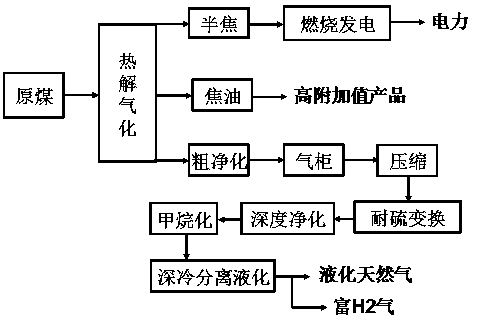

Process for co-producing LNG (Liquefied Natural Gas) by using pyrolysis gas generated in power generation system

A power generation system and pyrolysis gas technology, applied in the field of coal chemical industry, to achieve the effect of flexible raw material and product scheme and high product benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

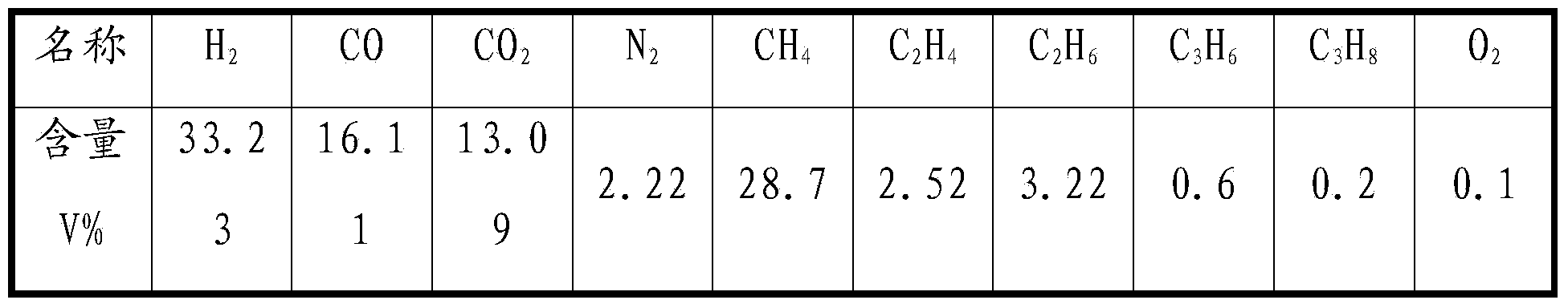

Embodiment 1

[0057] In the power system, bituminous coal is used to generate electricity, and a circulating fluidized bed is used to co-produce pyrolysis gas, wherein the main composition (vol%) of pyrolysis gas is: H 2 : 33.23, CH 4 : 28.7, CO: 16.11, CO 2 : 13.09, C n h m : 6.54, N 2 : 2.22, O 2 : 0.1. Air volume 30000Nm 3 / h at a temperature of 40°C.

[0058] The specific steps for producing LNG are: using Roots blower or centrifugal blower to pressurize the pyrolysis gas to 0.005-0.01MPa(G). The dry purification temperature swing adsorption method is used to remove macromolecular impurities such as tar, naphthalene, benzene, and dust in the pyrolysis gas, and the rough purified pyrolysis gas is obtained. Then use a reciprocating compressor or a centrifugal compressor to pressurize the pre-purified gas to about 5.0MPa. The semi-coke and separated hot ash produced after the pyrolysis and gasification of raw coal are directly sent to the boiler for combustion to generate electric...

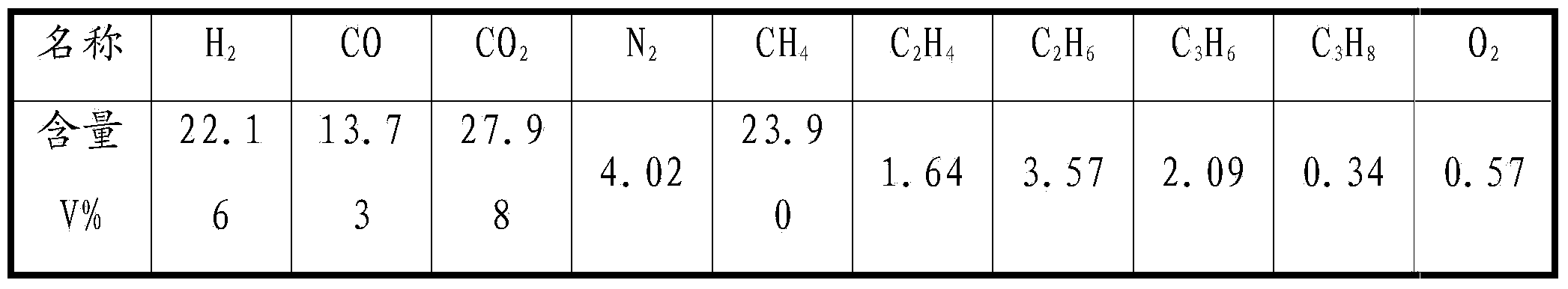

Embodiment 2

[0064] Using lignite, adopting solid heat carrier pyrolysis upgrading process, the main composition (vol%) of pyrolysis gas is: H 2 : 22.16, CH 4 : 23.90, CO: 13.73, CO 2 : 27.98, C n h m : 7.64, N 2 : 4.02, O 2 : 0.57. Air volume 30000Nm 3 / h, temperature 40°C.

[0065] The LNG production process is as follows: using a Roots blower or a centrifugal blower to pressurize the pyrolysis gas to 0.005-0.01MPa(G). The dry purification temperature swing adsorption method is used to remove tar, naphthalene, benzene and dust and other macromolecular impurities in the pyrolysis tail gas to obtain a rough purified pyrolysis gas. Use a reciprocating compressor or a centrifugal compressor to pressurize the pre-purified gas to about 2.5MPa. The semi-coke and separated hot ash produced after the pyrolysis and gasification of raw coal are directly sent to the boiler for combustion to generate electricity. The circulating fluidized bed boiler and the extraction condensing turbine gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com