Superfine coal based fluid fuel and its preparation

A fluid fuel, ultra-fine technology, used in liquid carbon-containing fuels, fuels, petroleum industries, etc., can solve problems such as high apparent viscosity, limiting pumping capacity, atomization performance and combustion effect, affecting static stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

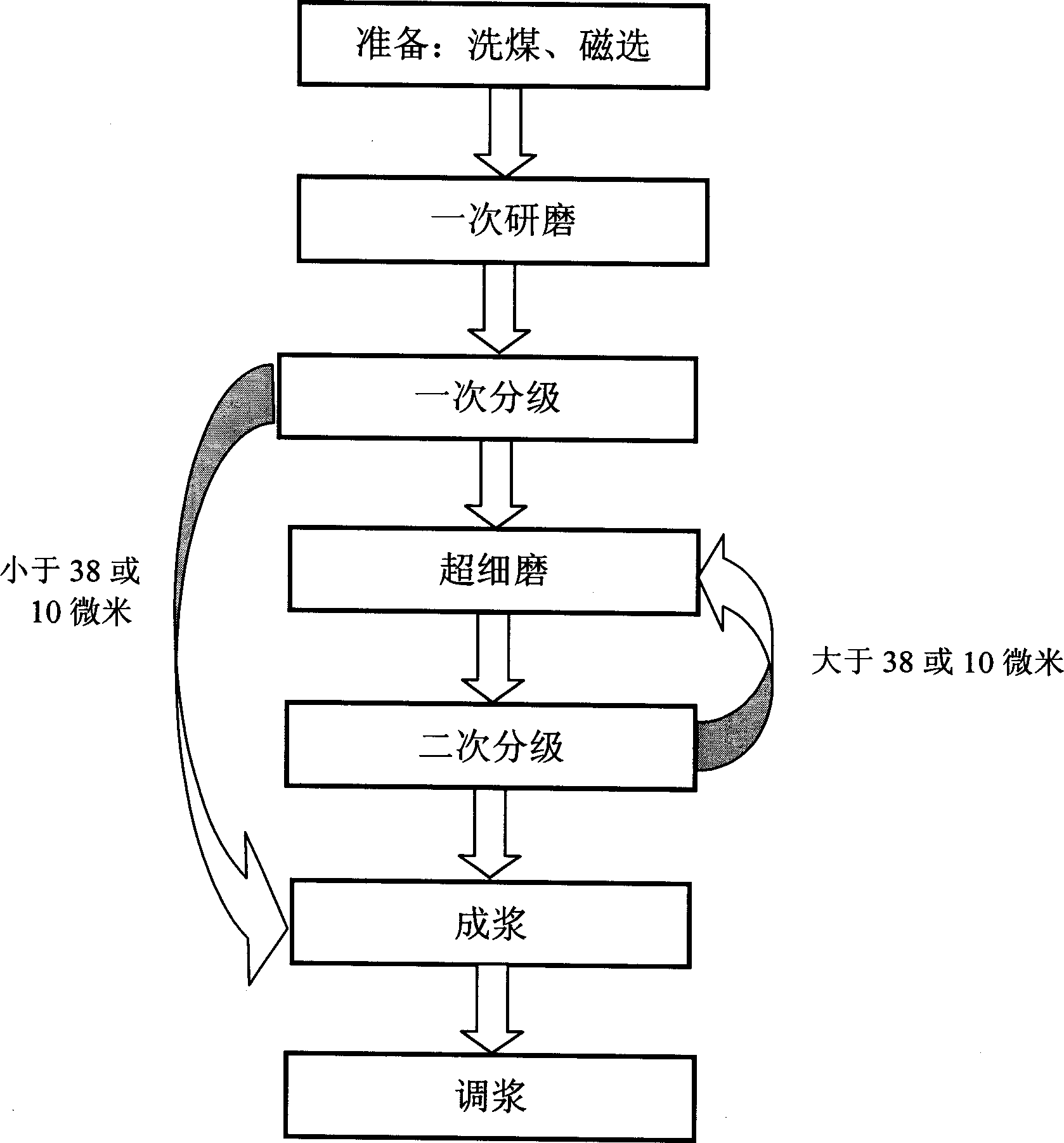

[0022] Coal raw materials (Lignite, long-flame coal with low degree of metamorphism, gas coal, fat coal, coking coal, lean coal, lean coal and various media between them can be selected, such as 1 / 3 coking coal, etc. ) After coal washing and magnetic separation are carried out with conventional coal washing equipment and magnetic separation equipment, the coal is ground with a grinder. Then use a classifier to classify the pulverized coal powder once. The pulverized coal particles smaller than 38 microns can directly enter the following slurrying process, and the pulverized coal particles larger than 38 microns enter the next ultrafine grinding process. The coal powder particles are ultra-finely ground with an ultra-fine mill, and the coal powder particles are classified again by a classifier. The coal powder particles smaller than 38 microns enter the next slurrying process, and the coal powder particles larger than 38 microns are returned to the ultra-fine The grinding proce...

Embodiment 2

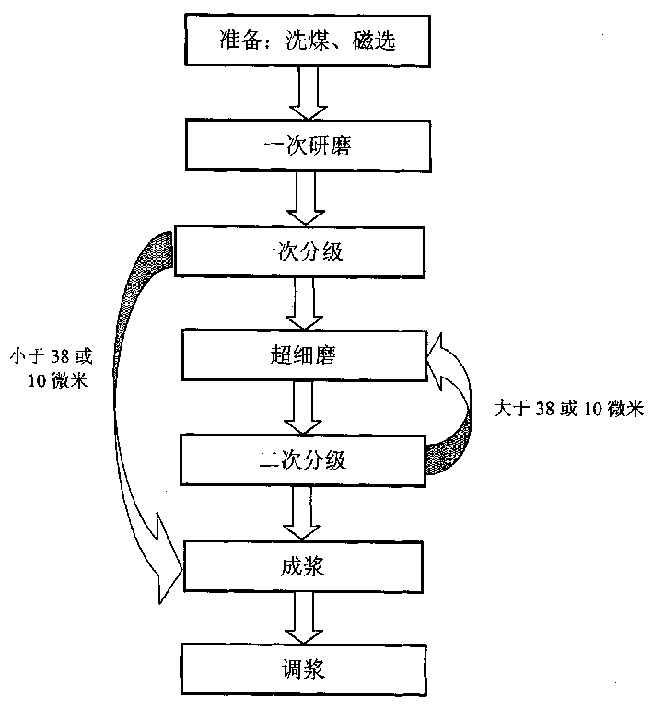

[0026] Coal raw materials (such as fat coal) are washed and separated by conventional coal washing equipment and magnetic separation equipment, and then the coal is ground by a grinder. Then use a classifier to classify the ground coal powder once. The coal powder particles smaller than 15 microns can directly enter the following slurrying process, and the coal powder particles larger than 15 microns enter the next ultrafine grinding process. The pulverized coal particles are ultra-finely ground with an ultra-fine mill, and the pulverized coal particles are classified again by a classifier. The pulverized coal particles smaller than 15 microns enter the next process, and the pulverized coal particles larger than 15 microns return to the ultra-fine mill. The process is again ultra-fine grinding. In this way, the desired coal powder particles can be obtained.

[0027] Take 1.5 kg of dispersant and 30 kg of water, mix it evenly, and put it into the slurry tank, slowly add 70 kg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com