System and method for ultralow volatile carbon-based fuel and lignite low-NOx blending combustion

A technology of volatile matter and lignite, which is applied in the direction of combustion methods, combustion using block fuel and powder fuel, graded combustion, etc., can solve the problems of easy oxidation and spontaneous combustion, easy weathering and fragmentation, and high greenhouse gas emissions, so as to avoid output Insufficient, weakening adverse effects, avoiding the effect of unsafe drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawing

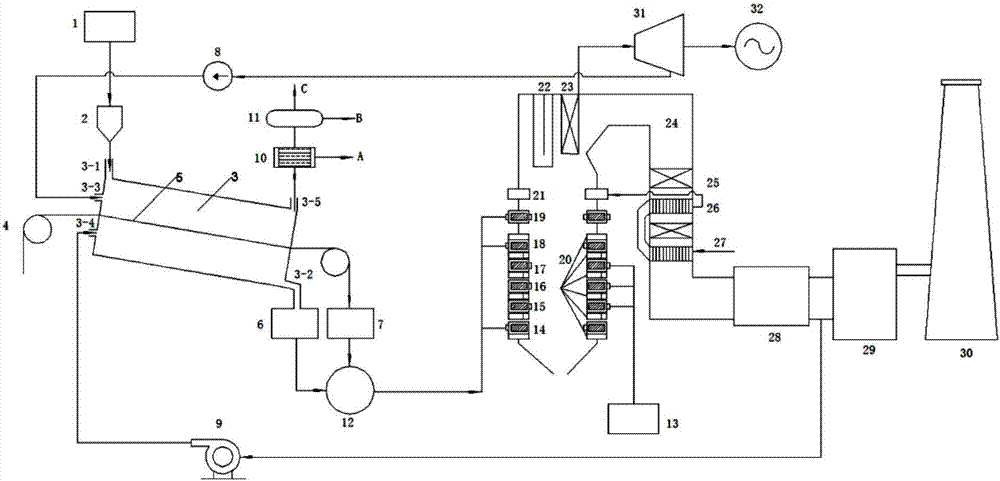

[0031] Such as figure 1 As shown, the present invention is an ultra-low volatile carbon-based fuel and lignite low NO x Co-firing system, including lignite drying system and co-firing system of ultra-low volatile carbon-based fuel and dry lignite.

[0032] The lignite drying system includes raw lignite bin 1, pulverizer 2, drying box 3, pulley 4, conveyor belt 5, small particle size dry lignite bin 6, large particle size dry lignite bin 7, steam pump 8, fan 9, condenser 10 , exhaust gas purification unit 11, steam turbine 31, hot flue gas pipeline and steam pipeline.

[0033]The blending system of ultra-low volatile carbon-based fuel and dry lignite adopts the method of "separate grinding and pulverization, layered blending in the furnace" combined with "fuel reburning", including fan coal mill 12, ultra-low volatile carbon-based fuel Powder bin 13, main burner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com