Gas furnace pipeline structure and four-section combustion technology

A technology for gas pipelines and gas furnaces, applied in gas fuel burners, burners, combustion methods, etc., can solve problems such as heat loss of gas furnaces, improve heating quality, strengthen heat transfer in furnaces, and have great energy saving potential. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

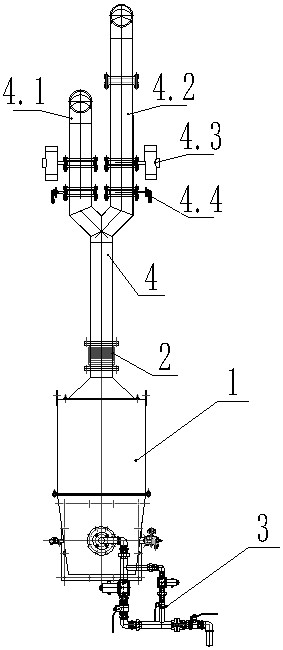

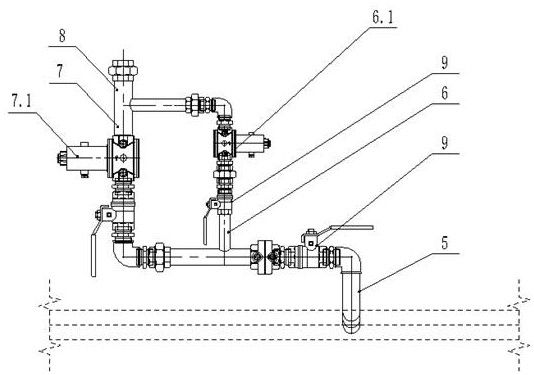

[0017] Embodiment one: by Figure 1 to Figure 2 Given, a gas furnace pipeline structure, including a furnace body 1, the furnace body 1 is connected to an air pipeline 4 and a gas pipeline 3, and the air pipeline 4 includes a first air inlet pipe 4.1 and a second air inlet pipe 4.2 , the first air intake pipe 4.1 and the second air intake pipe 4.2 are respectively provided with a regenerative burner, a reversing valve 4.3 and a hot air butterfly valve 4.4, and the gas pipeline 3 includes a gas inlet 5, a first gas pipeline 7. The second gas pipeline 6 and the gas outlet 8, the gas inlet pipe 5, the first gas pipeline 7 and the second gas pipeline 6 are respectively provided with valves 9, which are independent of each other and can be opened or closed as required. To control the amount of gas entering, a low-fire gas valve 6.1 is set on the second gas pipeline 6, a large-fire gas valve 7.1 is set on the first gas pipeline 7, and two connected regenerative burners are set insid...

Embodiment 2

[0018] Embodiment 2: On the basis of Embodiment 1, the gas inlet 5, the first gas pipeline 7 and the gas outlet 8 are connected to each other in an "L" shape, and the bends are connected by elbows. The first A gas pipeline 7 is grooved at the head and tail for the connection of the second gas pipeline 6, and the connection is welded to form the first gas pipeline 7 and the second gas pipeline 6 to be fed through the gas inlet, and The gas is discharged through the gas outlet, but the pipeline structure is independent of each other. The gas outlet 8 is connected to the furnace body through a joint. The diameter of the second gas pipeline 6 is smaller than the diameter of the first gas pipeline 7. The air The pipeline 4 is a "Y"-shaped tee, and communicates with the pre-furnace body 1 through the bellows 2 .

[0019] In the above embodiment, the second gas pipeline 6 uses a galvanized pipe with a diameter of 4 cm, the first gas pipeline 7 uses a galvanized pipe with a diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com