Dual-fuel nozzle for plasma catalysis gaseous fuel

A plasma and catalytic gas technology, applied in combustion chambers, combustion methods, combustion equipment, etc., to achieve the effects of good combustion characteristics, good combustion stability and completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

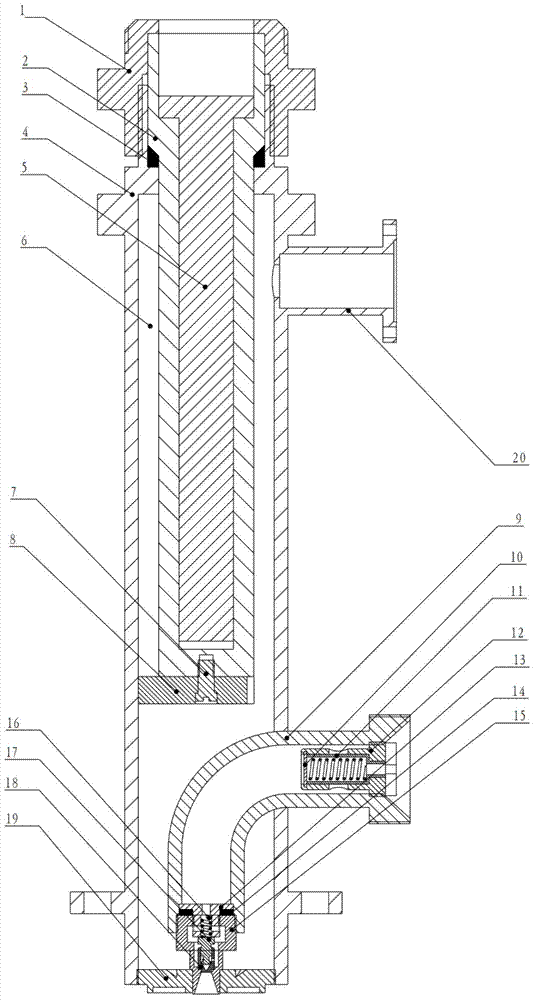

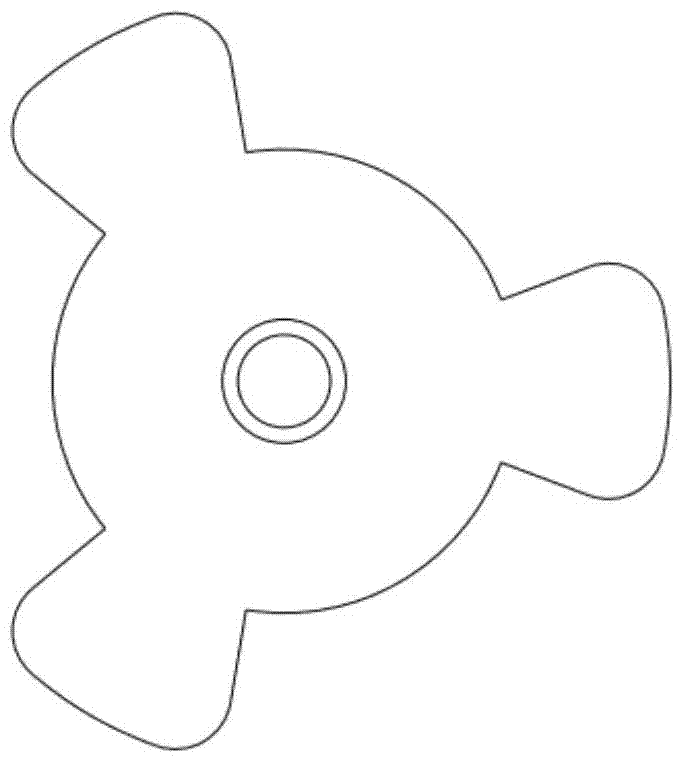

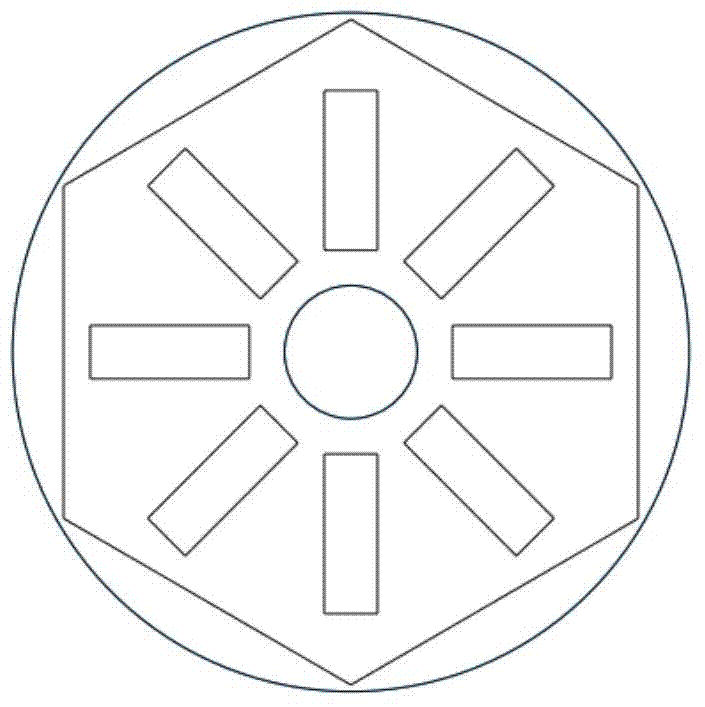

[0018] combine Figure 1~4 , the present invention includes a discharge assembly, a gas circuit assembly, an oil circuit assembly and a nozzle fixing device; the low-temperature plasma discharge assembly includes an outer electrode 4, an inner electrode 5, a ceramic dielectric tube 2, a sealing gasket 3 and a coaxial fixed disk 8, and the inner electrode 5 is included inside the ceramic dielectric tube 2, the outer electrode 4 includes the ceramic dielectric tube 2 and has an annular discharge gap 6, and the coaxial fixed disc 8 is used to ensure the coaxiality between the inner and outer electrodes, which can effectively avoid the arc at the end through experimental verification Discharge, to ensure the discharge uniformity and stability of the discharge area. The ceramic tube 2 is used as the barrier medium, because of its large dielectric constant, it can ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com