System for reducing carbon emission by blending combustion of ammonia gas and control method

A control method and carbon emission technology, applied in combustion methods, direct carbon dioxide emission reduction, combustion equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

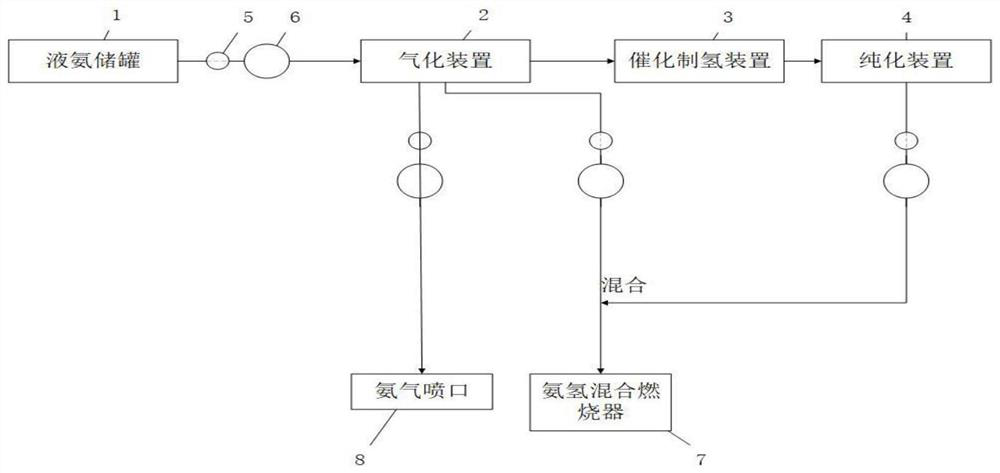

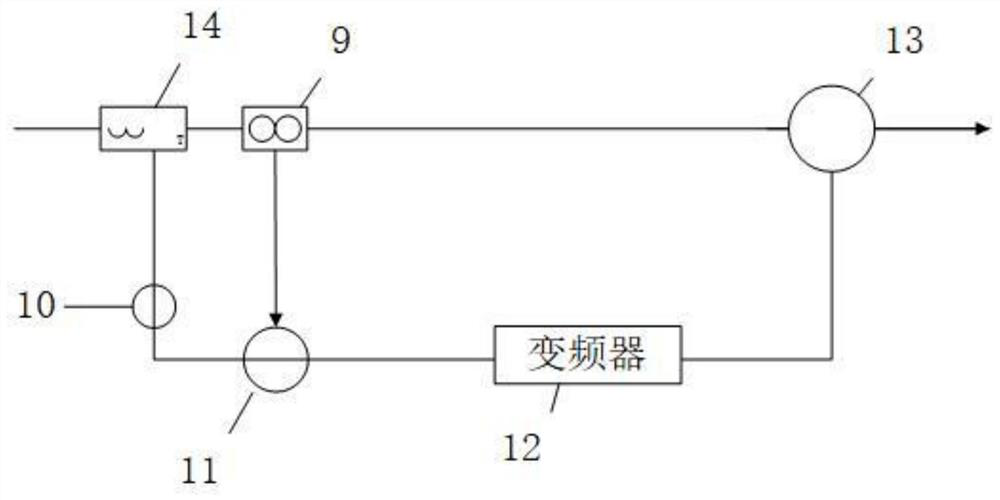

[0029] refer to Figure 1-3 , a system for reducing carbon emissions by blending ammonia gas, comprising an ammonia source, a gasification device 2, a hydrogen preparation device and a furnace.

[0030] The ammonia source is connected to the input end of the gasification device 2, and the output end of the gasification device 2 is divided into three outputs, the first output is connected to the input end of the hydrogen preparation device, the second output is the output of the hydrogen preparation device One end is connected with the ammonia-hydrogen mixed burner 7 on the furnace, and the third output is connected with the ammonia nozzle on the furnace.

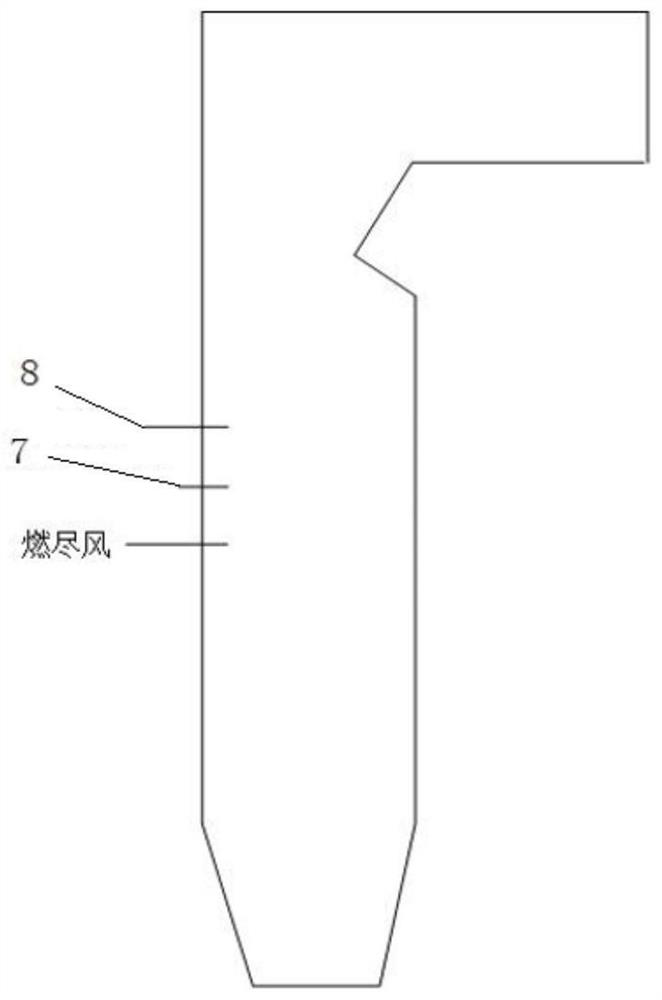

[0031] The ammonia-hydrogen mixed burner 7 is installed above the burnt-out air in the furnace, and the ammonia gas nozzle 8 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com