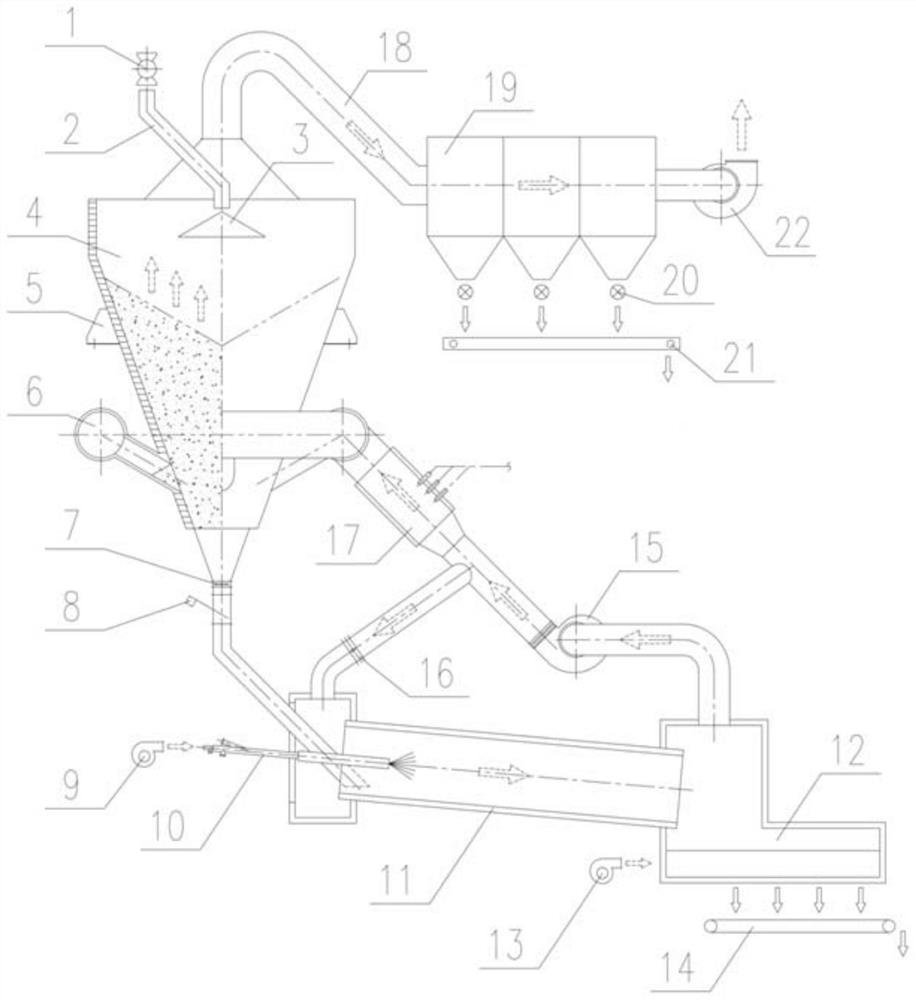

System and a method for generating active lime

A technology of active lime and production system, applied in the field of heat treatment and equipment, can solve problems such as not being widely promoted, adverse effects on lime quality, and immature process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Calcium carbonate is decomposed to produce quicklime. If it continues to be burned at high temperature, its loose and porous structure will collapse, forming a dense structure of burnt lime, and its activity will be greatly reduced; not only that, continuous overheating will cause calcium oxide and impurities to form a solid phase reaction, resulting in crusts or nodules. Therefore, the ideal temperature control principle is: all calcium carbonate is just decomposed into calcium oxide, and does not react with impurities such as silicon and phosphorus, and maintains the gap left after the escape of carbon dioxide;

[0031] In the production process of lime, the decomposition of calcium carbonate is an endothermic reaction, and the heat absorbed by the decomposition of calcium carbonate accounts for more than 60% of the heat consumption. In the existing vertical preheater with rotary kiln process, the rotary kiln is responsible for 70% of the calcium carbonate decompositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com