Biomass liquid fuel and metal particle co-combustion staged swirl combustion device

A technology of liquid fuel and metal particles, which is applied to burners, burners, and combustion methods for evaporating liquid fuels, and can solve the problems of restricting the wide use of metal fuels, agglomeration and slagging, and high combustion temperature, and achieve compact structure and promote Intensely blended, application-promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

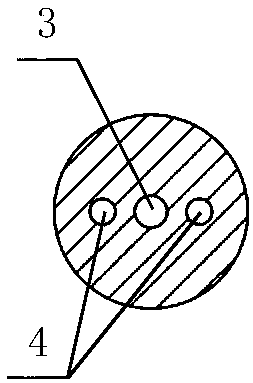

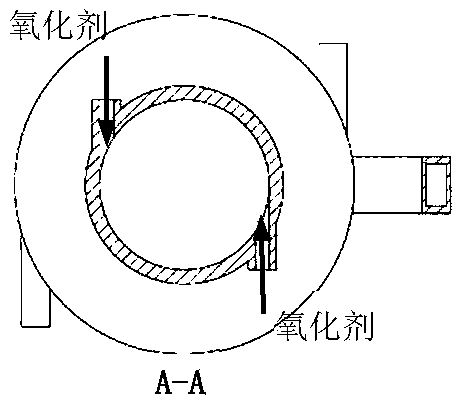

[0021] In this embodiment, nano-aluminum particles and ethanol are used as fuel, and air is used as an oxidant. Structurally, an inner layer structure and an outer layer structure constitute a two-stage swirl burner. The top of the inner layer structure is provided with an aluminum particle flow-carrying channel and 2 There are two ethanol channels, and there are two air swirl inlets on the side wall of each layer of the structure, and this is explained.

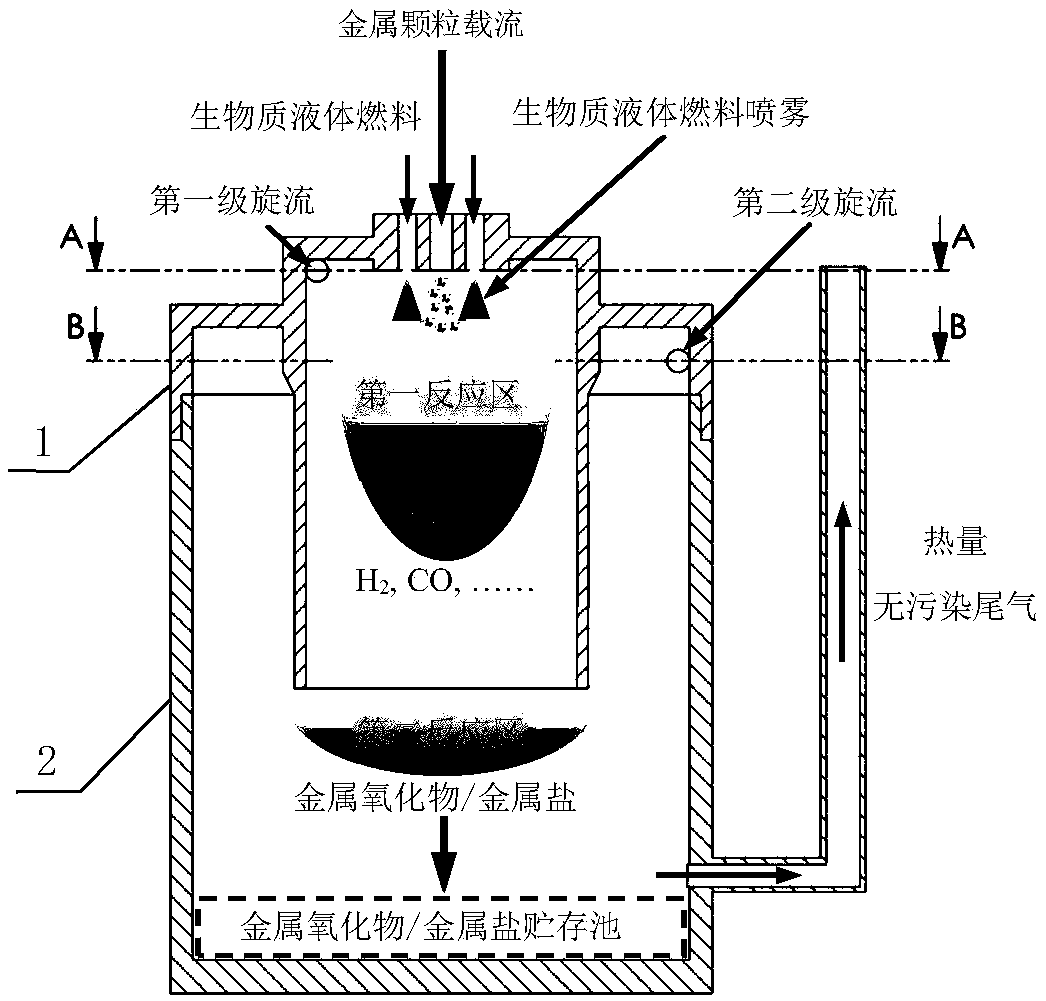

[0022] Such as figure 1 As shown, this embodiment discloses a staged swirl combustion device for co-combustion of biomass liquid fuel and metal particles, including: the upper part of the burner 1 and the burner base 2; the burner base 2 is a hollow structure with a bottom end seal, And there is an exhaust pipeline on the side wall; the upper part of the burner 1 includes an inner structure and a plurality of outer structures, and the inner structure is a hollow cylindrical structure with a top seal; two channels are opened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com