Patents

Literature

178results about How to "Improve combustion characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

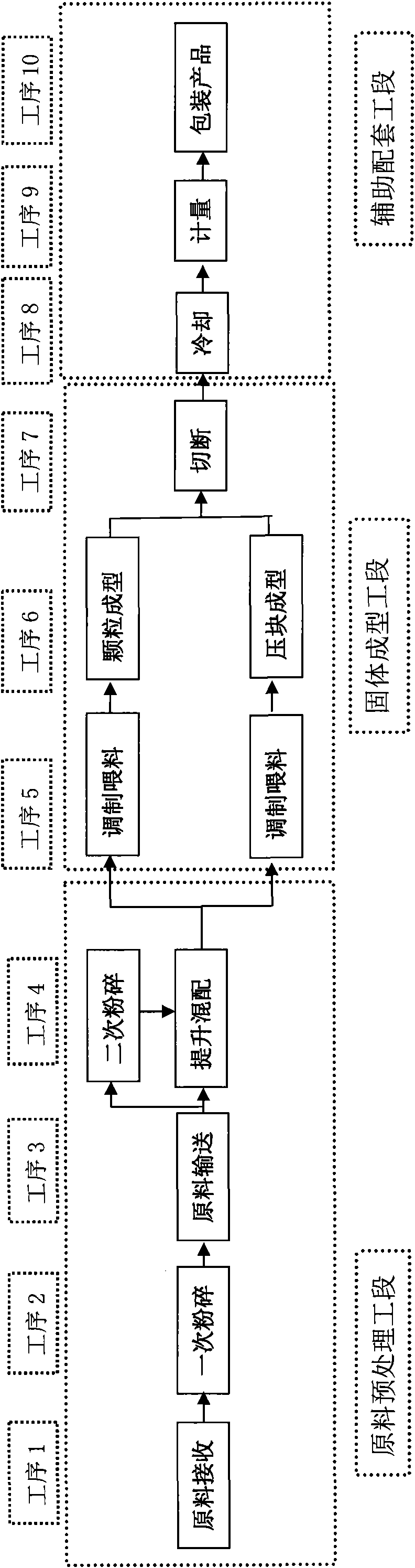

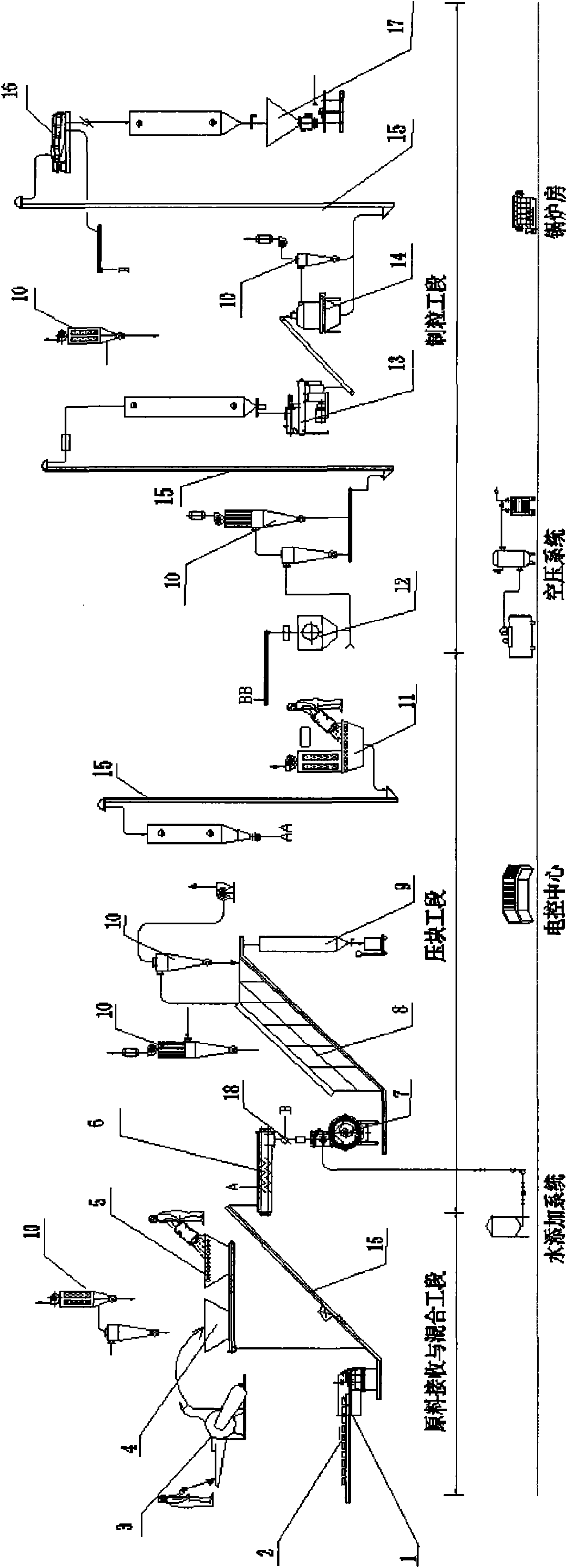

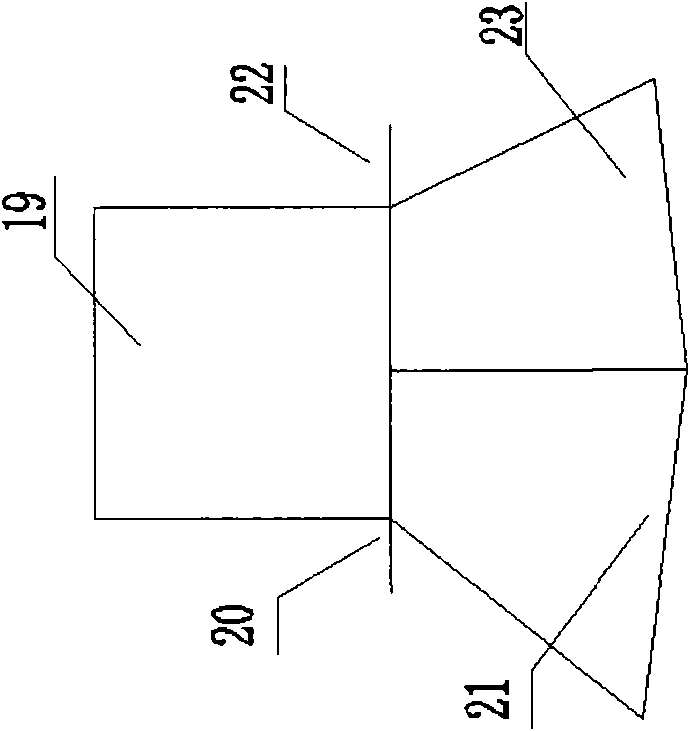

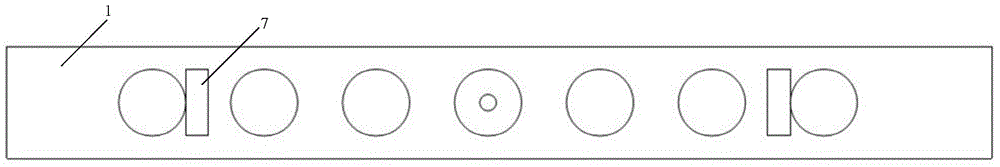

Processing method for biomass solid molding fuel

InactiveCN101555429AImprove processing capacityImprove market competitivenessBiofuelsSolid fuelsBiomassCrop

The invention discloses a processing method for biomass solid molding fuel, which pertains to the technical field of solid fuel and aims at solving problem of comprehensive use of energy and biomass energy in rural areas. The technical proposal is as follows: biomass energy such as crop straws, shrub forest, forestry residues and the like are used as raw materials, and the secondary crushing technique and the mixed technique combining continuous feeding with adjustable feeding are adopted, therefore, two types of solid fuels, namely, block-type and granular fuels, can be produced. The technical proposal comprises three stages namely, pre-treatment of raw materials, solid molding and auxiliary assorting, and the specific working procedures comprise raw material cracking, drying, conveying, mixing, feeding, molding, cutting, cooling and measuring and packaging and adding a compulsory ventilating dust-removing system during the whole process. The processing method for biomass solid molding fuel solves the problem of diversification of biomass raw materials, and the biomass solid fuel production line constructed by adopting the processing method realizes the industrial continuous and stable production, solves the problems of high energy consumption and low production efficiency in the existing small workshop-style production, and is also beneficial to solving the rural energy problem and improving the rural environment.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

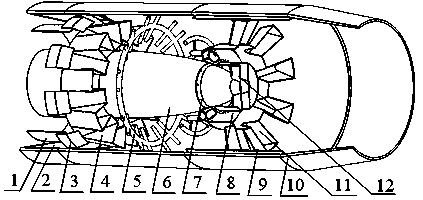

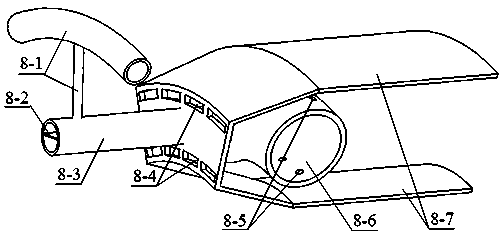

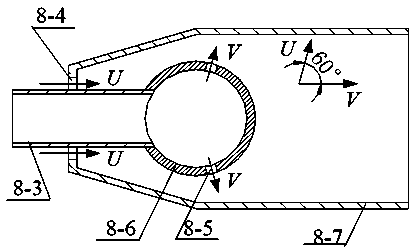

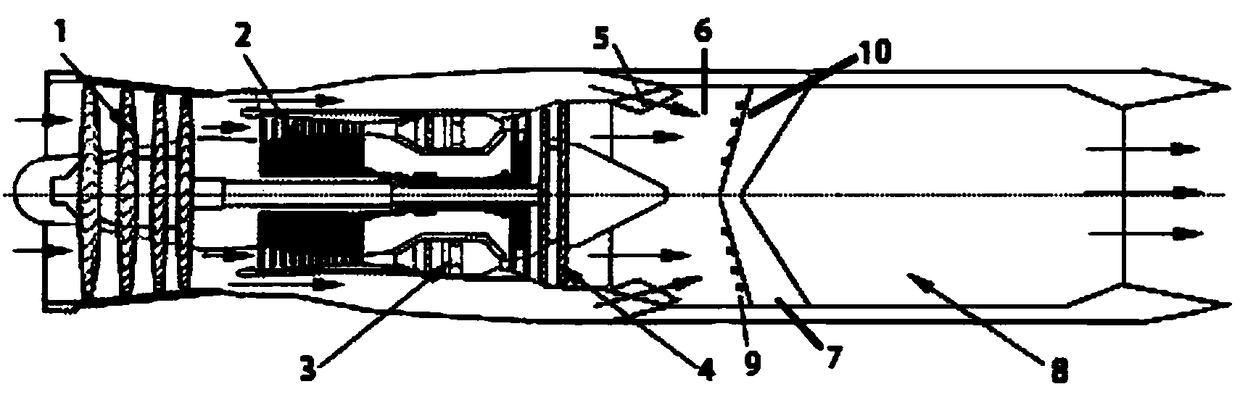

Turbine-based combined cycle engine super-combustion chamber

InactiveCN104019465ASatisfy Advancement RequirementsSolve key technical difficultiesContinuous combustion chamberRamjetGroove width

The invention discloses turbine-based combined cycle engine super-combustion chamber. Key parts of the super-combustion chamber comprise a shunt ring, a rear area-variable deflation valve, a flow guide tongue piece, a square lobe mixer, a first area fuel ejector, a center cone, a second area fuel injection ring, an evaporation tube flame stabilizer, a heat-isolating screen, a super-combustion chamber cylinder, an outer extending groove-width-variable radial flame stabilizer and an inner extending radial flame stabilizer. An internal flow field of the super-combustion chamber is reasonably distributed, the phenomenon of backflow from a punching duct to a turbofan duct can not occur, flow separation can not occur in the square lobe mixer, and the evaporation tube flame stabilizer can achieve soft ignition of the super-combustion chamber. The whole super-combustion chamber is high in mixing efficiency, little in cold flow resistance, high in combustion efficiency, reasonable in temperature distribution, and capable of meeting use requirements in a whole flight envelope of the super-combustion chamber in each work state and the requirement for boost of an turbofan ramjet.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Organic garbage and sludge mixed solid fuel and preparation method thereof

InactiveCN101215488AEasy to makeReduce processing costsSolid fuelsWaste based fuelFossil fuelPetroleum

The invention discloses solid fuel which is mixed by organic waste and sludge and a process for preparation. The solid fuel comprises the organic waste: 25%-55%, the sludge: 20%-50%, coal powder: 20%-50%, combustion improver: 0.15%-0.25% and desulfurization dechlorinating agent 0.5%-2%. The process for preparation comprises three stages of raw material preparation, molding and consolidation. The invention is tested by the solid fuel mechanical strength, burning characteristics, pollution control and the like. The solid fuel which is mixed by the organic waste and the sludge and prepared by the manufacturing process of the invention is comparatively ideal clean fuel with higher mechanical strength and can satisfy long-distance transportation with the falling strength more than 99%, the invention is the solid fuel with strong mechanical strength, good water resistance, excellent combustion characteristics, strong thermal stability and non pollution and can be extended to be applied in civilian uses and industrial sectors. The invention can also save a great amount of non-renewable fossil fuels such as petroleum, coal and the like with good social and environmental benefits.

Owner:TIANJIN URBAN CONSTR COLLEGE

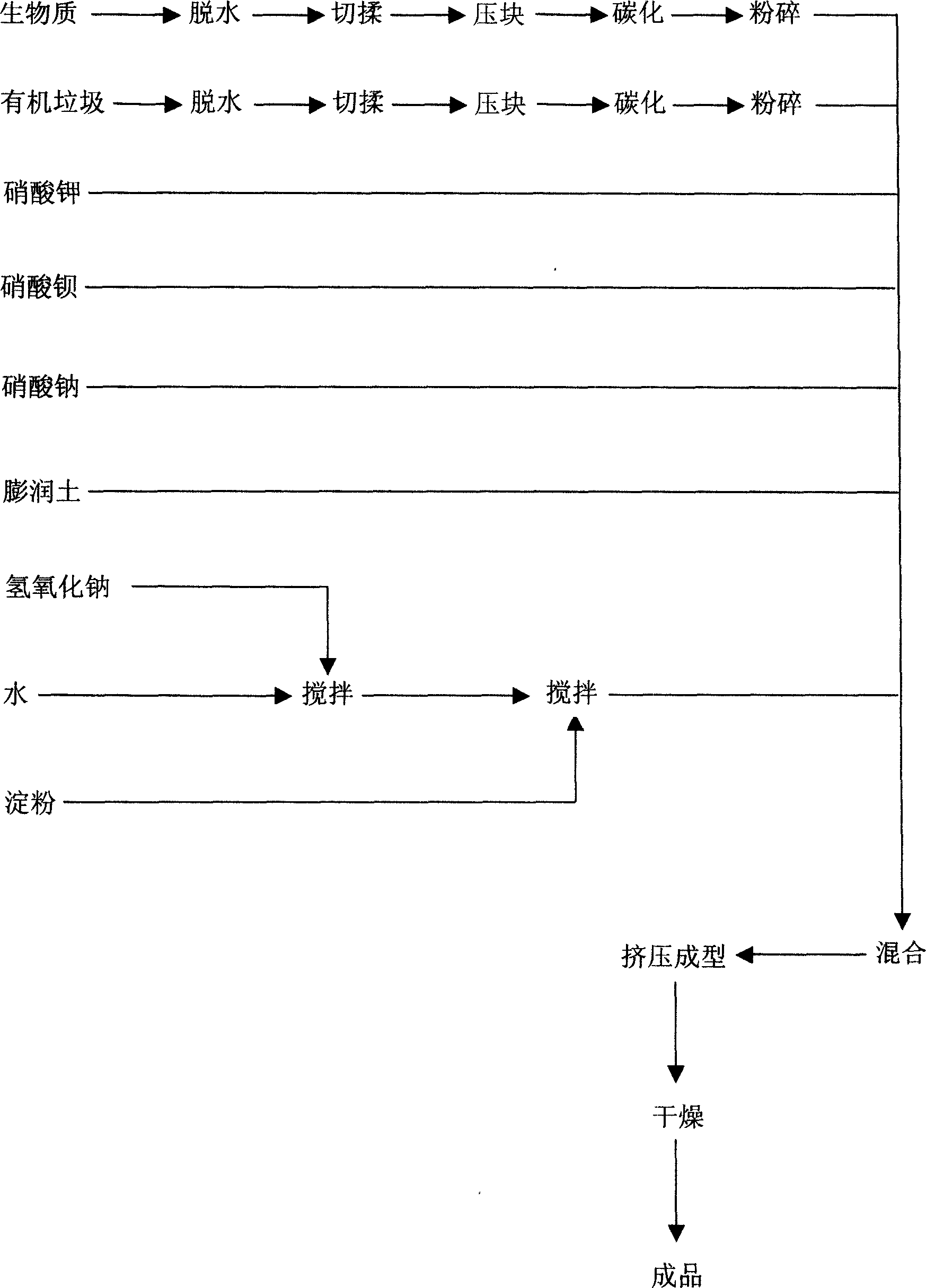

Biomass quick-combustion synthetic charcoal

InactiveCN1995297AReduce processing costsWon't emitBiofuelsSolid fuelsCarbonizationBiological materials

The invention synthesizing method of biological rapid-combustion charcoal, which comprises the following steps: adopting organic rubbish and biological material as main raw material; squeezing; moulding under 800-1000 deg. c; grinding into semi-charcoal from biological by-product and waste material; carbonating under 400-550 deg. c; grinding into charcoal powder with charcoal proportion at 25%-45% and semi-coal powder at 45%-65%; adding adhesive, water, combustion adjuvant, stabilizer, oxidant and or smoke suppressor.

Owner:BEIJING AOKE RUIFENG NEW ENERGY

Application of coal modifier in shaft kiln incineration and producing technique thereof

A 'SHENZHOUSHENGLONG' coal modifier mainly consists of a grinding aid, a catalyst, an oxidant, a smoke suppressor and combustion improver, a smoke suppressor and igniter, a sulfur fixation agent, a bulking agent, a penetrating agent, etc. The coal modifier is a powdery material and can be added into coal (at a ratio of 0.1% the actual coal weight) to improve the combustion temperature and the combustion speed of the coal, thus achieving catalytic combustion and improving the coal combustion effect as well as the coal utilization rate. Accordingly, the invention performs the functions of saving coal, substituting high-quality coal by poor-quality coal, improving the hourly output of cement clinker stage, improving the grade of cement clinker, fixing sulfur and reducing the discharge of harmful gases such as SO2 in the smoke, thus protecting environment and indeed achieving the green production of cement.

Owner:哈尔滨绿万家环保科技有限公司 +5

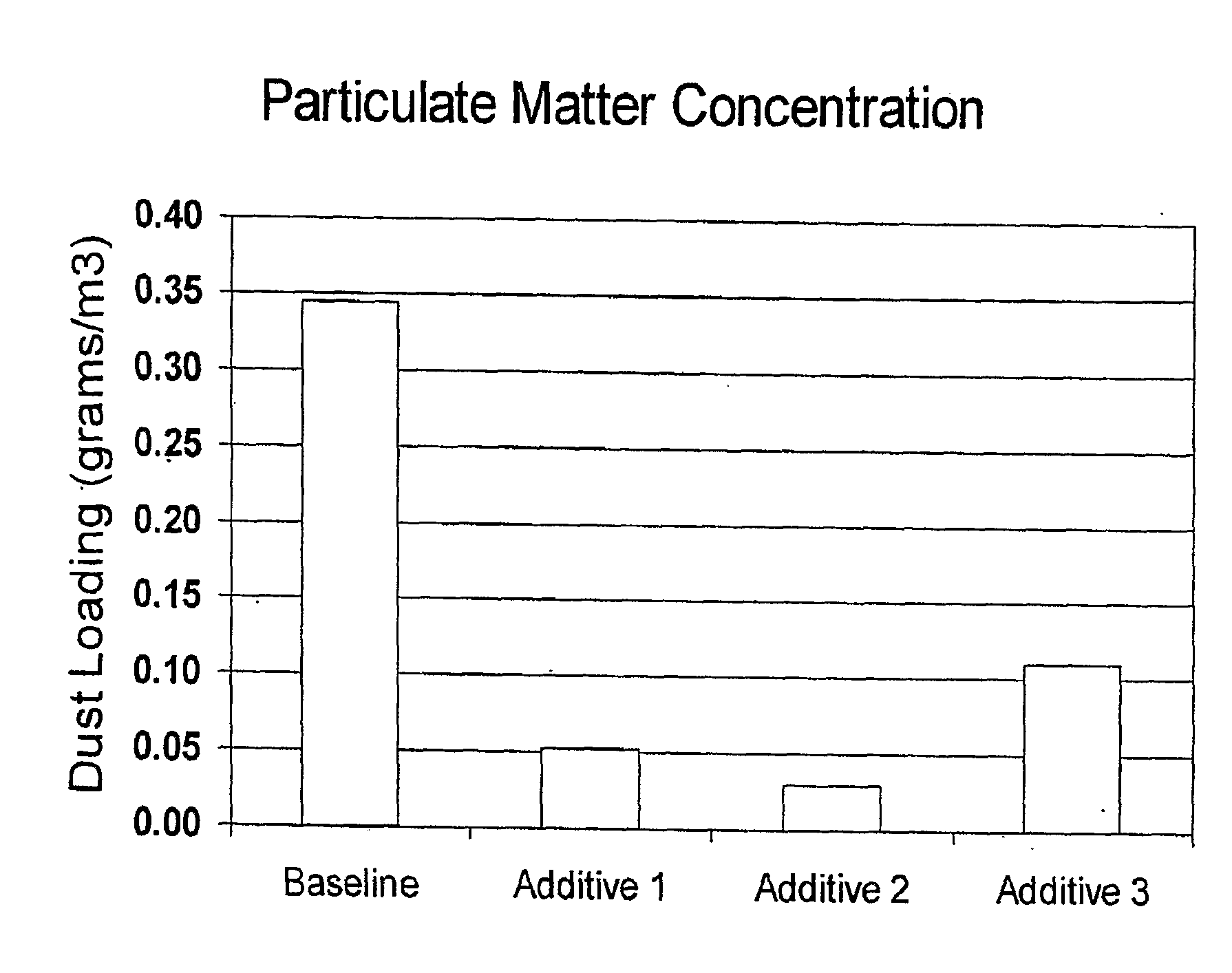

Residual fuel oil additive

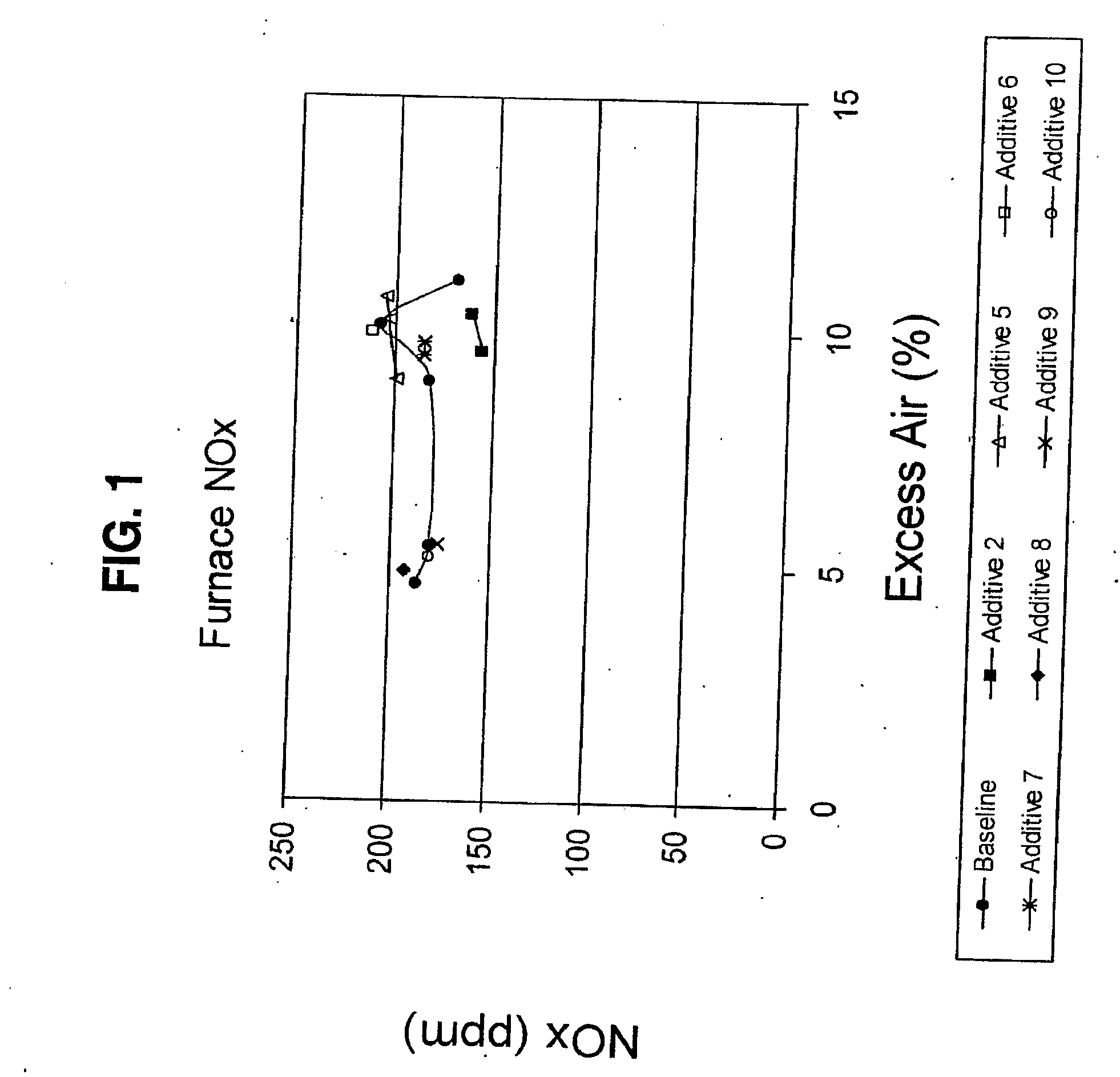

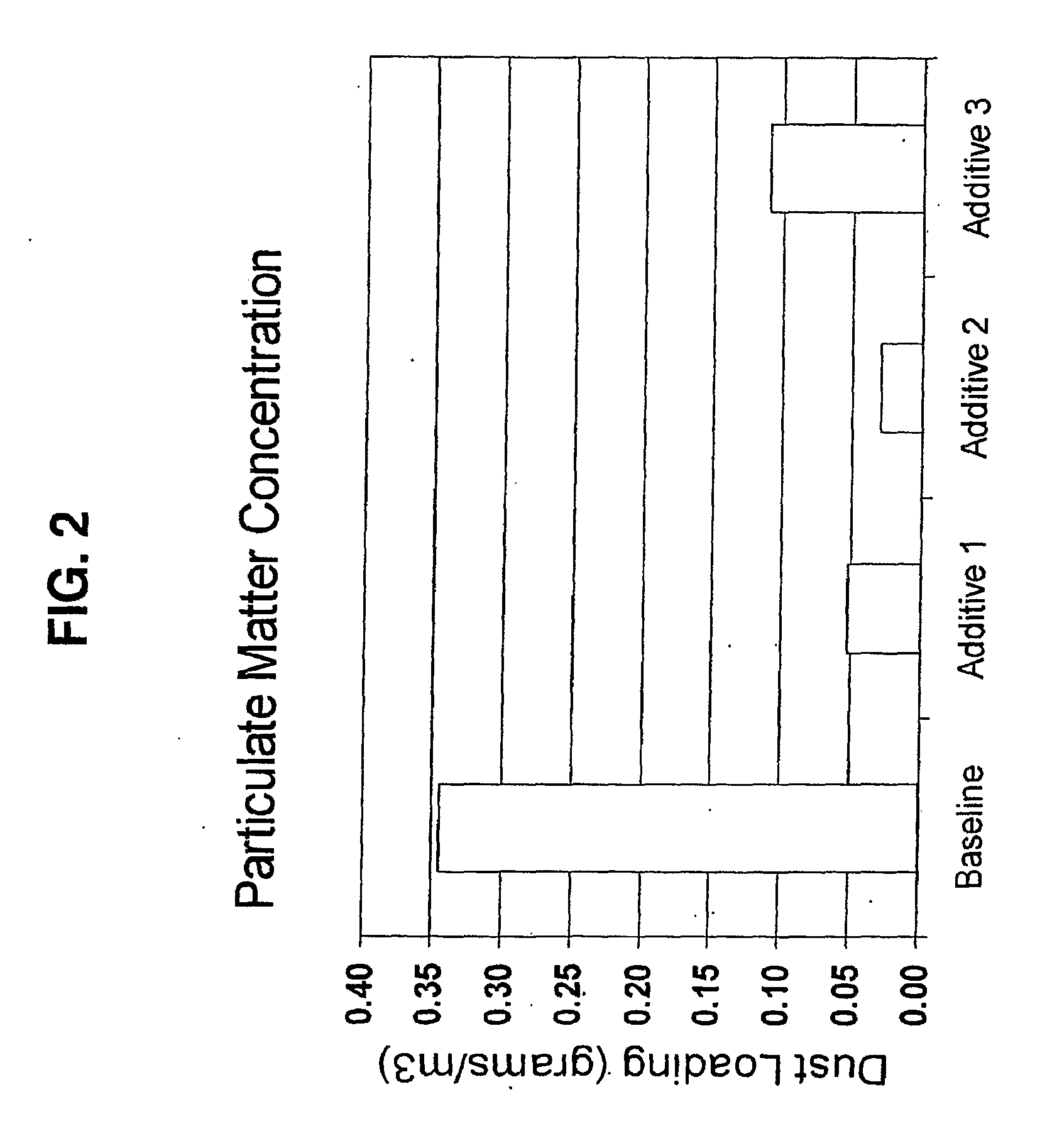

InactiveUS20090165365A1Improve combustion characteristicsReduce pollutant emissionsBiofuelsSolid fuelsCombustionOil additive

Fuel additives are disclosed for high-asphaltene carbonaceous fuels such as residual fuel oil or coal. Such additives provide improved combustion characteristics. Such improved combustion characteristics include one or both of improved efficiency and decreased emissions of pollutants. In particular, the fuel additives include an extract from a plant such as fescue, alfeque, or alfalfa, and optionally, an organometallic compound. The use of a fuel additive including both a plant extract and an organometallic compound is particularly useful in improving the combustion characteristics of fuels with particularly high asphaltene content.

Owner:AQ

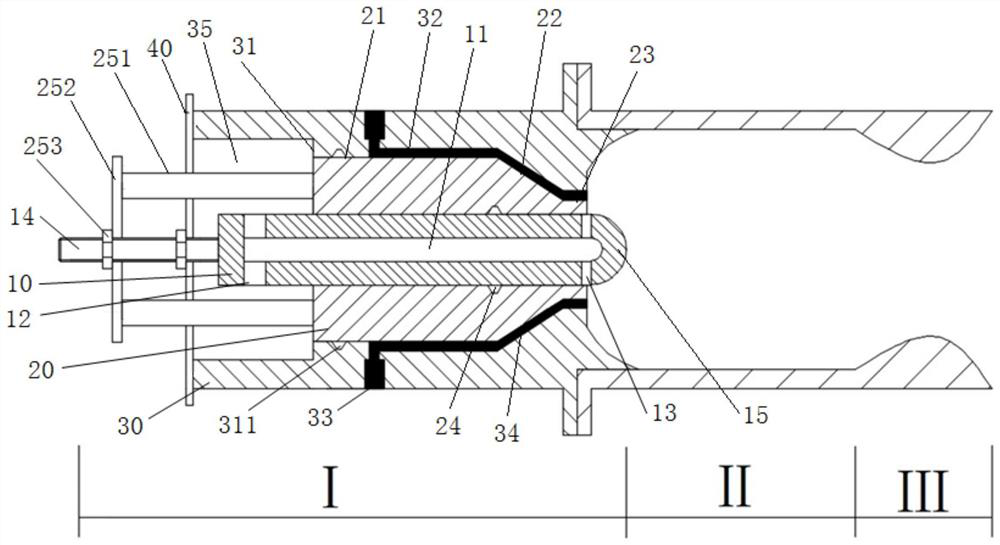

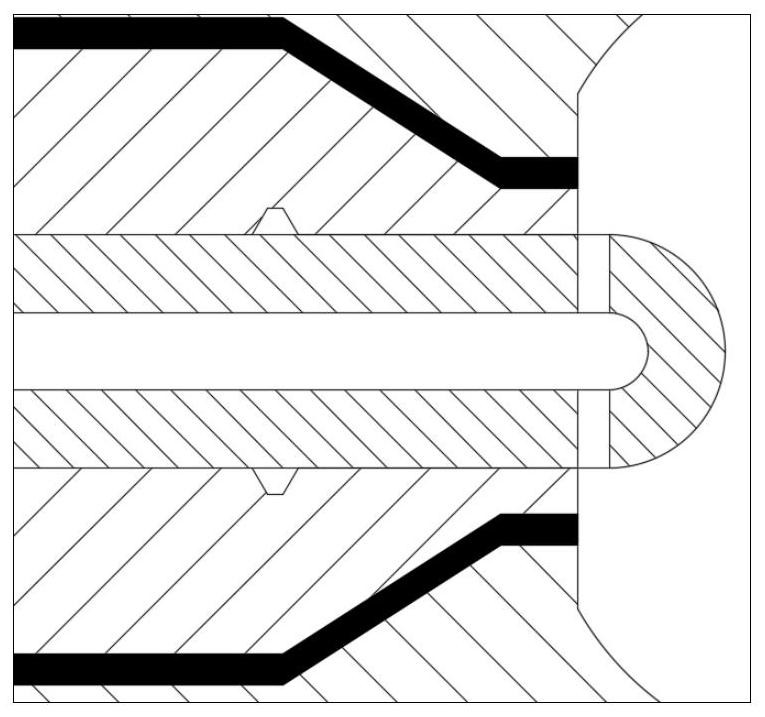

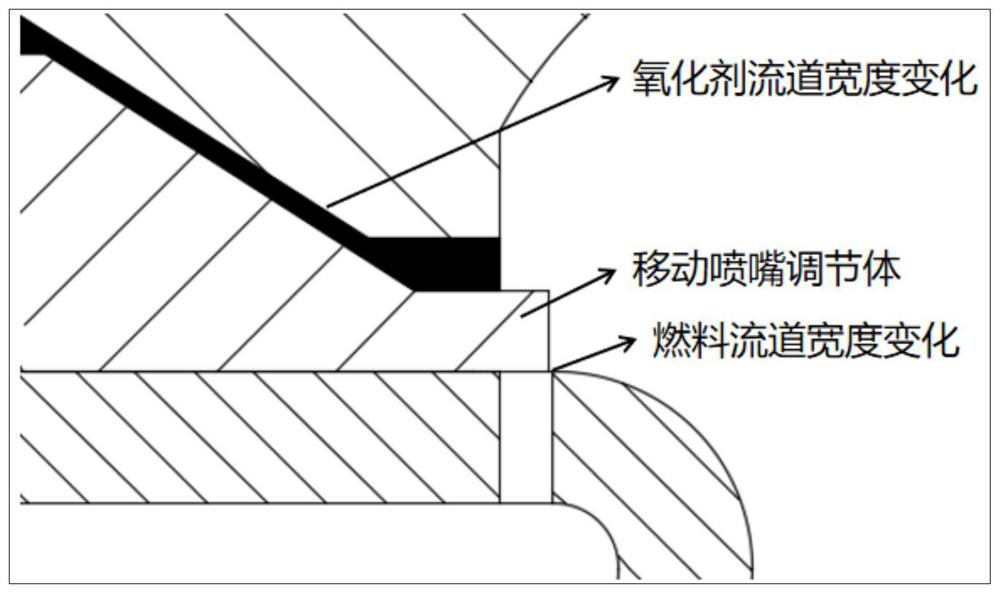

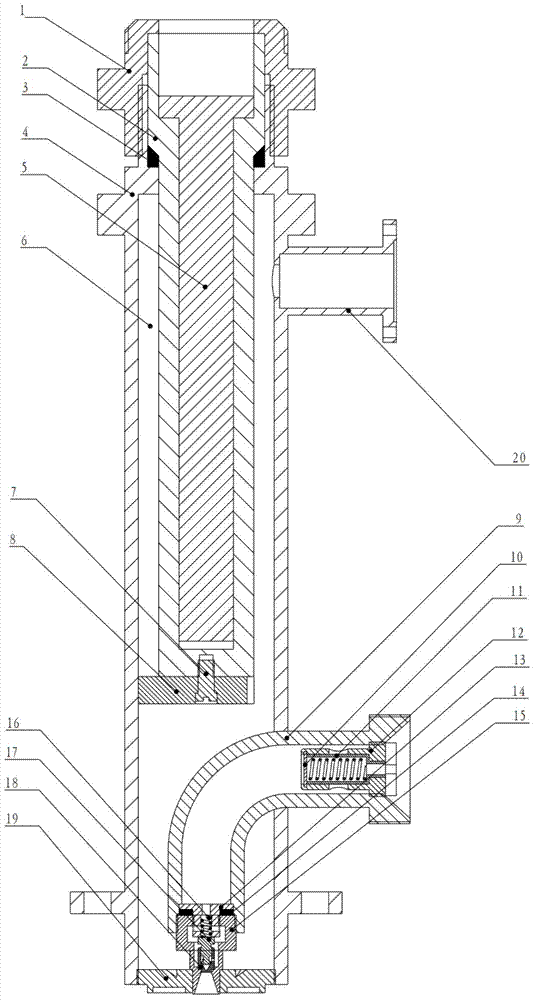

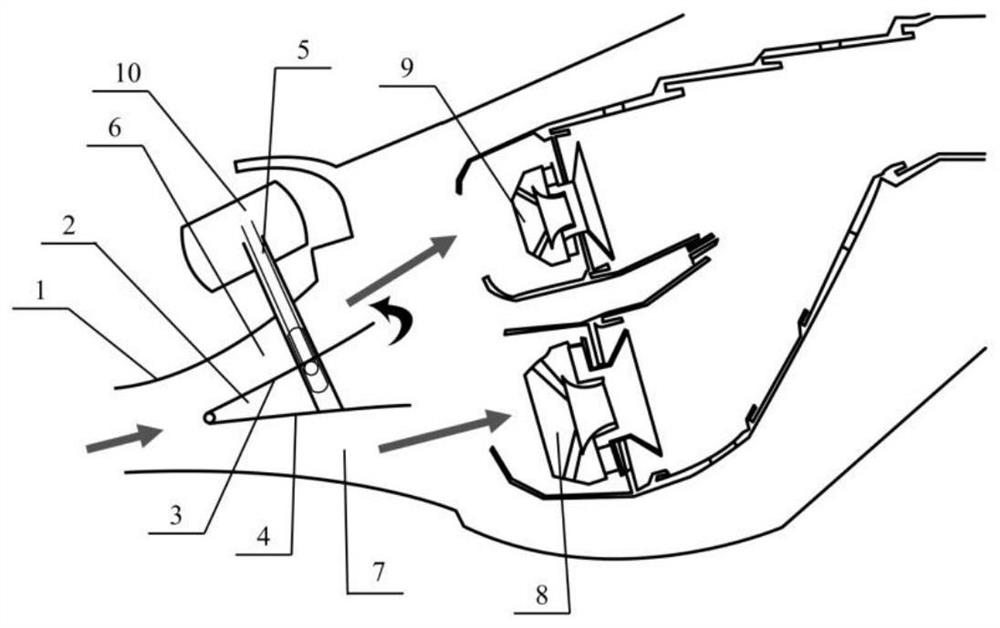

Two-component variable-thrust rotary detonation rocket engine based on pintle injector

ActiveCN113294264AStable mixing ratioReduce wasteRocket engine plantsCombustion chamberEquivalence ratio

The invention discloses a two-component variable-thrust rotary detonation rocket engine based on a pintle injector. The two-component variable-thrust rotary detonation rocket engine based on the pintle injector comprises the pintle injector, a rotary detonation combustion chamber and an exhaust nozzle which are sequentially and coaxially arranged in the axial direction; the pintle injector comprises a center rod inner nozzle, a nozzle adjusting body and an injector shell which are sequentially and coaxially arranged from inside to outside in a sleeving mode; a fuel injection runner is arranged in the center of the center rod inner nozzle, a plurality of fuel injection openings are formed in the head of the center rod inner nozzle in the circumferential direction, and a broken-line-shaped oxidizing agent runner is formed between the outer wall face of the inner side of the nozzle adjusting body and the inner wall face of the injector shell; and the nozzle adjusting body can slide in the axial direction, and therefore the injection area of the fuel injection openings and the sectional area of the oxidizing agent runner are adjusted. According to the two-component variable-thrust rotary detonation rocket engine based on the pintle injector, under the condition that the equivalence ratio is not changed, the flow of a two-component propellant can be changed, thrust can be generated and changed, a fuel flowing area can be stabilized and the combustion rate of fuel can be increased by effectively utilizing a backflow area at the head of a pintle, fuel waste is reduced, and the propellant is saved.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

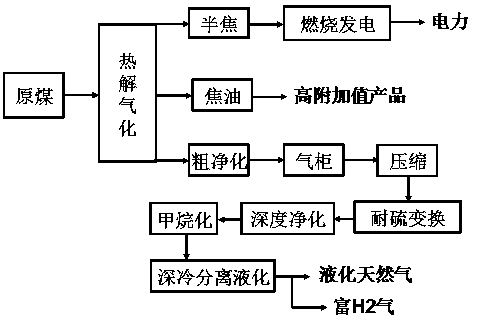

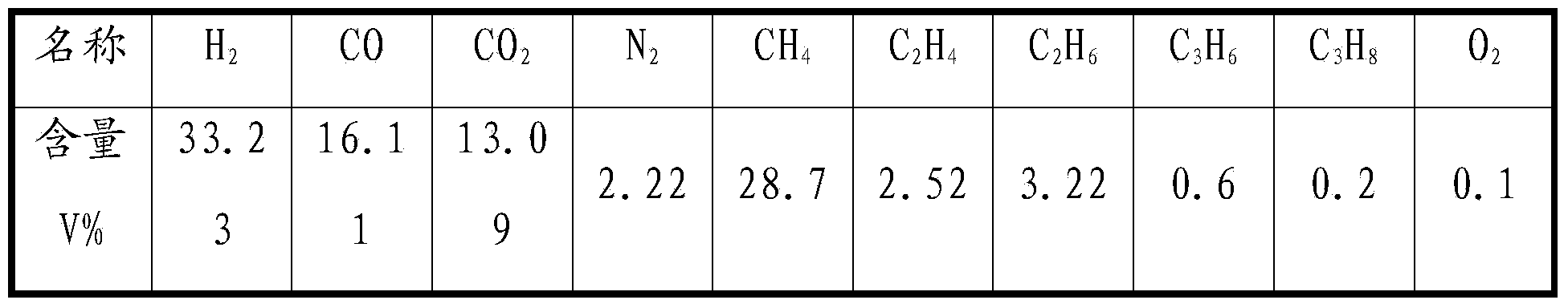

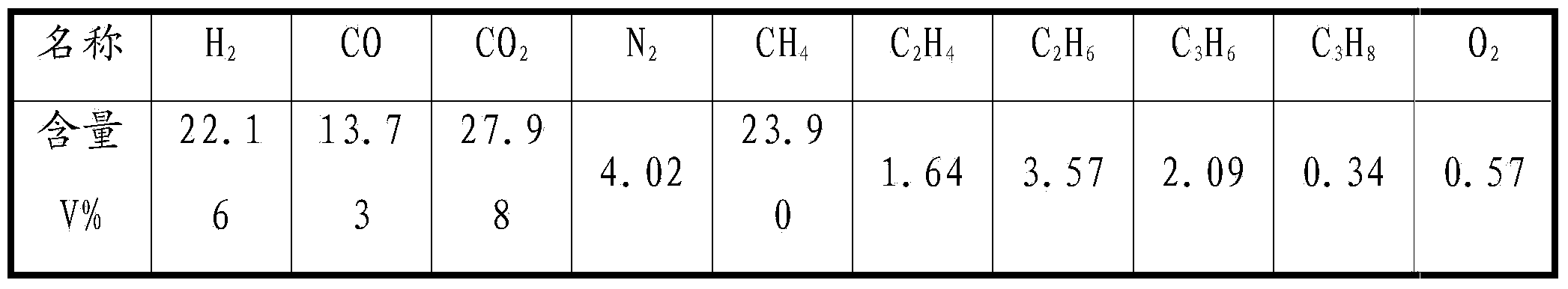

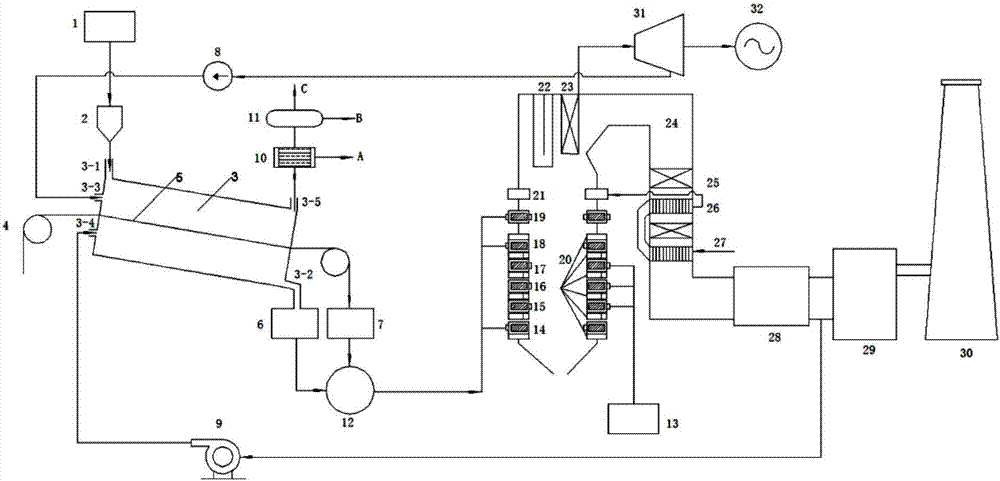

Process for co-producing LNG (Liquefied Natural Gas) by using pyrolysis gas generated in power generation system

InactiveCN103952197AHigh calorific valueImprove combustion characteristicsGaseous fuelsMethanationClean energy

The invention discloses a process for further co-producing LNG (Liquefied Natural Gas) by using pyrolysis gas generated after low-rank coal is used for generating power in a power generation system. According to the process, semi-cokes generated by coal in a pyrolyzing furnace and separated hot ash are fed into a power generating boiler system so as to be combusted and utilized, the generated power is used for LNG in the subsequent process, raw gas and fine ash particles generated through pyrolysis enter into a separation system, and products with high additional values can be extracted from the separated tar. The process specifically comprises the following steps of pressurizing the raw gas and then entering into a pretreatment process; removing impurities such as dust, oil tar, naphthalene and H2S in the raw gas; compressing pre-purified gas and then entering into units such as a pyrolysis gas deep purification unit, a methanation unit and cryopenic separation and liquidation units, thereby preparing clean energy liquefied natural gas which is short in China. According to the invention, coal pyrolysis and gasification are organically combined with gas, chemical, electric and heat production processes on the basis that heat supply and power generation are carried out by taking semi-cokes as solid fuels, so that graded transformation and step-by-step extraction of coal as well as economic benefit maximization are realized, the energy utilization efficiency is increased, and the economical efficiencies of thermoelectricity enterprises are increased.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

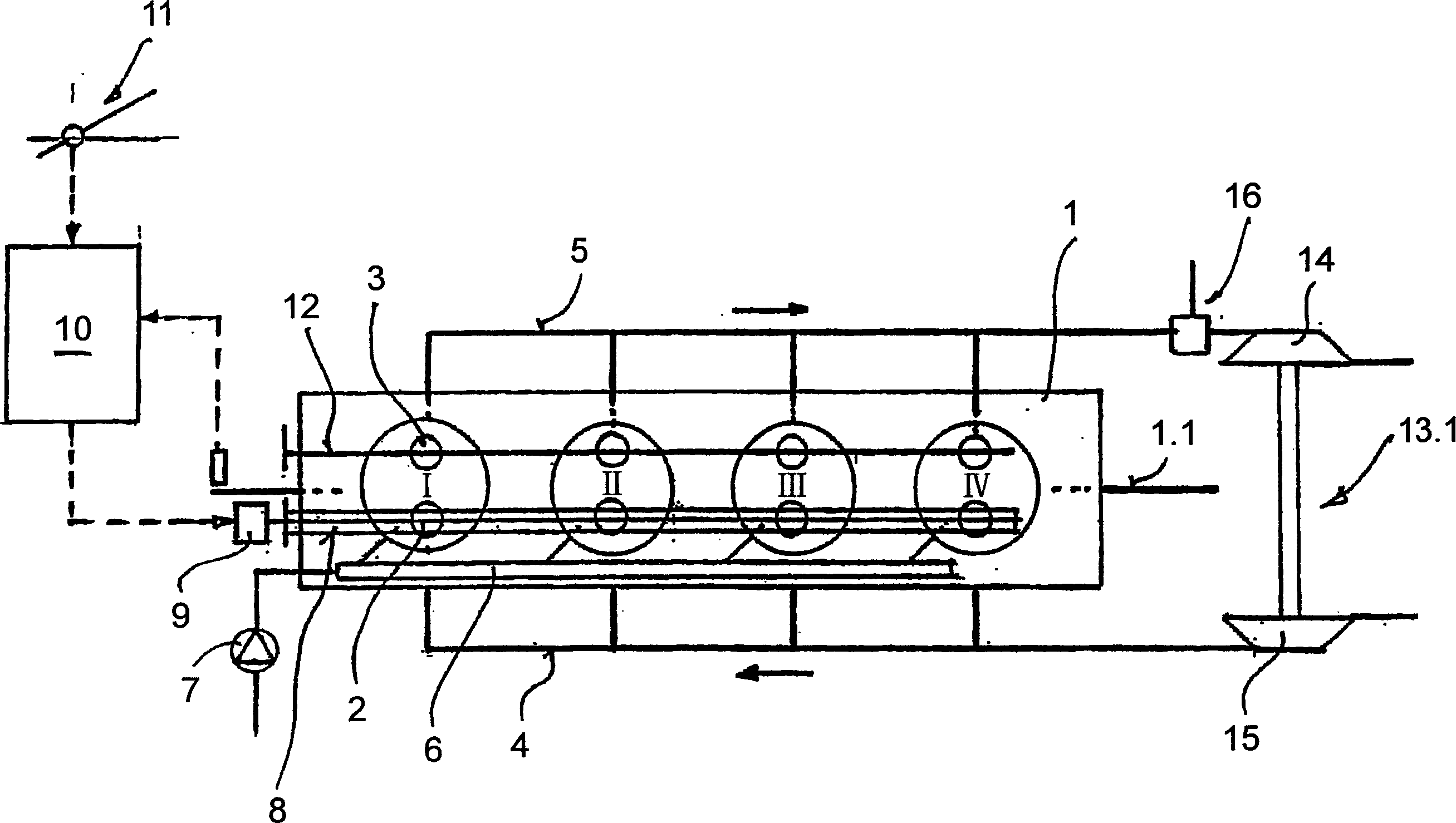

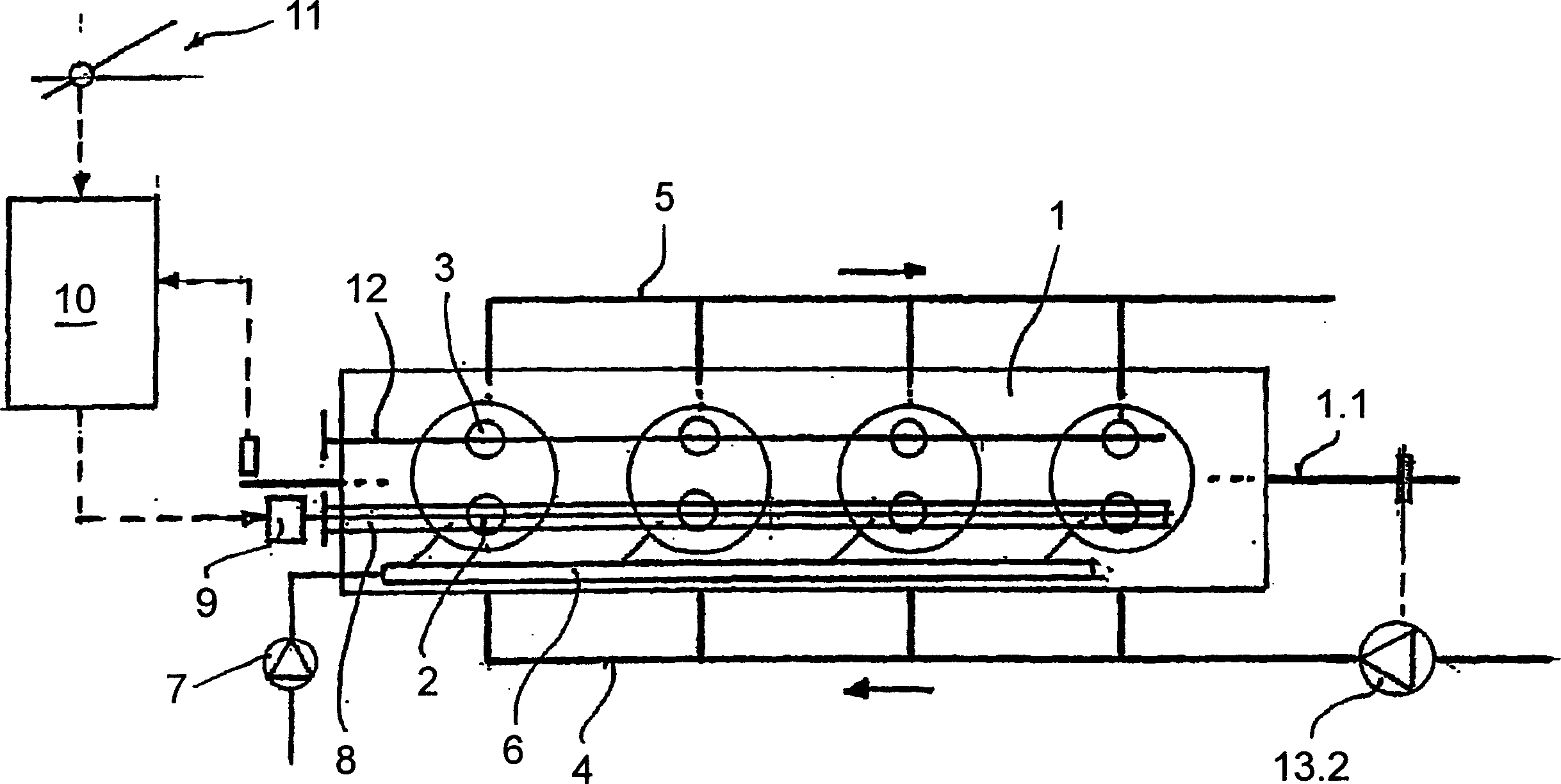

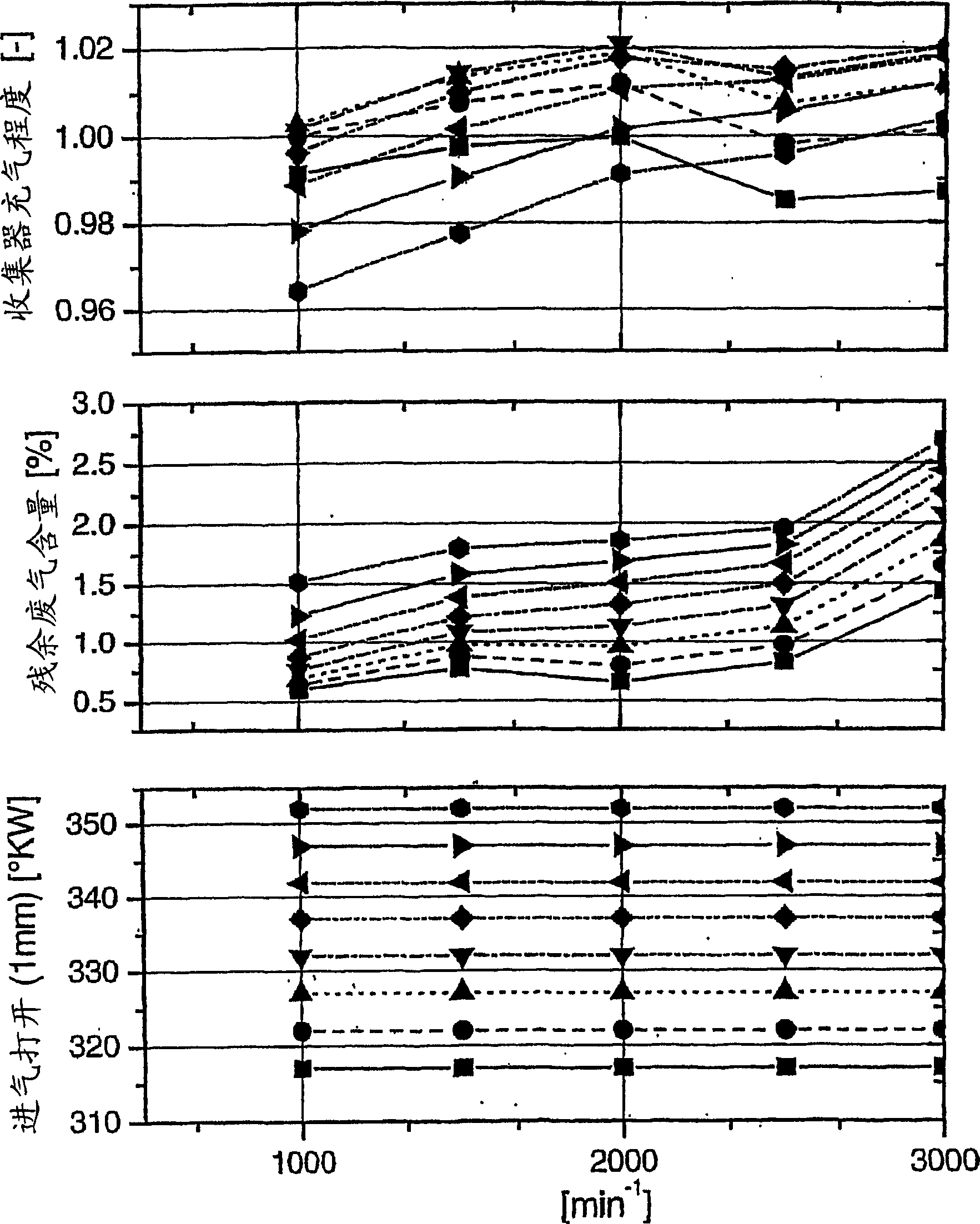

Method for optimizing the operation of a charged reciprocating internal combustion engine in the lower engine speed range

InactiveCN1863993AIncrease consumption levelSweeping reductionElectrical controlInternal combustion piston enginesTop dead centerCharge exchange

The invention relates to a method for operating a fuel-injected, especially a directly fuel-injected, reciprocating internal combustion engine. Said engine comprises at least one outlet valve per cylinder, communicating with an exhaust gas installation, and at least one inlet valve, communicating with an air inlet installation, and means for increasing the boost pressure in the air inlet installation. The method is characterized in that a control device for variably adjusting at least the opening times of the inlet valves is provided and that in the lower engine speed range the inlet opening times of the inlet valves can be adjusted via the control device in such a manner that there is a valve overlap with the closing time of the corresponding outlet valves, thereby scavenging the cylinder with fresh charge air before charge exchange in the area of top dead center.

Owner:FEV

Hybrid fuel and method for preparing the same

The invention discloses a composite fuel production method, which is characterized by the following: mixing the raw coal powder, vegetable fuel powder, sulfur-fixed agent, adhesive, hardener and oxygenation agent according to proportion with water; producing particle through particle moulding equipment; drying naturally into product. The invention reduces the environmental pollution, which is fit for industrial and civil fuel heat supply device.

Owner:魏文烃

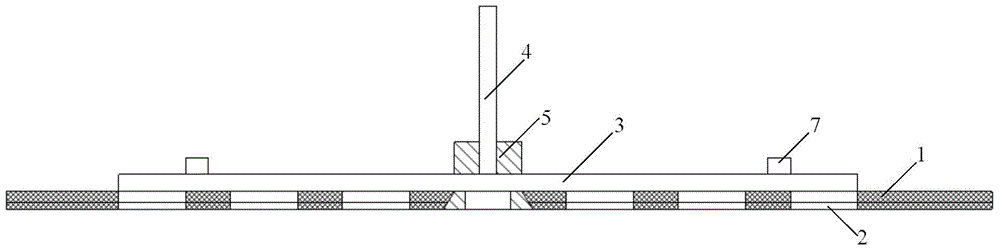

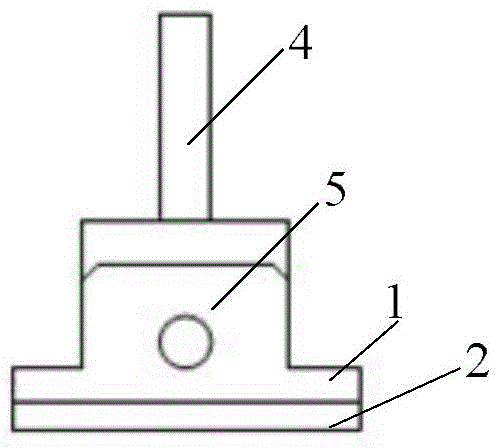

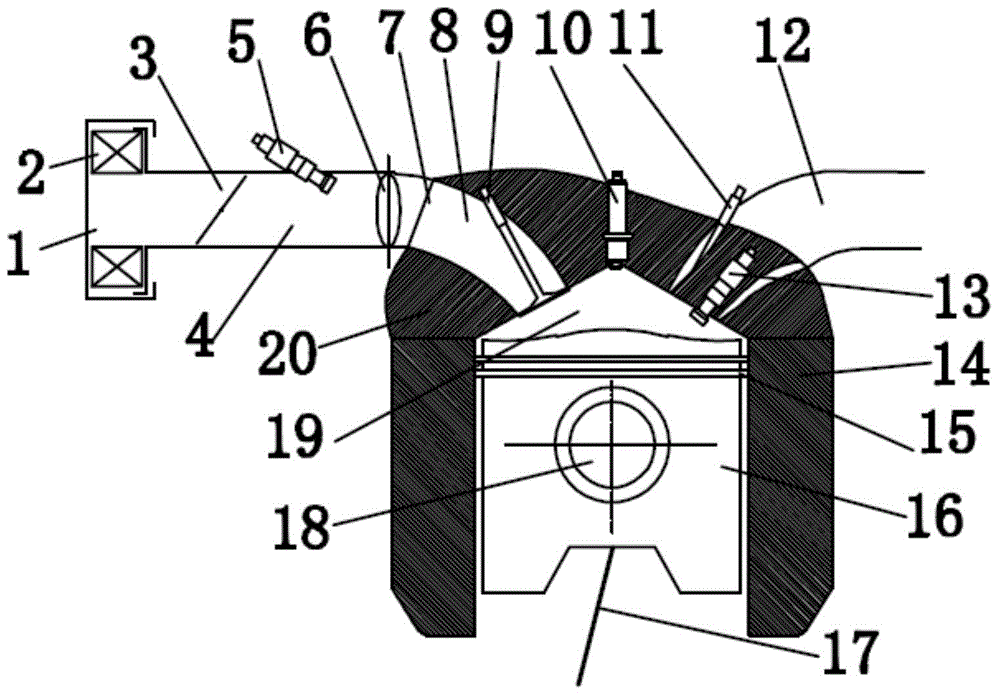

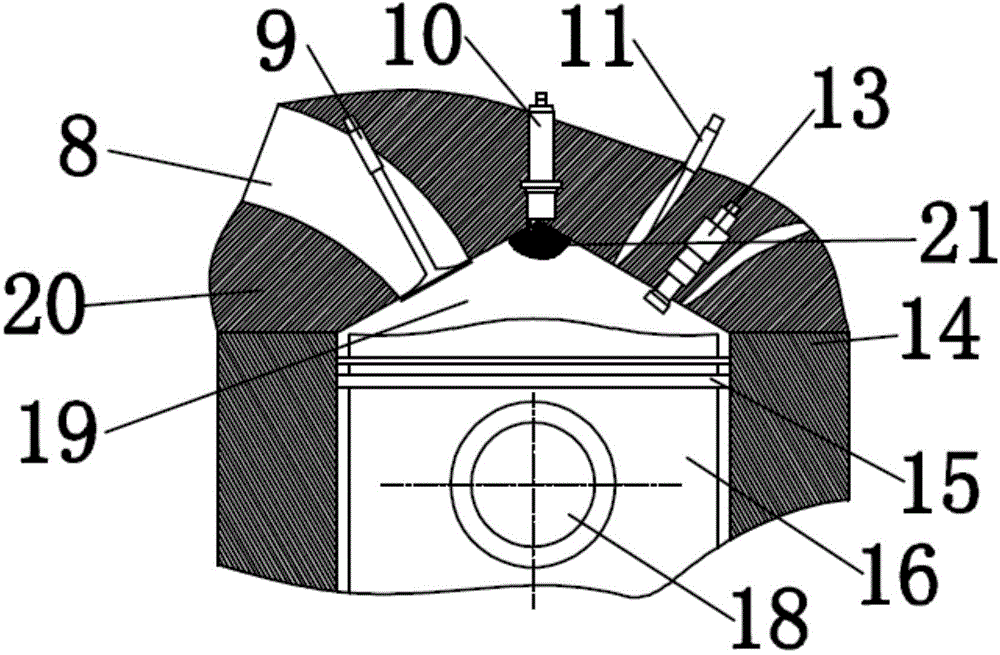

Low temperature plasma ignition device for internal combustion engine and internal combustion engine

ActiveCN104976016ADoes not affect ionizationImprove combustion characteristicsEngine ignitionMachines/enginesElectricityExternal combustion engine

The invention discloses a low temperature plasma ignition device for an internal combustion engine. The low temperature plasma ignition device comprises a medium plate in a sheet shape and arranged on the bottom of a combustion chamber of the internal combustion engine, a sensing electrode in a sheet shape and arranged on one side of the medium plate, and a discharging electrode arranged on the other side of the medium plate and electrically connected with a high pressure ignition coil. The invention further discloses an internal combustion engine comprising an air cylinder and any one low temperature plasma ignition device disposed in the air cylinder. The low temperature plasma ignition device can discharge along a dielectric surface and achieve quick and large scale ignition for a gasoline engine; inflammable hybrid gas can quickly burn; energy use and emission can be reduced, so contribution is made to haze elimination; and strong automobile power is provided and an energy-saving emission-reduction novel gasoline engine with advanced combustion technology is created.

Owner:邸绍斌

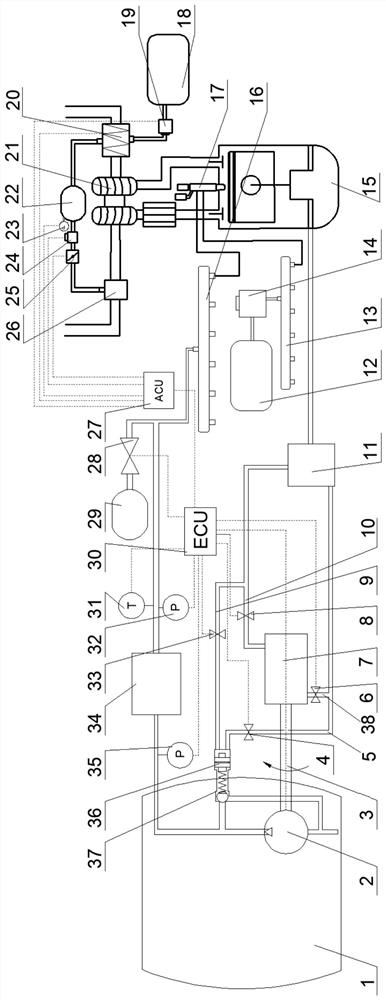

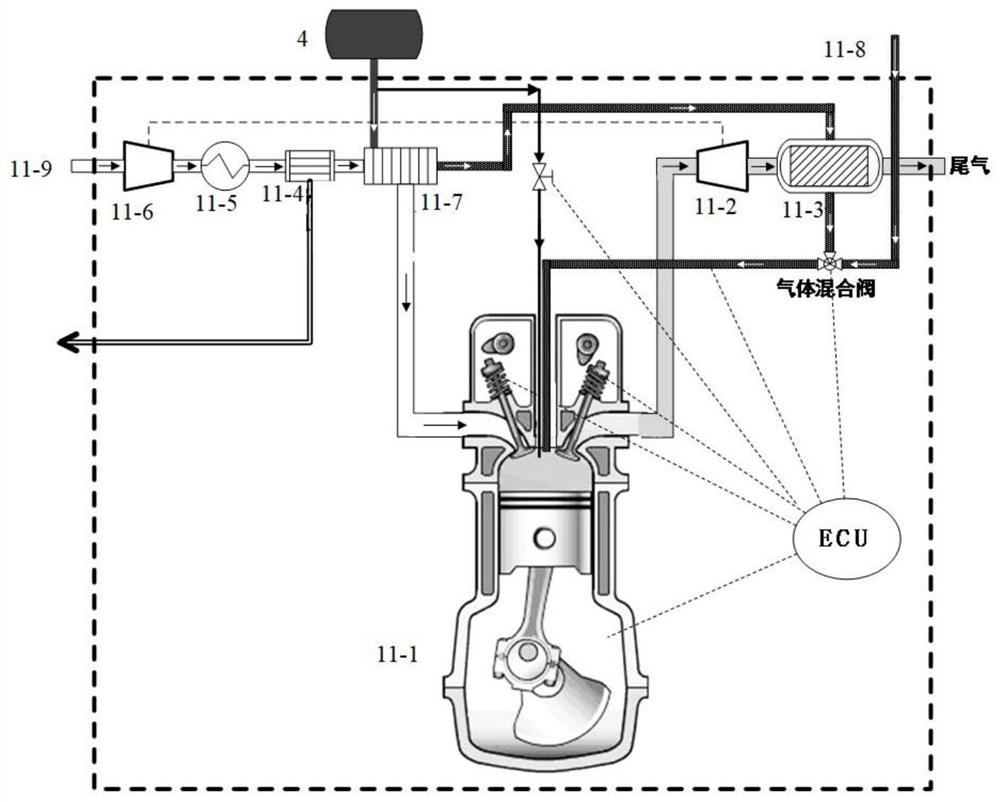

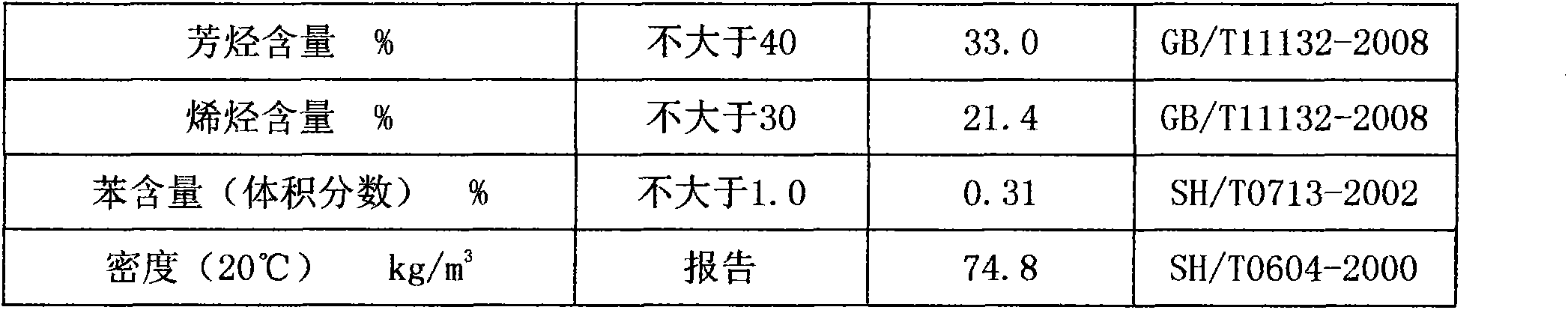

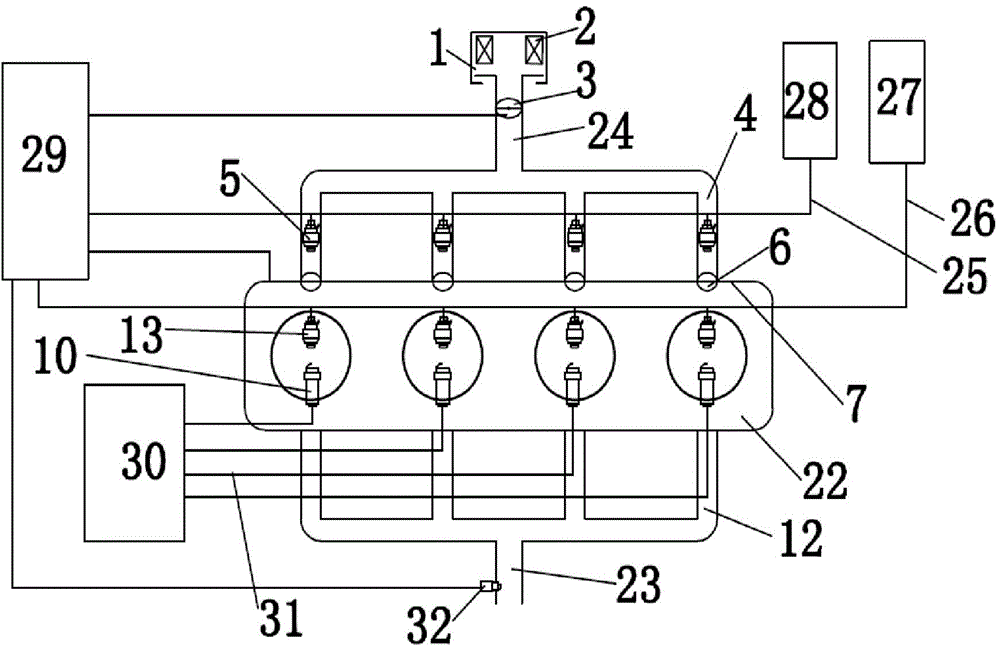

Direct injection natural gas engine system based on ammonia pyrolysis device and control method of direct injection natural gas engine system

ActiveCN112901339AReduce consumptionPromote combustionProcess control/regulationElectrical controlCatalytic pyrolysisGear pump

The invention discloses a direct injection natural gas engine system based on an ammonia pyrolysis device and a control method of the direct injection natural gas engine system. The engine system comprises an LNG boost pressure regulation and control device, an ammonia pyrolysis device and an ammonia pyrolysis device electric control unit. The control method comprises the steps of controlling the fuel gas supply process and controlling the ammonia pyrolysis device. According to the ammonia pyrolysis device, catalytic pyrolysis of ammonia is achieved, liquid ammonia is converted into ammonia pyrolysis gas, the ammonia pyrolysis gas is introduced into a gas inlet system of a high-pressure direct injection natural gas engine, a proper amount of the ammonia pyrolysis gas is supplied to an engine cylinder in the gas inlet process of the engine, the ammonia pyrolysis gas is optimized, combustion in the cylinder is improved, HC emission is reduced, and the high emission standard is met; and according to the LNG boost pressure regulation and control device, the original plunger pump boosting mode is improved into the combined application of an internal gear pump and the LNG boost pressure regulation and control device, and the high-pressure direct injection natural gas engine works under the working conditions of the optimal LNG boost pressure and the optimal LNG flow according to the pressure and the flow.

Owner:HEBEI UNIV OF TECH

Dual-fuel nozzle for plasma catalysis gaseous fuel

InactiveCN103900106AAchieve co-firingImprove economyContinuous combustion chamberEngineeringProduct gas

The invention provides a dual-fuel nozzle for plasma catalysis gaseous fuel. The dual-fuel nozzle for the plasma catalysis gaseous fuel mainly comprises a low-temperature plasma discharging assembly, a gas circuit assembly, an oil circuit assembly and a nozzle fixing device. Cracked gas fuel enters an annular discharging gap of the low-temperature plasma discharging assembly in the radial direction and has a reforming reaction under the low-temperature plasma catalytic action to be converted into reformed gas with the higher heat value, a gas plasma micelle remaining after the catalytic reaction can be contained inside the reformed gas, the inflammability of the reformed gas is improved, finally the reformed gas flows out in a rotating mode through a gas flow guiding plate to form a recirculating zone, and the stability of burning is improved. According to the dual-fuel nozzle for the plasma catalysis gaseous fuel, the oil circuit assembly stretches into an external electrode of the low-temperature plasma discharging assembly, space can be saved, the oil supply states of oil and gas circuits can be controlled, the oil and gas circuits can be closed independently or simultaneously, the requirements for starting power and variable working condition power are met, the gas circuit assembly can also be utilized for spraying water, and NOx emission is reduced.

Owner:HARBIN ENG UNIV

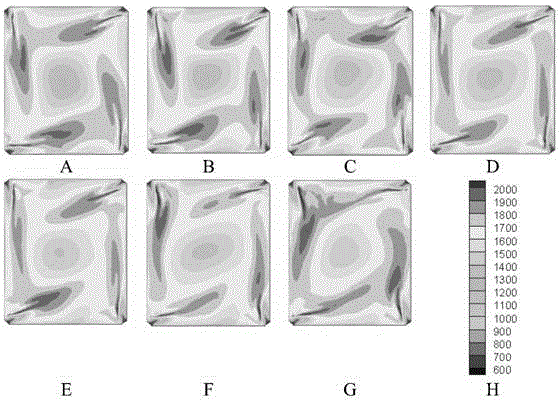

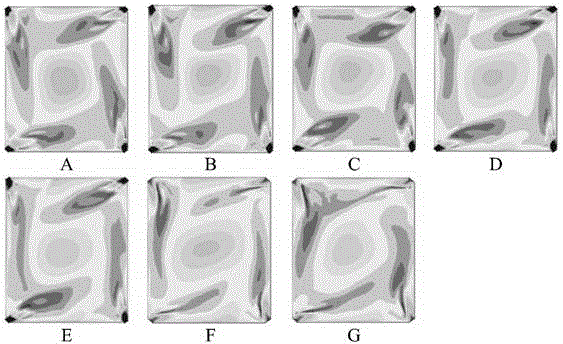

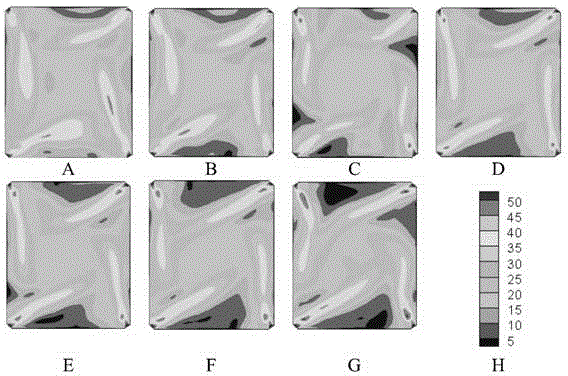

Acquisition method of combustion characteristic under different circumference air quantities after boiler improvement

ActiveCN103955599AImprove combustion characteristicsReproduce the combustion situationSpecial data processing applicationsAir volumeLow nitrogen

The invention discloses an acquisition method of a combustion characteristic under different circumference air quantities after boiler improvement, and belongs to the technical field of coal-fired boilers. According to the method, after meshing is carried out on a corner tangential firing boiler added with SOFA air, a structured grid model of the boiler is established, and combustor parameters, boundary condition parameters and coal powder parameters of the boiler are acquired; then, a mathematical model is established on the foundation to carry out combustion analog computation, so that the combustion characteristic of the boiler under different circumference air quantities is acquired. With the method, the combustion condition inside the boiler can accurately reappear, and total information of combustion condition inside the boiler is acquired, thus guidance is provided for low-nitrogen improvement added with SOFA air for the boiler, and comprehensive evaluation is carried out on the effect after low-nitrogen improvement.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

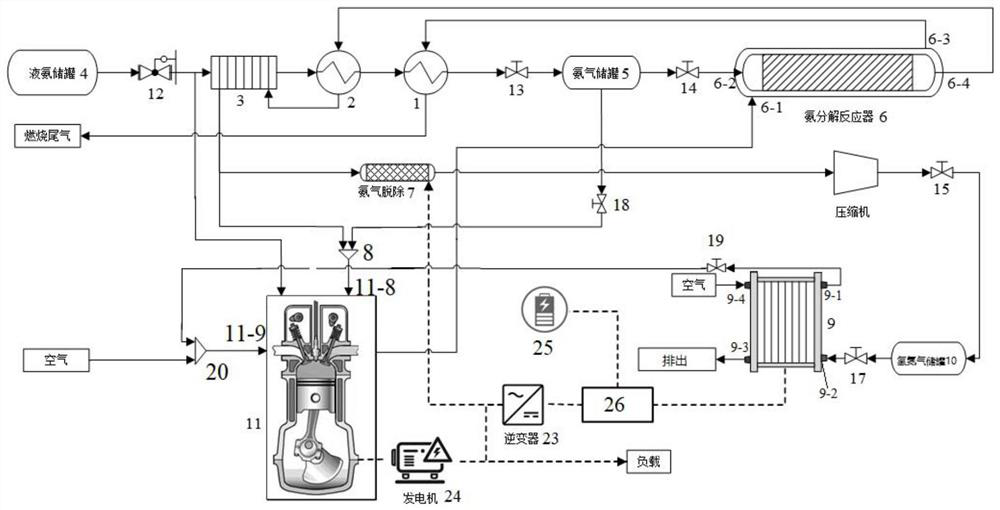

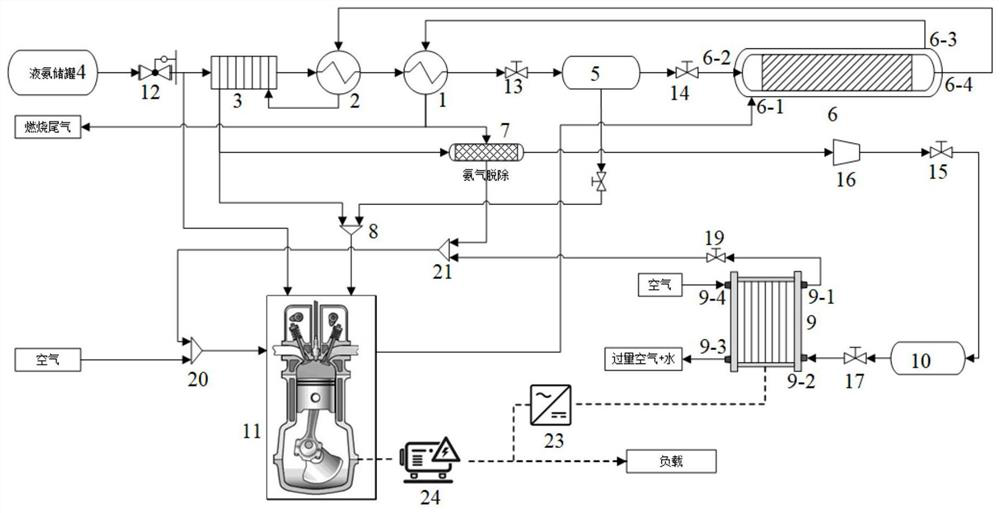

Supercharged engine and ammonia fuel hybrid power generation system

InactiveCN112761826AImprove inflation coefficientIncrease inflation coefficientInternal combustion piston enginesReactant parameters controlInternal combustion engineTurbine

The invention belongs to the technical field of ammonia decomposition, and particularly relates to a supercharged engine and an ammonia fuel hybrid power generation system. The supercharged engine comprises an internal combustion engine, a membrane separation assembly and an ammonia decomposition reaction assembly, wherein first gas is compressed and then enters the membrane separation assembly, nitrogen-rich gas and oxygen-rich gas are obtained through separation, the oxygen-rich gas exchanges heat with liquid ammonia from a liquid ammonia storage tank through a vaporizer assembly, then the oxygen-rich gas enters the internal combustion engine, and the liquid ammonia exchanges heat with the oxygen-rich gas through a vaporizer and then enters the ammonia decomposition reaction assembly to be subjected to ammonia decomposition reaction; tail gas generated by the internal combustion engine enters a turbine to do work, and the turbine drives a first compressor to compress the first gas; the first gas enters the membrane separation assembly after being compressed, oxygen-nitrogen separation or hydrogen-oxygen-nitrogen separation is achieved, the oxygen-rich gas enters the internal combustion engine, and the combustion characteristic is improved; and meanwhile, the oxygen-rich gas and the liquid ammonia exchange heat in the vaporizer, the temperature of the oxygen-rich gas is reduced, the temperature of the liquid ammonia is increased, the liquid ammonia is gasified into gas, and the inflation coefficient of the internal combustion engine is increased.

Owner:FUZHOU UNIV ASSET MANAGEMENT CO LTD

Natural gas re-burning nozzle for coal boiler

InactiveCN1483962AGood for burnoutPromote reductionDispersed particle separationIncinerator apparatusCombustionNitrogen oxide

The present invention relates to a coal-fired boiler natural gas secondary combustion nozzle, and is characterized by that the uniformly-layered arranged oblique-jet holes are cut on the semi-periphery of the jet pipe, and the included angle of the axis of oblique jet hole and axis of jet pipe is 15-75 deg., and on the end cover of the jet pipe the axial jet holes parallel to the axis of jet pipe are uniformly cut. Said invention can completely burn the natural gas, and does not produce fire-retardant carbon black.

Owner:SHANGHAI JIAO TONG UNIV

System and method for ultralow volatile carbon-based fuel and lignite low-NOx blending combustion

ActiveCN107289444AFully dryTake advantage ofDrying gas arrangementsStaged combustionAir preheaterSuperheater

The invention discloses a system and a method for lignite and ultralow volatile carbon-based fuel low-NOx blending combustion. The system comprises a lignite drying system consisting of a crusher, a drying box, a small-particle-size drying lignite bin, a large-particle-size drying lignite bin, a steam pump, a tail gas purifying unit, a hot smoke pipe, a steam pipe and the like, and a ultralow volatile carbon-based fuel and drying lignite blending combustion system consisting of a fan coal mill, an ultralow volatile carbon-based fuel powder bin, fuel nozzles, a combustor secondary wind nozzle, an over fire air nozzle, a superheater, a tail flue, a coal economizer, an air preheater, a dust remover, a desulfurization device, an over fire air pipe and the like. A lignite drying technology is organically combined with the ultralow volatile carbon-based fuel and drying lignite blending combustion system, so that lignite is safely and effectively used, the problem of difficult ignition and burnout of ultralow volatile carbon-based fuels is solved, and NOx emission is reduced. The system is economical, environmentally friendly, simple, reliable, wide in application range and broad in application prospect.

Owner:XI AN JIAOTONG UNIV

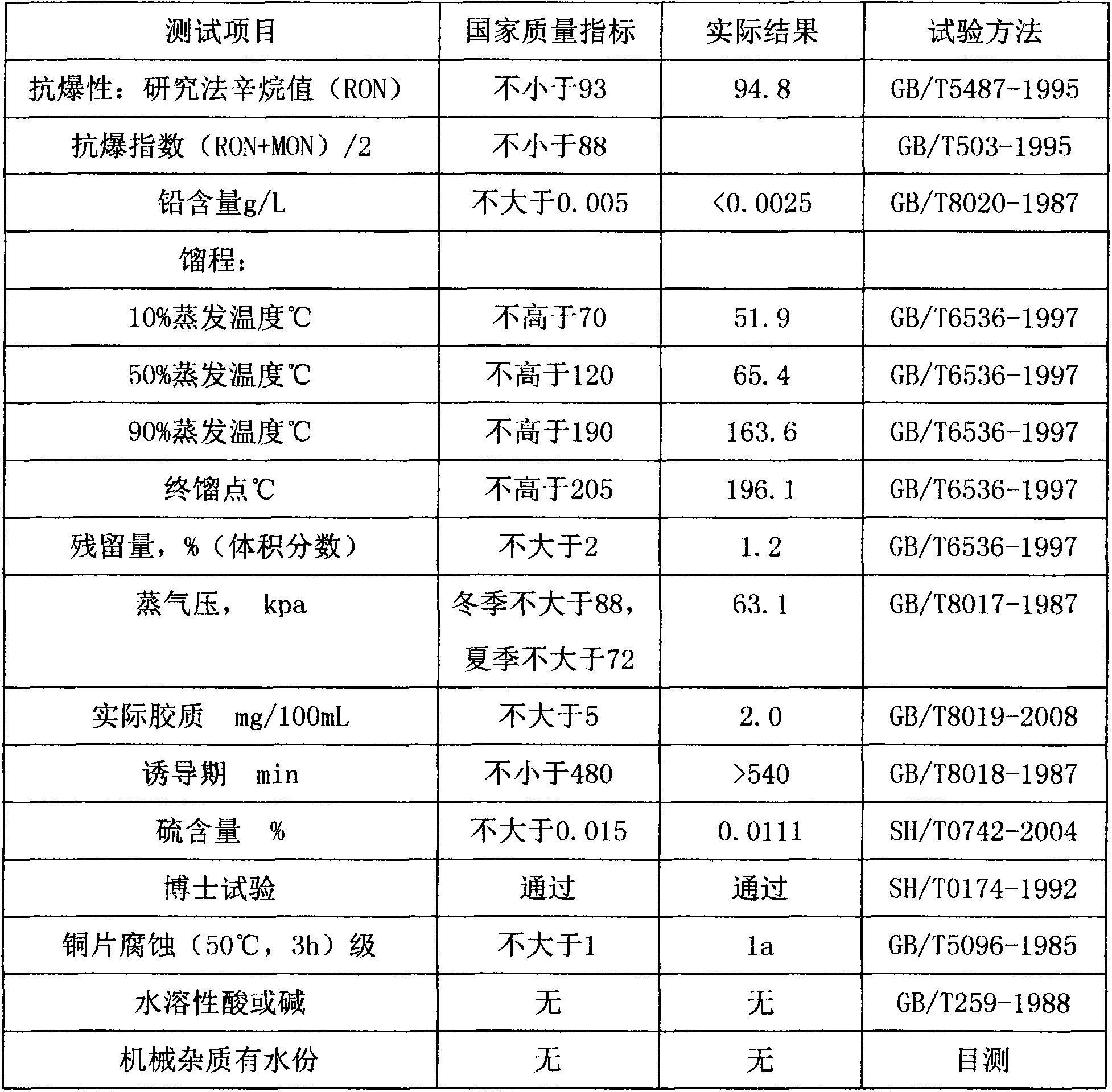

Methanol gasoline for vehicle and preparation method thereof

InactiveCN104004551AImprove combustion characteristicsIncrease profitLiquid carbonaceous fuelsAlternative fuelsTert butyl

The invention discloses methanol gasoline for a vehicle and a preparation method thereof. The methanol gasoline is prepared from the following raw materials in parts by weight: 60-70 parts of methanol, 15-25 parts of 90# gasoline, 10-15 parts of dipropylene glycol methyl ether acetate, 5-10 parts of tert amyl methyl ether, 5-10 parts of dimethyl carbonate, 4-8 parts of diethylene glycol dimethyl ether, 3-6 parts of 2,2-dimethoxypropane, 1-2 parts of ferrocene, 0.5-1.5 parts of methyl cyclopentadiene tricarbonyl manganese, 0.8-1.4 parts of 2,5-di-tert-butyl hydroquinone, 0.4-0.8 part of glycerol monolaurate, 0.5-1 part of sodium petroleum sulfonate, 0.3-0.6 part of N-Polyoxyethylated-N-tallow-alkylamine, 5-10 parts of wood tar, 3-6 parts of isopropanol, 2.5-4.5 parts of fish meal, 2-3 parts of bone meal, 1-2 parts of stearic acid and 0.5-1 part of urotropine. The methanol gasoline disclosed by the invention is favorable in combustion characteristic, high in utilization ratio, favorable in anti-detonating quality, low in corrosivity, high in safety and reliability, energy-saving and environment-friendly, can be used instead of any of 90#, 93#, 97# and 98# gasoline for a vehicle, is novel environment-friendly alternative fuel, and can reduce pollutant emission and carbon emission; and the combustion emission of the methanol gasoline meets the standards in Europe and America. The methanol gasoline has excellent economic benefits and far-reaching social benefits.

Owner:BEIJING DAMING QIAOHUA ENERGY SCI & TECH

Part control phase change air preheating system and air preheating method

InactiveCN103115377AImprove securityImprove adaptabilityCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention relates to a part control phase change air preheating system and an air preheating method. The part control phase change air preheating system and the air preheating method well solve the coupling problem of traditional air preheater low temperature corrosion and heat efficiency, an operating method of the air preheating system can be timely adjusted according to actual operation parameters, adjusting capability is greatly increased, and not only is economy and high efficiency of a thermal circulation system guaranteed, but also security and adaptability of the air preheating system can be improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

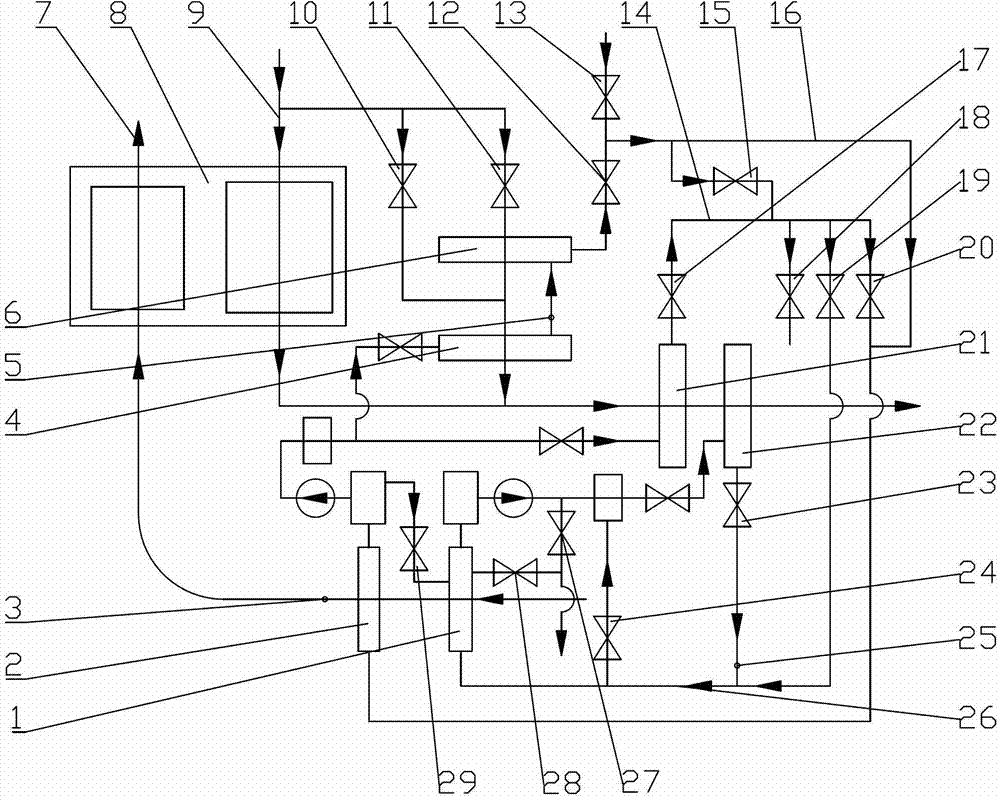

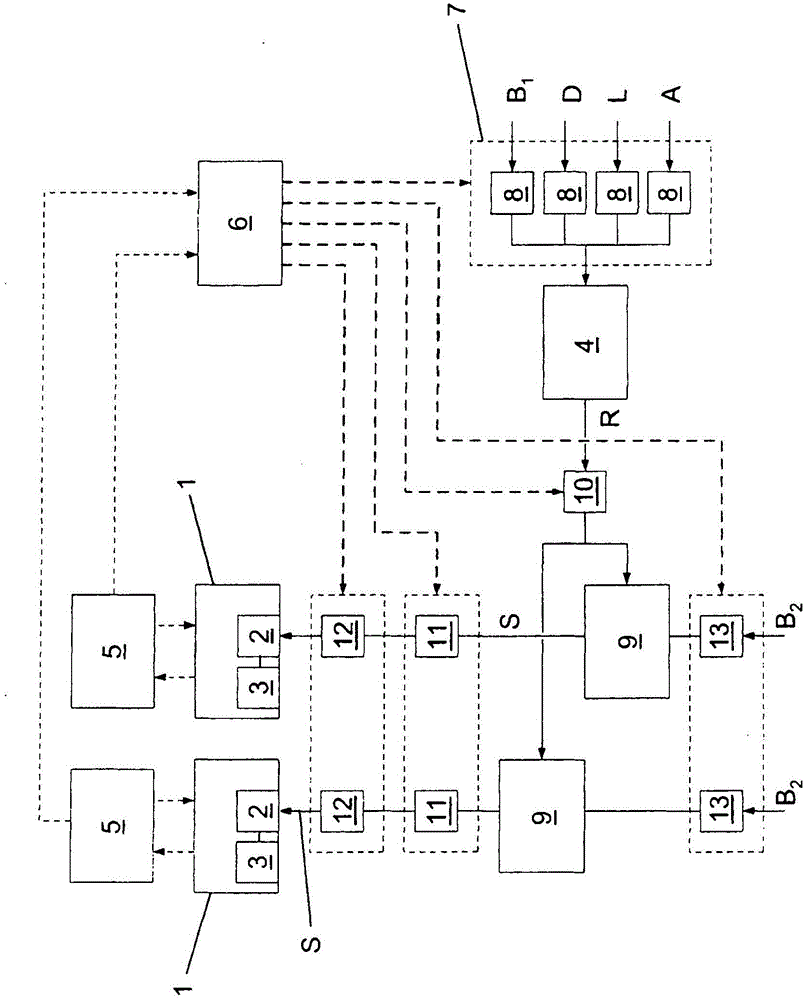

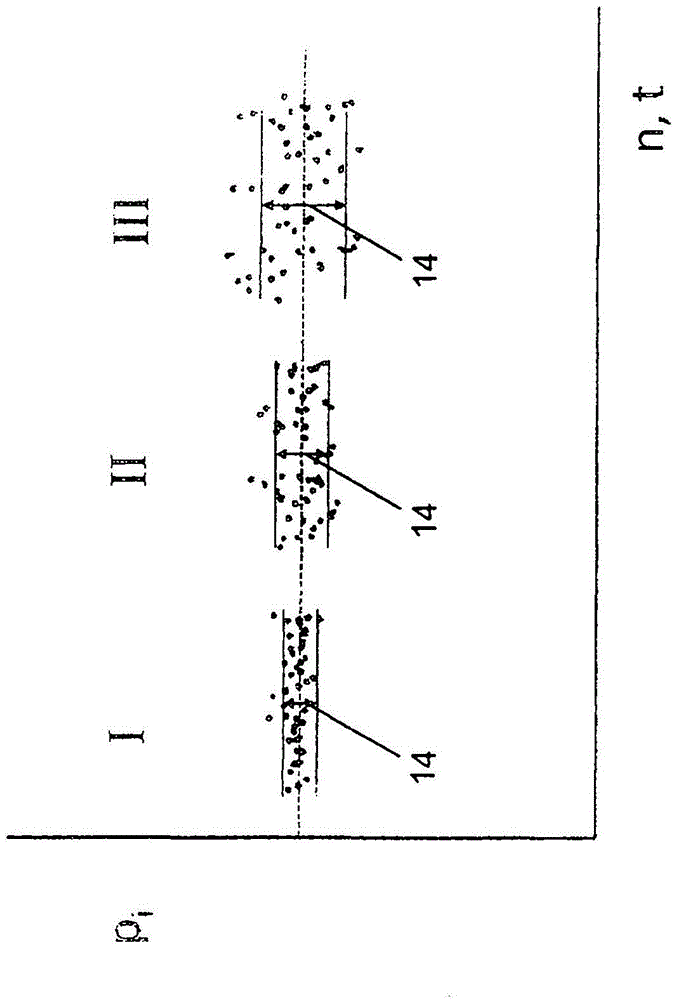

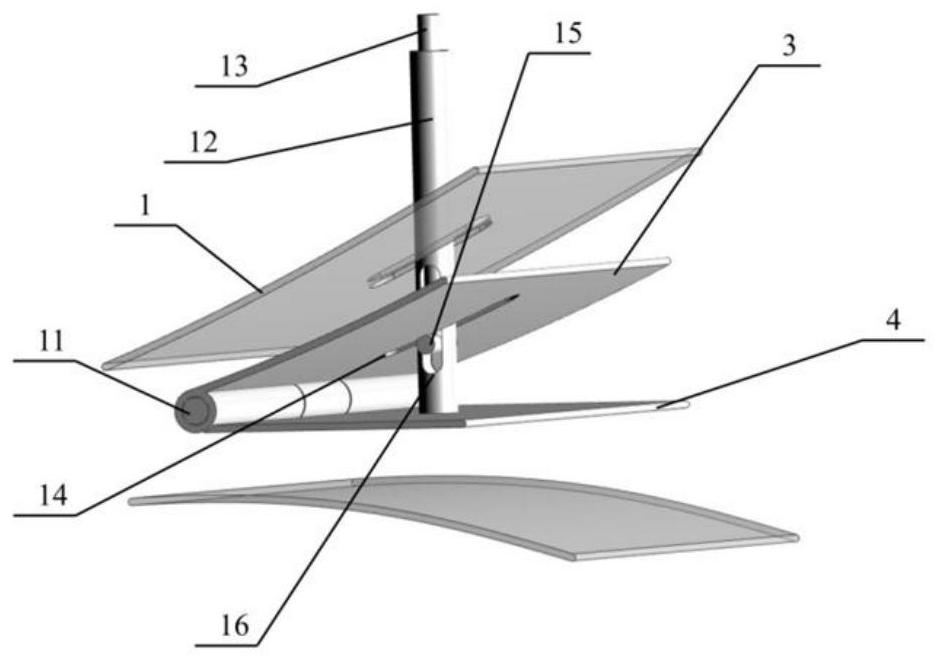

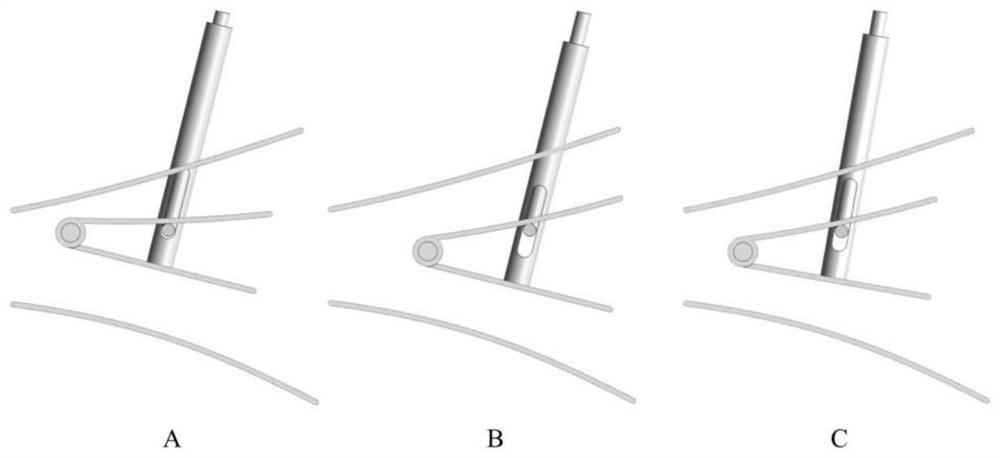

Method for operating at least one precombustion chamber-fired internal combustion engine

InactiveCN103958865AImprove combustion characteristicsBest chemical compositionElectrical controlInternal combustion piston enginesChemical compositionOtto cycle

The invention relates to a method for operating at least one precombustion chamber-fired internal combustion engine (1), in particular a stationary gas Otto cycle engine, having a pilot chamber (2) and a main combustion chamber (3) associated with the precombustion chamber (2), wherein a gas mixture is fed to the precombustion chamber (2) as flushing gas (S), wherein a synthesis gas (R) generated in a fuel reformer (4) and a fuel (B2) from a fuel source are fed to the flushing gas (S) and wherein a fuel (B1) and at least one further substance stream (D, L, A) are fed to the fuel reformer (4) for the reforming process, wherein at least one operating parameter of the at least one internal combustion engine is monitored, wherein in accordance with a change in the at least one operating parameter the chemical composition of the flushing gas (S); is modified by changing the mass stream of the at least one further substance stream (D, L, A).

Owner:GE JENBACHER

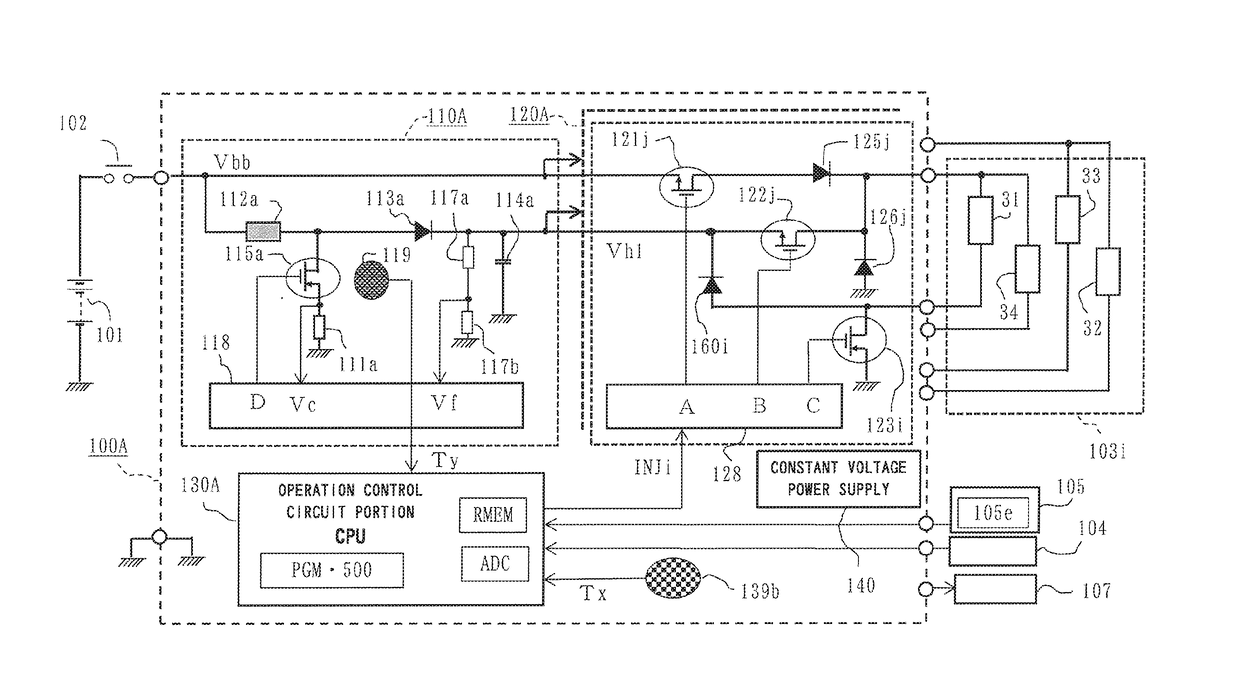

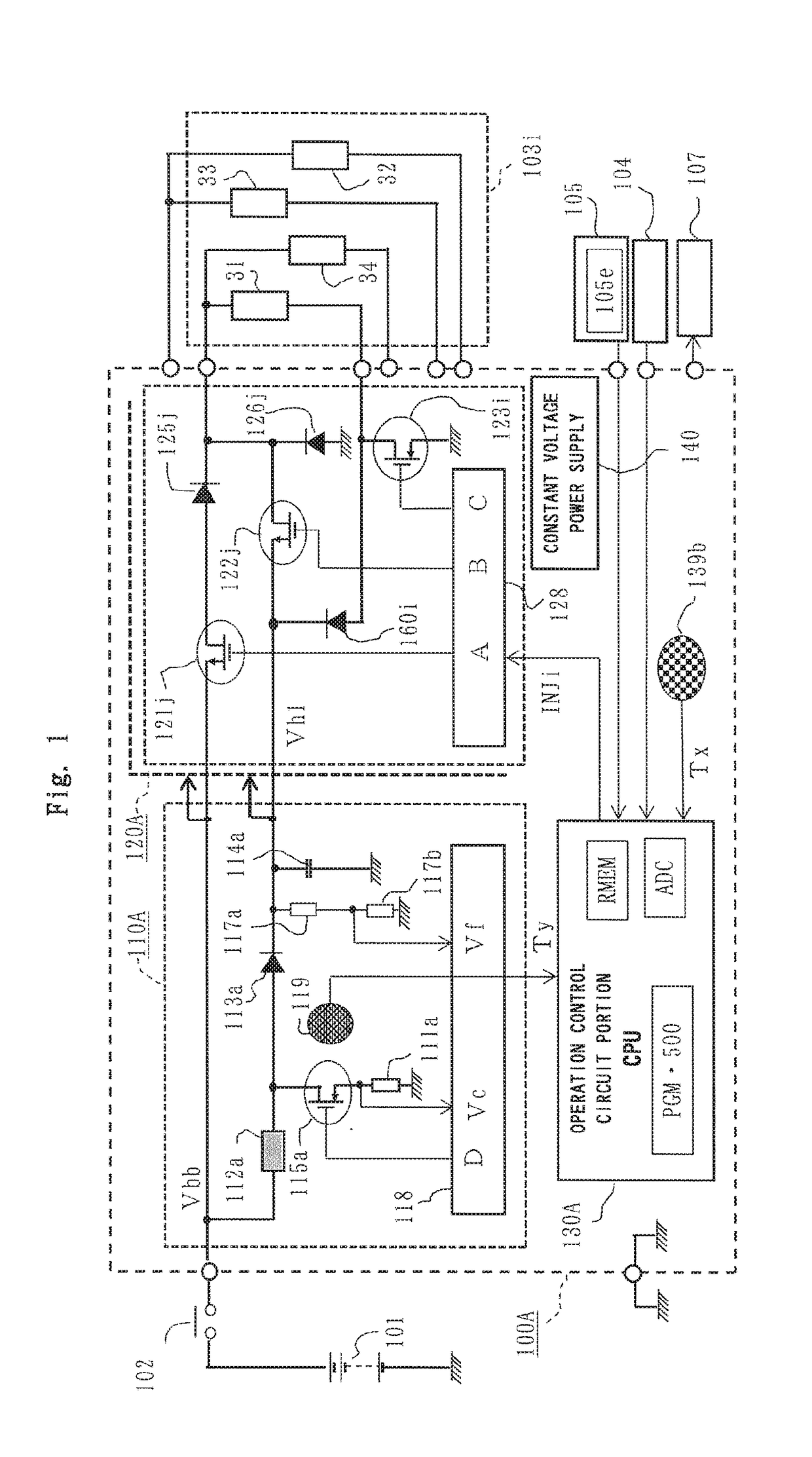

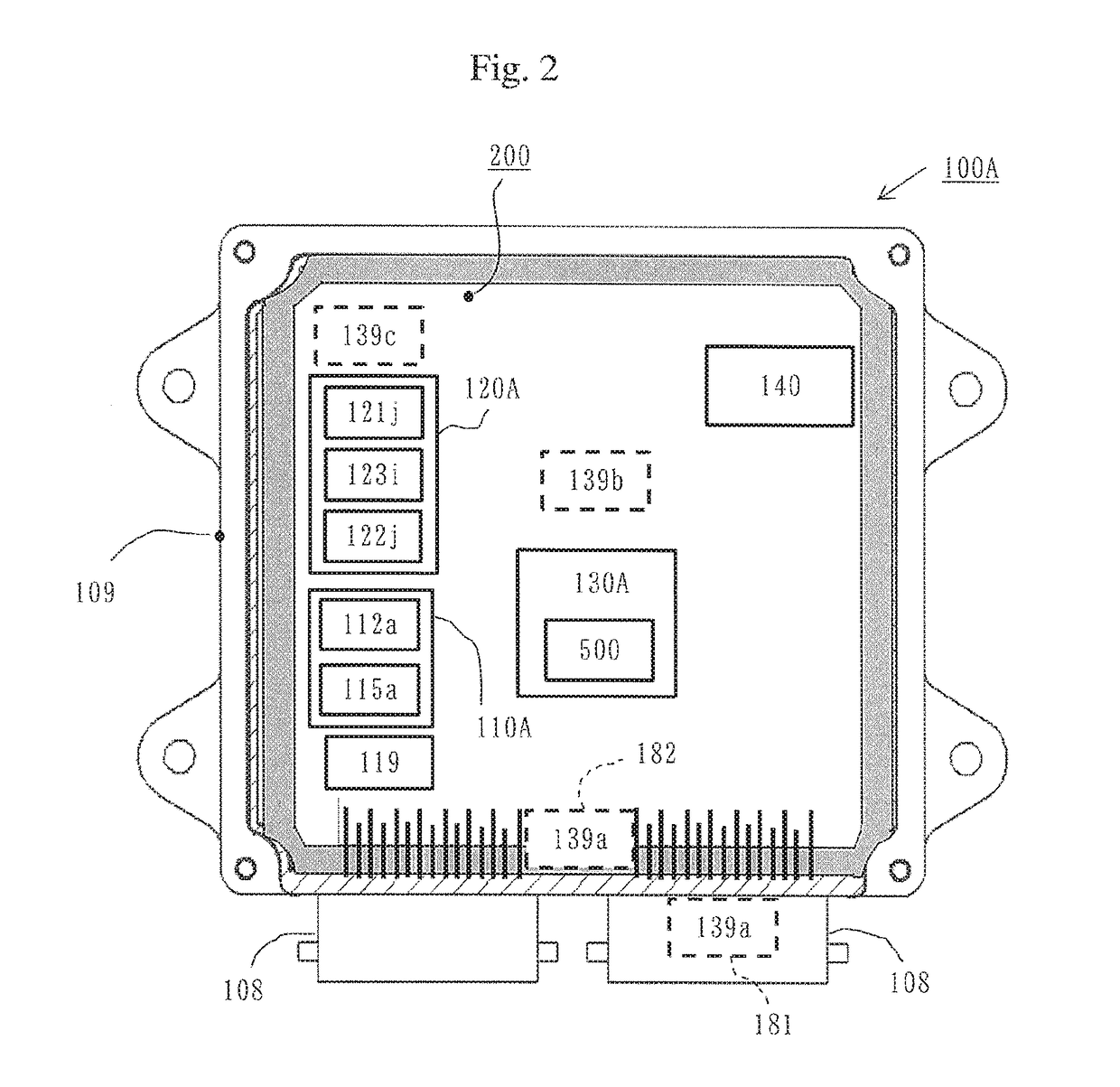

In-vehicle engine control apparatus

ActiveUS20170089292A1Improve combustion characteristicsReduce control loadElectrical controlInternal combustion piston enginesIn vehicleEngineering

An in-vehicle engine control apparatus allowing split injection frequency or split injection of fuel while preventing a driving switch element for fuel injecting electromagnetic coils and a boosting switch element for generating a boosted high voltage from being overheated. An operation control circuit portion has reference data of measured environmental temperature vs allowable engine rotational speed with a selected value of the split injection frequency being a parameter, and determines the selected value having, as an upper limit, a split injection frequency which makes the internal temperature of the boosting switch element or a rapidly exciting switch element a predetermined allowable limit value in association with the present environmental temperature detected by an average environmental temperature detection element in a case and the present engine rotational speed detected by an engine rotation sensor.

Owner:MITSUBISHI ELECTRIC CORP

Gas turbine main combustion chamber multi-channel diffuser with intelligently adjustable diffusion ratio

ActiveCN113983494AGood combustion characteristicsLow pollution emission performanceContinuous combustion chamberFriction lossCombustion chamber

The invention discloses a gas turbine main combustion chamber multi-channel diffuser with the intelligently adjustable diffusion ratio, and belongs to the technical field of gas turbine combustion. The diffusion ratio flowing through an inner diffusion channel and an outer diffusion channel can be intelligently set by adjusting the expansion angle of a cone located in a diffuser casing, the target diffusion ratio of each channel is set according to different working conditions, so that the sum of friction loss and separation loss of the diffuser is minimum; in addition, the multi-channel diffuser guides two air flows to a designated area of the head of the double-ring-cavity combustion chamber, the air flows of the main combustion stage and the pre-combustion stage of the double-ring-cavity combustion chamber can be intelligently distributed by adjusting the position of a flow dividing cone located in a diffuser casing, according to different working conditions, the set oil-gas ratio of each area is obtained, so that high combustion characteristics and low pollution emission are realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

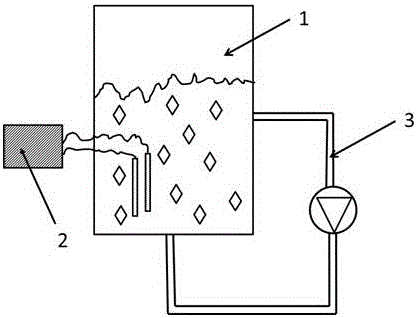

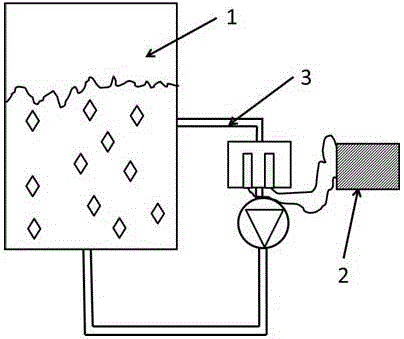

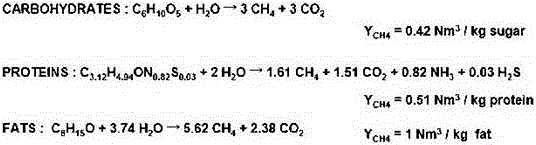

Method for increasing methane yield by assisting anaerobic microorganism treatment through electrolysis

InactiveCN106480102AQuality improvementIncrease gas productionWaste based fuelFermentationElectrolysisMethane yield

The invention discloses a method for increasing methane yield by assisting anaerobic microorganism treatment through electrolysis. According to the method, electrolyzed water is adopted to increase the methane yield, voltage of the electrolyzed water ranges from 1.8V to 12V, a non-precious metal catalytic material such as stainless steel, graphite, a graphite-base material, nickel, steel, metal alloy or metallic oxide is adopted to serve as an electrode material of the electrolyzed water, and a current density of the electrolyzed water is not larger than 0.01A / cm<2>, preferably 0.01-0.05A / cm<2>. The method has the advantages that within an appropriate voltage range, growth of microorganisms cannot be damaged, the methane yield can be increased, and methane quality can be improved; oxygen generated during electrolysis combines with hydrogen sulfide generated during microorganism degradation, so that the hydrogen sulfide is eliminated, and quality of the methane is improved; generated hydrogen combines with carbon dioxide under the action of the microorganisms so as to revert to methane, so that the methane yield is increased, a hydrolysis rate of organisms is increased, and a gas generating rate of the methane is increased.

Owner:CHANGSHA SHANGYI ELECTRONICS TECH CO LTD

In-cylinder direct injection double-gas-fuel internal combustion engine capable of realizing ultra-lean combustion and control method

InactiveCN104948296ASatisfy lean burn requirementsChange the disadvantage of lack of powerElectrical controlInternal combustion piston enginesInlet channelCombustion

The invention relates to an in-cylinder direct injection double-gas-fuel internal combustion engine capable of realizing ultra-lean combustion and a control method, aims to solve the problems that combustion is unstable in an ultra-lean-combustion mode of a gas fuel spark ignition type internal combustion engine, the oil consumption is high and emission is heavy under the work conditions of cold start and small load and the like and develops a spark ignition type in-cylinder direct injection double-gas-fuel internal combustion engine capable of realizing ultra-lean combustion and a control method of the internal combustion engine. The internal combustion engine adopts an internal combustion engine technology combining in-cylinder direct injection and gas inlet channel injection based on double gas fuel, the internal combustion engine is provided with a gas flow control device which cooperates with a piston roof in a special shape, and accordingly, good mixed gas layering is realized. According to the special combustion characteristic of gas fuel, ultra-lean mixed gas in higher compression ratio can be adopted; gas flow movement of the mixed gas entering a cylinder is controlled, meanwhile, gas inflow is increased, ultra-lean combustion of the mixed gas in the cylinder is realized, the heat transfer loss is reduced, the heat efficiency is improved, and oil consumption and pollutants are reduced.

Owner:JILIN UNIV

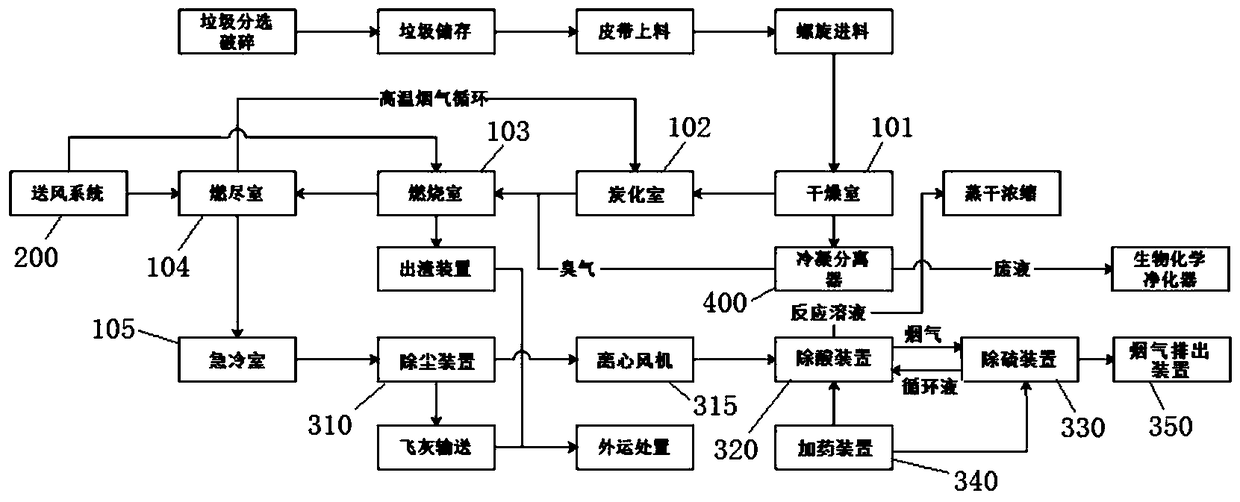

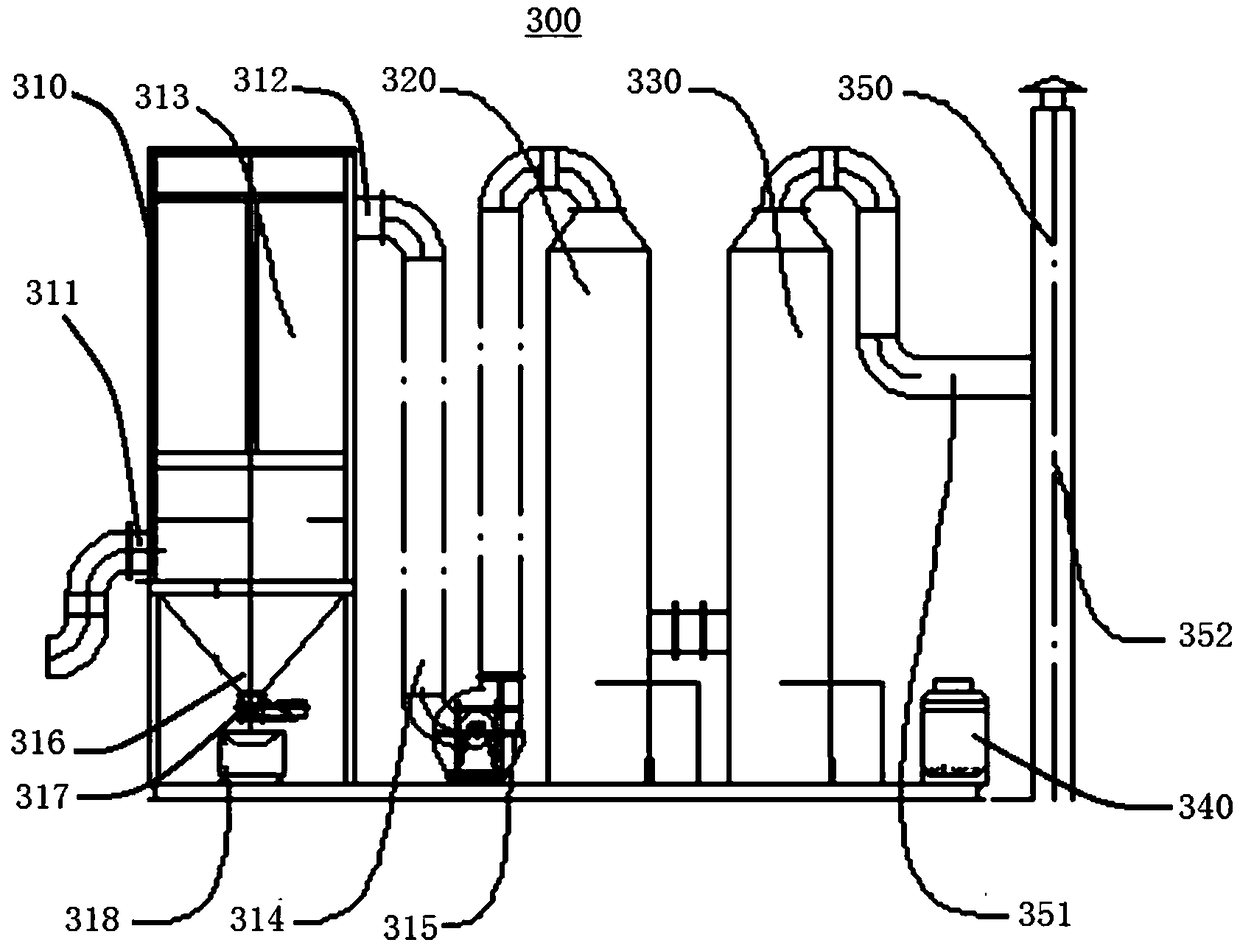

Garbage carbonization combustion treatment technology

ActiveCN108980847ABurn fullyImprove combustion characteristicsIncinerator apparatusCombustion chamberCombustor

The invention relates to a garbage carbonization combustion treatment technology. The garbage carbonization combustion treatment technology comprises the steps that garbage is conveyed onto a drying fire grate of a drying chamber; the garbage on the drying fire grate is subjected to dewatering and drying through ascending hot airflow generated during combustion of garbage in a combustor and hearthheat radiation; the drying fire grate is opened, the garbage subjected to dewatering and drying falls onto a carbonization fire grate of a carbonization chamber, and high-temperature oxygen-poor carbonization pyrolysis is conducted through the flame temperature and high-temperature flue gas during combustion of the garbage in the combustor; the carbonization fire grate is opened, the carbonized garbage falls onto a combustion fire gate of the combustor to be combusted; flue gas generated during combustion of the garbage in the combustor enters a burnout chamber for secondary combustion; the flue gas subjected to secondary combustion is fed into a flue gas treatment system after being cooled through a rapid cooling chamber; and the flue gas is exhausted after being processed through a dustremoval device, a deacidification device and a desulphuration device. Through the garbage carbonization combustion treatment technology, the technical problems that existing small-size garbage treatment equipment is low in garbage treatment efficiency and automation degree, incapable of reaching the exhaust gas emission standard, and the like can be solved.

Owner:YUNNAN HEXUN ENVIRONMENTAL TECH CO LTD

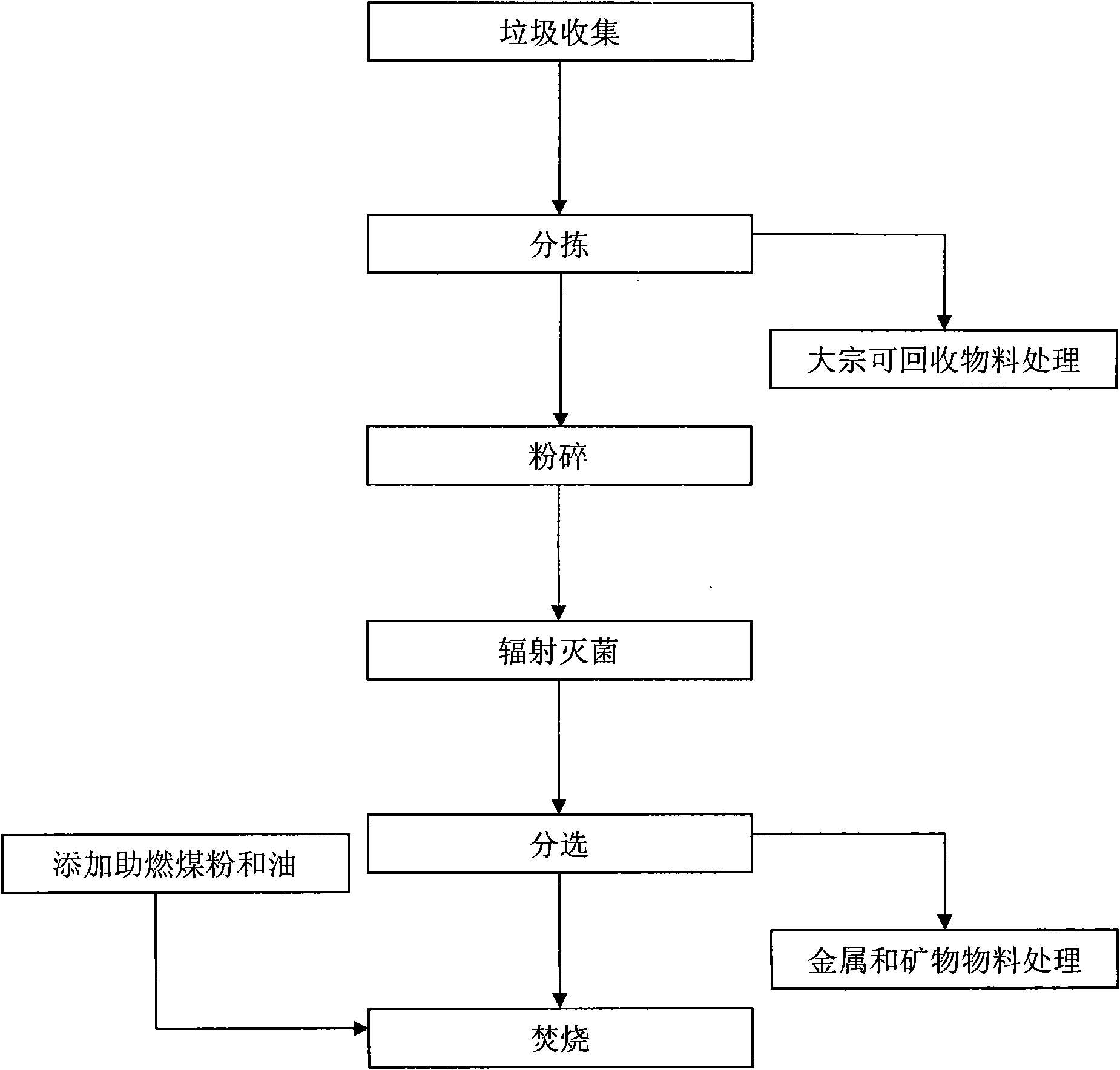

Medical waste separation, recovery, and incineration processing method

InactiveCN101590487AHigh recycling valueNo pollutionSolid waste disposalMedical waste disposalFiberAdditive ingredient

The invention relates to medical waste separation, recovery, and incineration processing method, comprising the following steps: 1. waste collection: collecting by adopting an enclosed way; 2. separation: the chunk material and bulk material which can be recycled separately are separated out; 3. smashing: all the material being processed collectively is smashed under the enclosed condition; 4. sterilization: all the smashed material is sterilized; 5. sorting: the medical waste is divided into two categories in a mechanical way according to the proportion of the material, the first is lighter material with the main ingredients being fiber and other organics, and the second is heavier material with the main ingredients being metal, sandrock and other mineral substances, the lighter material is dried and smashed to form incineration material; and 6. incineration: coal power is added into the incineration material as a combustion accelerator and fuel oil is sprayed into an incineration furnace as a second combustion accelerator. The invention is conducive for reasonable utilization of material in the medical waste and the reduction of energy consumption.

Owner:BEIJING JINAOHUARONG TECH

Citrus peel biomass energy particle and preparation method thereof by squeezing

The invention discloses a citrus peel biomass energy particle and a preparation method thereof by squeezing. The biomass energy particle is formed by squeezing and then carrying out mechanical pressing on citrus peel, agroforestrial wastes and an antifermentive agent. The preparation method of the biomass energy particle comprises the steps of squeezing, smashing, mixing, drying and moulding. According to the invention, massive waste peel produced by processing citrus in a large scale can directly enter into a pipeline processing system, and a particle biomass energy fuel which is dense, has high energy density and thermal efficiency more than 80%, is easy to store and transport and is convenient to popularize and apply can be processed within several hours only, the fuel is an efficient and clean energy product, and the fuel has the advantages of good combustion characteristic, high burning rate, less dust, low chemical pollution emission and citrus flavour.

Owner:赣州中橙果业科技开发股份有限公司

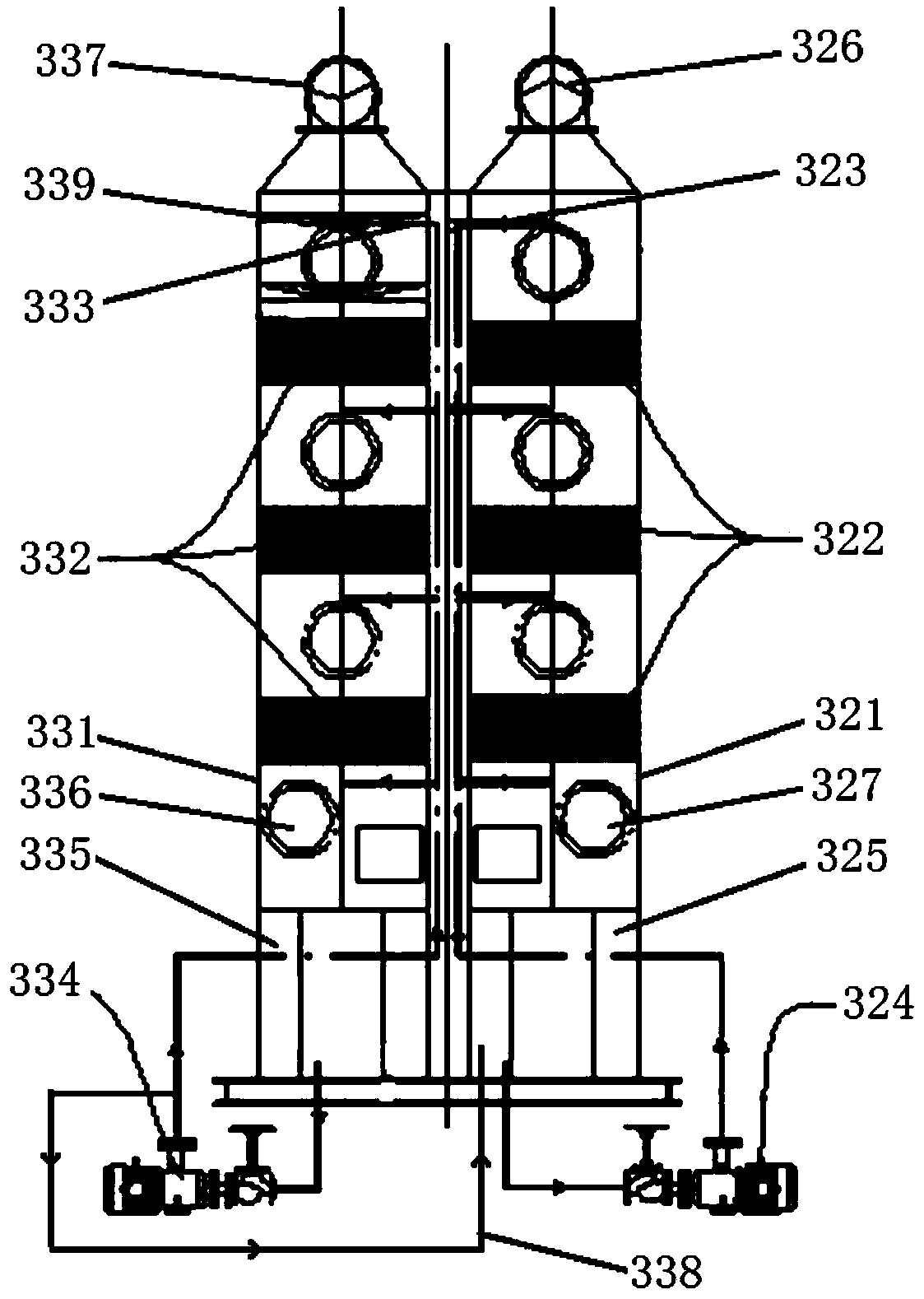

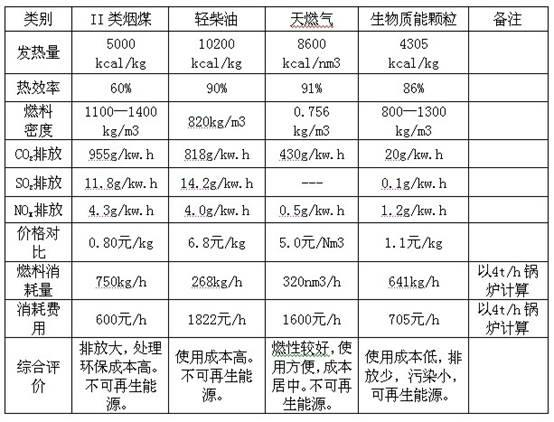

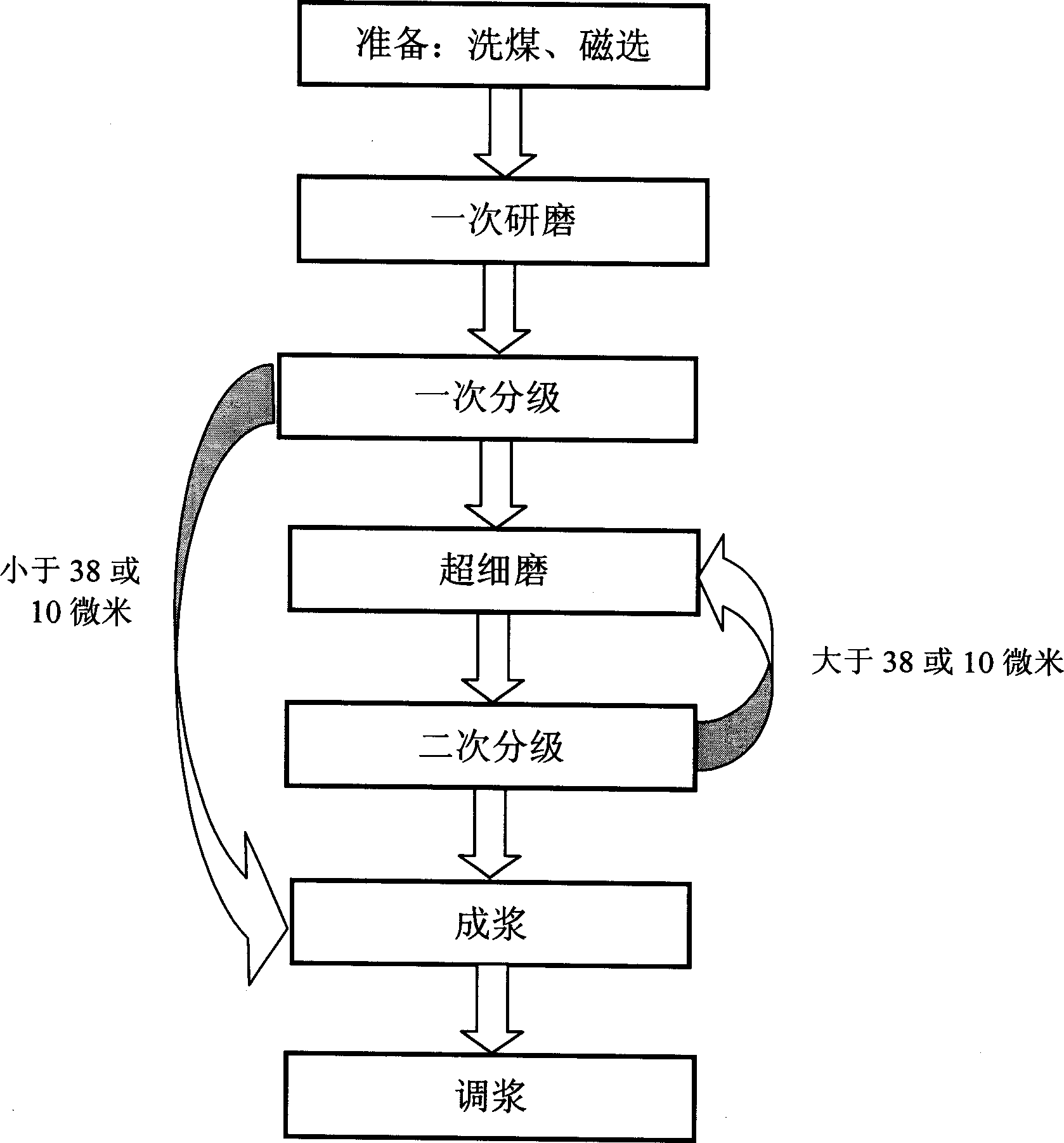

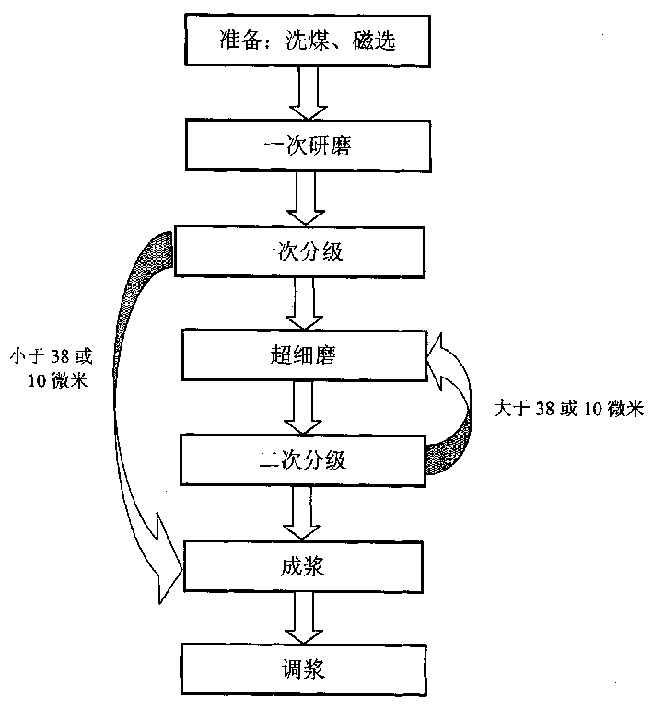

Superfine coal based fluid fuel and its preparation

InactiveCN1456642AReduce apparent viscosityEasy to pumpLiquid carbonaceous fuelsApparent viscositySlurry

A superfine coal-base fluid fuel is prepared from coal particles (4-5 microns in average), water, disperser, stabilizer, sulfur-fixing agent and combustion promoter through preparing raw materials, grinding, classifying, superfine grinding, classifying again, preparing slurry and regulating. Its advantages are low apparent viscosity, high atomizing and combustion effect, and good stability.

Owner:北京金泓毅新技术有限公司

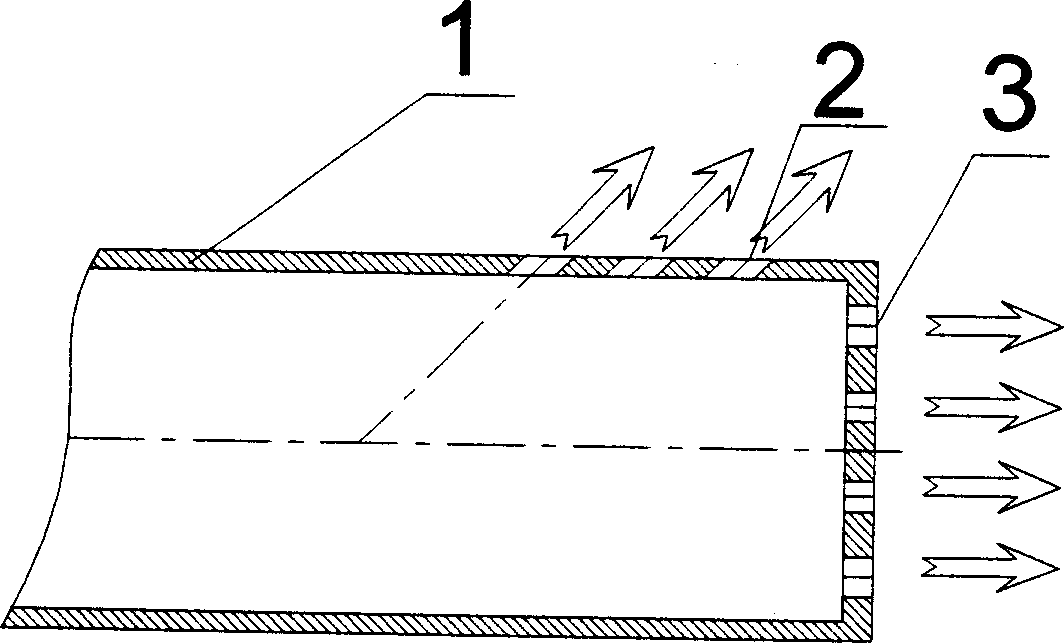

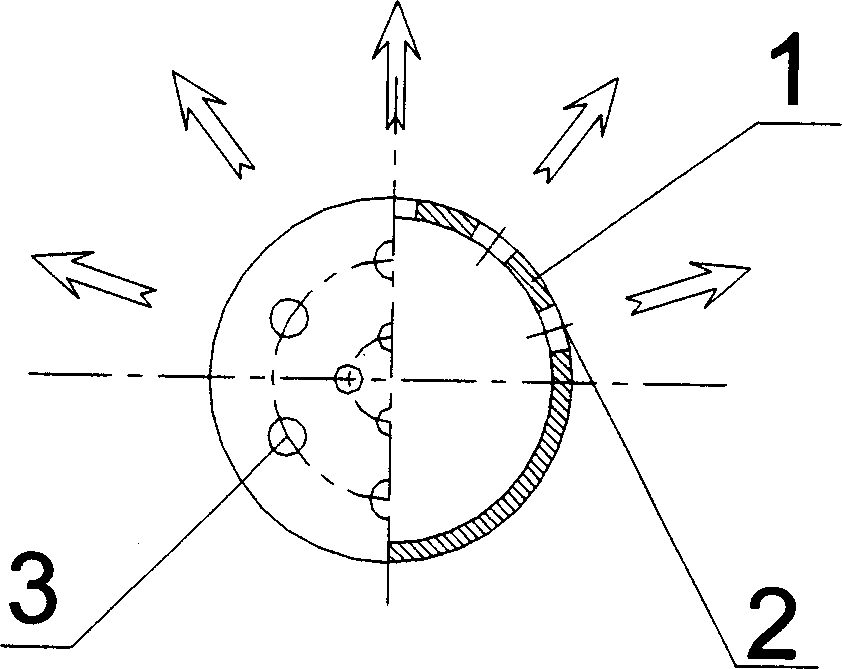

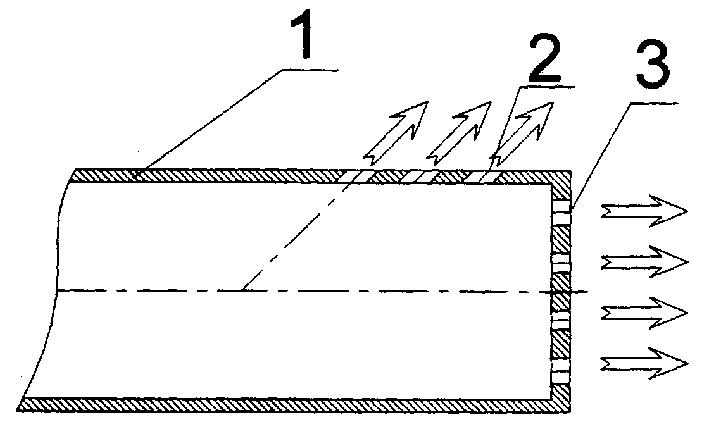

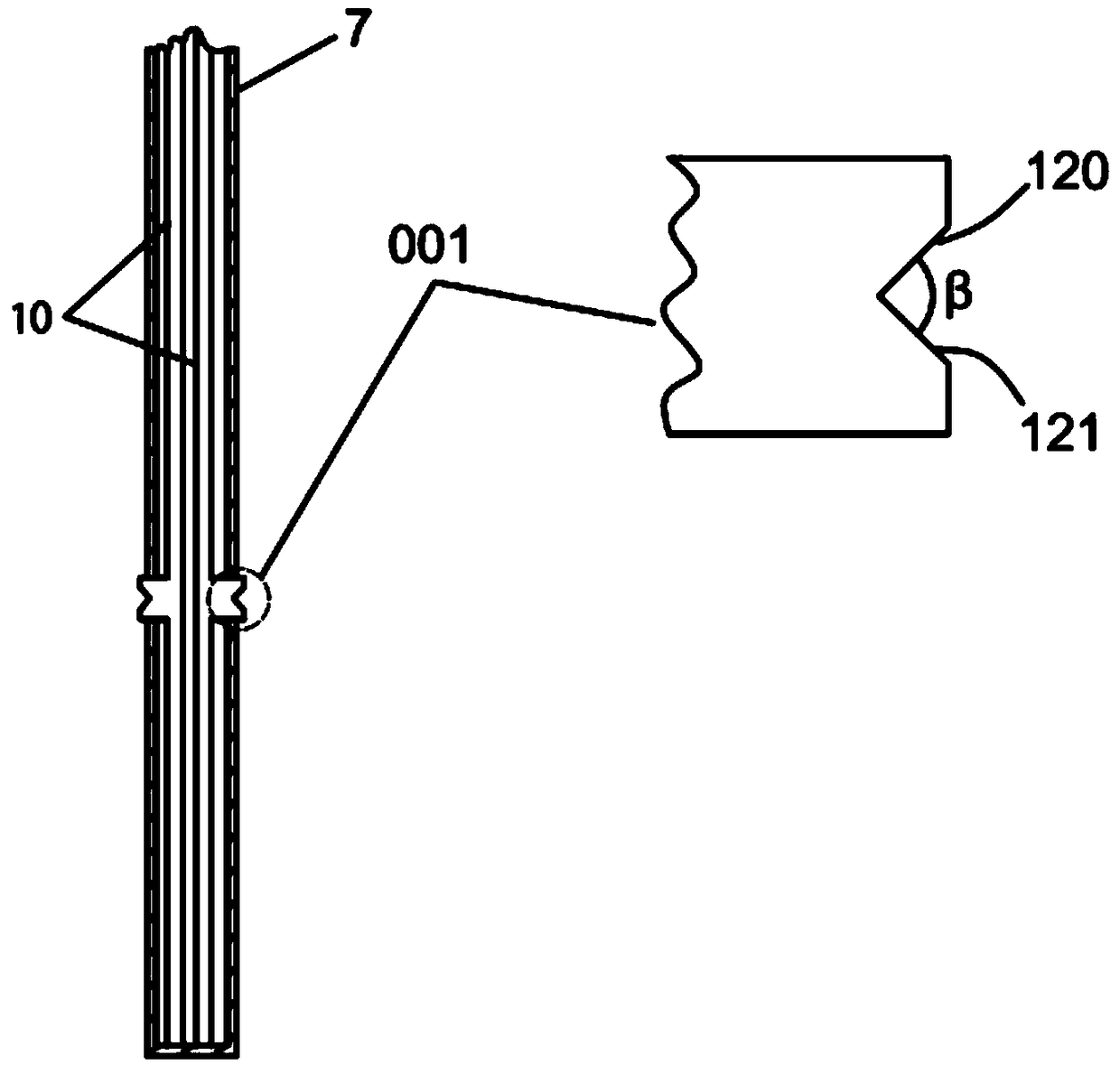

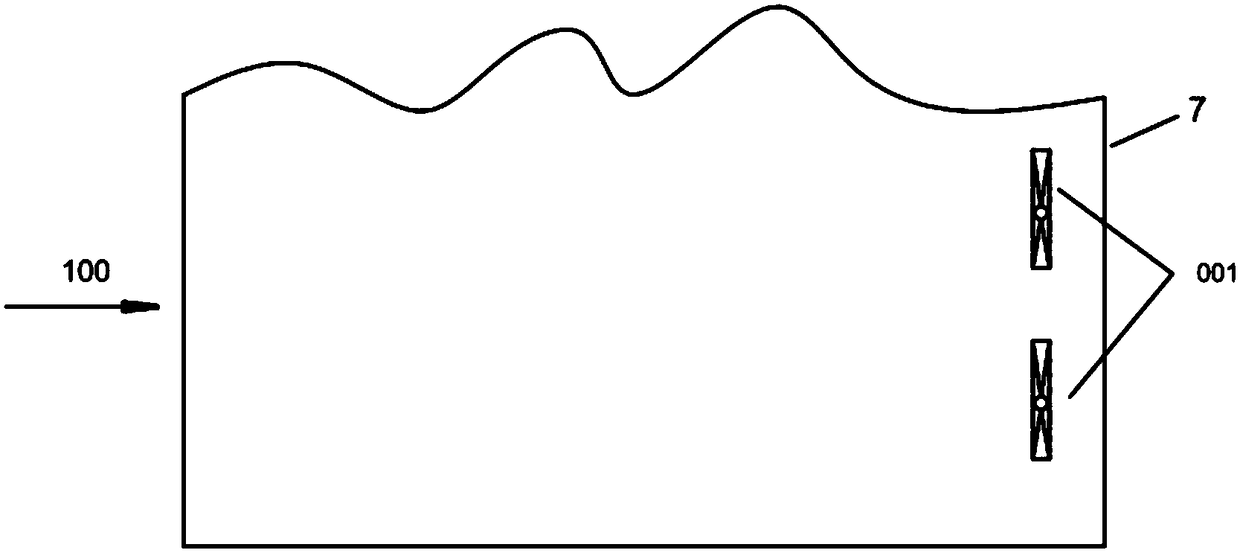

Afterburner adopting planar fan nozzles for oil supply

ActiveCN108844094AStable and reliable combustionAchieve atomizationContinuous combustion chamberSpray nozzlePerpendicular direction

The invention discloses an afterburner adopting planar fan nozzles for oil supply, and belongs to the field of aero-engines. The afterburner adopting the planar fan nozzles for oil supply is characterized in that supporting plates are arranged on an oil supply device in the afterburner, and are uniformly arranged along the circumference of the afterburner in the perpendicular direction; and oil spraying rods are arranged on the inner sides of the supporting plates in the radial direction, the planar fan nozzles are arranged on the side walls of the oil spraying rods in the radial direction, and the opening cross section of each planar fan fuel nozzle is V-shaped. According to the design of the afterburner adopting the planar fan nozzles for oil supply, the fuel spray extending angle is enlarged, the number of the nozzles is reduced, the diameter of each nozzle is increased, and meanwhile, the fuel radial and circumferential concentration distribution is more uniform, so that reliable and stable combustion of the afterburner is facilitated, and the problems in the prior art are solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

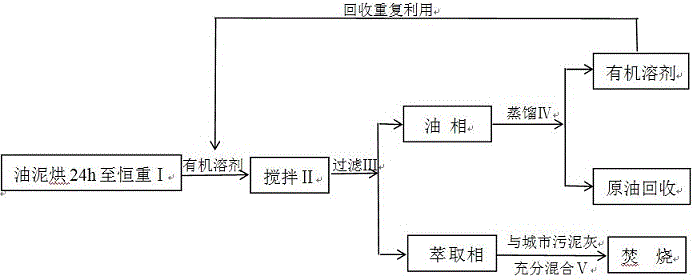

Method for recovering crude oil in petroleum oil sludge and comprehensively recycling residual mud and sand

InactiveCN105621833AAvoid secondary pollutionAvoid wastingSludge treatment by de-watering/drying/thickeningLiquid hydrocarbon mixture productionOrganic solventDistillation

The invention discloses a method for recovering crude oil in petroleum oil sludge and recycling residual mud and sand. The method comprises the steps of A, pretreatment-crude oil extraction-co-incineration: drying the oil sludge to a constant weight at a certain temperature and measuring a heat value of the oil sludge; B, a crude oil extraction process: mixing the oil sludge with an organic solvent according to a certain weight ratio, stirring at a certain temperature, and filtering to obtain oil phase and raffinate phase oil sludge; C, an organic solvent recovery process: selecting a boiling point of the organic solvent, recovering the organic solvent at 100 DEG C under the normal pressure through a distillation recovery device, and recycling the organic solvent; and D, a co-incineration process: drying the raffinate phase oil sludge, mixing the dried raffinate phase oil sludge with municipal sludge ash according to a certain ratio, measuring a heat value of a mixture, and performing incineration at 800-1,000 DEG C. The method is easy to implement and simple and convenient to operate; the crude oil subjected to extraction is recycled; the residual raffinate phase oil sludge still can take effects and is subjected to co-incineration together with the municipal sludge ash; and the heat value of the oil sludge is fully utilized.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com