Supercharged engine and ammonia fuel hybrid power generation system

A supercharged engine and power generation system technology, applied in the field of ammonia decomposition, can solve the problems of energy waste, low fuel utilization rate, poor combustion characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

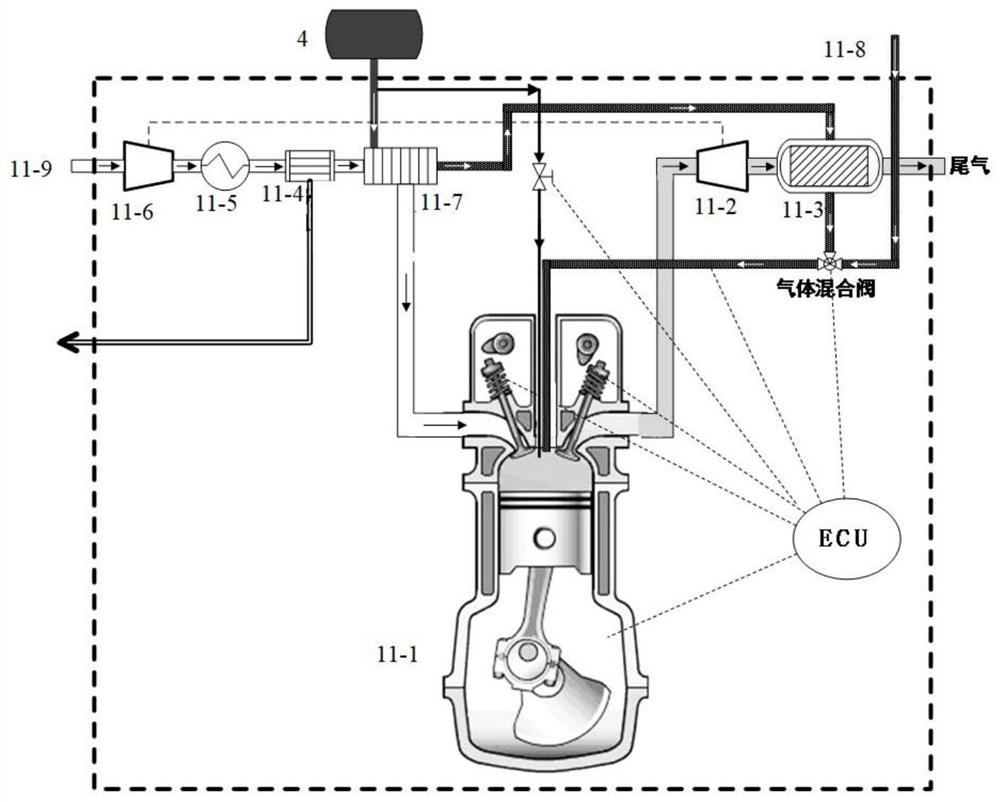

[0047] This embodiment provides a supercharged engine 11, such as figure 1 shown, including,

[0048] The internal combustion engine 11-1 communicates with the liquid ammonia storage tank 4, and the liquid ammonia in the liquid ammonia storage tank is transported to the internal combustion engine 11-1 as fuel;

[0049] The membrane separation module 11-7, the first gas enters the membrane separation module 11-7 after being compressed and boosted by the first compressor 11-6, cooled by the intercooler 11-5, and the first gas is separated to obtain nitrogen-enriched gas and Oxygen-enriched gas; nitrogen-enriched gas is discharged, and the oxygen-enriched gas enters the vaporizer 11-4, exchanges heat with liquid ammonia from the liquid ammonia storage tank 4, makes the liquid ammonia gasify, and the oxygen-enriched gas enters the internal combustion engine 11-1 after heat exchange Combustion, the liquid ammonia after heat exchange enters the ammonia decomposition reaction compon...

Embodiment 2

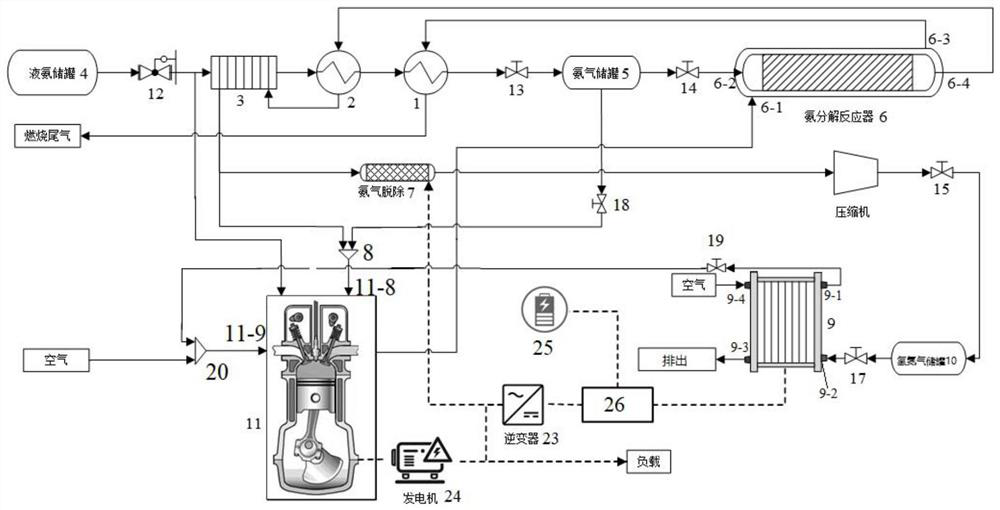

[0055] This embodiment provides an ammonia fuel hybrid power generation system, such as figure 2 As shown, it includes the supercharged engine 11 provided in Embodiment 1, and also includes a liquid ammonia storage tank 4, a first pressure reducing valve 12, an evaporator 3, a second heat exchange device 2, and a first heat exchange device 1 connected in sequence. and ammonia gas storage tank 5; wherein, the liquid ammonia in the liquid ammonia storage tank 4 enters the ammonia decomposition reactor 6 after passing through the evaporator 3, the second heat exchange device 2, the first heat exchange device 1 and the ammonia gas storage tank 5 successively The ammonia decomposition reaction takes place in the ammonia decomposition reactor, the first regulating valve 13 is used to control the flow of ammonia, the sixth regulating valve 14 is used to control the flow of ammonia entering the ammonia decomposition reactor, and the ammonia storage tank is used to store ammonia. When...

Embodiment 3

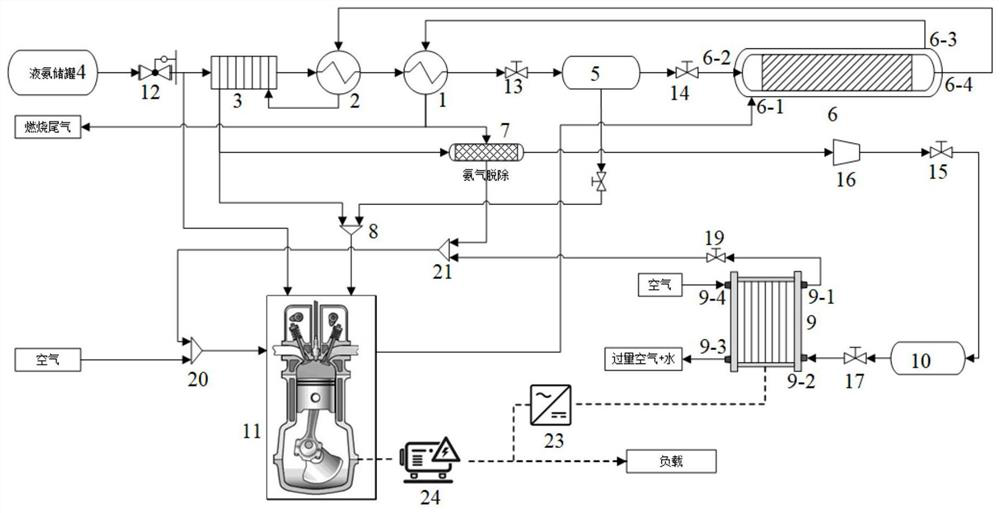

[0063] This embodiment provides an ammonia fuel hybrid power generation system, such as Figure 4 As shown, it includes the supercharged engine 11 provided by Embodiment 1, and also includes a liquid ammonia storage tank 4, an evaporator 3, a first heat exchange device 1 and an ammonia gas storage tank 5 connected in sequence, wherein the first regulating valve 13 is used for Control the flow of ammonia gas;

[0064] The ammonia fuel hybrid power generation system also includes,

[0065] The ammonia decomposition reactor 6 is communicated with the booster engine 11; the ammonia decomposition reaction is provided with a tail gas input port 6-1, which is used to transport the tail gas produced by the booster engine 11 to the ammonia decomposition reactor to provide heat for the ammonia decomposition reaction, Then the tail gas is exported to the first heat exchange device 1 through the tail gas output port 6-3, and enters the evaporator 3 after exchanging heat with the raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com