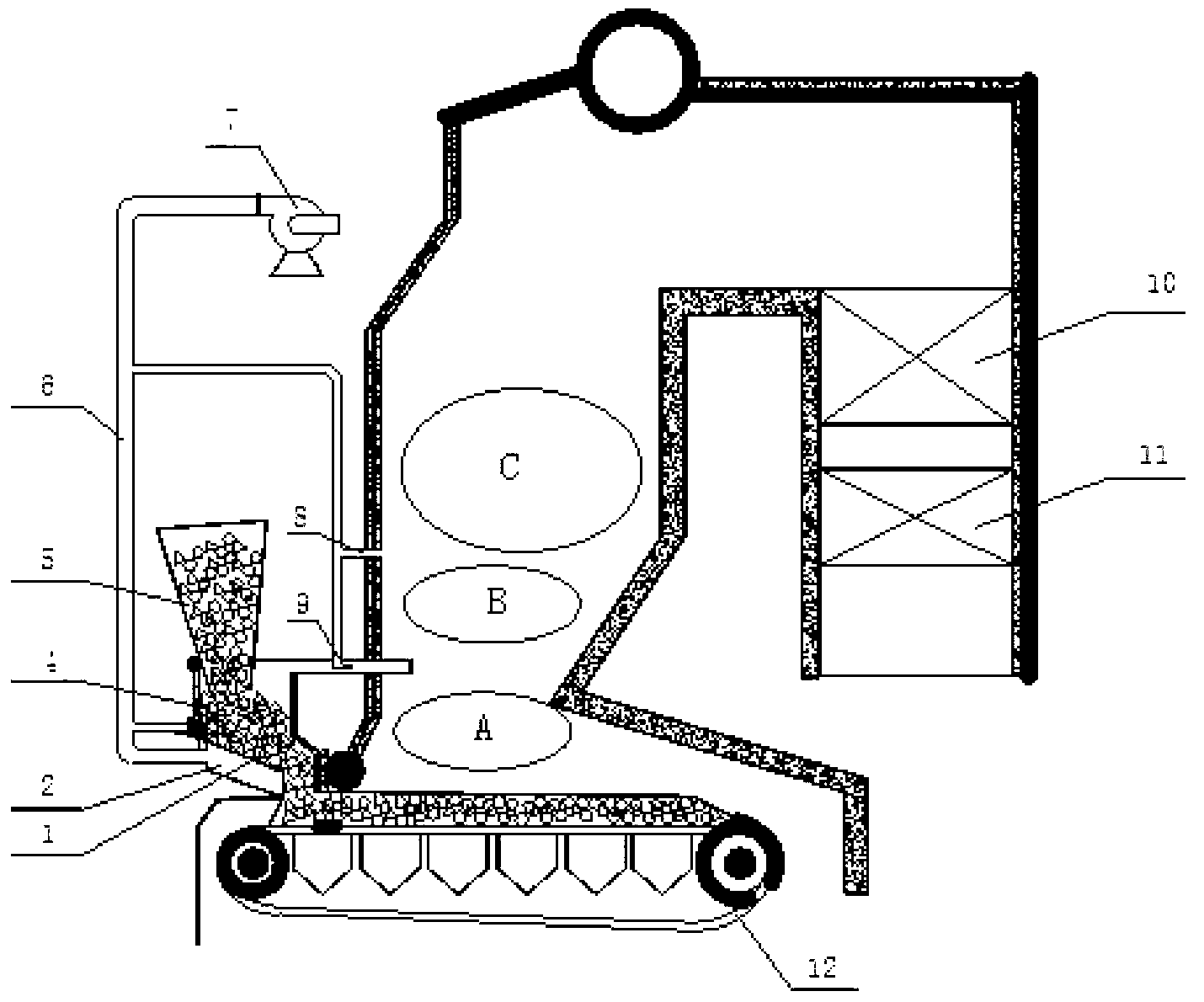

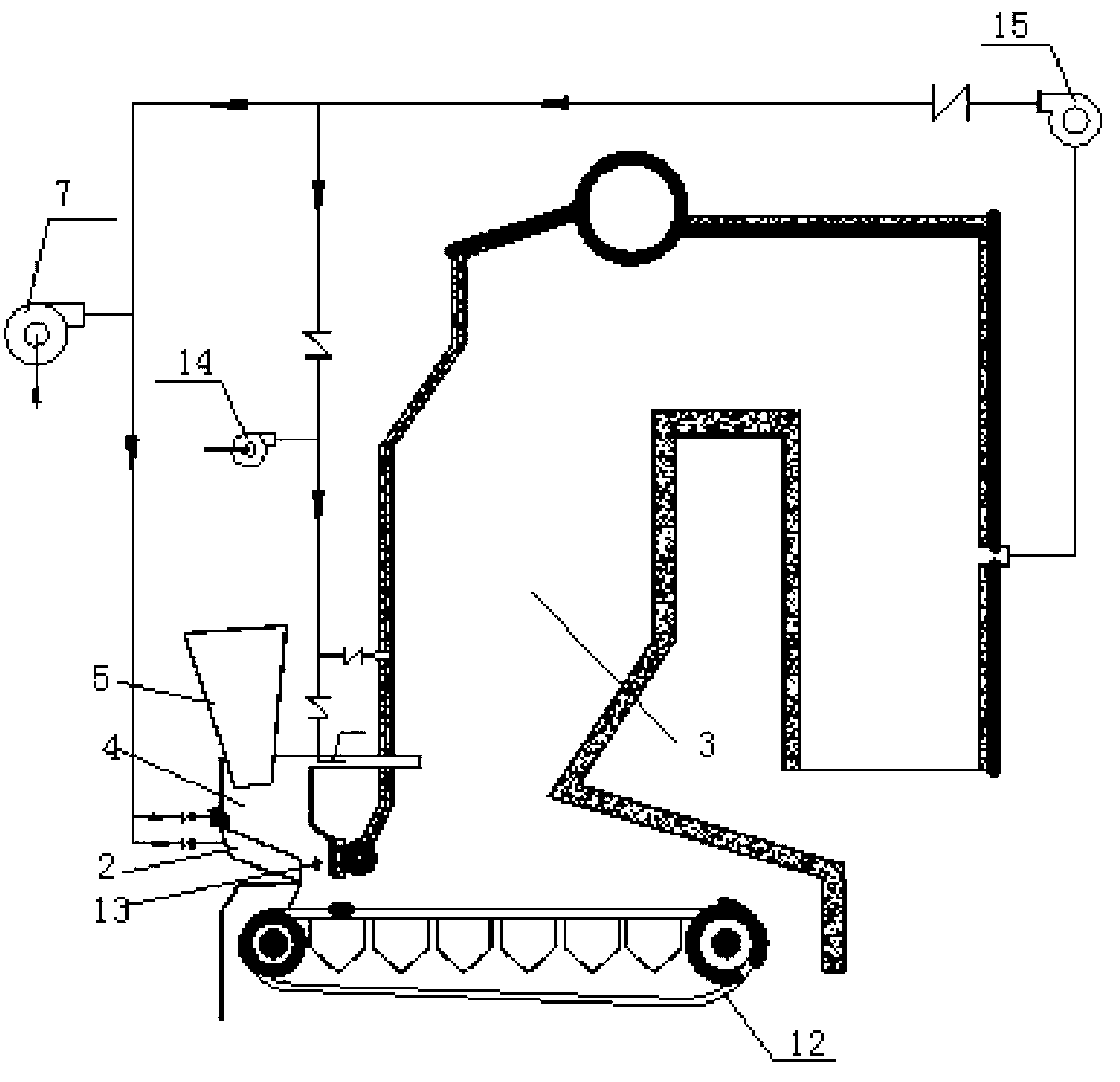

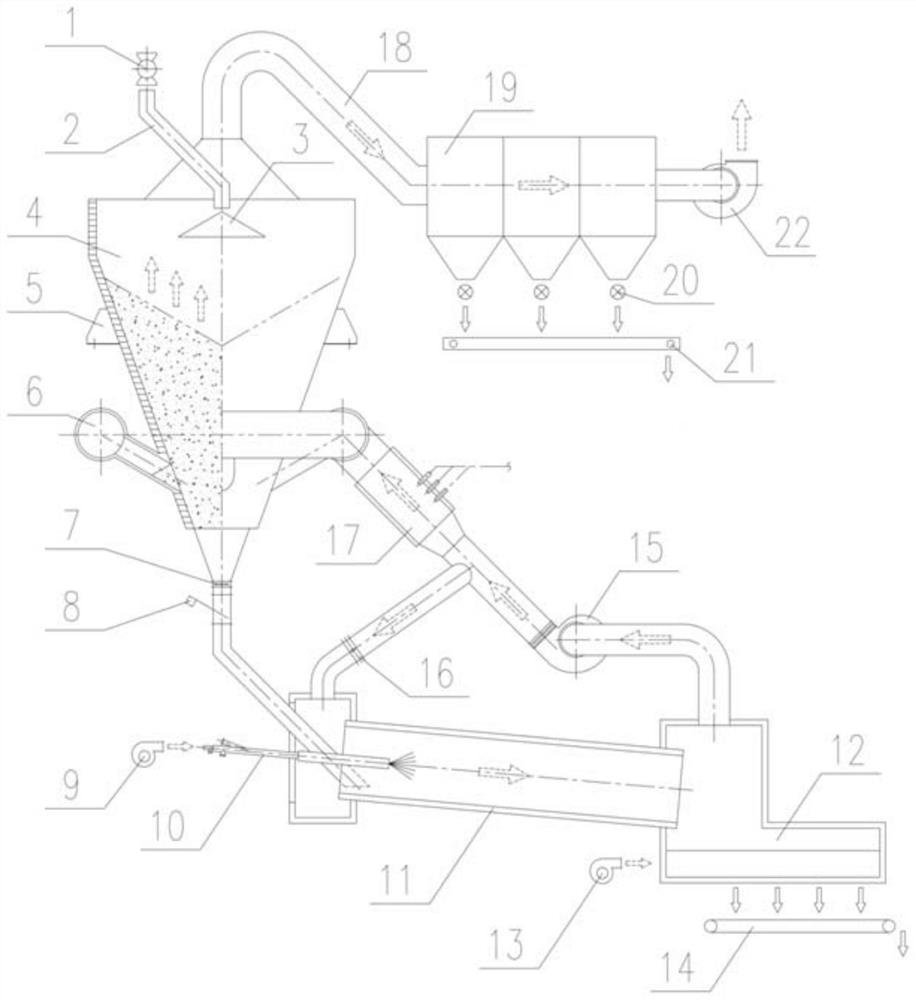

Front coal gasification grate-firing device and combustion method thereof

InactiveCN103234196ASpeed up the drying and heating processReduce incomplete combustion lossesSolid fuel combustionCombustion apparatusHearthGrate firing

The invention discloses a front coal gasification grate-firing device and a combustion method thereof. By the aid of the front coal gasification grate-firing device and the combustion method thereof, the problems of emission of the high NOx content and the high SOx content of traditional chain layer burners are solved, and the boiler efficiency is improved. The front coal gasification grate-firing device comprises a coal bucket, a coal gasification chamber and a coke discharge pipe which are communicated sequentially, a gas pipe is arranged at the top of the coal gasification chamber, an injection nozzle is arranged inside the gas pipe, communicated with a secondary air pipeline through an injection air pipeline and parallel with the secondary air pipeline, an opening of the injection nozzle faces towards a hearth, the secondary air pipeline and the gas pipe are arranged in parallel in an up-and-down mode and communicated with the hearth, a bottom bellows is installed at the bottom of the coal gasification chamber, communicated with a gasification air pipeline and communicated with the coal gasification chamber through a fire grate I, the fire grate I is inclined towards the inlet direction of the coke discharge pipe, a coke breaking machine is installed at the position of an inlet of the coke discharge pipe, and an outlet of the coke discharge pipe is located above a fire grate II at the bottom of the hearth.

Owner:SHANDONG UNIV

Micro-emulsion diesel oil additive and its application

The invention discloses a micro-emulsified diesel oil additive, comprising the following components mixed together according to weight proportion: 1-3 of cationic surfactant, 7-30 of middle chain alcohol; 60-90 of organic acid, 3-15 of ammonia and / or ethanolamine and 0-6 of ethanol. The invention has the advantages of transparency, long-preserving time, simple production technique and low cost; at the same time, by adopting the anionic-cationic surfactant mixed system, the invention has large water solubilization and is stable.

Owner:SHANDONG UNIV

Nitric acid production technology with double-pressurized method

InactiveCN105366653AIncrease profitImprove absorption rateEnergy inputNitric acidHigh concentrationPlatinum

The invention discloses a nitric acid production technology with a double-pressurized method. The technology includes the steps of: (1) mixing of raw materials; (2) operation of an ammoxidation reaction; (3) thermal recovery and cooling; (4) absorption; (5) bleaching; and (6) treatment of tail gas. The production technology is reasonable and simple, and has high ammonia utilization rate, low platinum consumption, high absorptivity, high concentration of finished acid, and low content of NOx in the tail gas. Moreover, the production technology avoids wasting of energy resources, is suitable for promotion in various nitric acid manufactures, and has good thermal recovery so that the steam is more than self-sufficient.

Owner:蒋小华

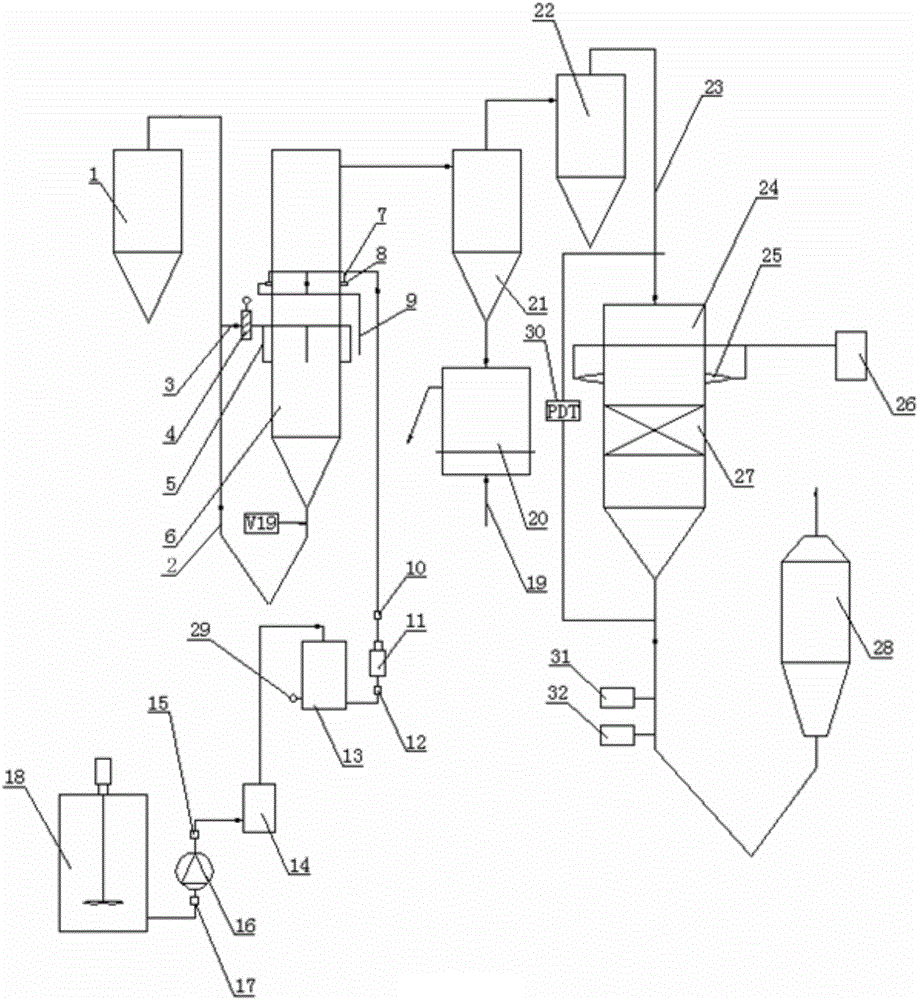

Reduction and oxidation combined denitration system and denitration method thereof

InactiveCN105251326AReduce NOx contentEasy to use directlyDispersed particle separationFlue gasProcess engineering

A reduction and oxidation combined denitration system comprises an SNCR denitration device, an SCR denitration device and an oxidation denitration device. The SNCR denitration device comprises a reducing agent storage device, a cyclone separator and a reducing agent jet device. The SCR denitration device comprises a reducing agent supplementation amount control device and a denitration catalyst layer. The denitration catalyst layer is arranged in the tail of a boiler flue gas pipeline. The oxidation denitration device is connected with the outlet of the boiler flue gas pipeline through a flue gas pipeline, and comprises an oxidization reaction device, a concentrate nitric acid absorption tower and an alkali liquor washing tower which are sequentially connected through flue gas pipelines. The oxidation denitration device conducts deep denitration processing on flue gas where denitration is conducted through the SNCR denitration device and the SCR denitration device. The invention further provides a method for conducting boiler flue gas denitration through the system; by means of the method, reduction denitration and oxidization denitration are combined, the denitration effect is better, and upgrading and reconstructing of an existing denitration system are facilitated.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

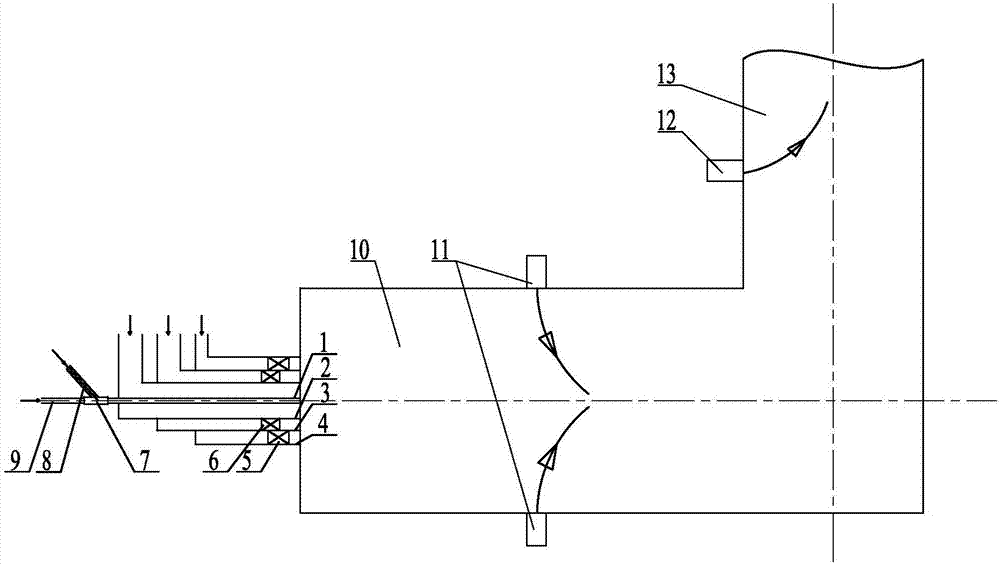

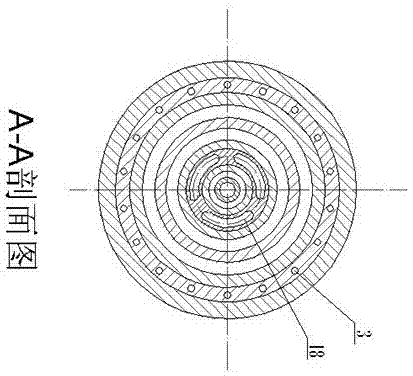

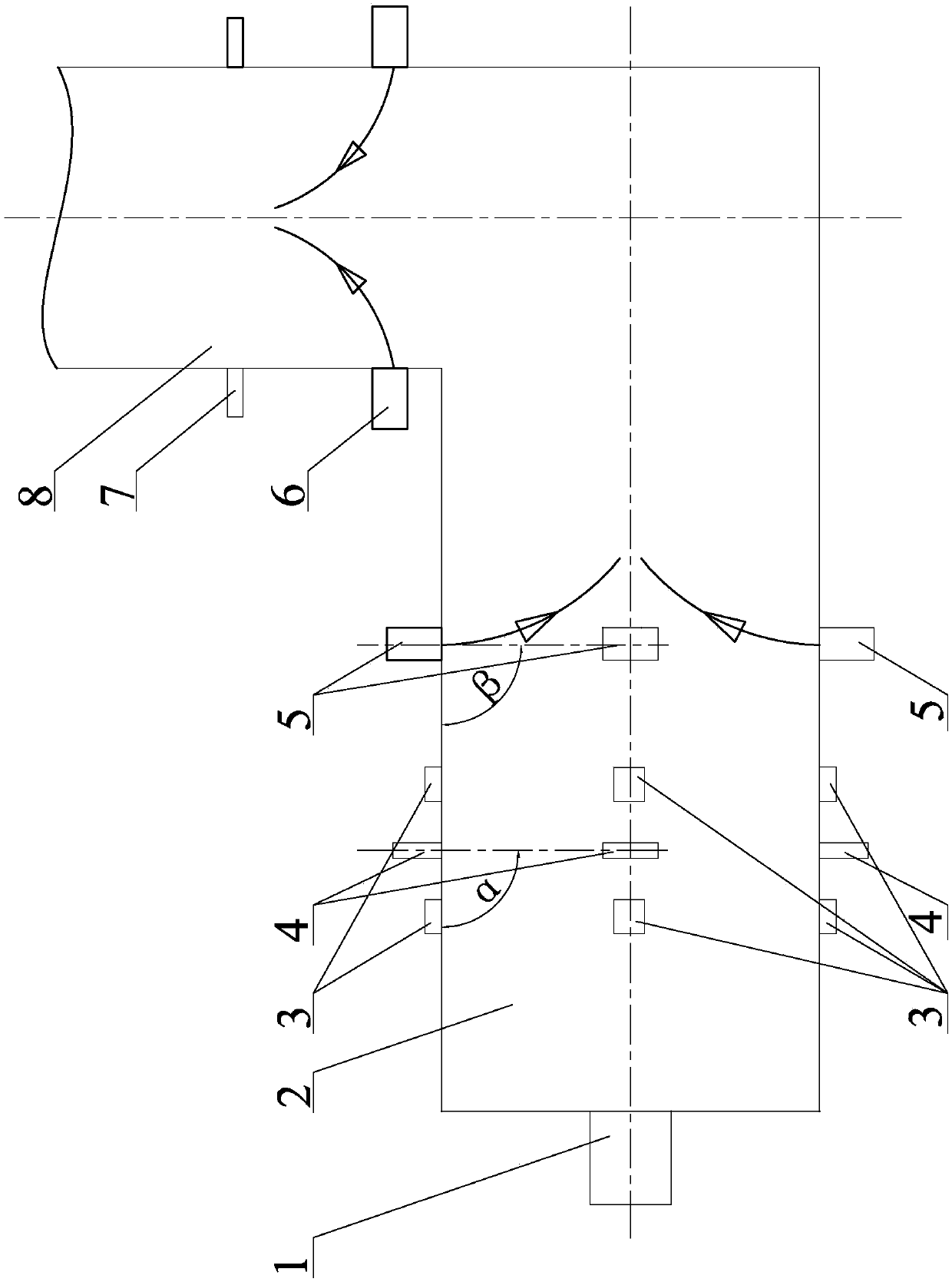

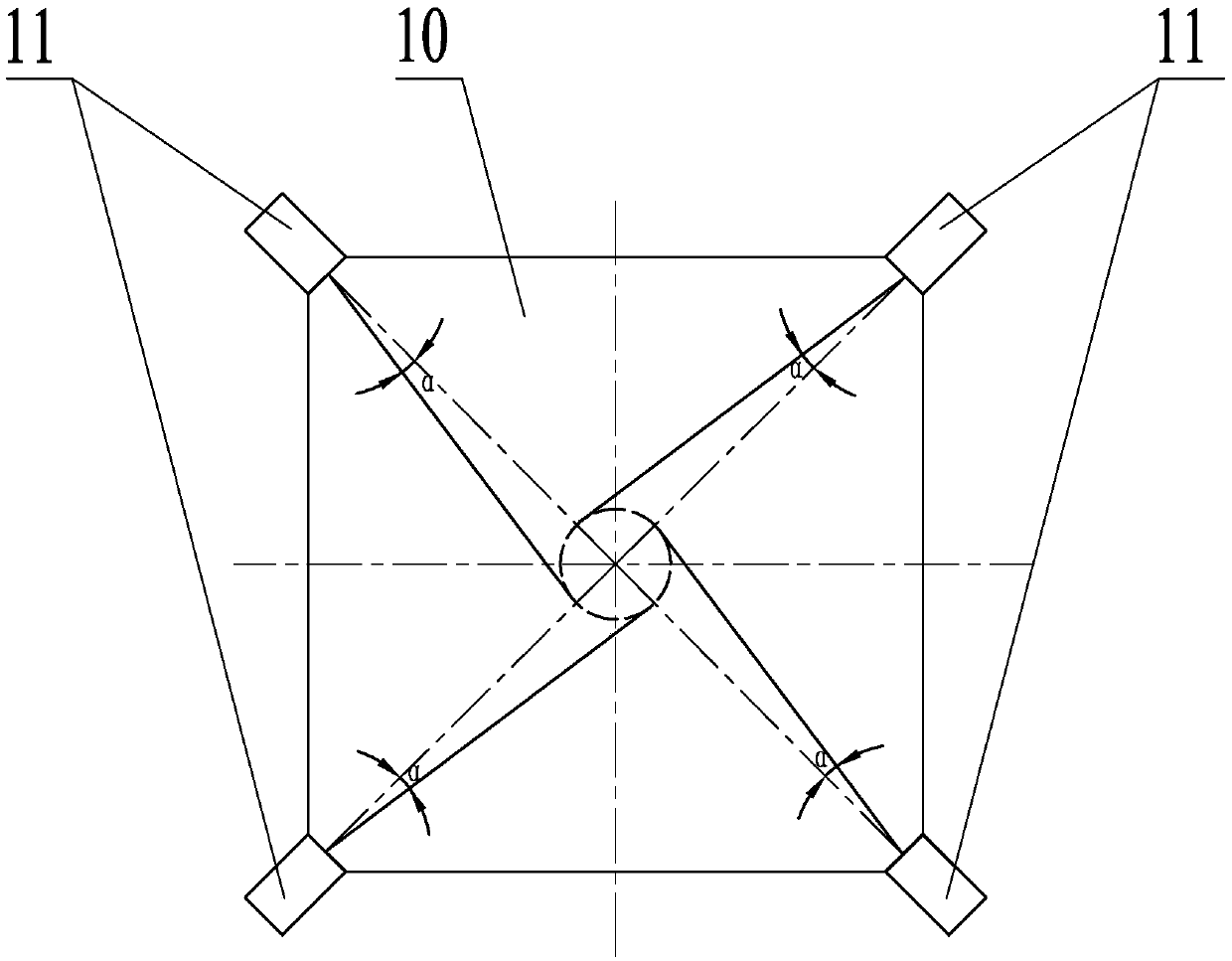

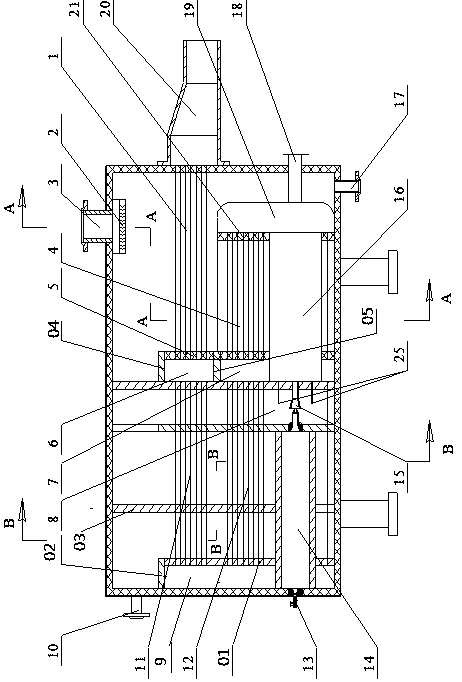

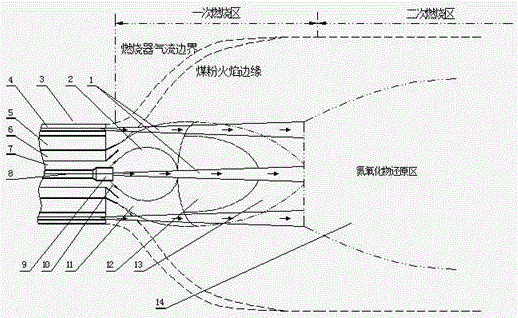

Industrial pulverized coal boiler burning device used for spraying ammonia in center of burner

ActiveCN107477573AEmission reductionImprove reducibilityPulverulent fuel combustion burnersCombustion apparatusCombustorEngineering

The invention provides an industrial pulverized coal boiler burning device used for spraying ammonia in the center of a burner, and relates to the technical field of industrial pulverized coal boilers. The problems that according to an existing horizontal industrial pulverized coal boiler, the NOx emission amount is high, the NOx emission reduction cost is high, the burnout condition of pulverized coal is poor, the adjusting capacity for load change is poor, the boiler thermal efficiency is low, and slagging is severe are solved. The burning device comprises a primary air pipe, a direct flow secondary air pipe, a rotational flow inner secondary air pipe, a rotational flow outer secondary air pipe, a mixer, an amino reducing agent conveying pipe, a concentrated pulverized coal conveying pipe, a hearth and a two-stage over-fire air system. The primary air pipe, the direct flow secondary air pipe, the rotational flow inner secondary air pipe and the rotational flow outer secondary air pipe are sequentially arranged from inside to outside. The amino reducing agent conveying pipe and the concentrated pulverized coal conveying pipe are connected with the inlet end of the mixer. The outlet end of the mixer is connected with the inlet end of the primary air pipe. The two-stage over-fire air system is arranged on the wall of the hearth. The burning device is used for an industrial pulverized coal boiler.

Owner:HARBIN INST OF TECH

Spiral-flow type fishtail high-efficiency energy-saving burner

ActiveCN103629705AHeating up fastHeat up fastDomestic stoves or rangesStoves/ranges topsAir preheaterEngineering

The invention discloses a spiral-flow type fishtail high-efficiency energy-saving burner. The spiral-flow type fishtail high-efficiency energy-saving burner comprises a burner and a hearth. The burner comprises a spiral-flow type air register, a cylindrical channel, a return pipe, combustion gas holes and an air preheater. The hearth comprises a furnace ring and an expansion cover. The expansion cover is a hollow interlayer and comprises an inner expansion cover, a middle expansion cover and a flue gas chamber between the inner expansion cover and the middle expansion cover. An upper opening of the inner expansion cover and a lower opening of the furnace ring form an annular flue gas shunting opening and the annular flue gas shunting opening is communicated with the flue gas chamber, flue gas holes, the air preheater and a gas outlet hole. The outer wall of the middle expansion cover is provided with a hot water sleeve. The hot water sleeve is provided with a water inlet and a water outlet. A temperature-resistant heat-collection corrosion-resistant sleeve is arranged in the inner expansion cover and the lower periphery of the temperature-resistant heat-collection corrosion-resistant sleeve is provided with a flue gas backflow hole communicated with the flue gas chamber. When the spiral-flow type fishtail high-efficiency energy-saving burner burns, the flame in a fishtail shape radially burns closely to the surface of the inner expansion cover, a pan clings to the furnace ring and is closely heated and high-temperature flue gas goes through the flue gas chamber from the annular flue gas shunting opening and then enters into the air preheater to heat air so that the hearth has a high temperature, foods can be heated fast and work efficiency is high. The spiral-flow type fishtail high-efficiency energy-saving burner is environmentally friendly, saves energy, can supply hot water and can effectively improve a kitchen environment.

Owner:湖北满天星节能环保科技有限公司

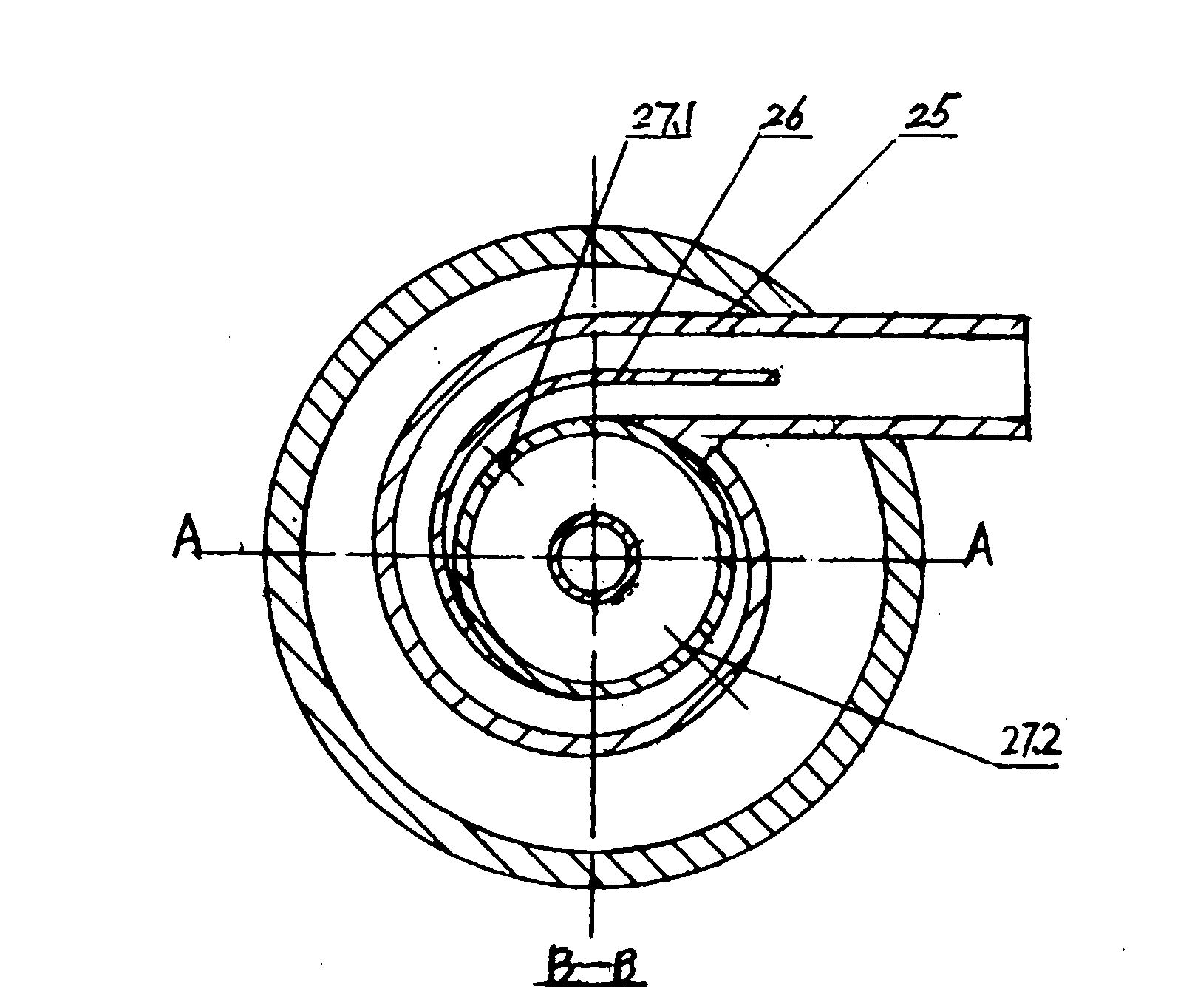

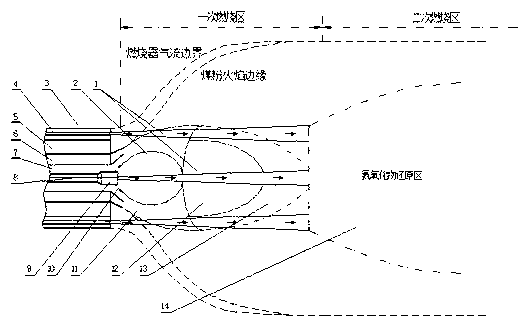

Multichannel rotational flow flame stabilization stepless regulation multifuel combustion combustor

The utility model relates to a multi-channel swirling flow stabilizing flame stepless adjustable mixed combustion burner, which relates to a burner, in particular to a mixed combustion burner using pulverized coal and gas as fuel or a single combustion burner of pulverized coal and gas. It is equipped with a conical ring flame stabilizer in the center of the burner shell, the small head of the flame stabilizer is connected to the central air pipe and the gas pipe, and the outer wall of the gas pipe is connected to a gas mixer. A volute swirler and an adjustment pull rod are arranged on the outer wall of the gas ring joint and the gas pipe at the other end. The outer layer of the gas pipe is equipped with a fire channel, a primary air channel, a secondary air channel and a clean air channel. The secondary air duct and the clean air duct are equipped with swirlers and conical air nozzles respectively. The outer wall of the outlet of the clean air inner pipe and the secondary air inner pipe is made with a cone angle of 15-20° that expands outwards, and the cross-sectional area of the outlet can be changed arbitrarily in the axial direction, and the airflow velocity can be changed. The flame stabilizer can move axially to change the outlet angle of the central air. In this way, the heat load flame shape can be adjusted steplessly, and the combustion temperature can be organically combined with the process conditions. The invention is a pulverized coal and gas burning device with high efficiency, energy saving and low emission of NOx.

Owner:湖北满天星节能环保科技有限公司

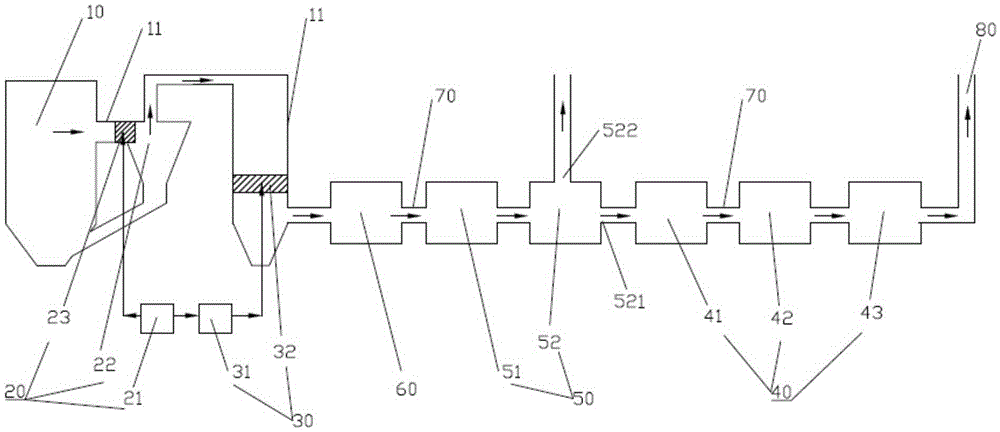

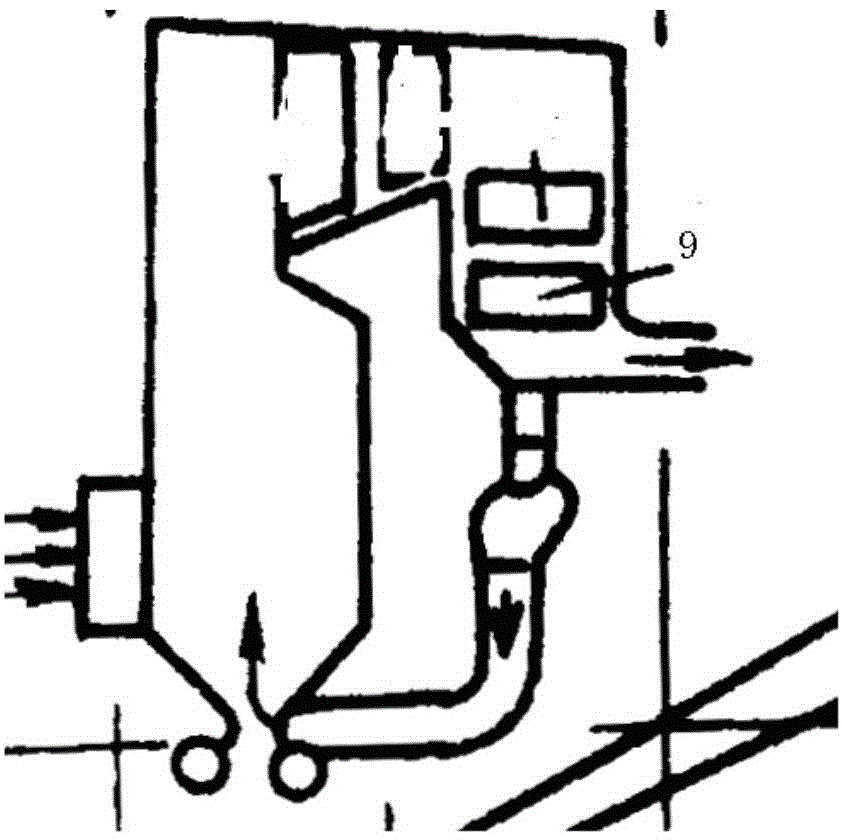

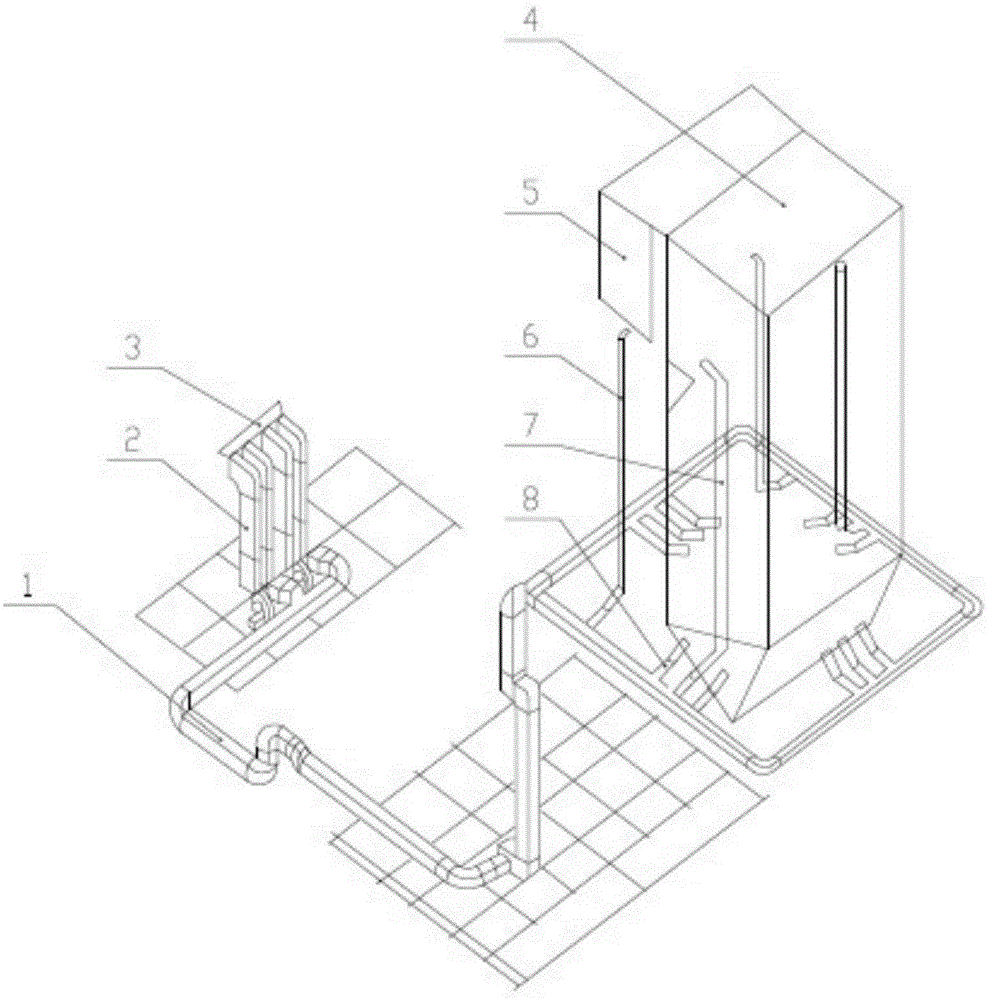

Boiler system for cold flue gas recirculation and cold flue gas recirculation method

The invention provides a boiler system for cold flue gas recirculation and a cold flue gas recirculation method. The boiler system for cold flue gas recirculation comprises collection pipes communicated with a de-duster outlet and used for collecting cold flue gas, a concentration pipe connected with the collection pipes and a guide pipe connected with the concentration pipe and used for conveying cold flue gas into a boiler body. The boiler system for cold flue gas recirculation and the cold flue gas recirculation method have following beneficial effects: by adopting cold flue gas behind the de-duster as circulation flue gas, flue gas can be directly and conveyed to the boiler body after pressure rise in an induced draft fan due to low flue gas temperature and low smoke concentration behind the de-duster; by adjusting the boiler and then increasing steam temperature, coking is prevented; temperature of a heating surface pipe wall is decreased; and content of NOx is reduced.

Owner:上海汉鼎环保技术工程有限公司

Horizontal boiler with SNCR and OFA arranged in staggered manner

ActiveCN107606602AEmission reductionComplete restorationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorPoor adaptive skills

The invention provides a horizontal boiler with SNCR and OFA arranged in a staggered manner and relates to an industrial boiler. The horizontal boiler with the SNCR and the OFA arranged in the staggered manner aims at solving the problems that a horizontal industrial coal powder boiler in the prior art is high in denitration cost, consequently, the NOx emission amount of an industrial coal powderboiler is high, the coal powder over-fire effect is poor, the adaptive capacity on load changes is poor, and the heat efficiency is low. The horizontal boiler with the SNCR and the OFA arranged in thestaggered manner comprises a combustor, a hearth, an upstream flue, a set of primary amino reducing agent spraying ports, a set of primary over-fire air spraying ports, a set of secondary over-fire air spraying ports, a set of secondary amino reducing agent spraying ports and two sets of temperature sensors; the combustor is installed at the front end of the hearth; the upstream flue is communicated with the top of the rear end of the hearth; the primary amino reducing agent spraying port and the primary over-fire air spraying port are fixedly installed on the side wall, from the front end tothe back end, of the hearth; and the secondary over-fire air spraying port and the secondary amino reducing agent spraying port are sequentially installed on the side wall of the upstream flue from bottom to top. The invention is used in the industrial boiler coal powder combustion field.

Owner:HARBIN INST OF TECH

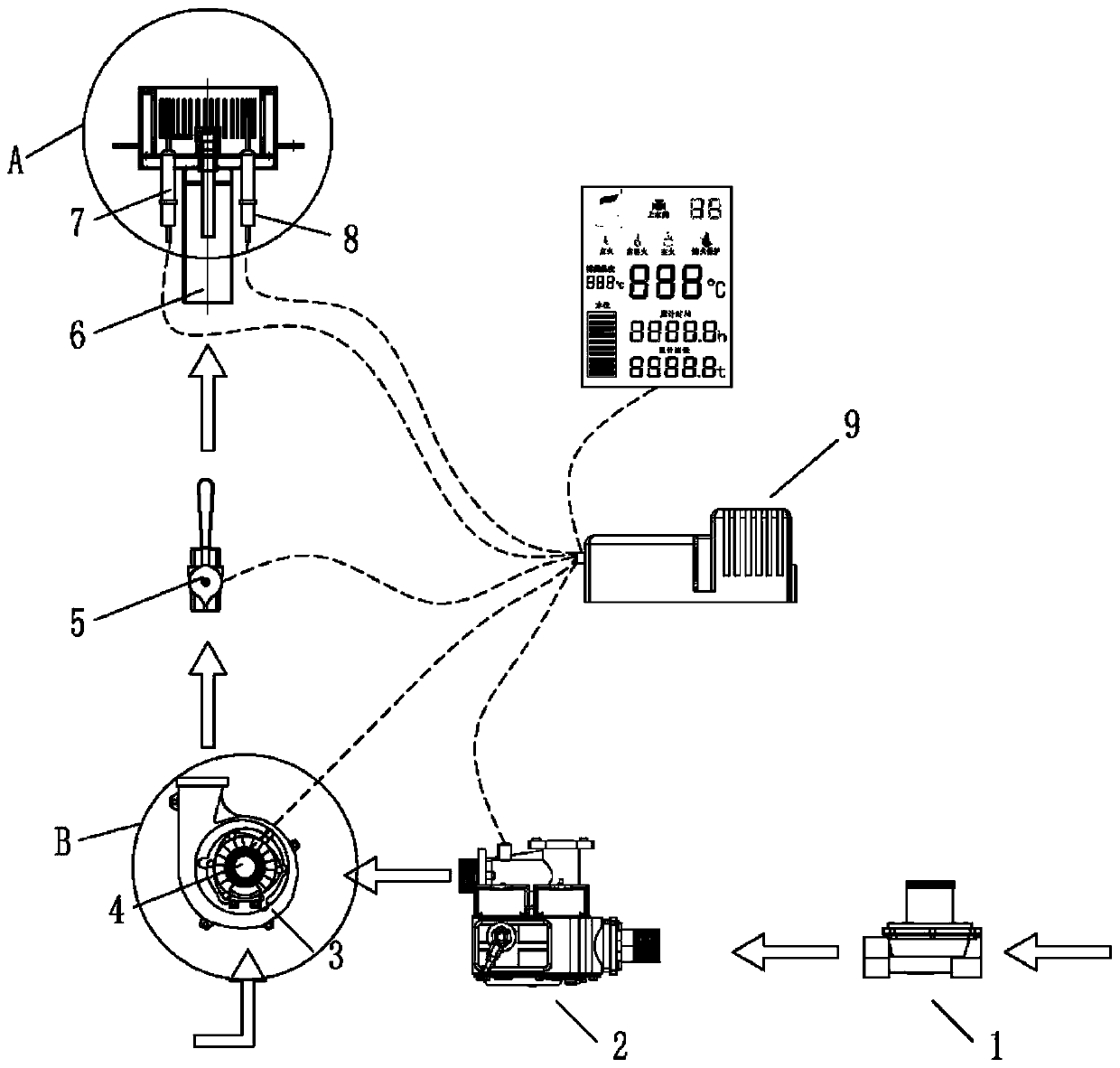

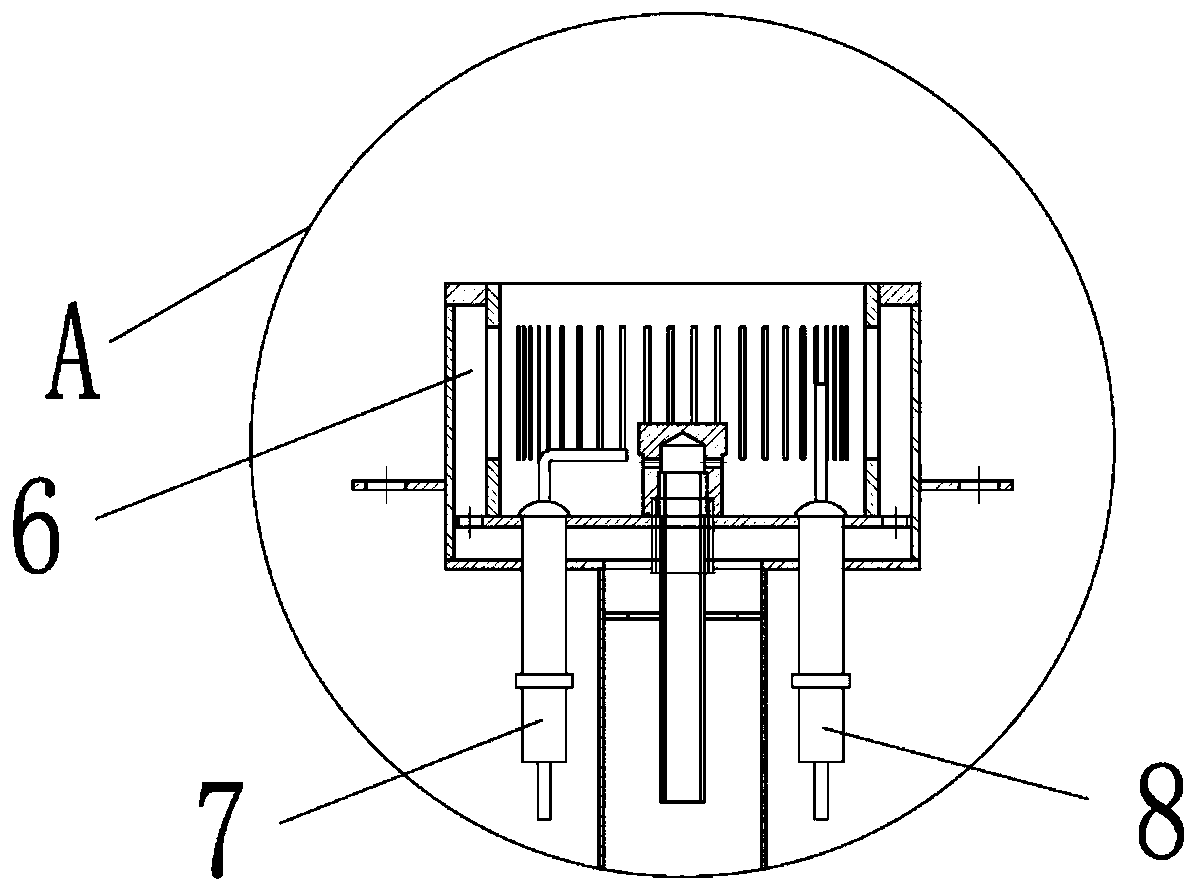

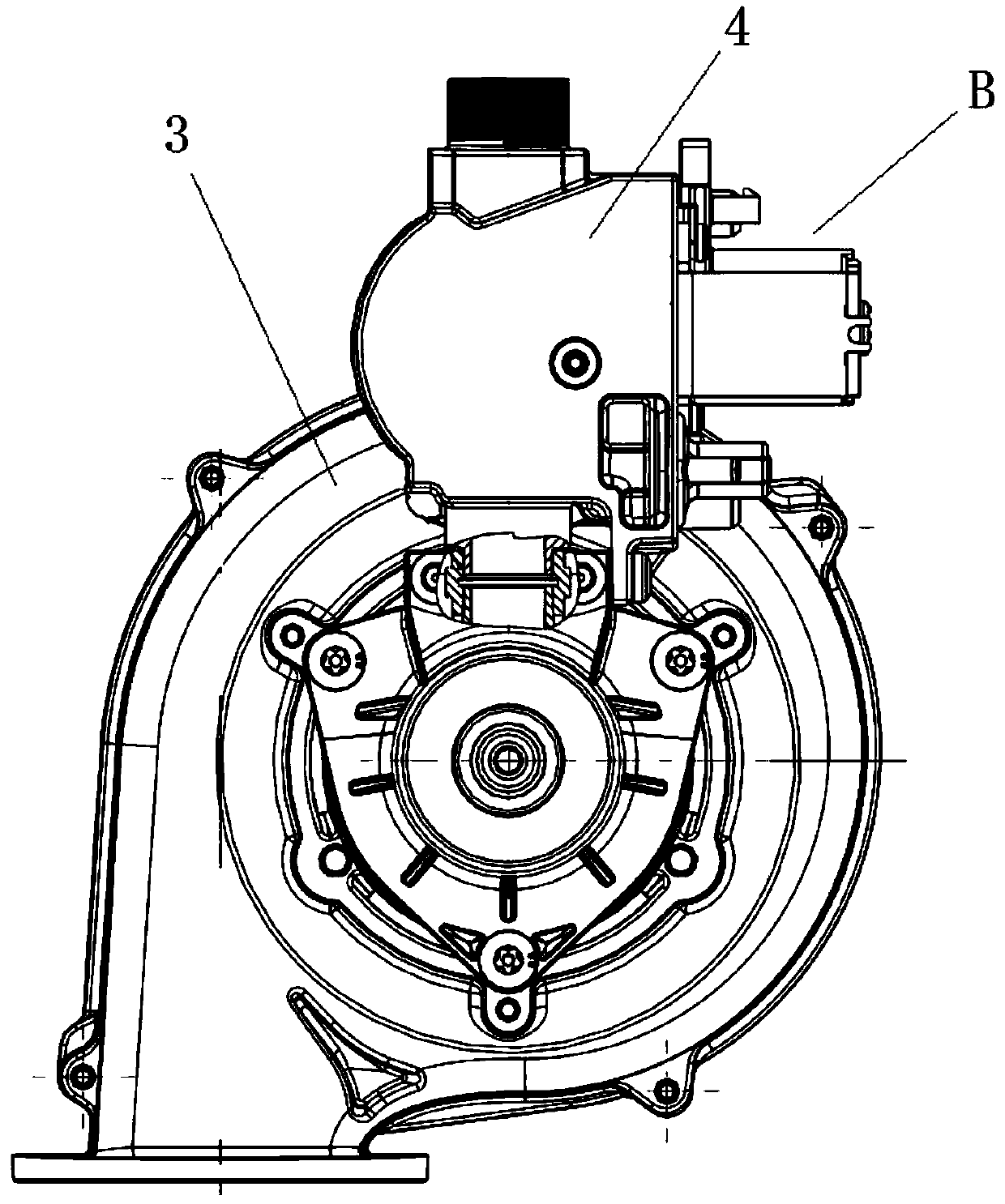

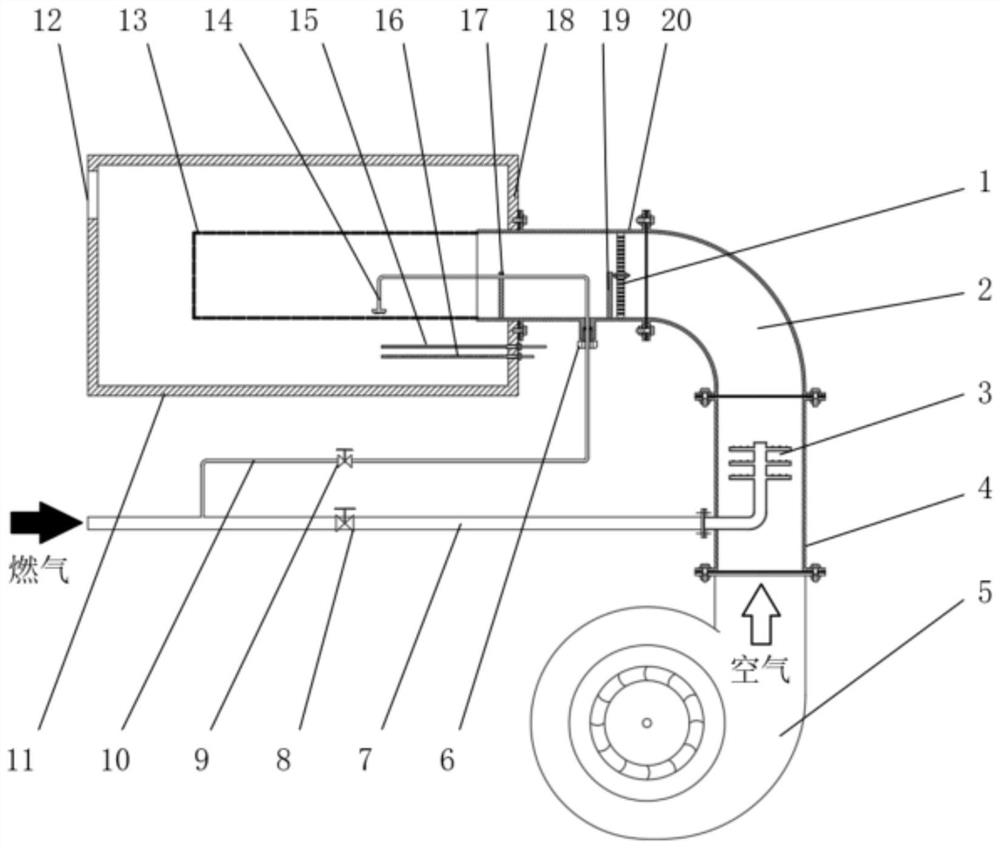

Front pre-mixing combustor used for commercial fuel gas stove

The invention discloses a front pre-mixing combustor used for a commercial fuel gas stove. The front pre-mixing combustor comprises a stove head, an ignition needle, an ion needle, a fuel gas valve, aPWM fan, a Venturi pre-mixer, a zero-pressure header tube fuel gas solenoid valve, a pressure stabilizing vale, a commercial fuel gas stove front pre-mixing controller. The front pre-mixing combustoradopts a front pre-mixing type technology for completely mixing fuels with air before the fuels and the air enter a spray nozzle of a stove head combustion chamber, so that gas molecules are sufficiently stirred and mixed, and therefore, mixing is more complete, combustion speed is not limited by physical conditions such as gas diffusion velocity, combustion speed is higher, efficiency is higher,and emission of harmful CO in smoke gas is reduced. And meanwhile, an automatic pre-mixing technology is applied, so that mixing is guaranteed to be relatively precise. The front pre-mixing combustorguarantees working safety, and is free of phenomena such as flame-lifting, flame-floating and tempering.

Owner:合肥中科顺昌余热利用科技有限公司

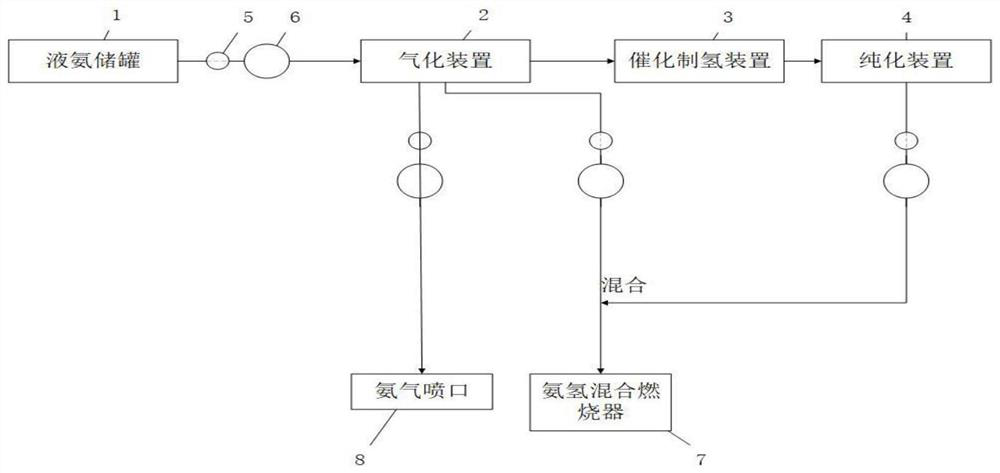

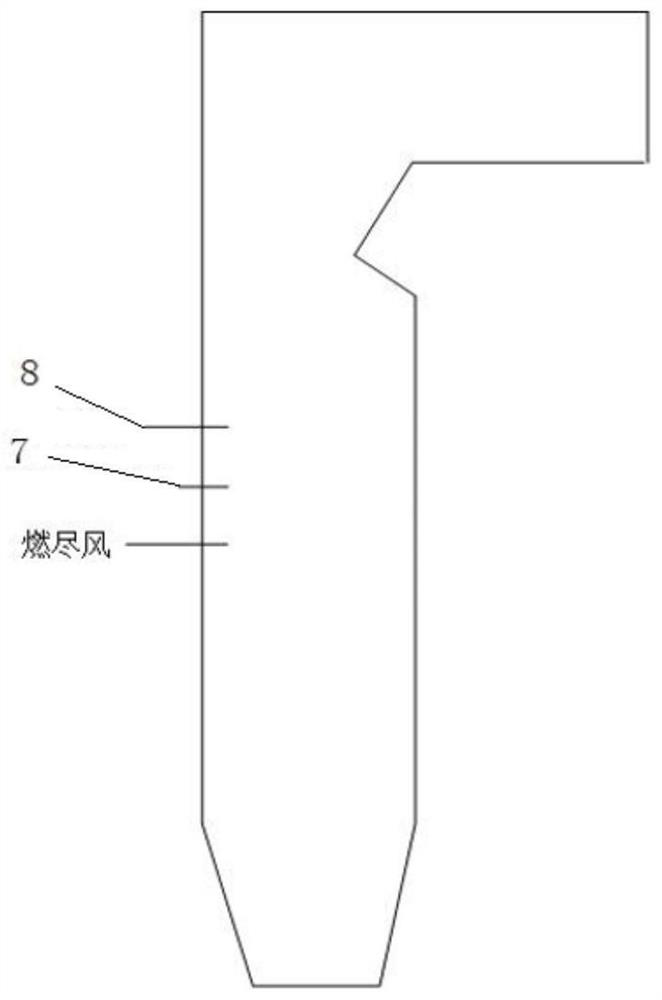

System for reducing carbon emission by blending combustion of ammonia gas and control method

PendingCN113405116AImprove combustion characteristicsEmission reductionGaseous fuel feeder/distributionDirect carbon-dioxide mitigationThermodynamicsCombustor

The invention discloses a system for reducing carbon emission by blending combustion of ammonia gas and a control method. The system comprises an ammonia gas source, a gasification device, a hydrogen preparation device and a hearth; an ammonia gas nozzle and an ammonia-hydrogen mixed burner are arranged above the over fire air of the hearth; and the ammonia gas source is connected with the input end of the gasification device, the output end of the gasification device is divided into three paths of output, the first path of output is connected with the input end of the hydrogen preparation device, the second path of output is connected with the output end of the hydrogen preparation device and the ammonia-hydrogen mixed burner, and the third path of output is connected with the ammonia gas nozzle on the hearth. The combustion characteristic of ammonia gas is improved by doping hydrogen, the hydrogen is doped in a direct current mode, the investment cost is reduced, the application risk is reduced, emission of CO2 is reduced by doping ammonia gas into an active-service coal-fired unit to replace fire coal with the same heat value and replacing carbon-containing fuel with non-carbon fuel; and meanwhile, active-service thermal power unit resources are fully utilized, so that the survival status of a thermal power generating unit is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

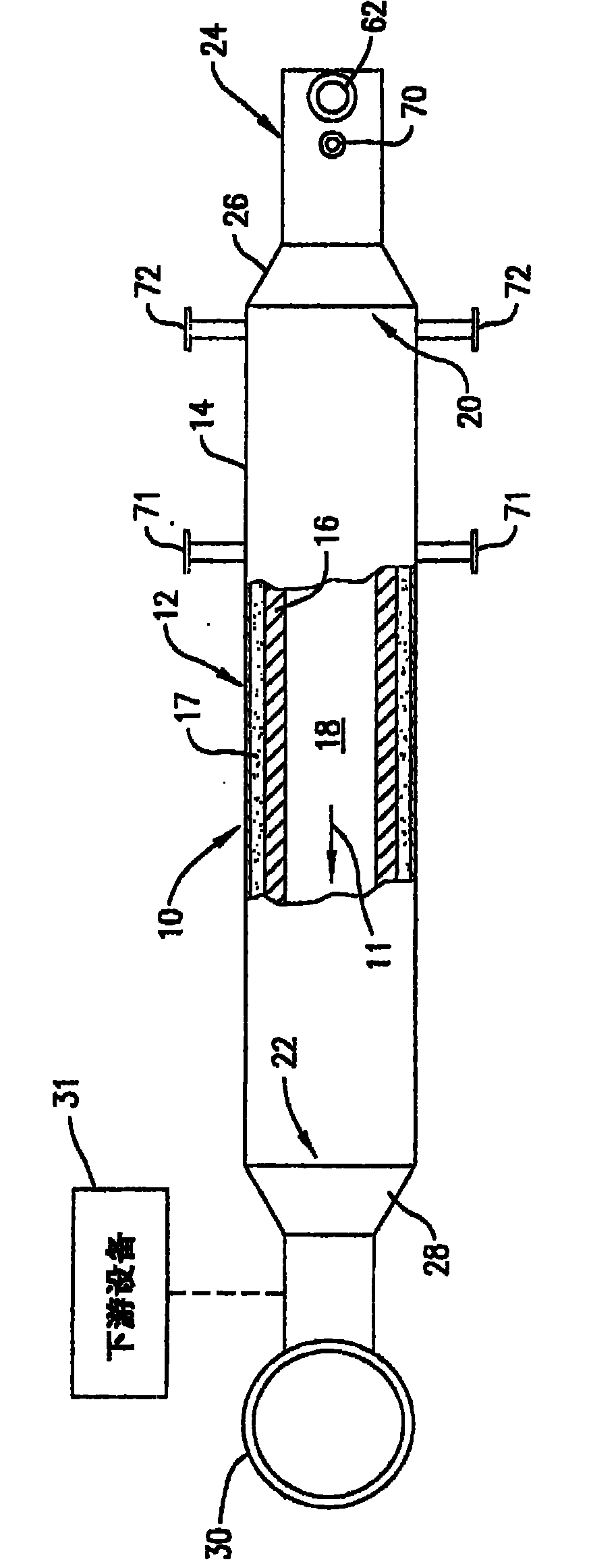

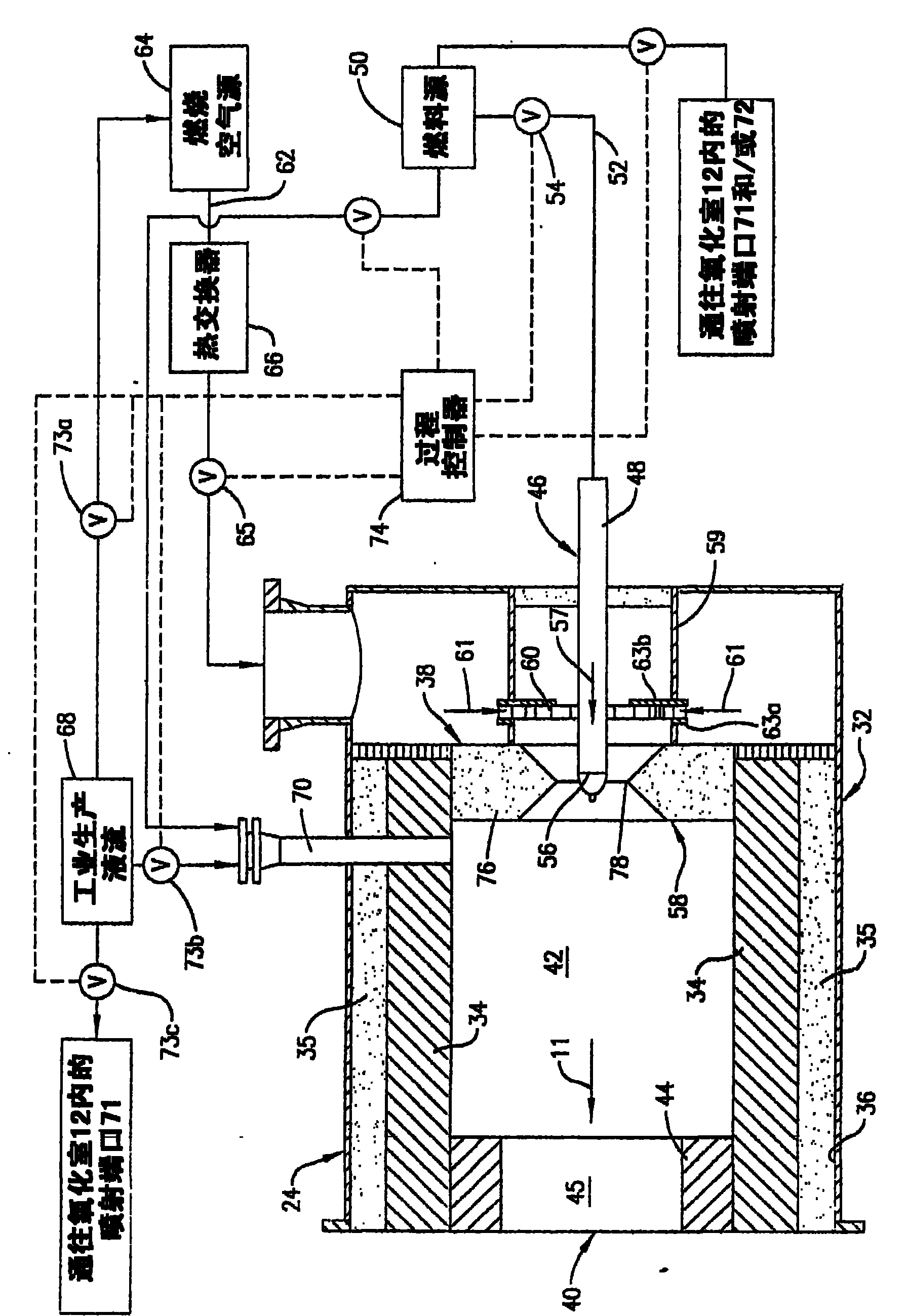

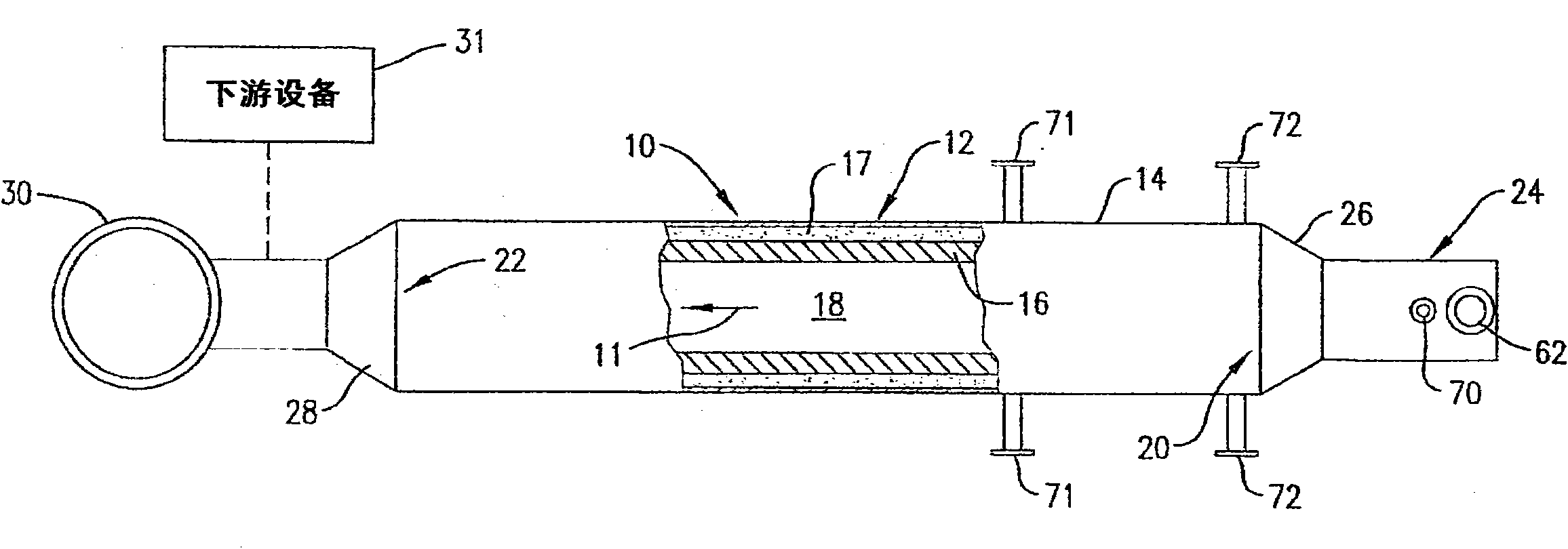

Flameless thermal oxidation apparatus and methods

InactiveCN101874180AAchieving NOx contentReduce NOx contentCapillary burnersIndirect carbon-dioxide mitigationThermal oxidizerChemistry

A thermal oxidizer is provided in which off-gases in a process stream are thermally oxidized within substantially the entire interior volume of an oxidation chamber. The thermal oxidation is conducted without the presence of a flame or with only a minor portion of one or more fuels being combusted in a flame.

Owner:JOHN ZINK CO LLC

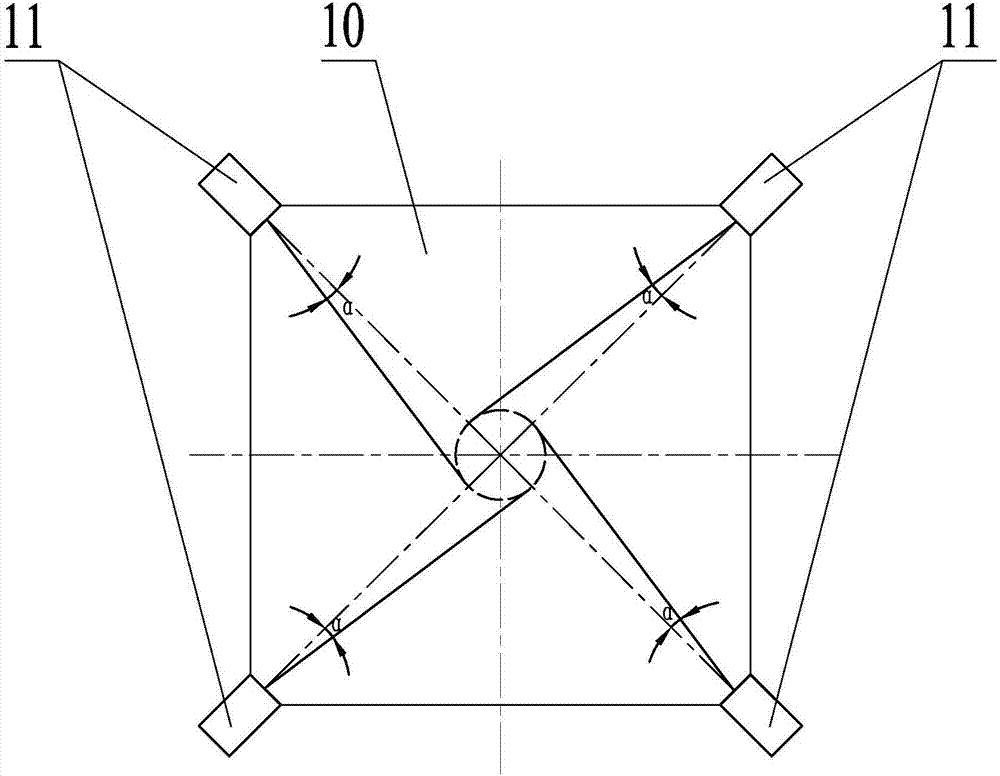

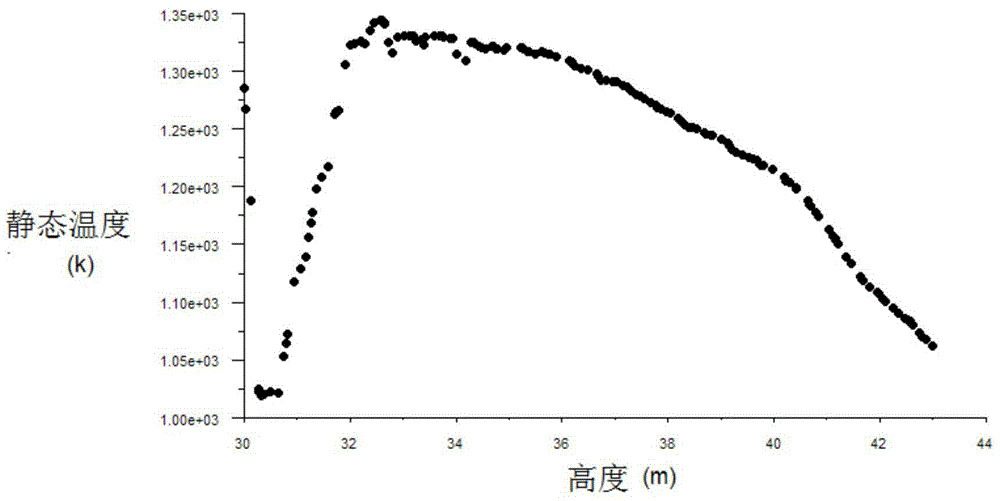

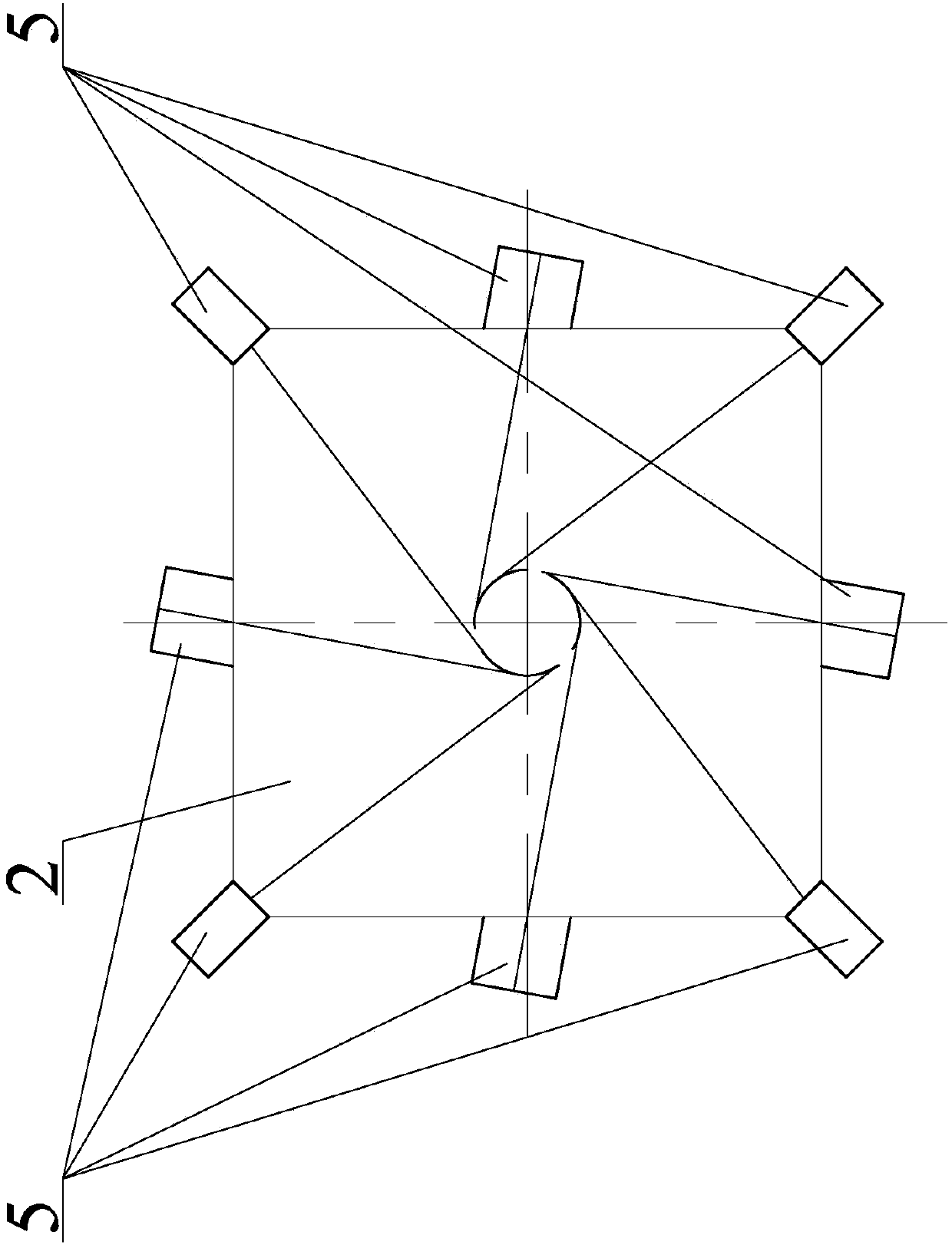

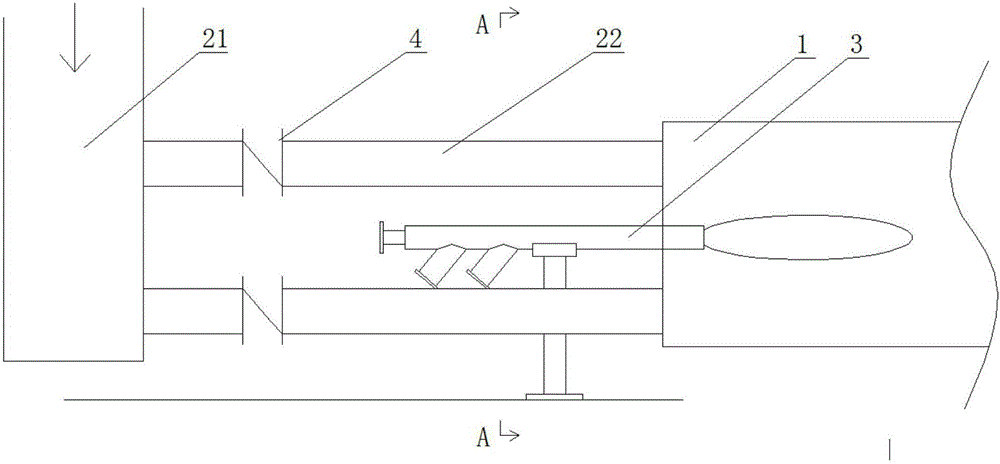

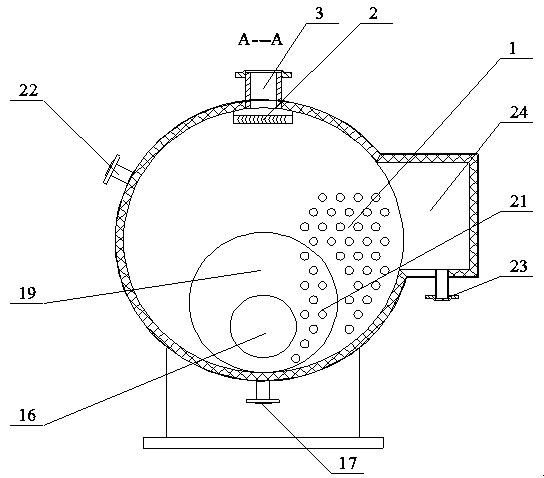

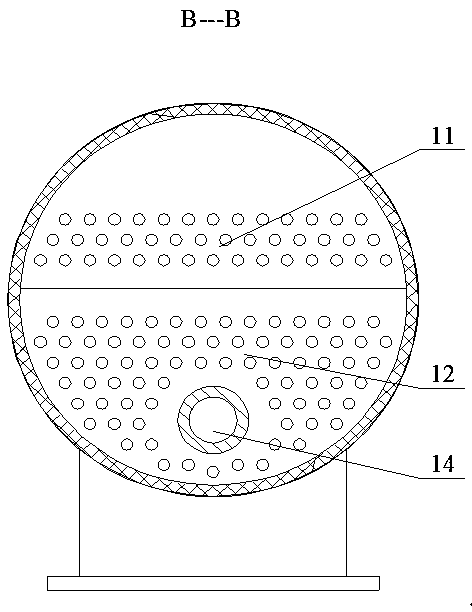

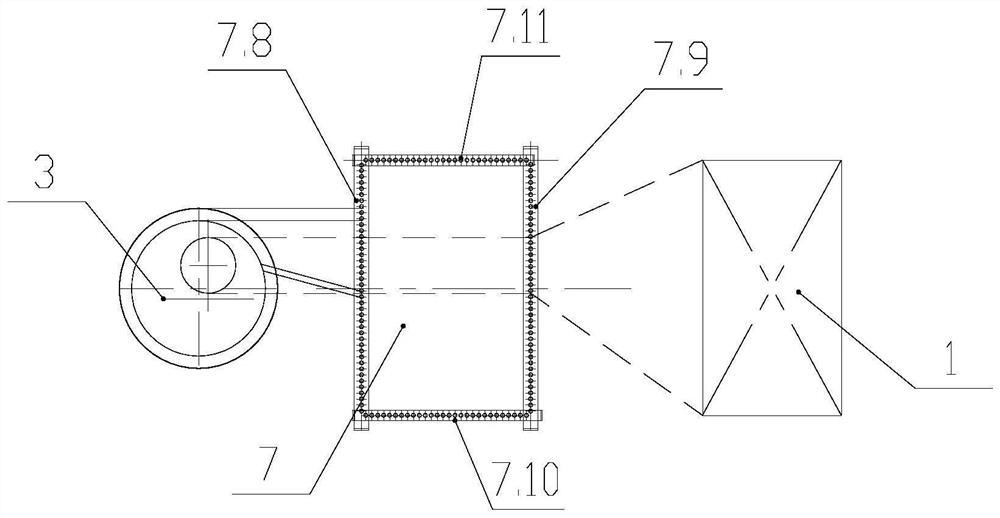

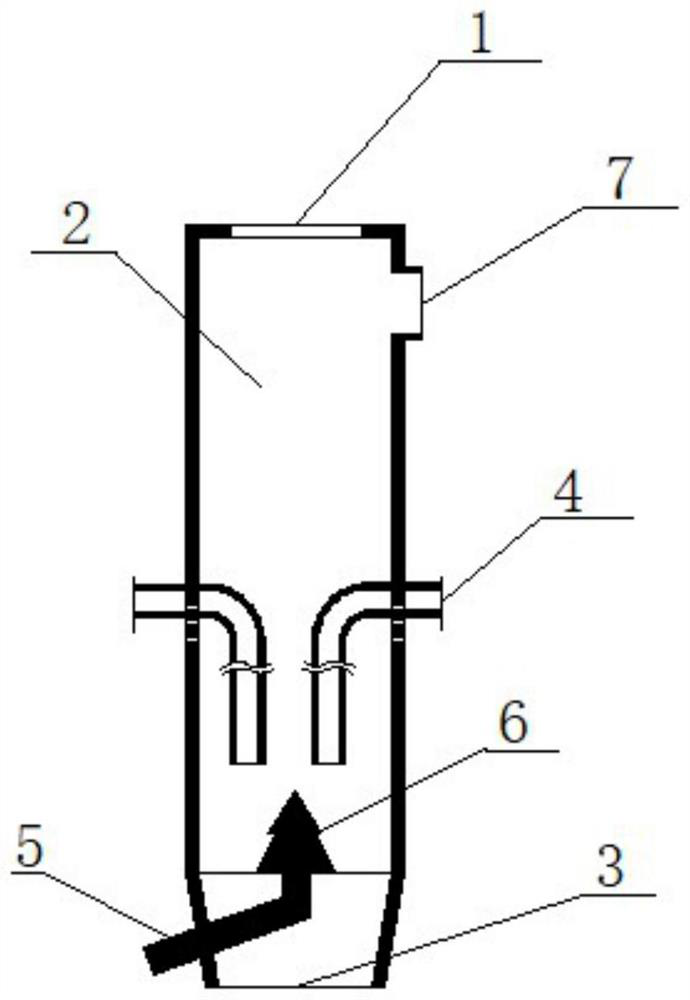

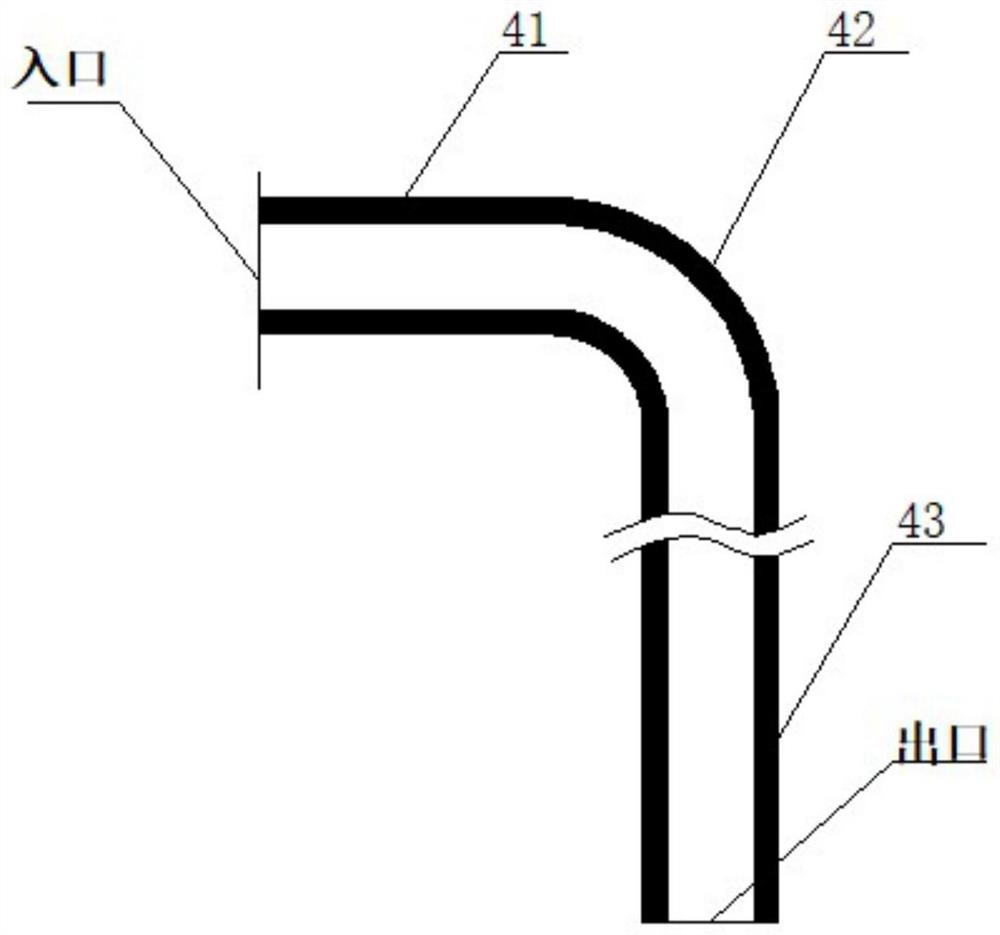

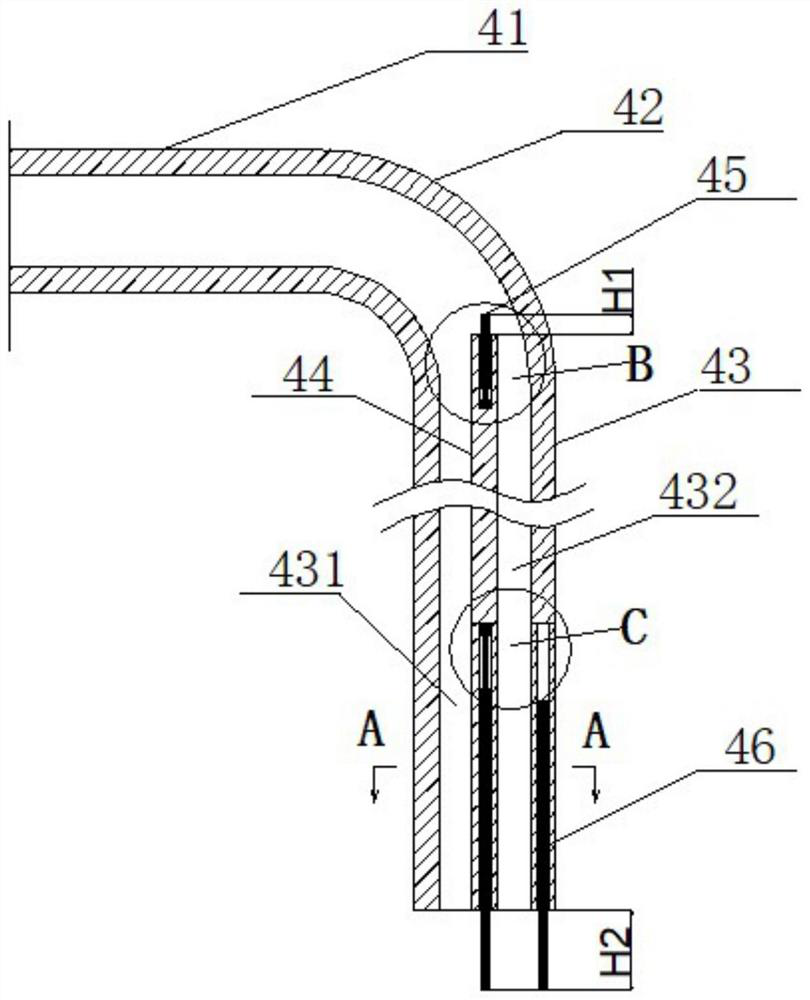

Low-NOx clean combustion type rotary kiln and combustion control method thereof

The invention discloses a low-NOx clean combustion type rotary kiln and a combustion control method thereof. The low-NOx clean combustion type rotary kiln comprises a rotary kiln body (1), a center burner (3) and a secondary air pipe (2). The center burner (3) and the secondary air pipe (2) are arranged on the rotary kiln body (1). The low-NOx clean combustion type rotary kiln is characterized in that the secondary air pipe (2) comprises a secondary air header pipe (21) and a plurality of secondary air branch pipes (22) communicating with the secondary air header pipe (21). The secondary air branch pipes (22) are each provided with a flow valve (4) and are led into the rotary kiln body (1) from different positions of a kiln head box of the rotary kiln body (1) correspondingly in a multiple-point mode. According to the low-NOx clean combustion type rotary kiln and the combustion control method thereof, long-time fixed overlapping of an oxygen-rich area and a high-temperature area can be avoided in the rotary kiln, thus the NOx generation rate is lowered effectively, and clean production of a rotary kiln system is achieved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Heat pipe type steam generator

PendingCN109578966AExtended service lifeAvoid inhalationCombustion technology mitigationSteam boilersCombustorHeight difference

The invention relates to a steam generation device, in particular to a heat pipe type steam generator. The heat pipe type steam generator comprises a boiler, a generator body and a combustor. The combustion end of the combustor stretches into a hearth of the boiler. The boiler is connected with the generator body. A heat pipe is arranged in the generator body. A primary side channel is formed outside the heat pipe. A secondary side channel is formed in the heat pipe. Media in the primary side channel exchange heat with media in the secondary side channel. The boiler is connected with the primary side channel of the generator body so that a primary side cycle loop can be formed, and the primary side cycle loop is vacuum and is closed. The height of the lowest liquid level of the primary side channel is larger than the height of the highest liquid level of the boiler. By utilization of the height difference between the liquid level in the primary side channel and the liquid level of theboiler, it is guaranteed that in the primary side cycle loop, the water solution in the generator body can still return into the boiler under the situation that no water pump supplies power, accordingly, outside oxidized gas is prevented from being sucked into the primary side water cycle loop, and the service life of the boiler is prolonged.

Owner:杭州联赫节能环保科技有限公司

A combustion device for injecting ammonia in the center of the burner for industrial pulverized coal boilers

ActiveCN107477573BEmission reductionImprove reducibilityPulverulent fuel combustion burnersCombustion apparatusCombustorHearth

Owner:HARBIN INST OF TECH

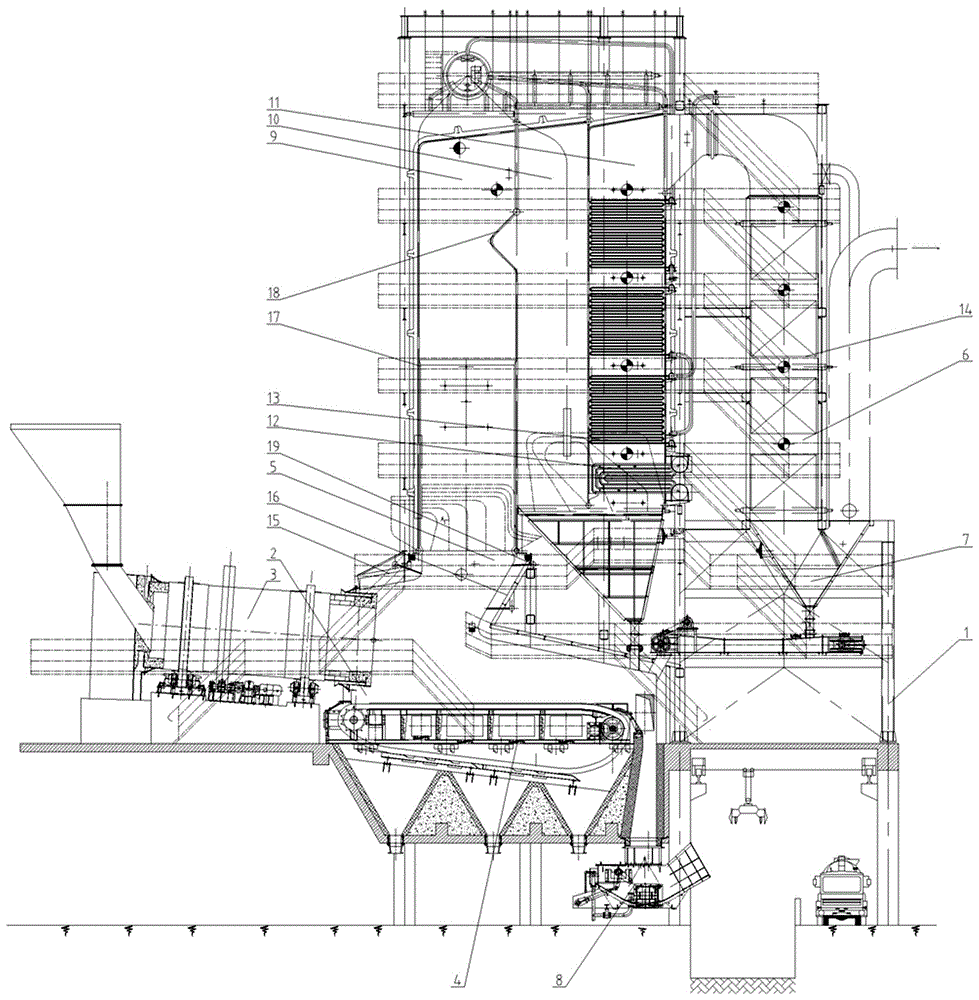

Mixed firing boiler of industrial waste and domestic waste

InactiveCN106705065AAdaptable to changeSolve incomplete combustionIndirect carbon-dioxide mitigationCasings/liningsCombustion chamberFlue gas

The invention discloses a mixed firing boiler of industrial waste and domestic waste. The mixed firing boiler comprises a steel frame, combined combustion equipment, a furnace chamber, a tail flue gas duct, an ash falling device and a deslagging device, wherein the combined combustion equipment comprises a rotary kiln and a grate; the industrial waste and the domestic waste enter from a feeding port of the head of the rotary kiln; the tail of the rotary kiln is connected with an inlet of the furnace chamber; an outlet of the furnace chamber is connected with the tail flue gas duct; the furnace chamber and the tail flue gas duct are mounted on the steel frame; the ash falling device is arranged below the tail flue gas duct; the grate is arranged below the furnace chamber; the deslagging device is mounted below the grate; and the furnace chamber comprises a combustion chamber, a reburning chamber and a triple-pass. According to the structure disclosed by the invention, the industrial waste and the domestic waste can be efficiently treated and the problem of co-firing of various kinds and components of industrial waste and domestic waste can be solved. Besides, the problem of small space of the deslagging chamber is solved, so that continuous and efficient operation of the boiler is guaranteed.

Owner:ZHEJIANG WEIMING ENVIRONMENT PROTECTION

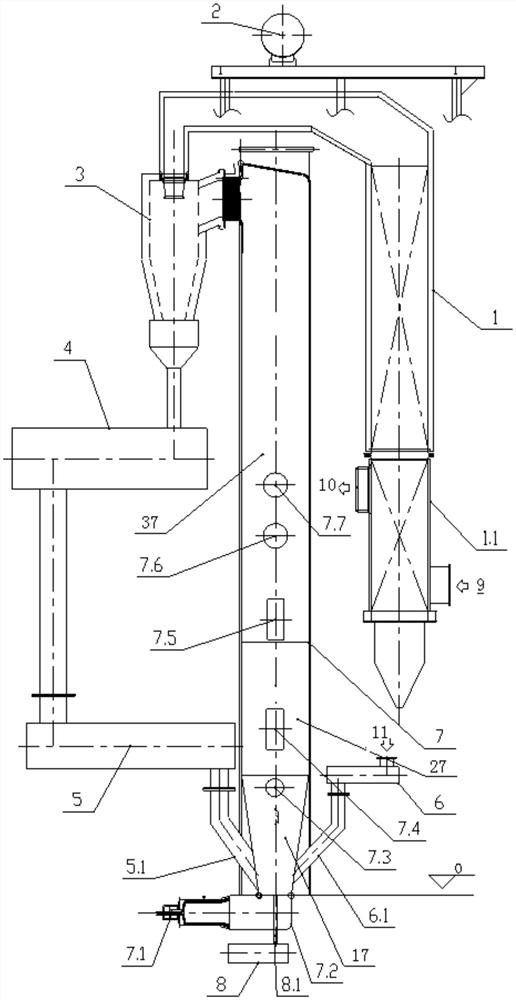

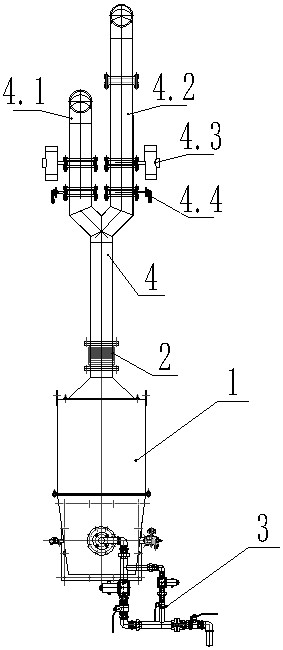

Fume denitration device for aluminum oxide suspension calcinator and use method thereof

PendingCN106621752AReduce air volumeLess heat consumptionGas treatmentDispersed particle separationCycloneChemical solution

The invention discloses a fume denitration device for an aluminum oxide suspension calcinator and a use method of the fume denitration device. The denitration device comprises a calcining main furnace, one side of the calcining main furnace is connected onto a cooling cyclone separator, the other side of the calcining main furnace is connected onto a roasting auxiliary furnace, hot air exhausted from the cooling cyclone separator is divided and enters a first branch pipe and a second branch pipe, the first branch pipe is connected to the bottom of the calcining main furnace, the tail end of the second branch pipe is connected with an air nozzle, the air nozzle is arranged in the middle of the calcining main furnace, the second branch pipe is provided with a louver electric valve, an atomizing nozzle is arranged above the air nozzle and is connected with a compressed air pipe and a liquid adding pipe to allow a chemical solution to be added in the calcining main furnace and react in the calcining main furnace, the rear end of the calcining auxiliary furnace is connected with a preheating cyclone separator, an air outlet pipe of the preheating cyclone separator is connected with a reactor, and the reactor is filled with a catalyst to denitrate the high-temperature flue containing ammonia gas in the reactor. The denitration device is high in denitration efficiency, the content of NOx in the flue exhausted in the atmosphere is greatly reduced, the heat consumed by aluminum oxide is reduced, and the cost is reduced.

Owner:SHENYANG XINBO IND TECH

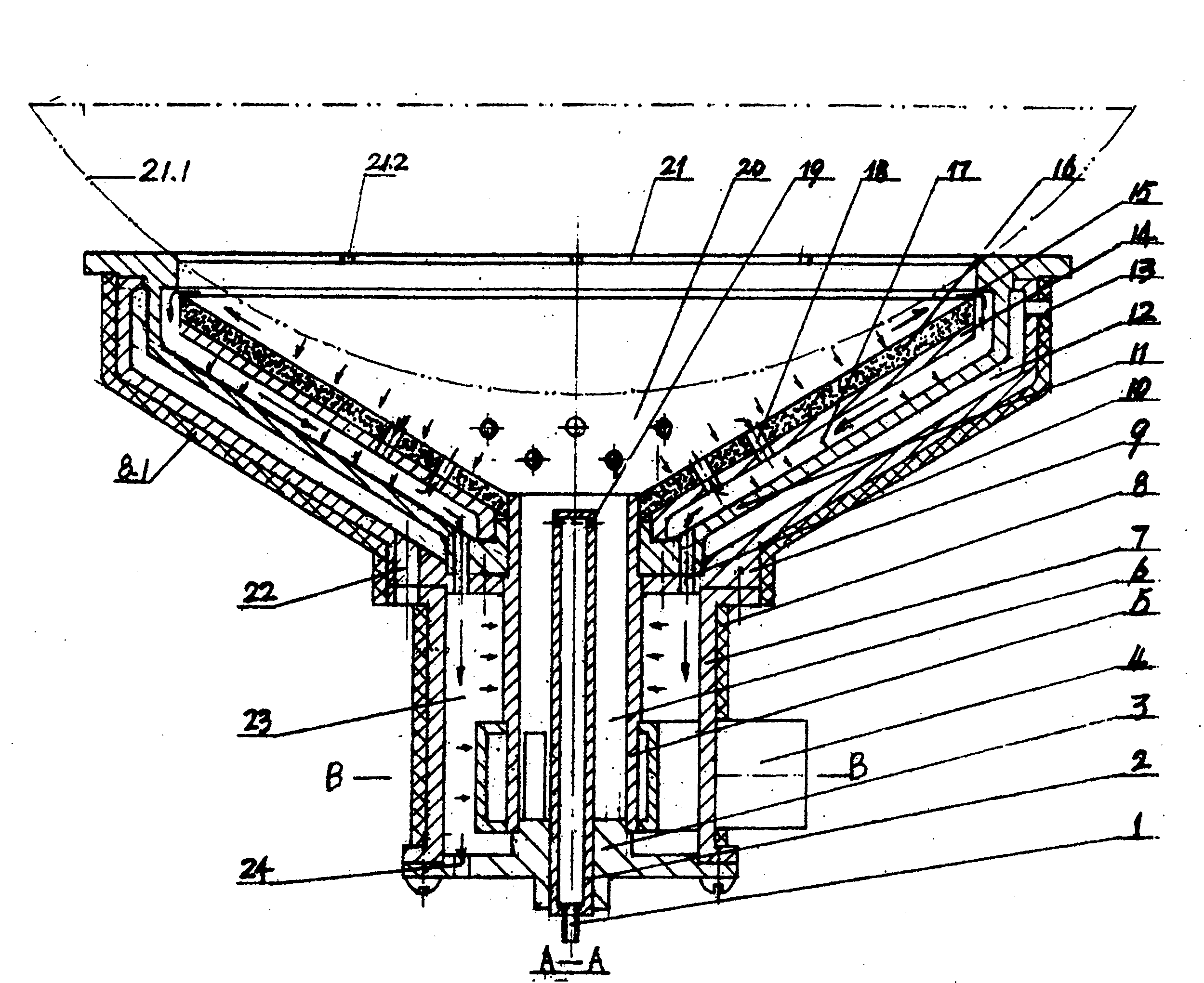

System and a method for generating active lime

ActiveCN113185153AIncrease available spaceOvercoming the "edge wall effect"Combustion chamberCalcination

The invention discloses a system and a method for generating active lime, a V-shaped roasting furnace enables the air flow of the cross section of the furnace to tend to be balanced, overcomes the side wall effect and increases the available space of the furnace. On the premise of ensuring the product quality, the unit volume productivity is improved. According to the invention, raw materials are scattered towards four sides after colliding with the material guide cone to form an umbrella-shaped material curtain, and fine powder in the raw materials is taken away by dust collection airflow in advance, so that the calcining condition is improved. By arranging the main combustion chamber, heat is distributed to the preheater in an inclined mode, the proportion of limestone decomposition outside the kiln can be increased, the heat load of the rotary kiln can be reduced, and the heat efficiency of the whole system can be improved; and if the thermal load of the rotary kiln is kept unchanged, the system yield can be improved, and as the heat dissipation of the rotary kiln body is unchanged, the heat consumption of a unit product can be reduced. In the second stage of lime calcination, downstream calcination is adopted, the temperature in the kiln can be better controlled, overheating is avoided, and the product activity degree is improved.

Owner:HEFEI CEMENT RES DESIGN INST

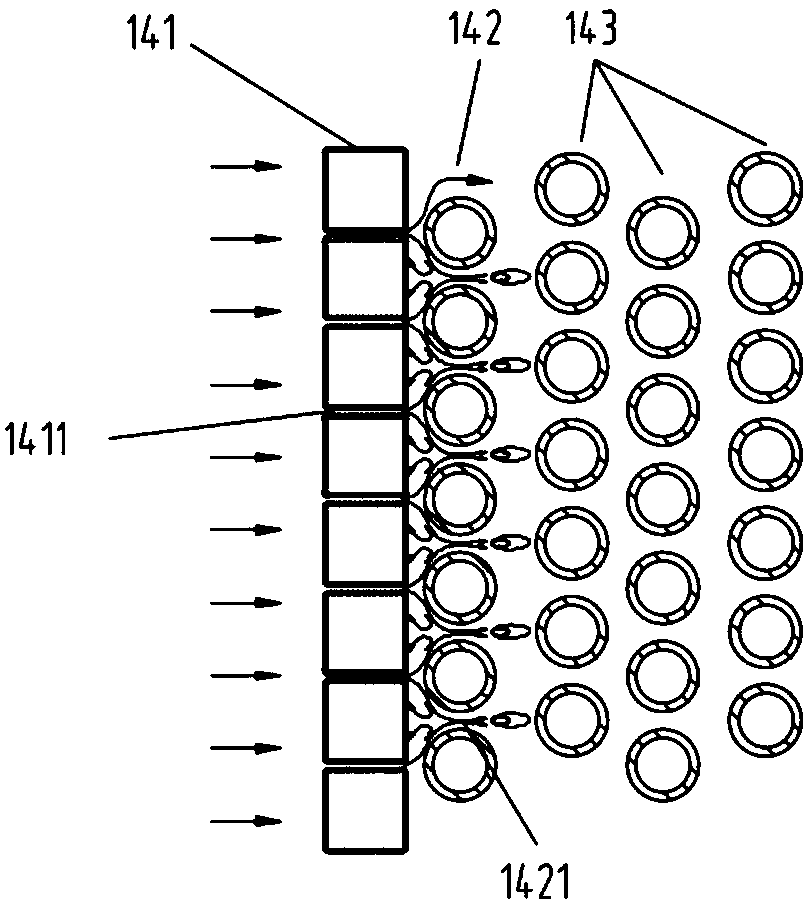

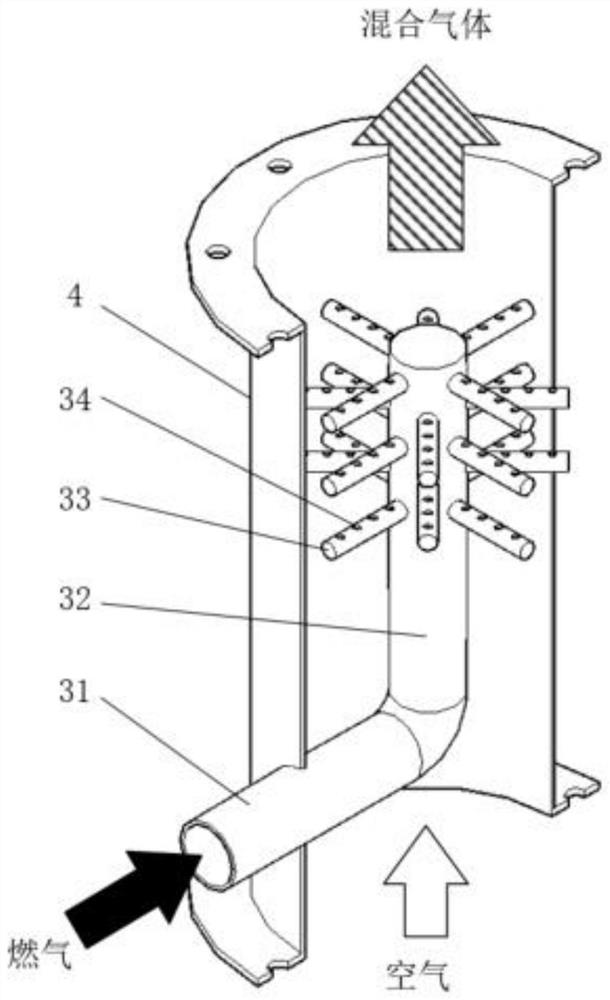

Biomass gas steam generator

ActiveCN110043883AReduce NOx contentSmall temperature changeSteam boilersGaseous fuel burnerCombustion chamberLithium bromide

The invention discloses a biomass gas steam generator. The generator comprises a pre-combustion chamber, a mixing chamber, a lean combustion chamber, a smoke tube, a smoke returning chamber, an axialblade combustor and an ejector; lithium bromide dilute solution or water is introduced through an introduction opening, the lithium bromide dilute solution or water is heated through the lean combustion chamber, a second return smoke pipe, a third return smoke pipe, a lower middle smoke returning chamber, an upper middle smoke returning chamber and a pipe plate to form saturated steam; lithium bromide concentrated solution is introduced into a low-pressure generator from a outlet opening through a liquid bag; the saturated steam is led out from the outlet opening, secondary air is introduced from a secondary air inlet opening, hot air formed by heating is mixed with the weak reducing flue gas at an outlet of the pre-combustion chamber in the mixing chamber through the ejector to form high-temperature high-speed lean air, then the high-temperature high-speed lean air is sprayed into the lean combustion chamber, and is mixed with secondary biomass gas to realize lean combustion. The biomass gas steam generator has the advantages of rich combustion and lean combustion, the energy consumption of a fan is low, the radiant heat flux is high, the temperature field uniformity is good, thecombustion is stable, the Nox generation amount is low, the greenhouse gas emission is low, and the structure is compact.

Owner:ZHONGYUAN ENGINEERING COLLEGE

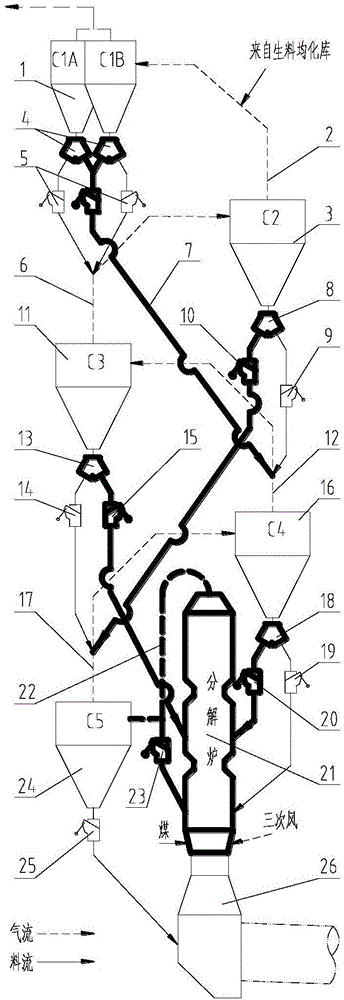

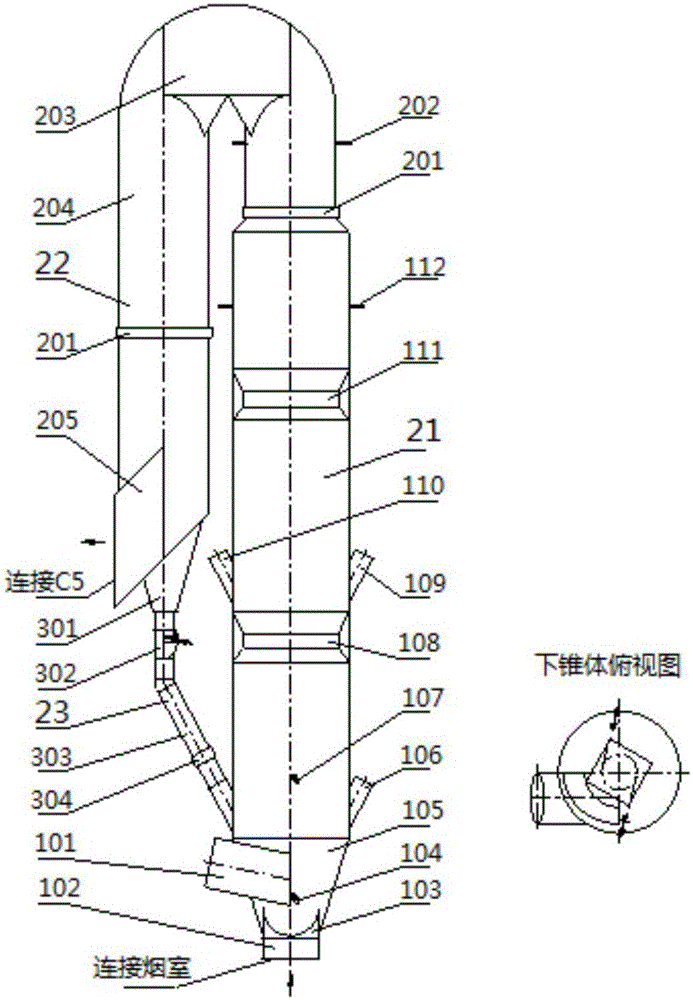

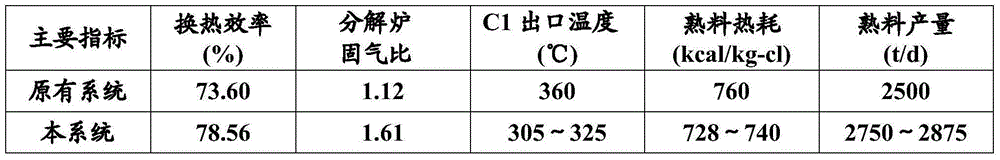

Large-temperature-difference crossed material preheating and precalcining system and method thereof

ActiveCN106152794AReduce the temperatureFully absorbedRotary drum furnacesPreheating chargesGas solidCyclone

The invention relates to a large-temperature-difference crossed material preheating and precalcining system, which comprises a cyclone preheater system, a calciner system and a feed-end chamber. The cyclone preheater system comprises N stages of cyclone cylinders; the other cyclone cylinders except for the N stage of cyclone cylinder comprise material distribution valves; the first stage to the N-2 stage of cyclone cylinders respectively feed parts of materials in blanking holes through the material distribution valves into the cyclone cylinders in the lower stages, and feed the other parts of materials into cyclones cylinders with higher flue-gas temperature compared with the cyclone cylinders in the lower stages or the calciner system, so that the gas-solid temperature differences in the cyclone cylinders and the calciner system are increased. The invention further relates to a large-temperature-difference crossed material preheating and precalcining method. The raw material heat exchange efficiency is improved, the system waste gas temperature is reduced, and the raw material decomposition rate is improved. The large-temperature-difference crossed material preheating and precalcining system and the large-temperature-difference crossed material preheating and precalcining method provided by the invention are applicable to the establishment of a cement preheating and precalcining system and the improvement of an existing cement preheating and precalcining system, and also can be applied to a powder heat exchange system in the industries of metallurgy, chemical engineering and the like.

Owner:甘肃土木工程科学研究院有限公司

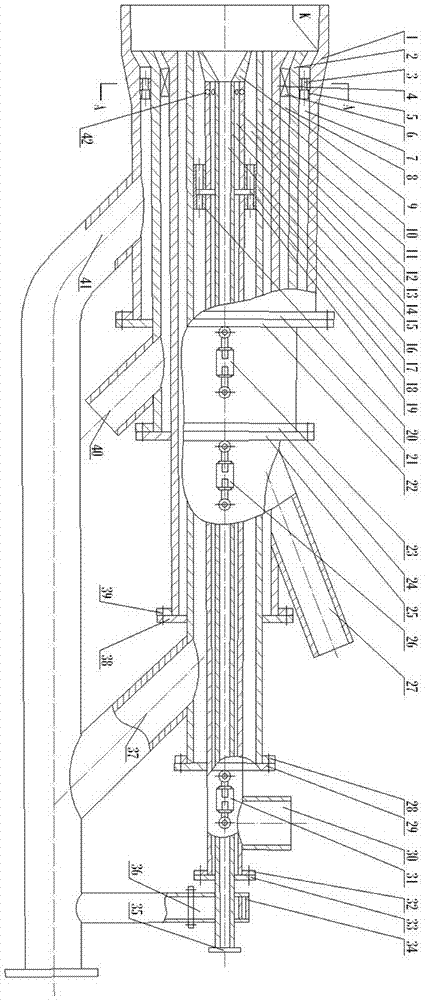

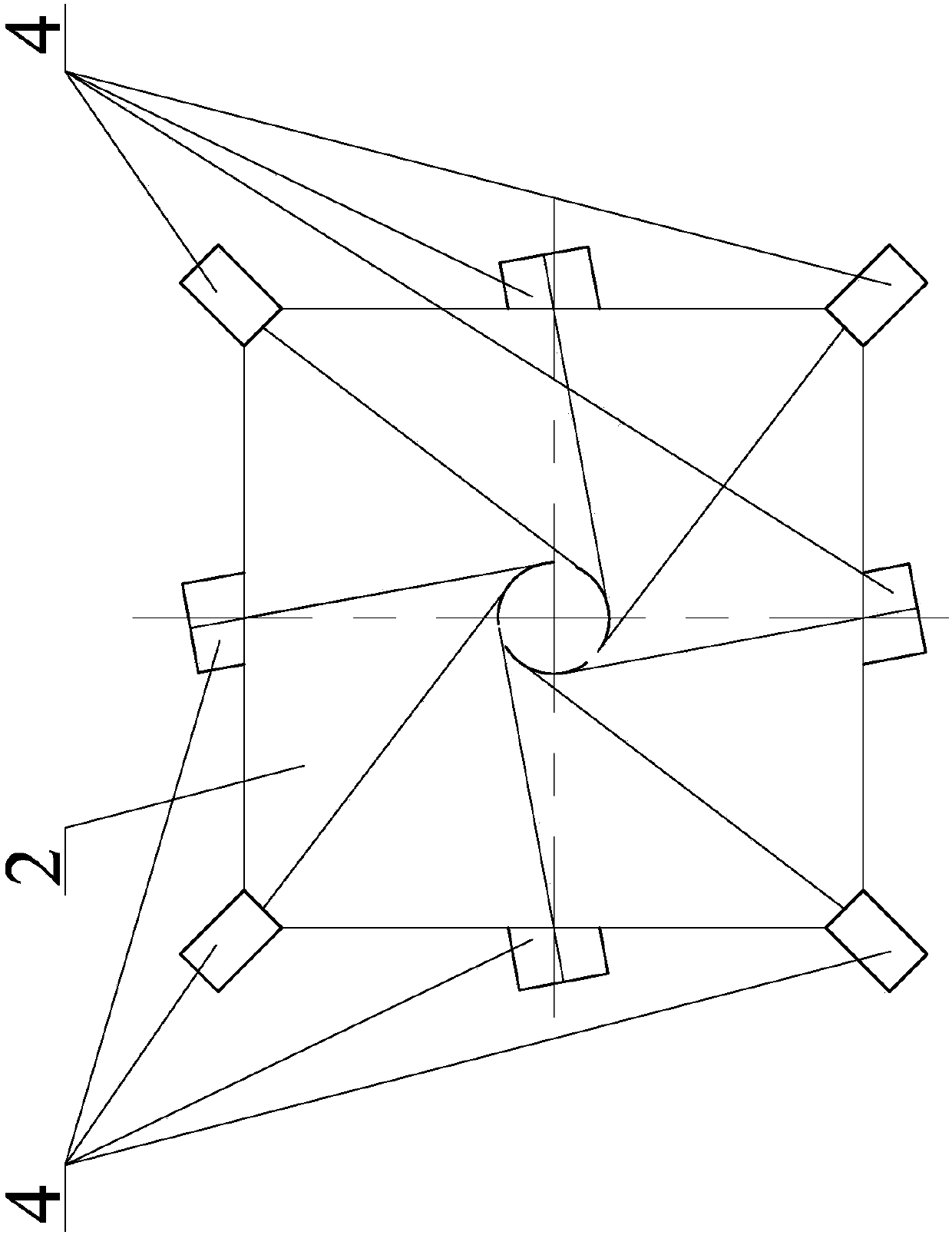

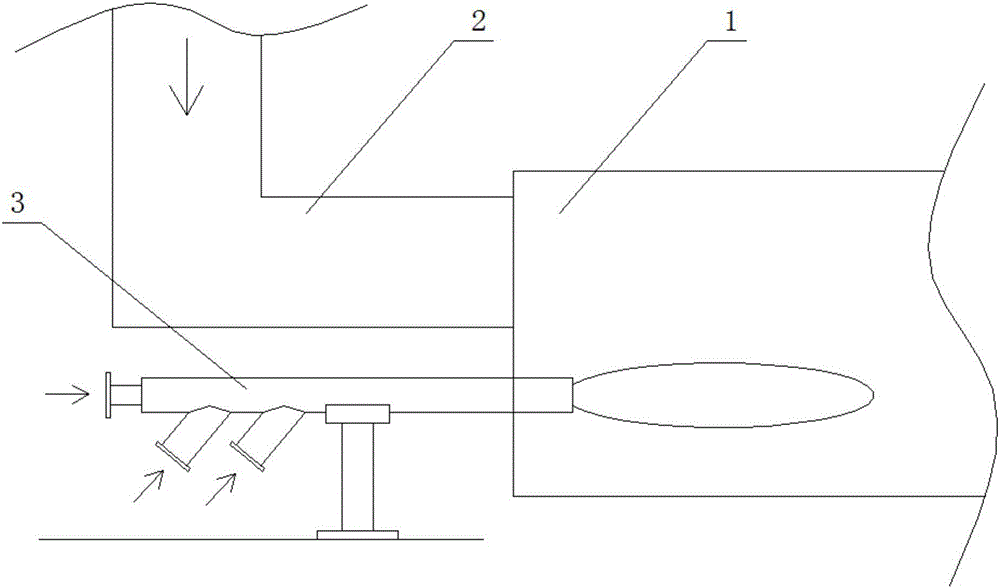

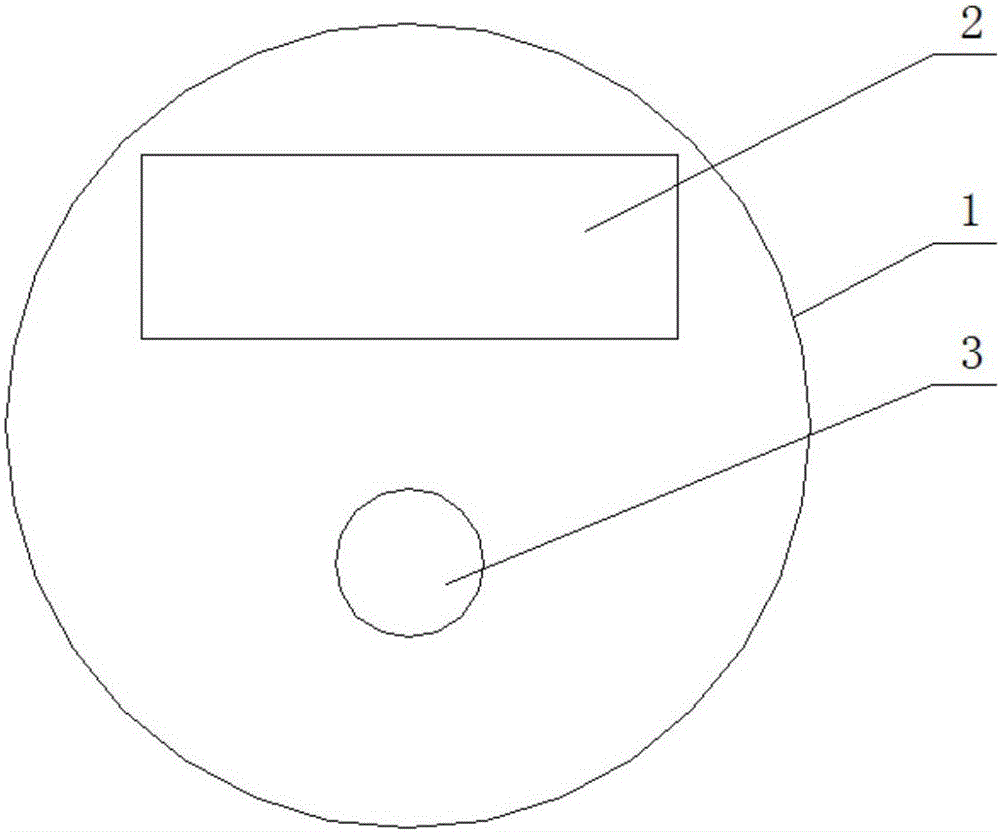

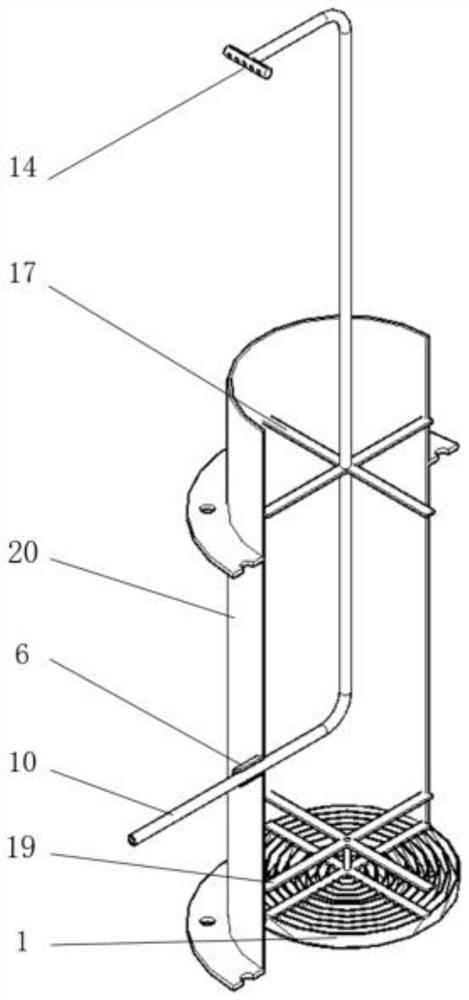

Device and method for expanding types of coal suitable for small and medium-sized industrial pulverized coal boilers

ActiveCN103307595APromote fireImprove combustion conditionsCombustion using gaseous and pulverulent fuelCombustion apparatusPoor adaptive skillsSpray nozzle

The invention discloses a combustion apparatus and a combustion method, and particularly discloses a device and a method for expanding types of coal suitable for small and medium-sized industrial pulverized coal boilers. The device comprises a cyclone burner; a central delivery pipe, a central air duct, a primary air powder duct and a secondary air pipe are arranged at a nozzle of the cyclone burner sequentially from inside to outside, wherein the secondary air pipe comprises an internal secondary air duct and an external secondary air duct, and the internal secondary air duct is arranged at the inner side of the external secondary air duct; an outer ring nozzle is arranged in the external secondary air duct; an outlet end of the central delivery pipe is provided with a double-layer two-way gas nozzle; the gas nozzle comprises a forward nozzle and an outward nozzle, wherein the forward nozzle is arranged at the inner layer, is consistent with the direction of the central axis and can inject forwards; the outward nozzle is arranged at the outer layer, forms an angle of 45-60 degrees together with the central axis, and can inject in a way of a ring shape. The device and the method solve the problems that the types of coal of the small and medium-sized industrial pulverized coal boilers are poor in adaptive capacity and overhigh in NOx content. The device and the method realize the combined combustion of pulverized coal and liquefied petroleum gas in a vortex state.

Owner:SHANXI LANTIAN ENVIRONMENTAL PROTECTION EQUIPCO

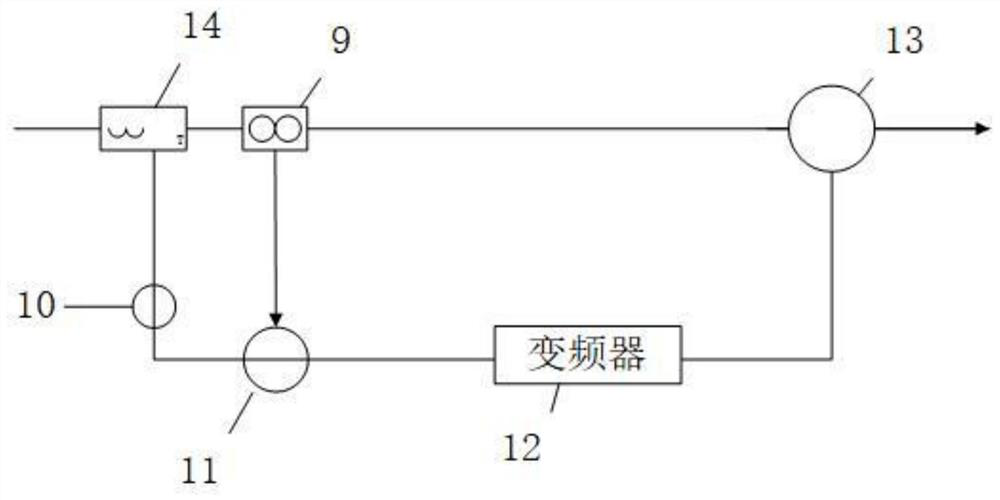

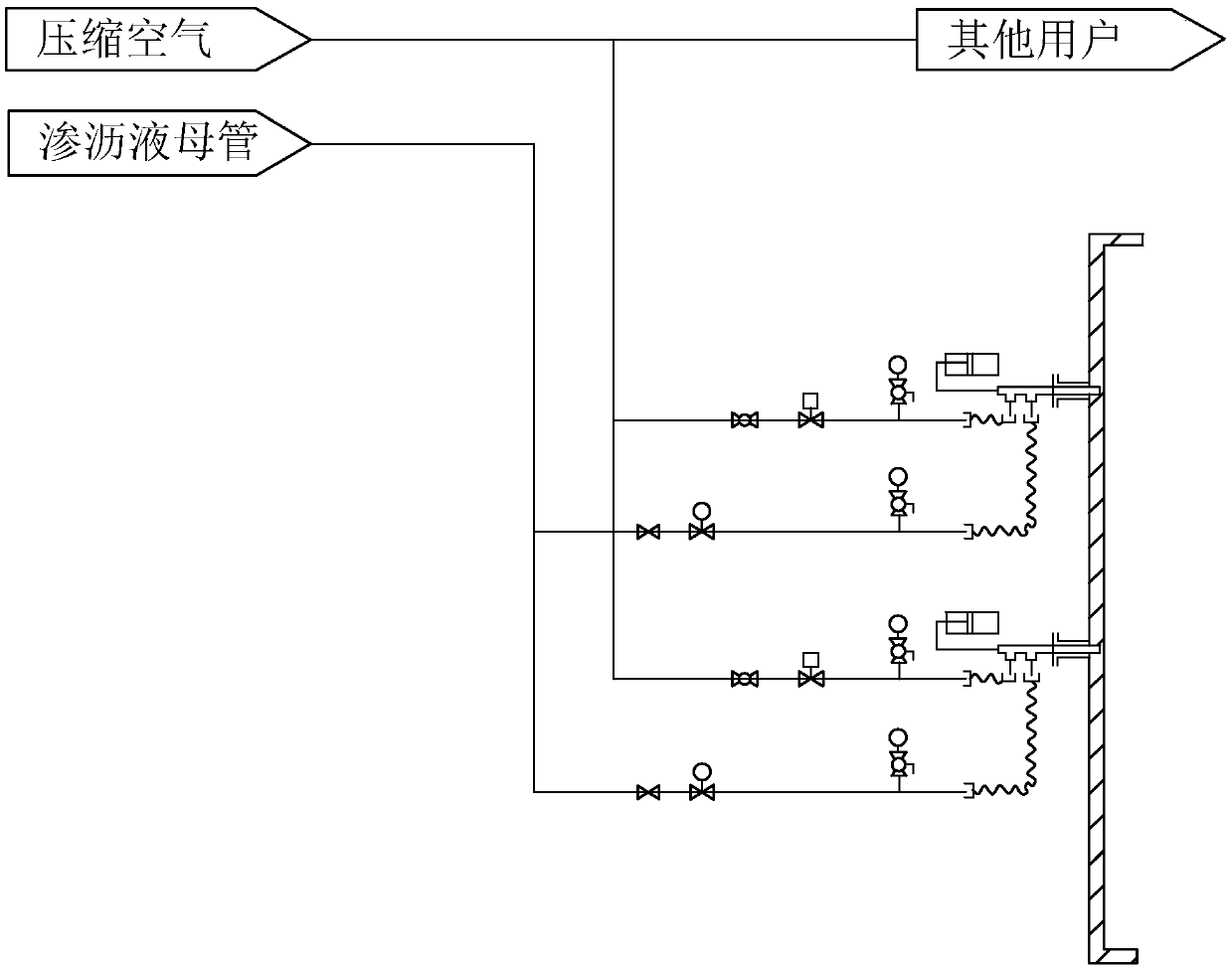

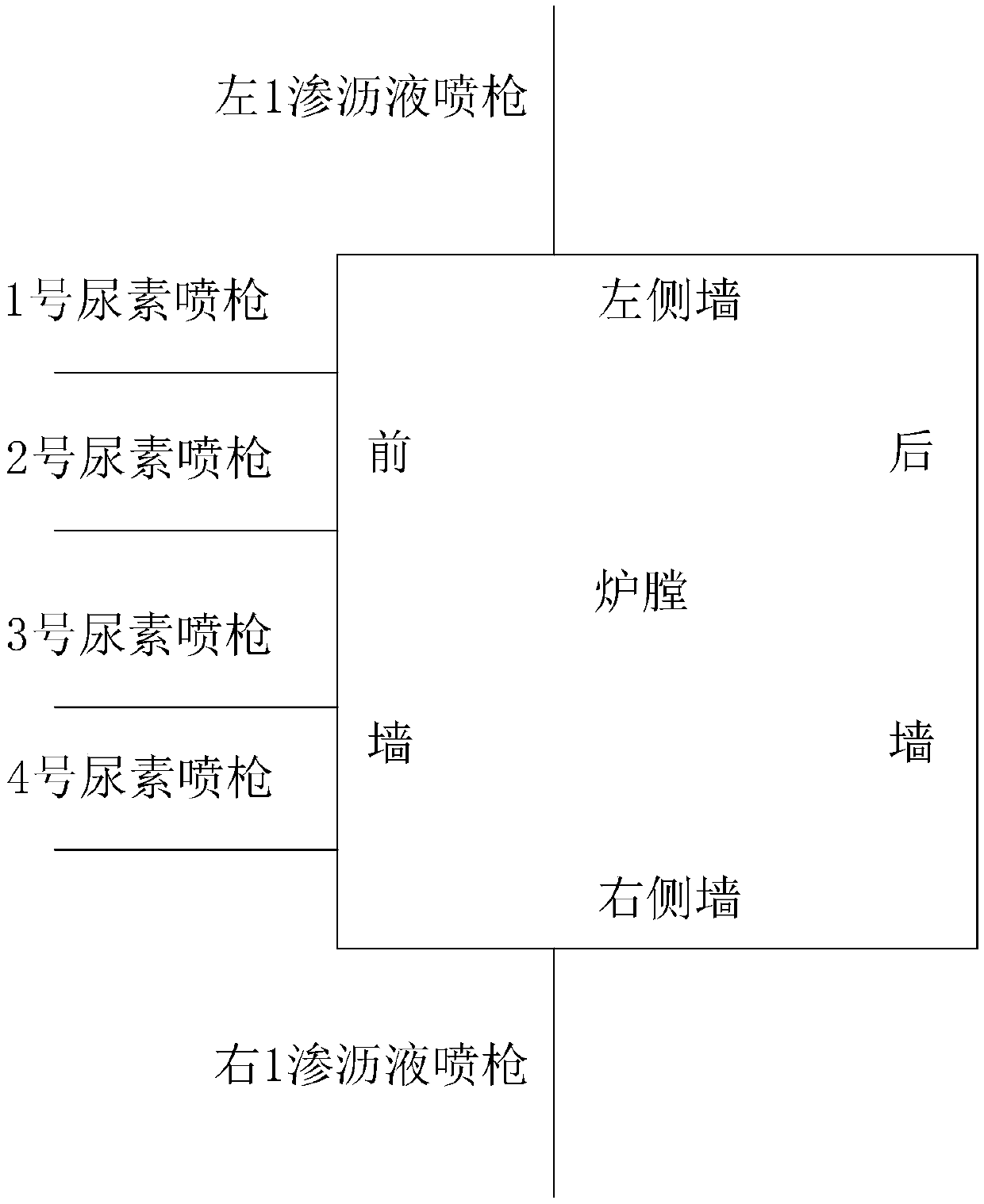

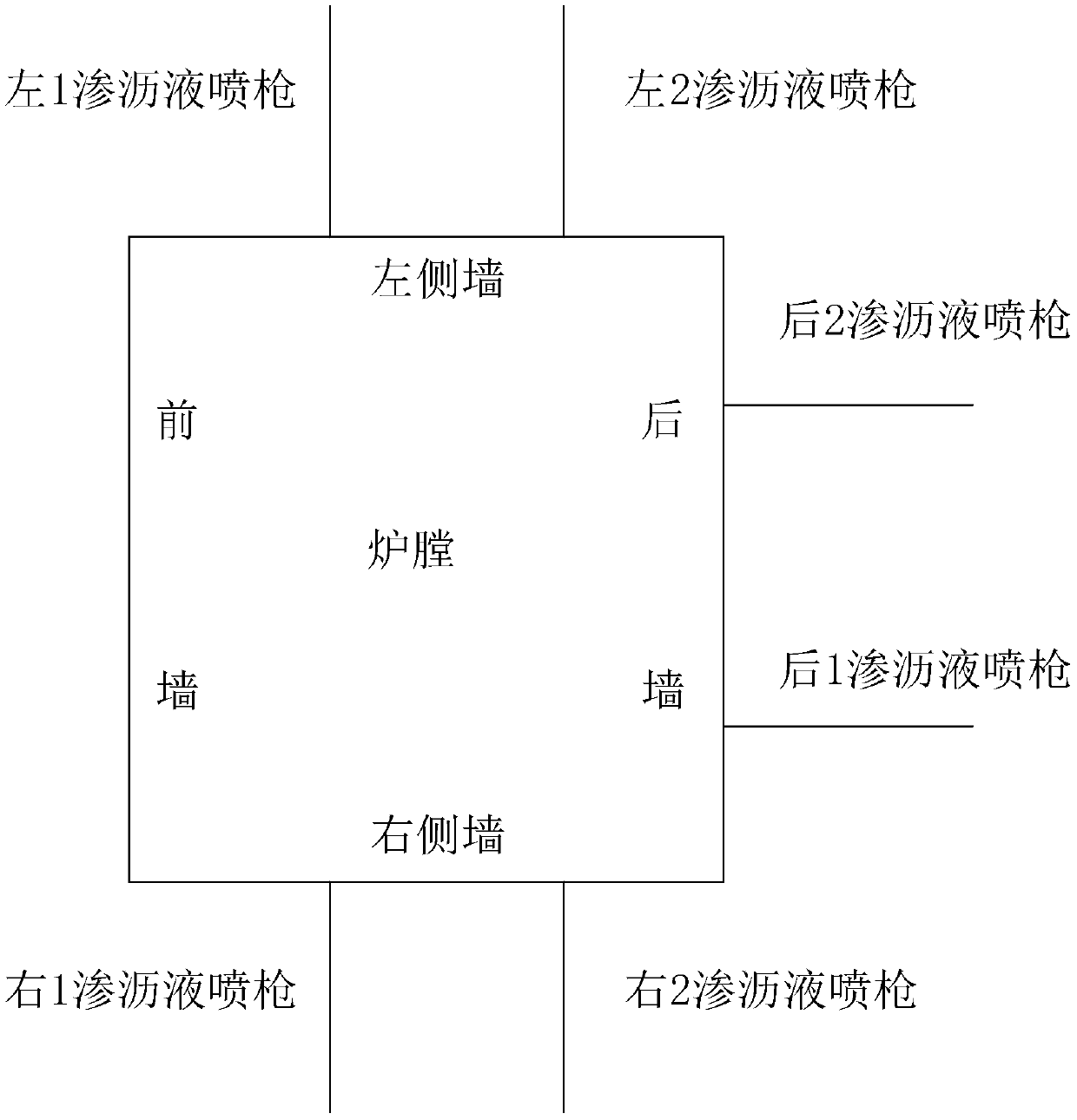

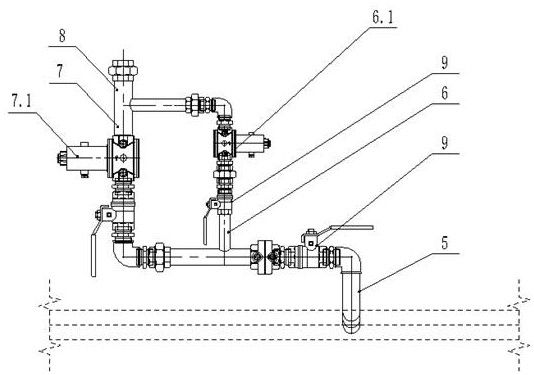

Leachate back-injection system of garbage incineration boiler and method for reducing NOx content

PendingCN109092040AReduce processingEmission reductionNitrous oxide captureDispersed particle separationHearthProduct gas

The invention discloses a leachate back-injection system of a garbage incineration boiler and a method for reducing NOx content, and relates to the technical field of garbage treatment. The technicalscheme of the system is characterized by comprising a leachate back-injection device and an ammonia supplementing system, wherein the leachate back-injection device comprises a leachate spray gun mounted on a hearth; the ammonia supplement system comprises a central controller, a NOx content detection module, an ammonia nitrogen content detection module, an output control module and an NH3 supplement module. The problem of insufficient denitration caused by the fixed amount of sprayed leachate due to the change of NOx concentration of garbage incinerated by the garbage incineration boiler is solved, atomization stability is improved by improving the leachate injection manner, the leachate is supplemented with ammonia as required, the removal effect of NOx from garbage incineration is enhanced, and the content of NOx in exhaust gas is reduced.

Owner:北京高安屯垃圾焚烧有限公司

Oil-gas-solid multi-fuel solid heat carrier furnace

PendingCN113137608AUniform temperatureReduce NOx contentFluidized bed combustionIndirect carbon-dioxide mitigationHeat carrierChemistry

The invention provides an oil-gas-solid multi-fuel solid heat carrier furnace, which can comprehensively utilize various fuels such as pyrolytic oil, pyrolytic gas and pyrolytic carbon obtained after pyrolysis of household garbage, supplements external solid heat carriers to serve as circulating ash, achieves multi-fuel combustion of the various fuels such as oil, gas and carbon, guarantees combustion stability, and enables temperature fields in the furnace to be evenly distributed. According to the solid heat carrier furnace, pyrolytic oil, pyrolytic gas and pyrolytic carbon obtained after pyrolysis of household garbage can be comprehensively utilized, and meanwhile large-proportion blending combustion of gas-state fuel and oil-state fuel is achieved. Compared with a conventional circulating fluidized bed, the oil-gas-solid multi-fuel solid heat carrier furnace has the advantages that different types of combustors are arranged in a layered mode, so that a partitioned combustion mode that a large amount of pyrolytic gas and pyrolytic oil are fed into the furnace from a dilute-phase area to be combusted and pyrolytic carbon is combusted at the bottom of the furnace is achieved, the temperature in a hearth is more uniform, and the excess air coefficient of overall air distribution is smaller.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Spray gun, spray gun control method and lime kiln with spray gun

The invention discloses a spray gun, a spray gun control method and a lime kiln with the spray gun. A fixed partition plate arranged in the spray gun divides a vertical pipe of the spray gun into a thin fuel area and a thick fuel area. When the pulverized coal passes through the bent pipe, the pulverized coal concentration in the rich fuel area is high and the pulverized coal concentration in thelight fuel area is low because of the inertia effect; the telescopic positions of the sliding partition plate and the sliding sleeve are adjusted, the fuel pulverized coal concentration difference between the thin fuel area and the thick fuel area is adjusted; a primary combustion area with low pulverized coal concentration and a secondary combustion area with high pulverized coal concentration are naturally formed at an outlet of a spray gun in the lime kiln so that NOx formed by combustion in the primary combustion area can be better reduced into N2 in the secondary combustion area, and thecontent of NOx in the lime production process is reduced.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Preparation method of sulfur transfer agent for FCC regenerated flue gas

InactiveCN100478055CImprove adsorption capacityHigh mechanical strengthCatalytic crackingDispersed particle separationFlue gasSulfur

The invention relates to a method for preparing fluid catalyst crack regenerate smoke sulfur transfer agent, wherein it uses co-precipitation method to prepare MgAlZnFeCe-HTL hydrotalcite; mixes 60 deals MgAlZnFeCe-HTL product, 20 deals caoline, 10 deals rare-earth Y, 100 deals aluminum gel (10% solid), and 210 deals chemical water, beating, atomizing and drying. The inventive transfer agent has high-effect SOX adsorption and high mechanical strength, while it can reduce the NOx content of smoke.

Owner:EAST CHINA NORMAL UNIV

A method of using a device for expanding the applicable coal types of small and medium-sized industrial pulverized coal boilers

ActiveCN103307595BEasy to igniteImprove combustion conditionsCombustion using gaseous and pulverulent fuelCombustion apparatusPoor adaptive skillsLiquefied petroleum gas

The invention discloses a combustion apparatus and a combustion method, and particularly discloses a device and a method for expanding types of coal suitable for small and medium-sized industrial pulverized coal boilers. The device comprises a cyclone burner; a central delivery pipe, a central air duct, a primary air powder duct and a secondary air pipe are arranged at a nozzle of the cyclone burner sequentially from inside to outside, wherein the secondary air pipe comprises an internal secondary air duct and an external secondary air duct, and the internal secondary air duct is arranged at the inner side of the external secondary air duct; an outer ring nozzle is arranged in the external secondary air duct; an outlet end of the central delivery pipe is provided with a double-layer two-way gas nozzle; the gas nozzle comprises a forward nozzle and an outward nozzle, wherein the forward nozzle is arranged at the inner layer, is consistent with the direction of the central axis and can inject forwards; the outward nozzle is arranged at the outer layer, forms an angle of 45-60 degrees together with the central axis, and can inject in a way of a ring shape. The device and the method solve the problems that the types of coal of the small and medium-sized industrial pulverized coal boilers are poor in adaptive capacity and overhigh in NOx content. The device and the method realize the combined combustion of pulverized coal and liquefied petroleum gas in a vortex state.

Owner:SHANXI LANTIAN ENVIRONMENTAL PROTECTION EQUIPCO

Metal surface burner

PendingCN113776054AReduce volumeSimple structureElectric spark ignitersGaseous fuel burnerCombustorEngineering

The invention discloses a metal surface burner which comprises a premixing pipeline and a tail end pipeline, wherein the gas inlet end of the premixing pipeline is connected with a fan, a branch-shaped gas distributor is arranged in the premixing pipeline, the gas inlet end of the branch-shaped gas distributor penetrates through the premixing pipeline and then is connected with a main gas pipe, the tail end pipeline is arranged on the front wall of a hearth in a penetrating mode, the gas inlet end outside the hearth of the tail end pipeline is connected with the gas outlet end of the premixing pipeline, the gas outlet end inside the hearth of the tail end pipeline is connected with a micropore metal cylinder, a flame-retardant disc is arranged in the tail end pipeline, a built-in ignition nozzle is arranged in the micropore metal cylinder and connected with an ignition gas pipe, and the ignition gas pipe is connected with the main gas pipe. The metal surface burner is more compact in structure, better in gas premixing effect and capable of achieving stable combustion in a small-hearth boiler and ultralow emission of NOx.

Owner:李亭立

Gas furnace pipeline structure and four-section combustion technology

PendingCN112524609AImprove energy savingExpansion of emission application fieldsIndirect carbon-dioxide mitigationGaseous fuel burnerThermodynamicsProcess engineering

The invention relates to the technical field of gas furnaces, in particular to a gas furnace pipeline structure and a four-section combustion technology. An existing gas furnace is serious in heat loss. The gas furnace pipeline structure comprises a furnace body, the furnace body is connected with an air pipeline and a gas pipeline, and the air pipeline comprises a first air inlet pipe and a second air inlet pipe. The first air inlet pipe and the second air inlet pipe are separately provided with a regenerative burner, a reversing valve and a hot air butterfly valve, the gas pipeline comprisesa gas inlet, a first gas pipeline, a second gas pipeline and a gas outlet, the second gas pipeline is provided with a soft fire gas valve, and the first gas pipeline is provided with a big fire gas valve. Energy conservation and emission reduction are achieved, and good development prospects are realized in the technical field of gas furnaces.

Owner:HENAN TIANLI THERMOTECHNICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com