Internal-combustion electromagnetic hydraulic engine

A hydraulic engine, electromagnetic technology, applied in hydraulic mechanical drag. , In the field of vehicle power, it can solve the problems that the fuel ignition time can be set in a small range and cannot be stored in advance, and achieve the effect of simple structure, overcoming side friction, and improving compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

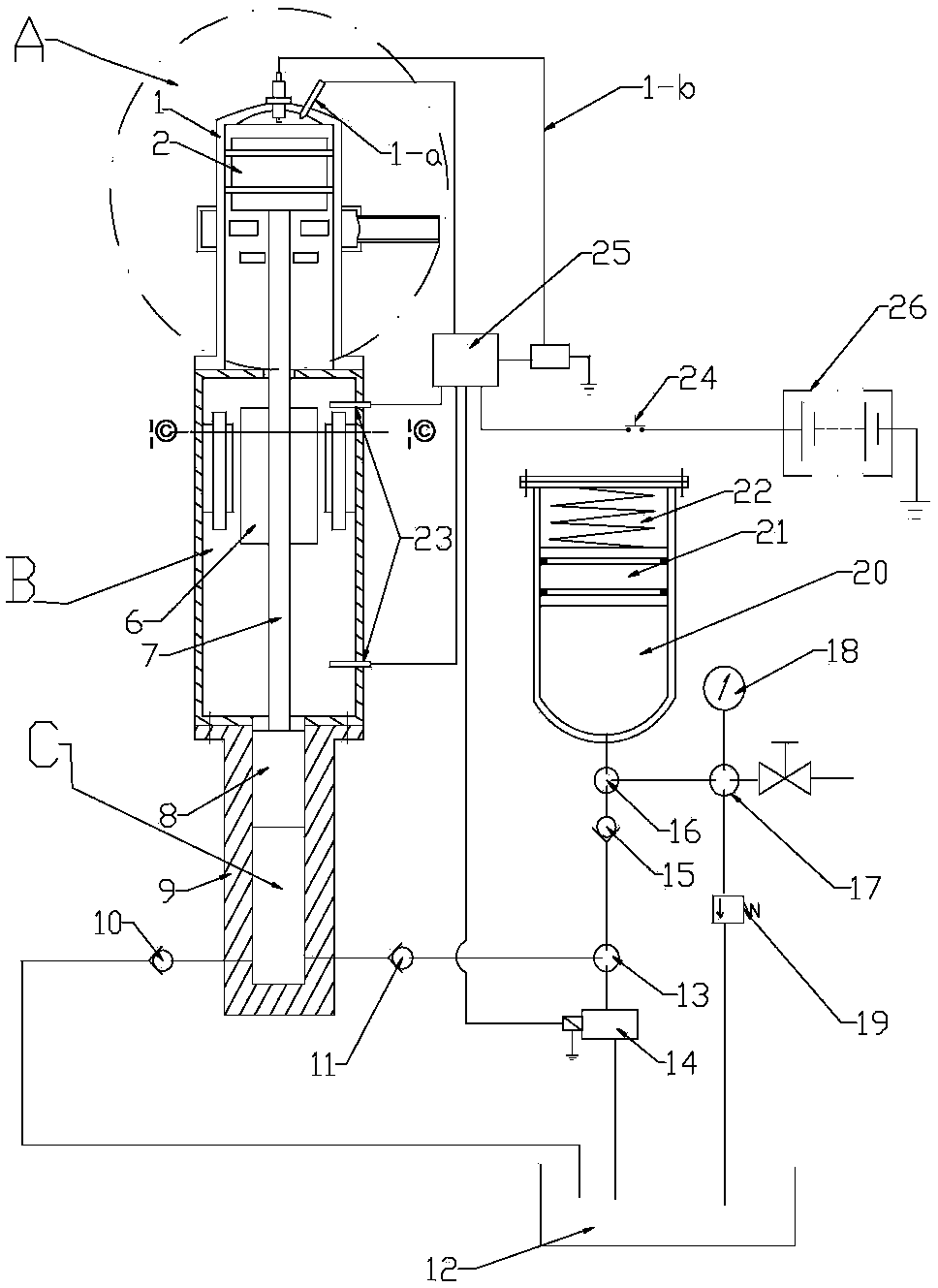

[0020] specific implementation

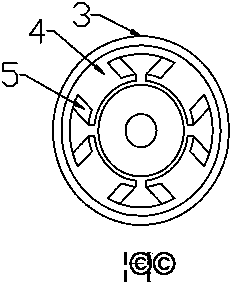

[0021] An internal combustion electromagnetic hydraulic engine, comprising: a single-cylinder internal combustion engine A, a linear magneto B, a plunger pump C, a hydraulic oil tank 12 for supplying oil to the plunger pump, an oil storage tank 20 for storing hydraulic energy for the plunger pump C, and PLC circuit 25 and battery 26 for power supply of the whole machine; it is characterized in that: the single-cylinder internal combustion engine A only cancels the crank connecting rod mechanism and the crankcase; the linear magneto B is punched with four inner salient poles The ring-shaped silicon steel sheets are stacked to form the iron core 4, the excitation coil 5 with salient poles embedded in the iron core 4, and the casing 3 of the iron core 4 forms the stator 3-4-5; the tubular permanent magnet 6 is fixed on the tubular The output shaft 7 in the center hole of the permanent magnet 6 forms the mover 6-7, and the length of the tubular per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com