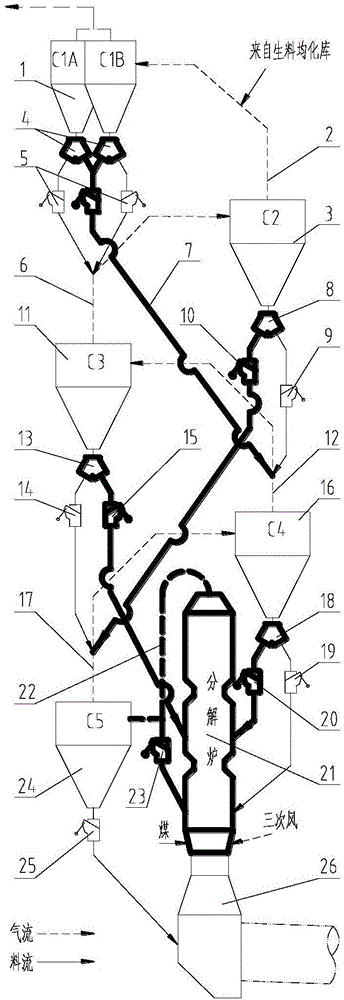

Large-temperature-difference crossed material preheating and precalcining system and method thereof

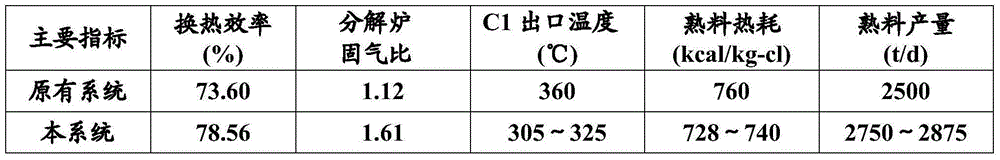

A pre-decomposition, large temperature difference technology, applied in the directions of preheating, lighting and heating equipment, furnaces, etc., can solve the problems of inability to adapt to the natural environment in high altitude areas, difficult technical indicators, high power consumption of fans, and improve gas-solid exchange. Effects of heat rate, extended residence time, increased adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

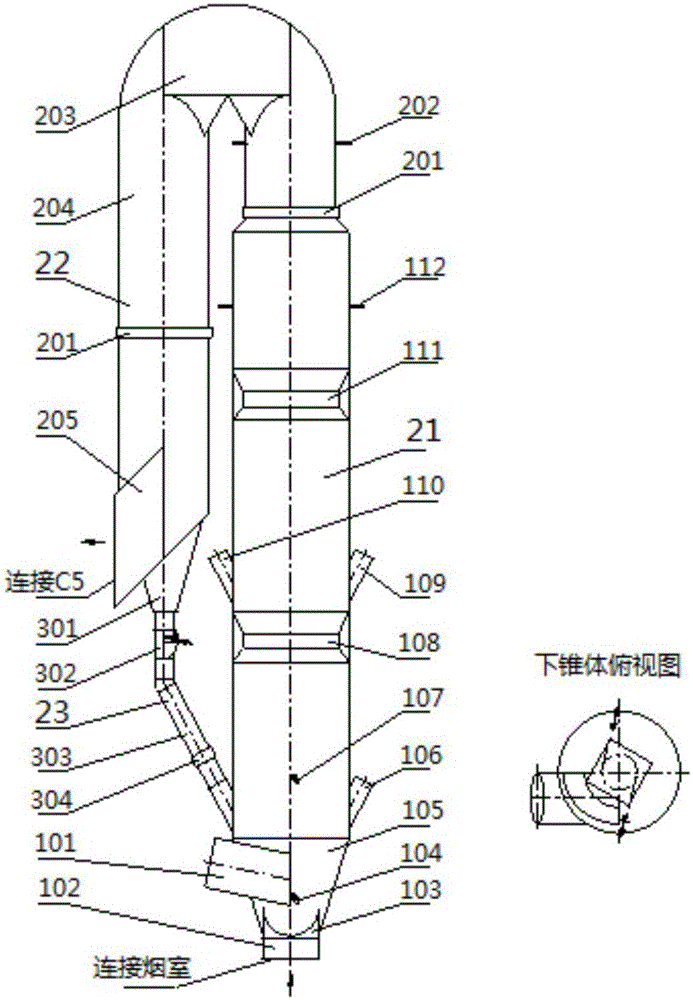

[0052] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art know that the present invention is not limited to the drawings and the following embodiments.

[0053] One, theoretical basis and principle of the present invention

[0054] 1. According to the law of thermodynamics, "Heat is always spontaneously transferred from a high-temperature object to a low-temperature object. If there is a temperature difference between the two fluids, heat must be transferred." For the cement suspension preheating system, the heat transfer between the raw meal and the gas is convective heat exchange. According to the basic law of convective heat transfer - Newton's law of cooling, the heat flow of convective heat transfer is proportional to the temperature differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com