Ten-hole total temperature measuring probe

A technology for measuring probes and probes, which is applied in the direction of temperature measurement, measuring devices, and heat measurement of moving fluids. It can solve the problems of small air flow in and out of the total temperature probe, large thermal inertia, and inability to accurately measure the total temperature of the flow field. , to achieve the effect of accurately measuring the total temperature of the flow field and reducing the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

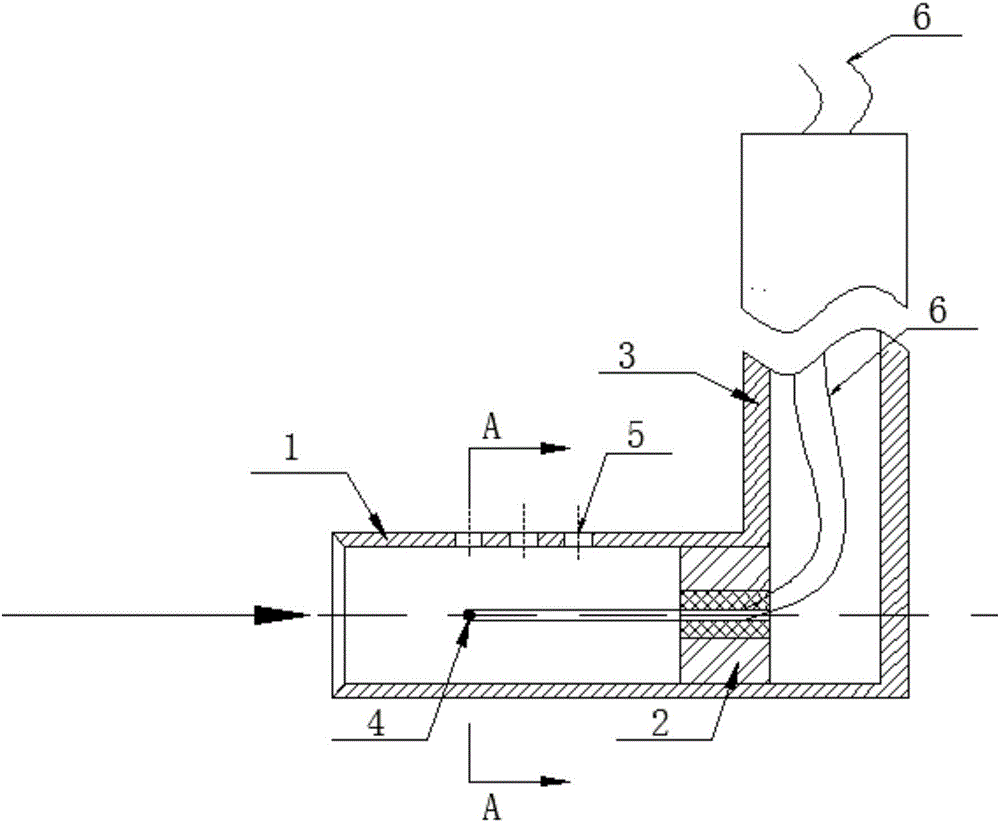

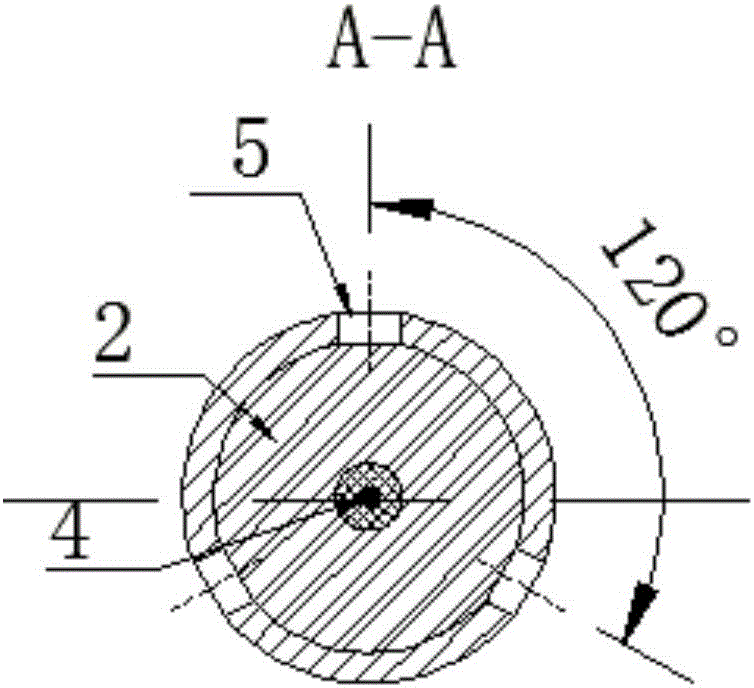

[0015] Such as figure 1 As shown, the ten-hole total temperature measuring probe of the present invention comprises a stagnation cover (1), a thermal insulation seal (2), a probe pole (3), a temperature sensor (4), a convective heat exchange hole (5) and The temperature measuring lead wire (6) has an incoming flow direction as shown by the arrow in the figure, and the stagnation cover (1) is connected to the probe support rod (3) in an "L" shape, wherein the diameter of the stagnation cover (1) is 7 millimeters, the diameter of the probe pole (3) is 7 millimeters. One end of the stagnation cover (1) has an air inlet, the diameter of the air intake is 6 millimeters, and there are 60 ° chamfers, and nine convection heat exchange holes (5) are arranged on the side wall of the stagnation cover (1), and the shape of the holes is Circular, with a hole diameter of 2 mm, along ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com