Spray gun, spray gun control method and lime kiln with spray gun

A technology of spray gun and telescopic length, which is applied in the field of lime kiln, can solve the problems of high NOx, unfavorable environmental performance of equipment, etc., and achieve the effect of reducing the content of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make those skilled in the art better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be described clearly and completely below with reference to the accompanying drawings.

[0036] The technical solution of the present application is based on the low NOx combustion theory of fuel staging combustion. The so-called fuel staging combustion means that the fuel is fed into the furnace in stages to form a primary combustion zone with a small fuel concentration and a secondary combustion zone with a large fuel concentration in the combustion zone. . The NOx formed in the primary combustion zone is reduced to N2 under the high temperature and reducing atmosphere of the secondary combustion zone, which can significantly reduce the NOx emission during the combustion process.

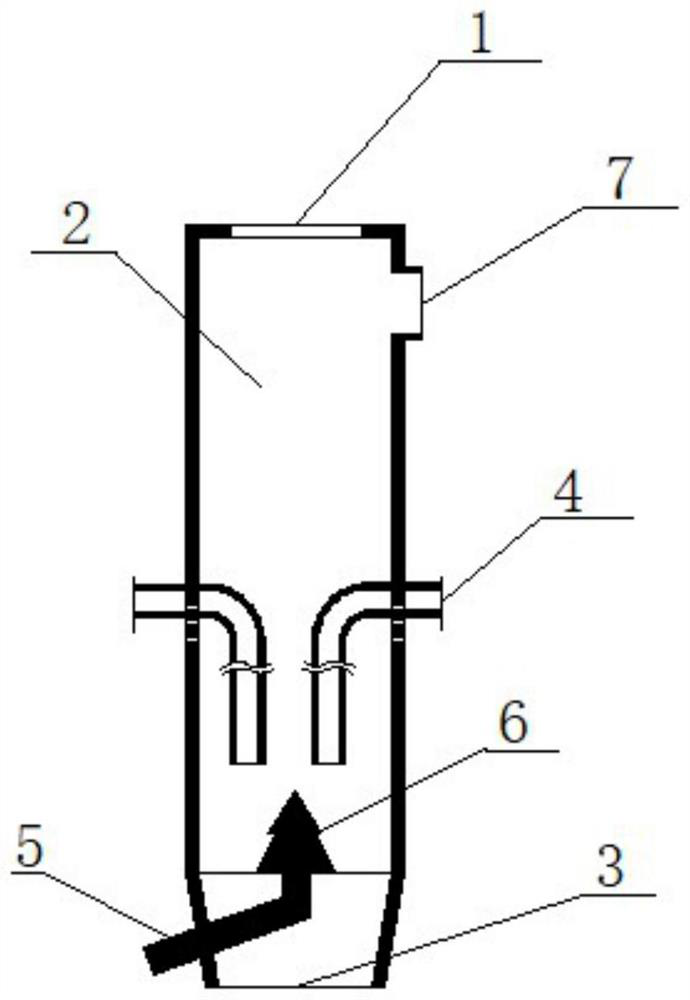

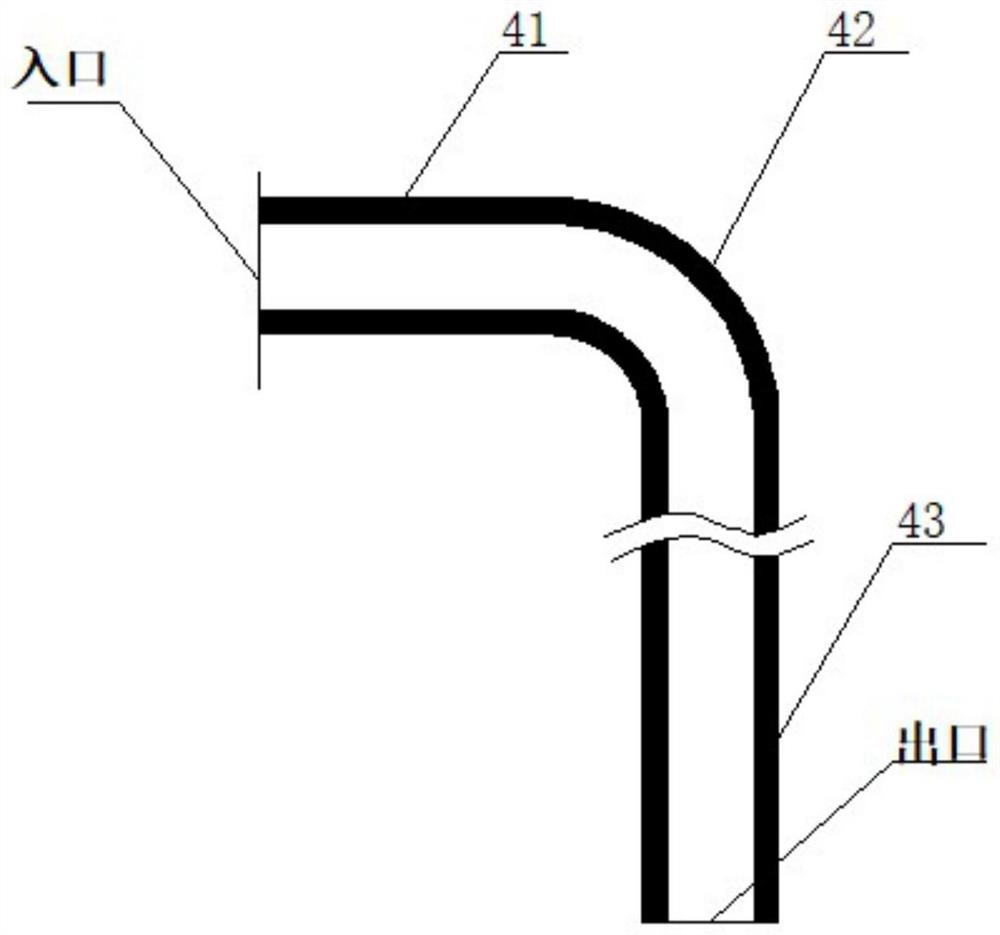

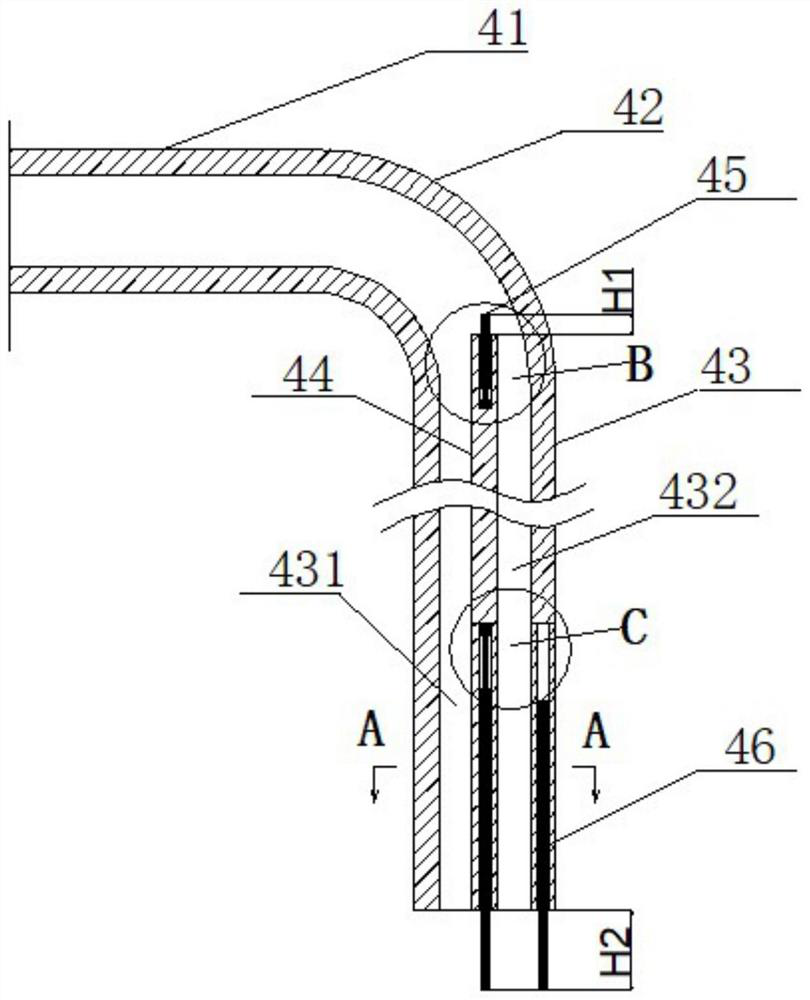

[0037] Based on the above fuel staged combustion theory, see image 3, the application provides a spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com