End surface air inlet device for rotor engine

A technology of rotary engine and air intake device, applied in combustion engine, machine/engine, internal combustion piston engine, etc., can solve the problems of sharp turn of end-face intake air flow, small inflation coefficient and average effective pressure, large fluid resistance, etc. The effect of improving the inflatable coefficient, good inflatable coefficient, and improving the inflatable coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

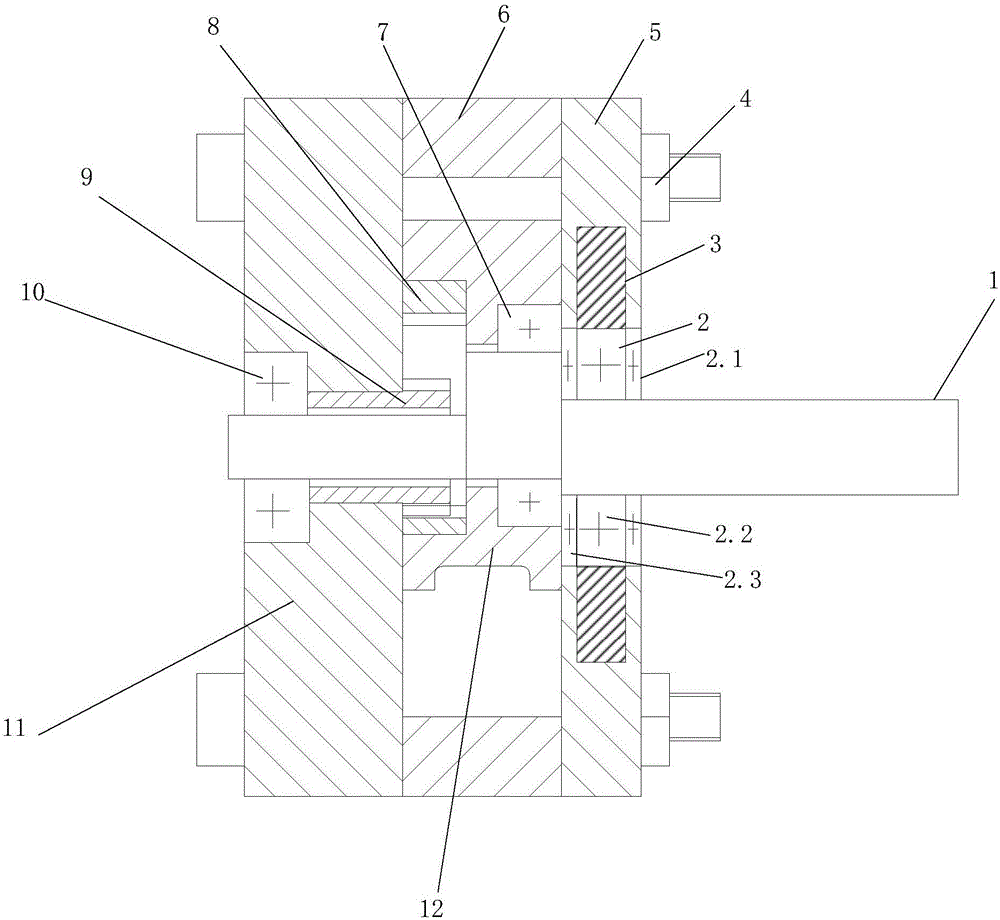

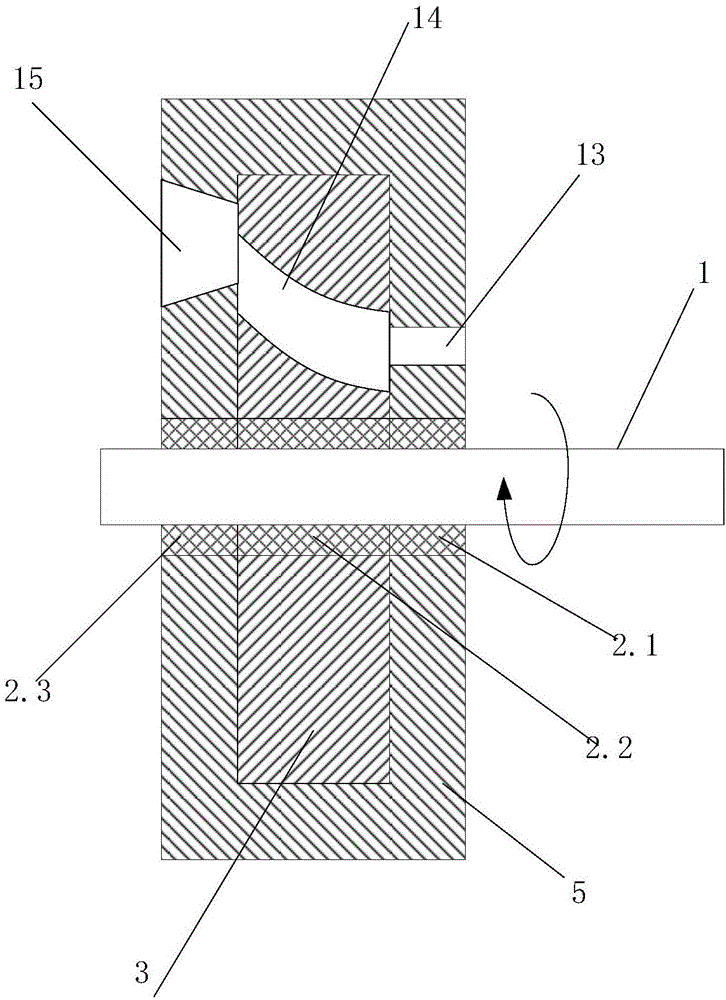

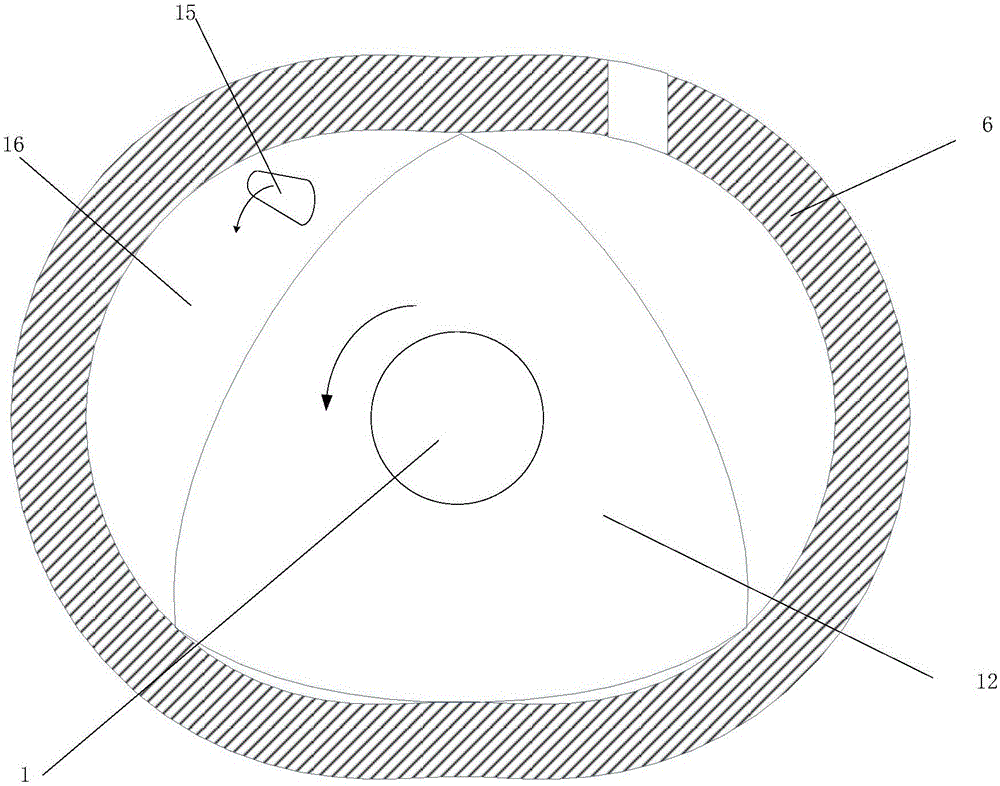

[0029] Such as figure 1 , 2 As shown, the end face air intake device for a rotary engine disclosed in this embodiment includes a crankshaft 1, a bearing 2, a first rotor 3, a bolt 4, a front end cover shell 5, a cylinder 6, a fourth bearing 7, an internal gear 8. External gear 9, fifth bearing 10, rear end cover 11, second rotor 12, first air intake 13, second air intake 14, third air intake 15 and combustion chamber 16. The front end cover includes a front end cover shell 5 and a first rotor 3, the first rotor 3 is placed in the front end cover shell 5, and the left and right sides of the front end cover shell 5 are respectively opened with a third air inlet 15 and a first air inlet 13 , the first rotor 3 has a second air inlet 14; the bearing 2 includes a first bearing 2.1, a second bearing 2.2 and a third bearing 2.3; the first bearing 2.1 cooperates with the first rotor 3, and the second bearing 2.2 , The third bearing 2.3 cooperates with the front end cover shell 5 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com