Patents

Literature

88results about How to "Efficient and clean utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

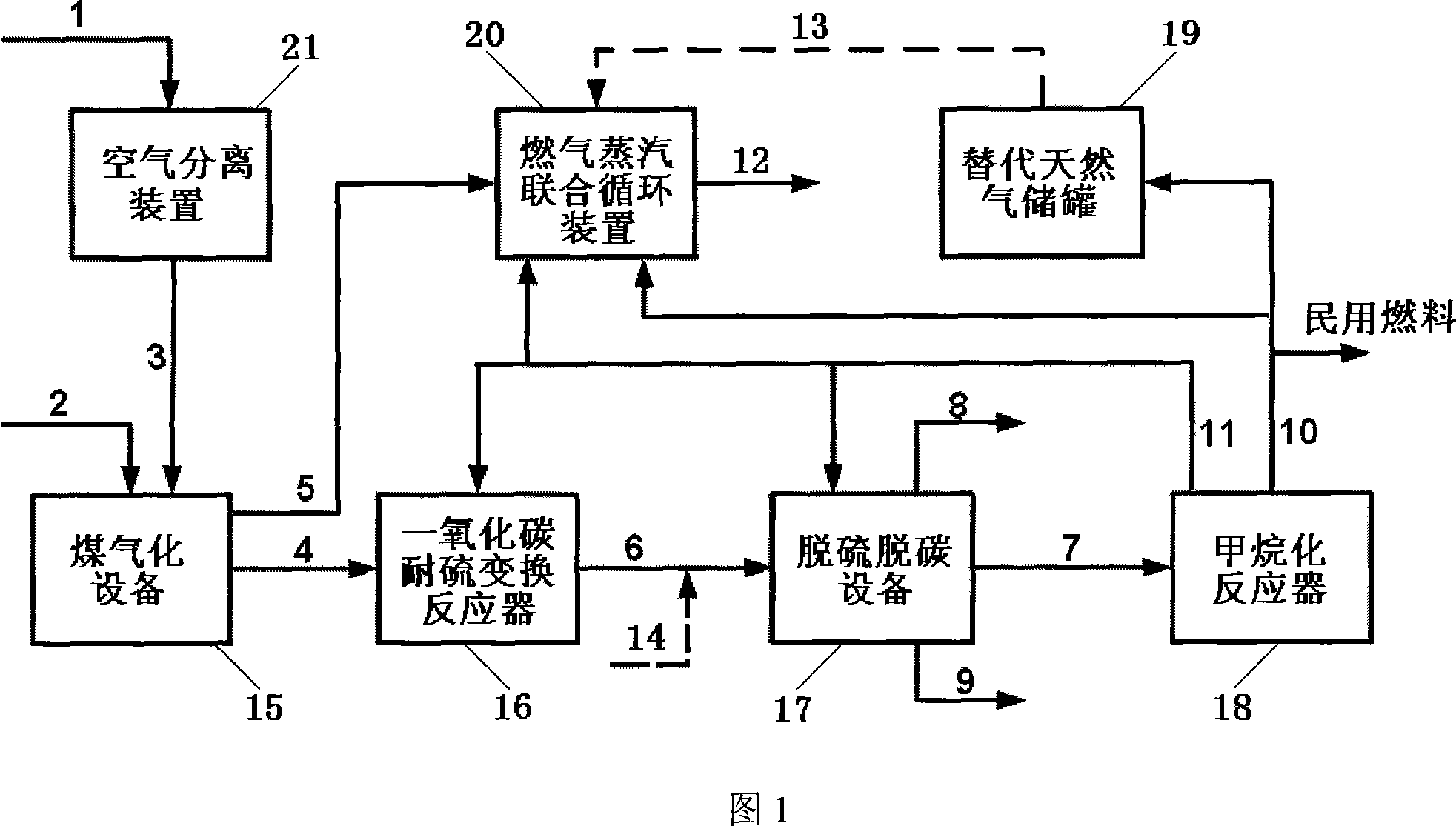

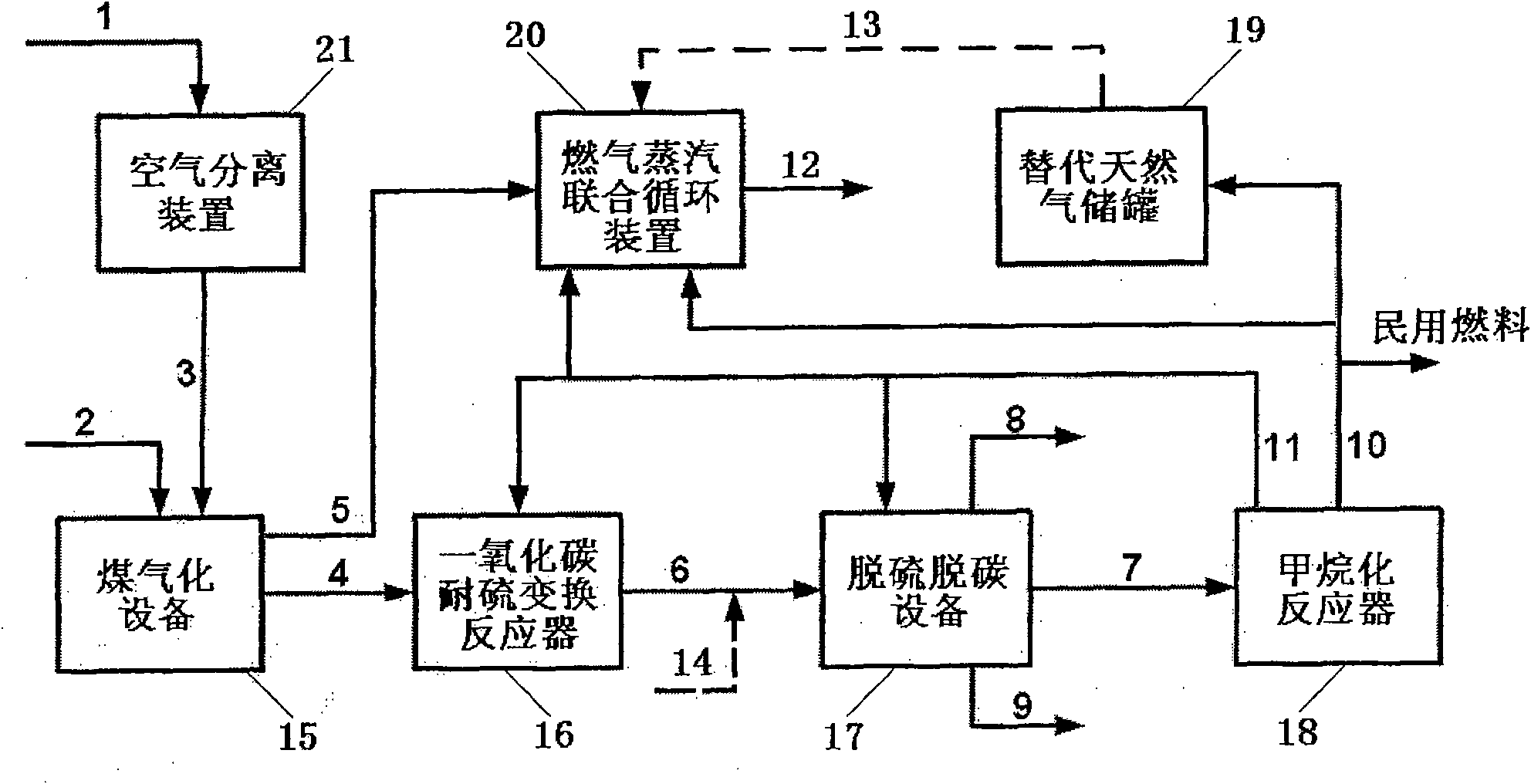

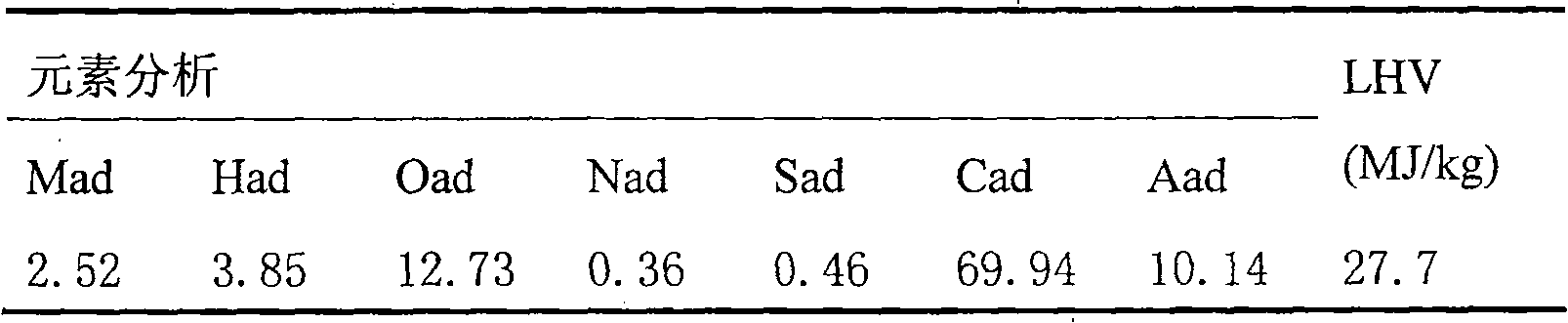

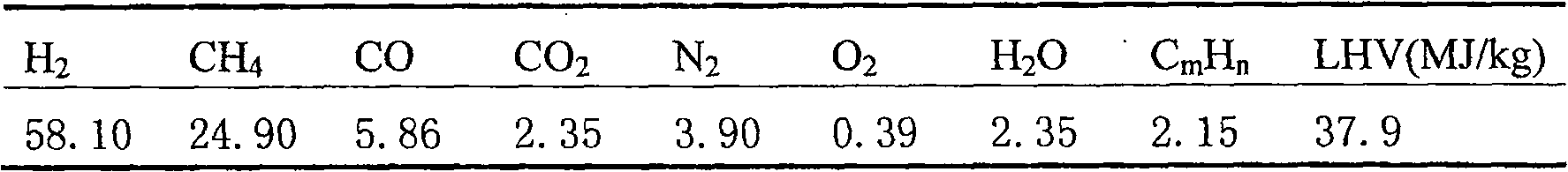

Combined system and process for producing electric-substituted natural gas based on coal gasification and methanation

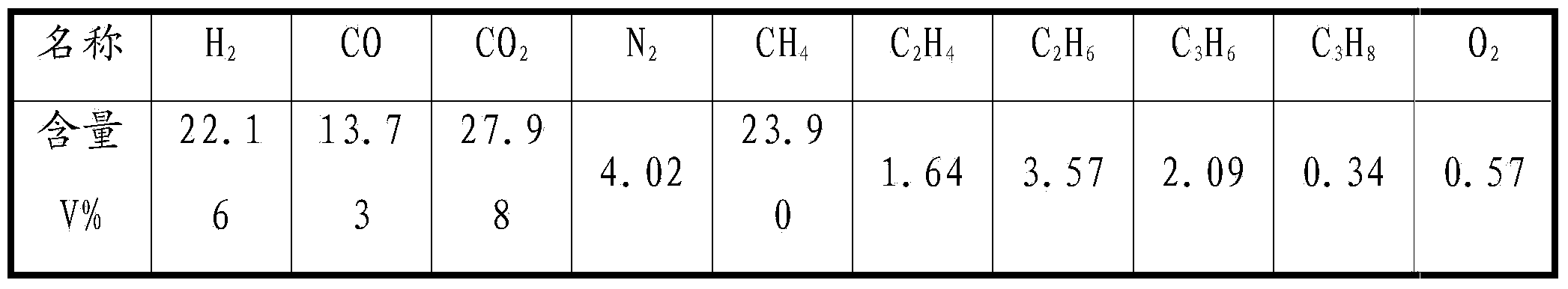

ActiveCN101074397AEfficient and clean utilizationEfficient use ofCombustible gas chemical modificationCombustible gas purificationMethanationSlurry

An electric-substituting natural gas combined system and process based on coal gasification and methanation are disclosed. The process is carried out by delivering oxygen, powdered coal or water-gas slurry into gasified apparatus, recovering for crude gasified gas by wet heat, delivering into sulfur-resisting carbon monoxide carbon reactor, adjusting hydrogen-carbon ratio, entering into desulfurizing decarbonizer, recovering elementary sulfur while enriching carbon dioxide, delivering synthetic gas into methane reactor to generate substituted natural gas as domestic gas partially, entering into gas and steam combined circulator partially, and entering into substituted natural gas storage tank partially. It integrates coal gasified, methanation and gas steam combined circulation together, it's efficient and clean, has better utilizing rate, no CO2 discharge and need for changing gas turbine or load.

Owner:TSINGHUA UNIV

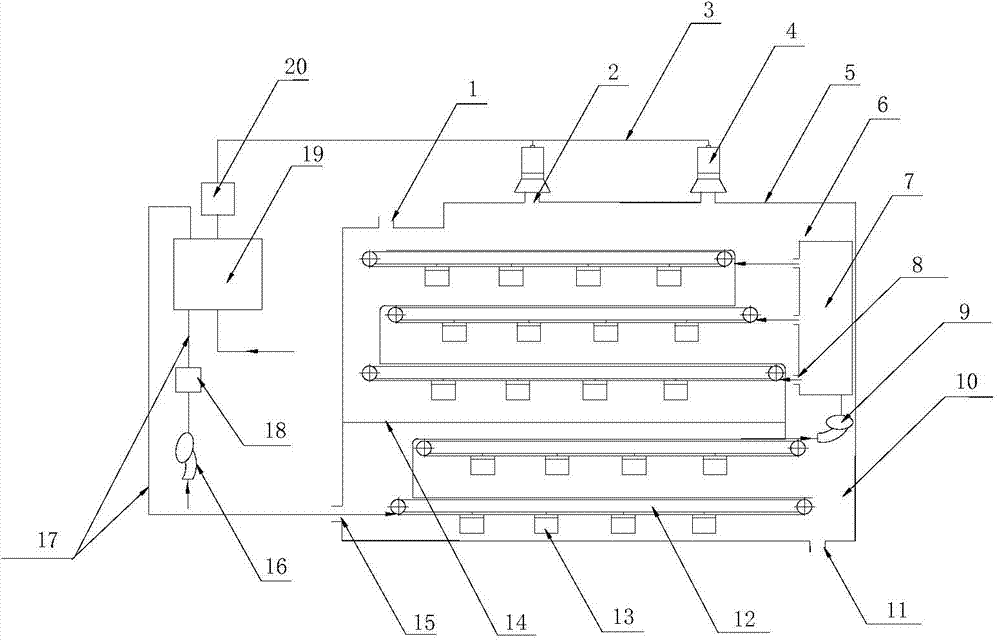

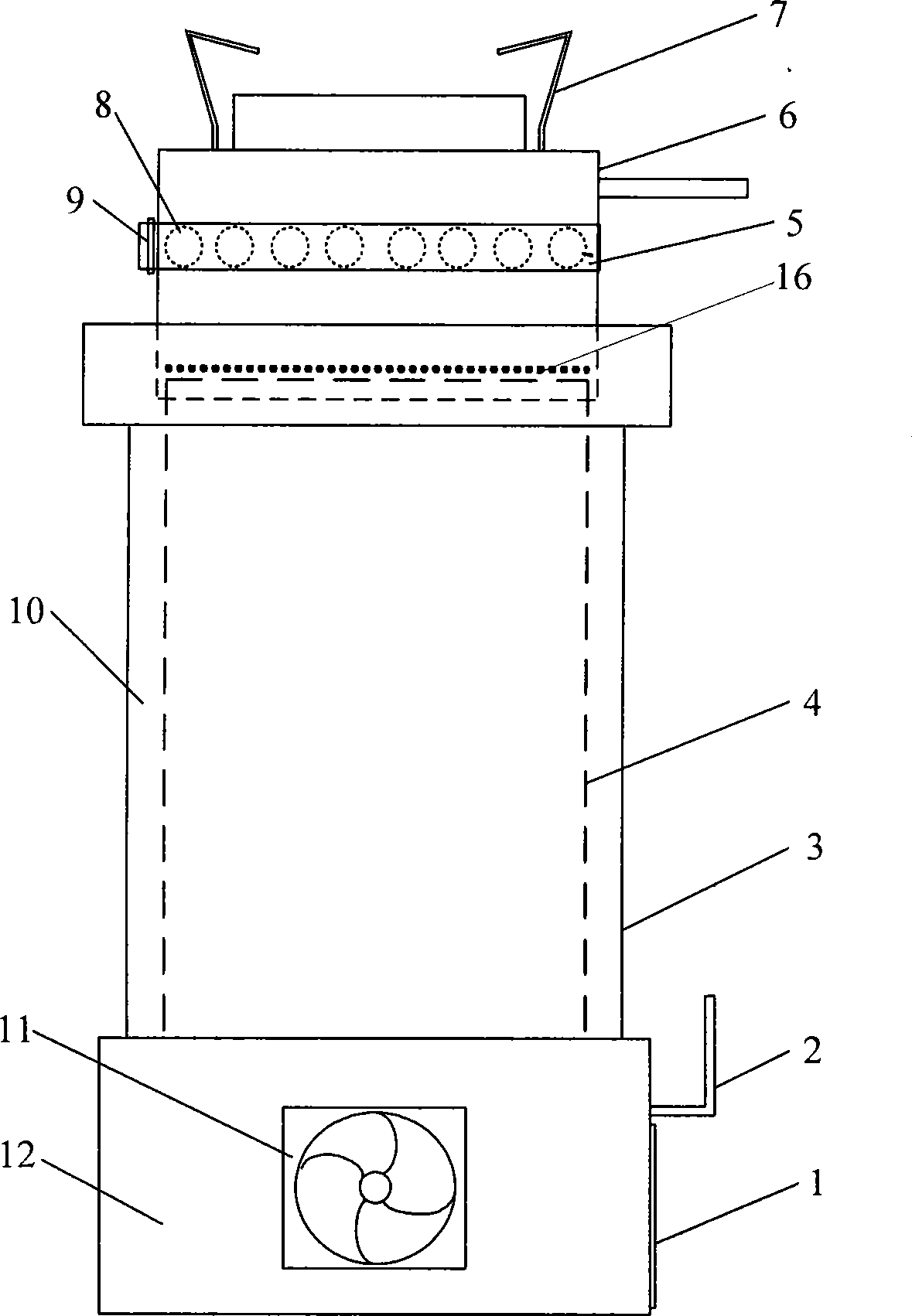

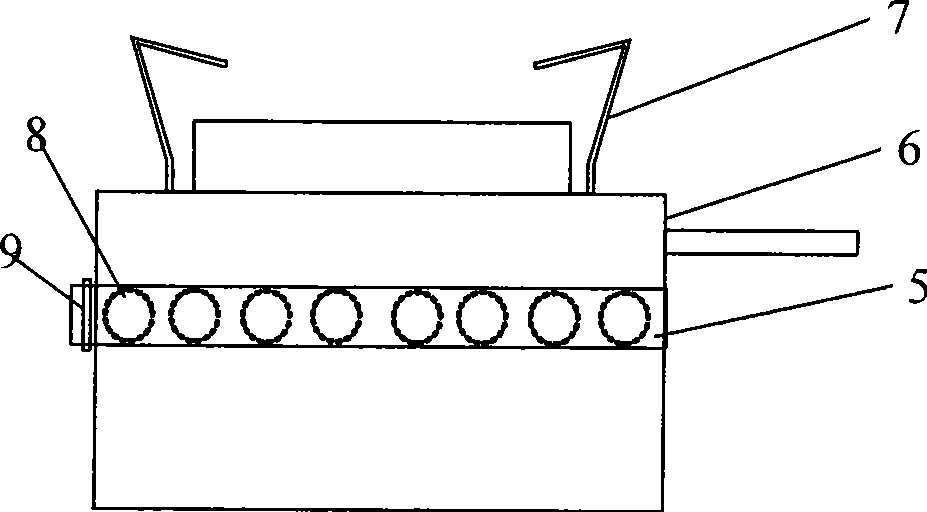

Multi-layer belt type drying system

ActiveCN103575077AEfficient and clean utilizationSimple structureDrying gas arrangementsDrying machines with progressive movementsExhaust gasEnergy consumption

The invention discloses a multi-layer belt type drying system. The multi-layer belt type drying system comprises a drying box with an exhaust port in the top and multiple layers of transmission net belts in the drying box, wherein the input end of the lower-layer transmission net belt is connected with the output end of the adjacent upper-layer transmission net belt, and a plurality of circulation fans are arranged under each layer of transmission net belt. A horizontal separation plate dividing the drying box into a drying chamber and a cooling chamber is arranged in the drying box, an air feeding port is formed in the bottom of the cooling chamber, a draught fan used for exhausting the air is arranged inside the cooling chamber, the air feeding port and the draught fan are arranged at two sides of the transmission net belts, a heater is arranged in the drying chamber, an air inlet of the heater is communicated with an air outlet of the draught fan, and a plurality of air outlets corresponding to the transmission net belts in the drying chamber one to one are formed in the heater. The multi-layer belt type drying system is simple in structure and reasonable in arrangement, preheats a heating medium by recycling waste heat of off gas and utilizing dried upgrading materials with high temperature, and lowers the energy consumption in the drying process.

Owner:ZHEJIANG UNIV

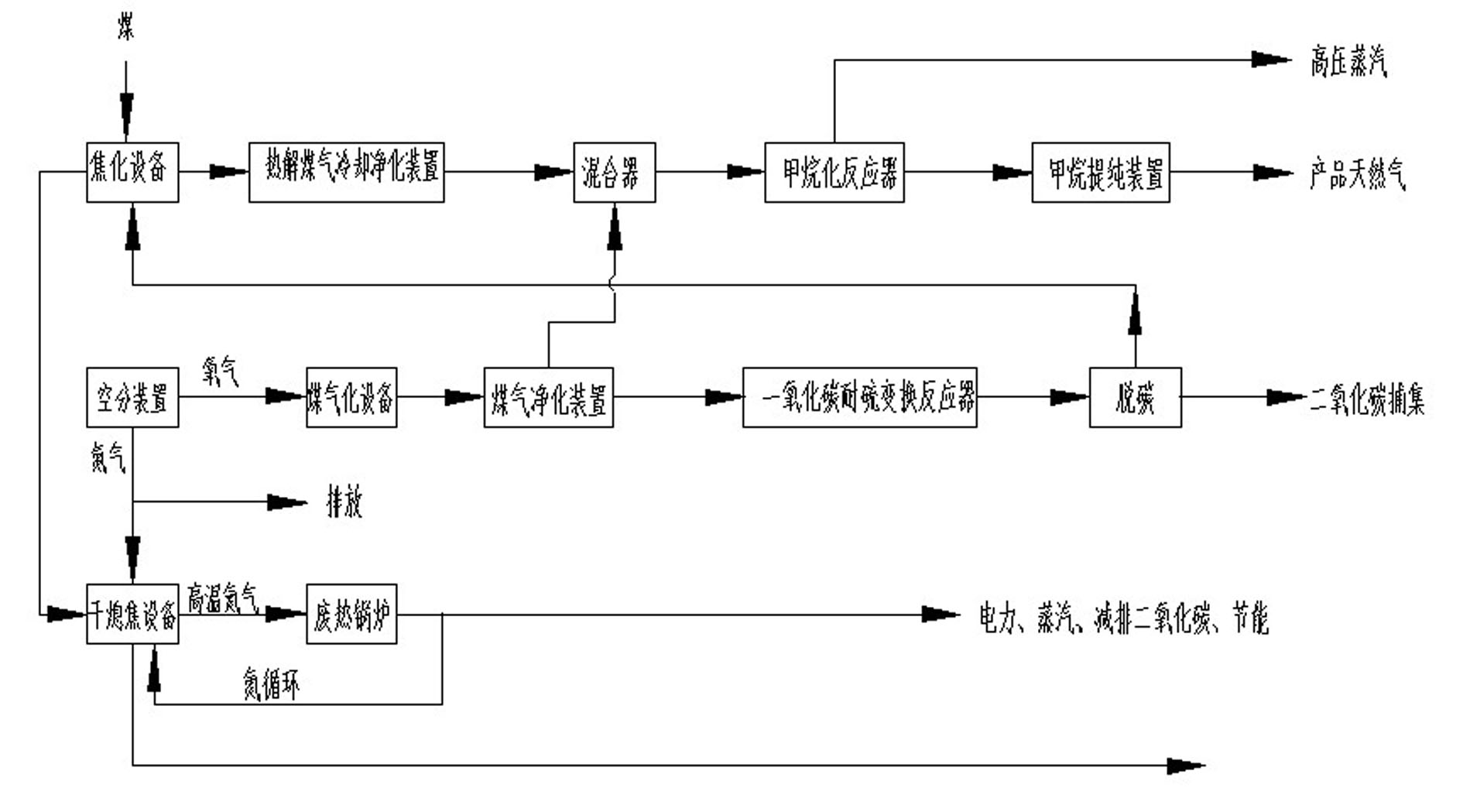

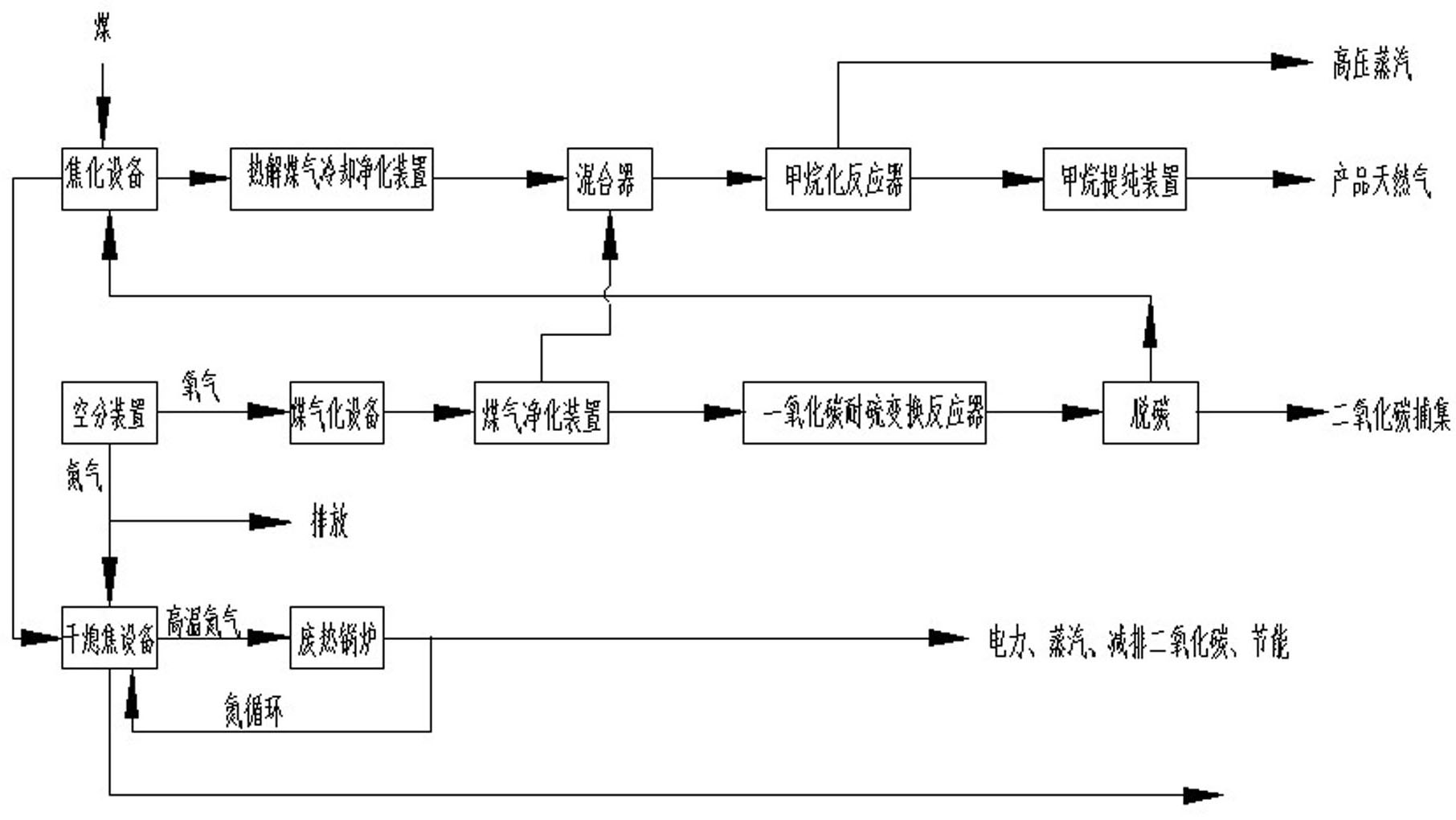

Process for producing natural gas by coal coking and pyrolysis coal gas thereof

InactiveCN102181315AAchieve emission reduction targetsQuality improvementCoke quenchingCombustible gas coke oven heatingHeat carrierMethanation

The invention relates to a process for producing natural gas by coal coking and pyrolysis coal gas thereof, in the process, raw coal gas generated by a coke oven taking H2 as fuel is purified and then completely sent to a mixer for being directly mixed with part of clean gasified coal gas for regulating hydrogen-carbon ratio, and then methanation reaction is performed under the action of a catalyst so as to prepare a product, namely the natural gas; and transformation and decarburization are performed on the other part of the clean gasified coal gas, then carbon dioxide is enriched and caught, and produced hydrogen is sent to the coke oven for burning and supplying heat. In the process, coal gasification and coke dry quenching are simultaneously performed, and a set of air separation device is realized for providing a heat carrier, namely N2, and a gasifying agent, namely O2, for the coke dry quenching and the coal gasification respectively, thereby enabling the air separation processeffect to be higher. Coke making by hydrogen burning, air separation, the coke dry quenching, the coal gasification and methanation of the coal gas of the coke oven are organically integrated, and the clean production in the coking industry and the economic and high-efficient utilization of the pyrolysis coal gas are realized, thereby having great application value in the aspects of energy utilization, CO2 emission reduction and environmental protection.

Owner:TAIYUAN UNIV OF TECH

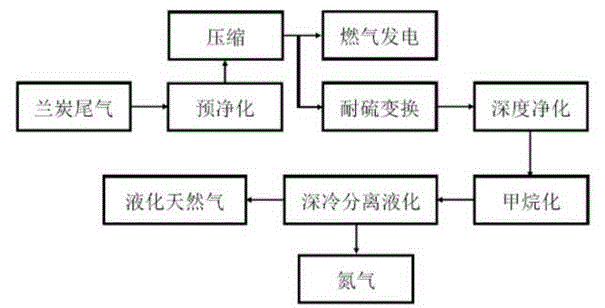

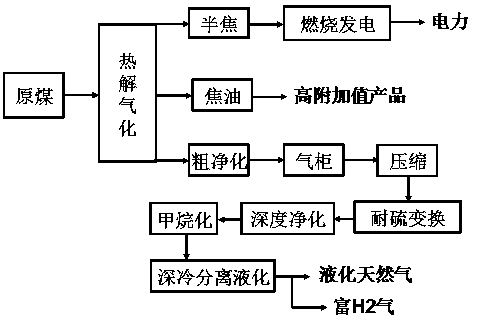

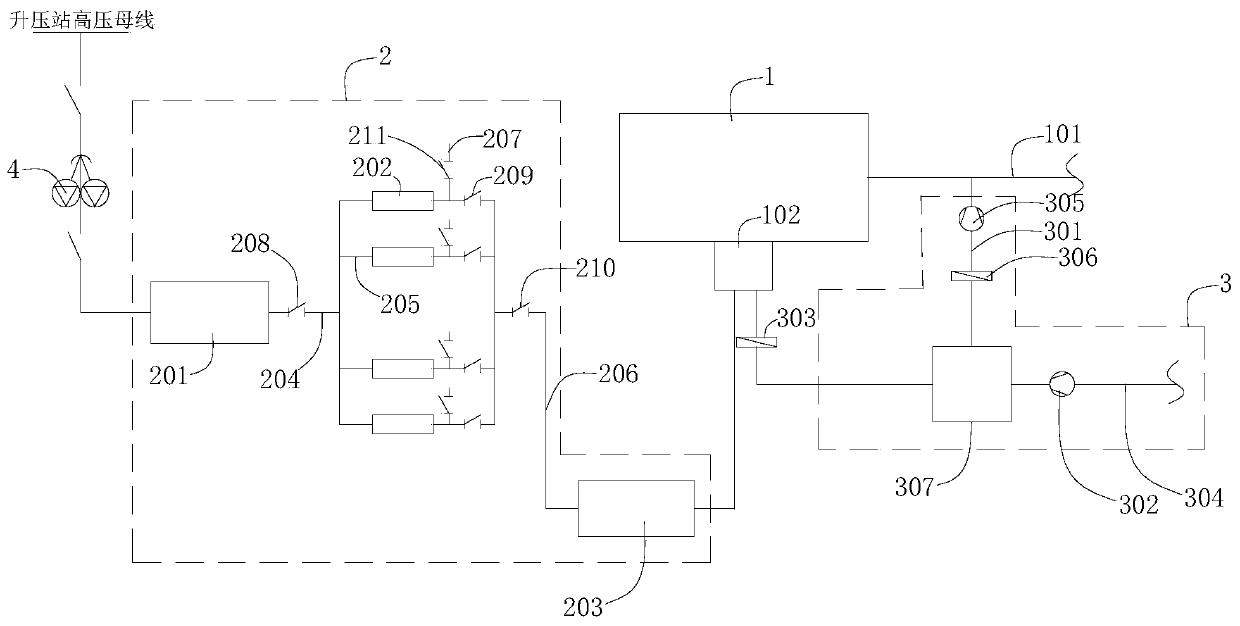

Combination method using semi-coke tail gas for power generation to cogenerate liquefied natural gas

InactiveCN102942970AImprove economyRealize efficient and clean utilizationInternal combustion piston enginesCombustible gas catalytic treatmentLiquefied natural gasGas generator

The invention discloses a combination method using semi-coke tail gas for power generation to cogenerate liquefied natural gas. The semi-coke tail gas is pressurized by an air blower and enters a pretreatment process, and impurities of tar, naphthalene, hydrogen sulfide and the like in the semi-coke tail gas are removed; a small part of preliminary purified gas after compression enters a gas generator unit directly, and the generated power is used for liquefying natural gas in a subsequent work section; and a large part of the preliminary purified gas enters a liquefied natural gas work section and is subjected to tar and naphthalene refined removing, sulfur resistance conversion, deep purification, methanation, liquefied cryogenic separation and the like to manufacture the liquefied natural gas. According to the combination method using semi-coke tail gas for power generation to cogenerate liquefied natural gas, all chemical engineering units operate according to set rated operating conditions and need not purchase electricity externally, problems of self power generation limits and ultra-low on-grid electricity price are solved for enterprises, and the economy of semi-coke enterprises is enhanced. Simultaneously, industrial exhausted semi-coke tail gas is prepared into the clean energy of the liquefied natural gas which is shortage in China, and accordingly, efficient and clean usage of the semi-coke tail gas is achieved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

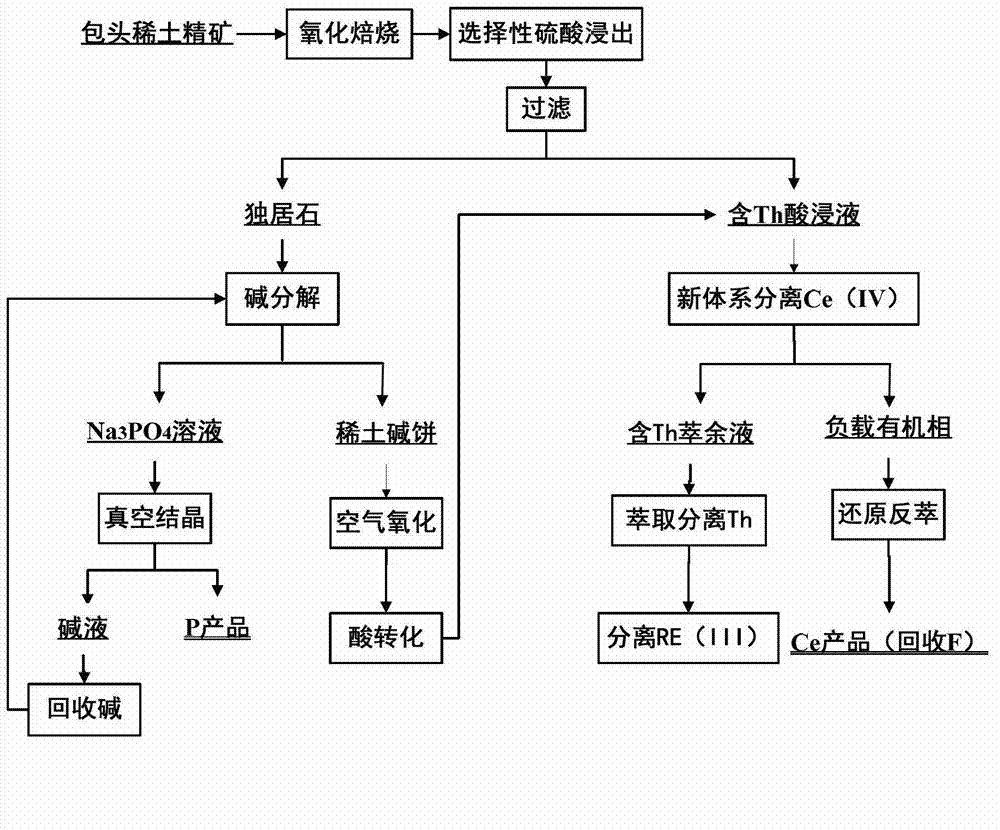

Technique for decomposing Baotou rare-earth ores

InactiveCN103045851AReduce stockpilesReduce processingProcess efficiency improvementPregnant leach solutionSodium phosphates

The invention relates to a technique for decomposing Baotou rare-earth ores. The invention solves the technical problems of environmental pollution and resource loss caused by the rare-earth ore separation technique in the prior art. The technique comprises the following steps: carrying out oxidizing roasting on mixed rare-earth concentrate; leaching the roasted ores with an H2SO4 solution to obtain a leach solution and urdite; extracting and separating Ce (IV), F and Th as well as single RE (III) from the sulfuric acid leach solution; and carrying out alkali conversion on the urdite to obtain a rare-earth alkali cake, carrying out size mixing, filtering, and crystallizing the alkaline solution to recover sodium phosphate, wherein the residual alkali liquor is used for cyclically leaching urdite slag. When being used for treating the mixed rare-earth concentrate, the technique provided by the invention can implement multi-step extraction of bastnaesite and urdite in the mixed ores. Besides, the invention is beneficial to further effectively recovering Th, F and P from baotite, thereby avoiding environmental pollution, enhancing the rare-earth yield, saving the cost and implementing clean production and comprehensive resource utilization in deed.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Biomass gasified gas re-burning mode and system for coal-fired fluidized bed

InactiveCN101915419AImprove combustion efficiencyImprove emission reduction efficiencyFluidized bed combustionApparatus for fluidised bed combustionSlagCoal dust

The invention belongs to the technical field of N2O emission reduction in a coal-fired fluidized bed, and particularly relates to a biomass gasified gas re-burning mode and a biomass gasified gas re-burning system for a coal-fired fluidized bed. The wall of a fluidized bed boiler is provided with a plurality of biomass gasified gas nozzles, biomass gasified gas is introduced into a hearth of the fluidized bed boiler, and the biomass gasified gas is reacted with N2O-containing smoke generated by burning of coal dust in the hearth to realize multi-stage re-burning so as to improve the burning efficiency of the whole fluidized bed and reduce the emission of N2O. Compared with pyrolysis and direct burning, the biomass gas rich in combustible substances such as H2, CH4, CO and the like has low ash content and extremely low sulfur content, has no sulfur removal problem, is ideal re-burning fuel and can effectively reduce the emission of nitrogen oxides by using mixed burning of the biomass gasified gas and the coal dust; and because of low alkali metal and chlorine content in the gasified gas, problems of slag formation and corrosion can be avoided, utilization of the coal dust is not affected and efficient clean utilization of the biomass can be realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

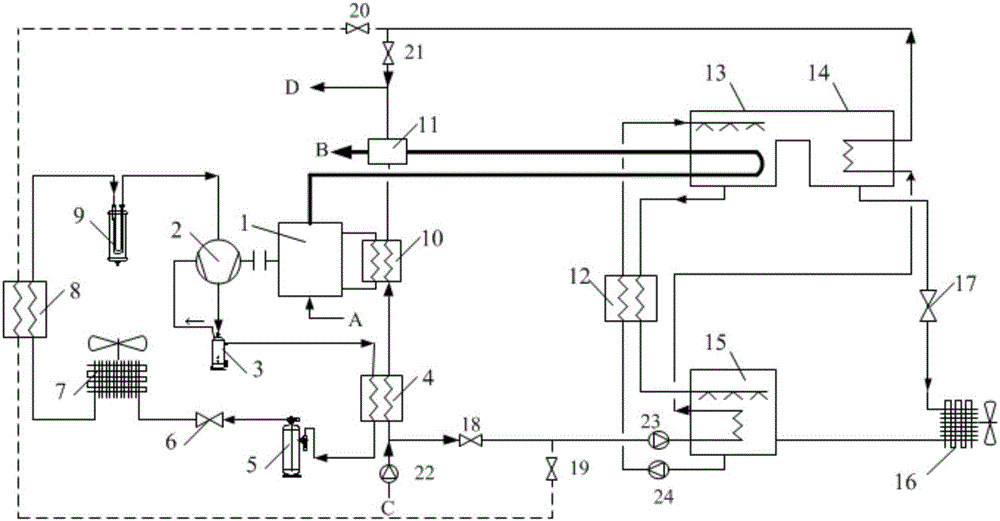

Series connection and parallel connection switching type heat supplying method of compressing absorbing hybrid heat pump of gas engine

ActiveCN106595122AEfficient and clean utilizationReduce power consumptionClimate change adaptationFluid circulation arrangementEngineeringThermal water

The invention discloses a series connection and parallel connection switching type heat supplying method of a compressing absorbing hybrid heat pump of a gas engine. The method involves a parallel connection mode and a series connection mode; when the environmental temperature is high, a hybrid heat pump heat supplying system enters the parallel connection mode, and user returned water is divided into two parts; one part of the returned water is sequentially heated through a first condenser, a cylinder sleeve heat exchanger and a smoke heat exchanger through connecting pipes; another part of the user returned water sequentially flows through a first valve, a second water pump, an absorber, a second condenser and a fourth valve by the connecting pipes and then is mixed with previous hot water; when the environmental temperature is low, the hybrid heat pump heat supplying system enters the series connection mode, and the user returned water is sequentially heated through the first condenser, the cylinder sleeve heat exchanger and the smoke heat exchanger so as to produce water supplied to a user. With the adoption of the method, the heating capacity of the whole system can be greatly improved, and meanwhile, the smoke exhaust temperature can be reduced.

Owner:TIANJIN CHENGJIAN UNIV

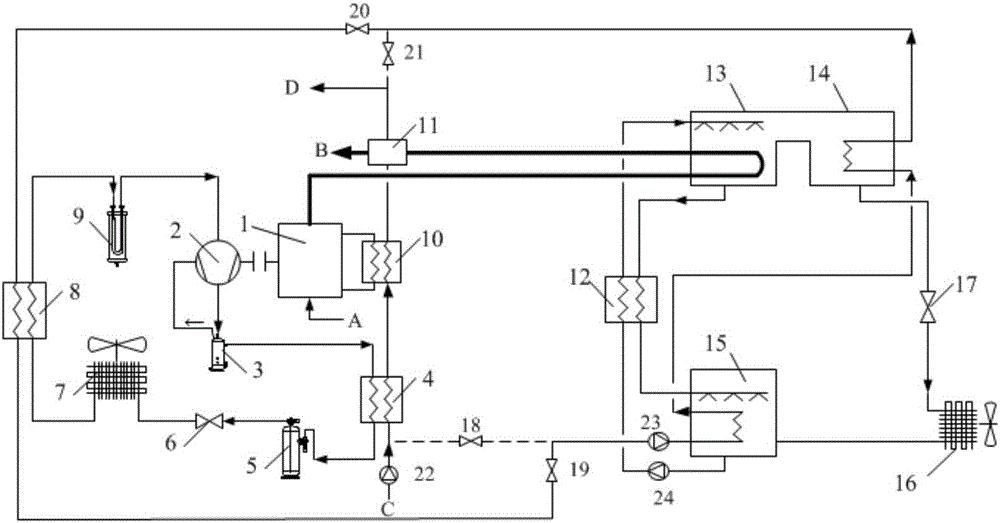

Process for co-producing LNG (Liquefied Natural Gas) by using pyrolysis gas generated in power generation system

InactiveCN103952197AHigh calorific valueImprove combustion characteristicsGaseous fuelsMethanationClean energy

The invention discloses a process for further co-producing LNG (Liquefied Natural Gas) by using pyrolysis gas generated after low-rank coal is used for generating power in a power generation system. According to the process, semi-cokes generated by coal in a pyrolyzing furnace and separated hot ash are fed into a power generating boiler system so as to be combusted and utilized, the generated power is used for LNG in the subsequent process, raw gas and fine ash particles generated through pyrolysis enter into a separation system, and products with high additional values can be extracted from the separated tar. The process specifically comprises the following steps of pressurizing the raw gas and then entering into a pretreatment process; removing impurities such as dust, oil tar, naphthalene and H2S in the raw gas; compressing pre-purified gas and then entering into units such as a pyrolysis gas deep purification unit, a methanation unit and cryopenic separation and liquidation units, thereby preparing clean energy liquefied natural gas which is short in China. According to the invention, coal pyrolysis and gasification are organically combined with gas, chemical, electric and heat production processes on the basis that heat supply and power generation are carried out by taking semi-cokes as solid fuels, so that graded transformation and step-by-step extraction of coal as well as economic benefit maximization are realized, the energy utilization efficiency is increased, and the economical efficiencies of thermoelectricity enterprises are increased.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

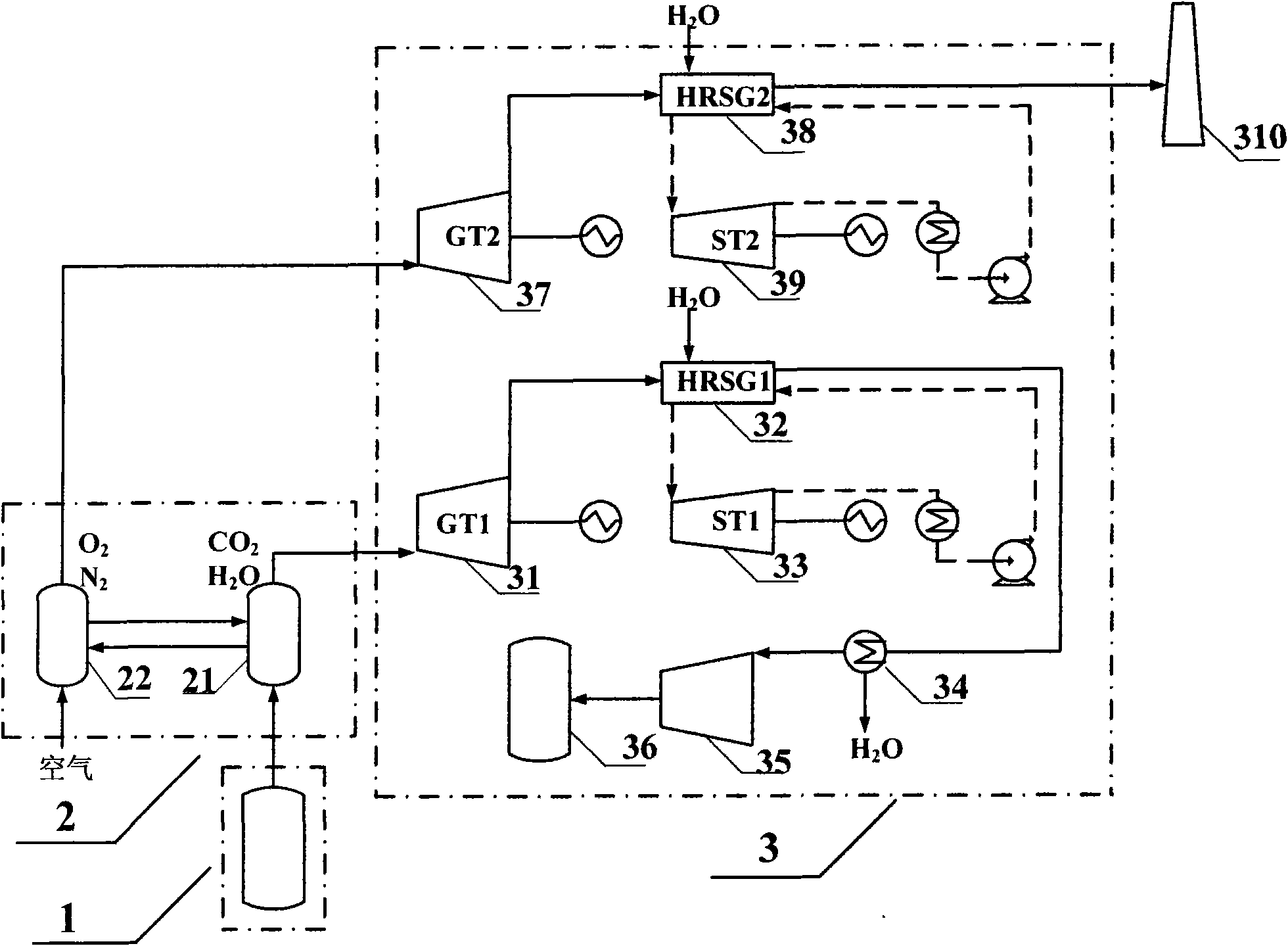

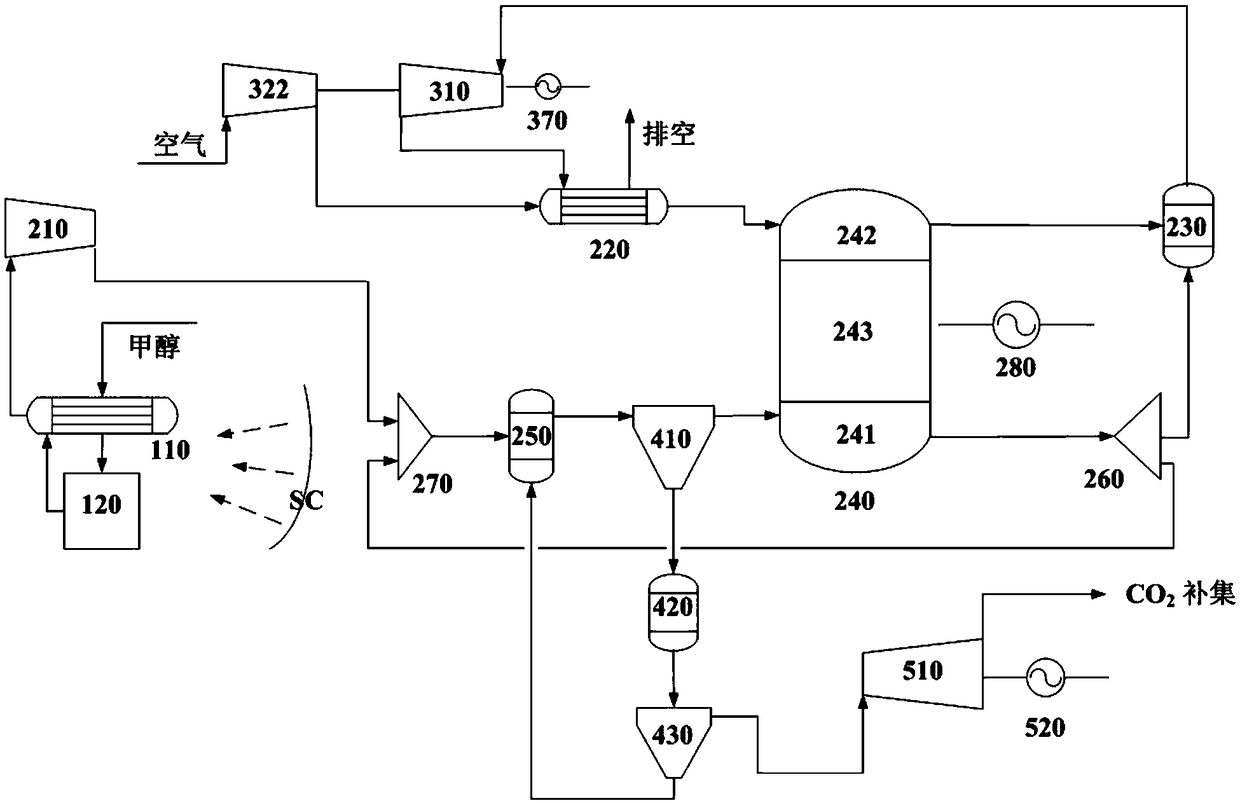

A chemical looping combustion power generation process and system using landfill gas

InactiveCN101550846AEfficient and clean utilizationAchieve indirect combustionGas treatmentGas turbine plantsSingle substanceWater vapor

The present invention discloses a chemical looping combustion power generation process and system using landfill gas, which falls into the range of efficient landfill gas cleaning and utilization technique. This power generation system is composed of a landfill gas collection system, a chemical looping combustion system, and a gas and steam combined cycle power generation system. In the process, the simple substance metal in the air reactor takes oxidation reaction with air, the landfill gas and the obtained metal oxide take reduction reaction in the fuel reactor to generate single substance metal, CO2 and water vapor, and the reduced simple substance metal returns to the air reactor via the refeed line and completes the regeneration of metal oxide; the gas at the outlet of the fuel reactor and the gas at the outlet of the air reactor are led to two separate gas and steam combined cycle power generation systems for power generation and CO2 recovery.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

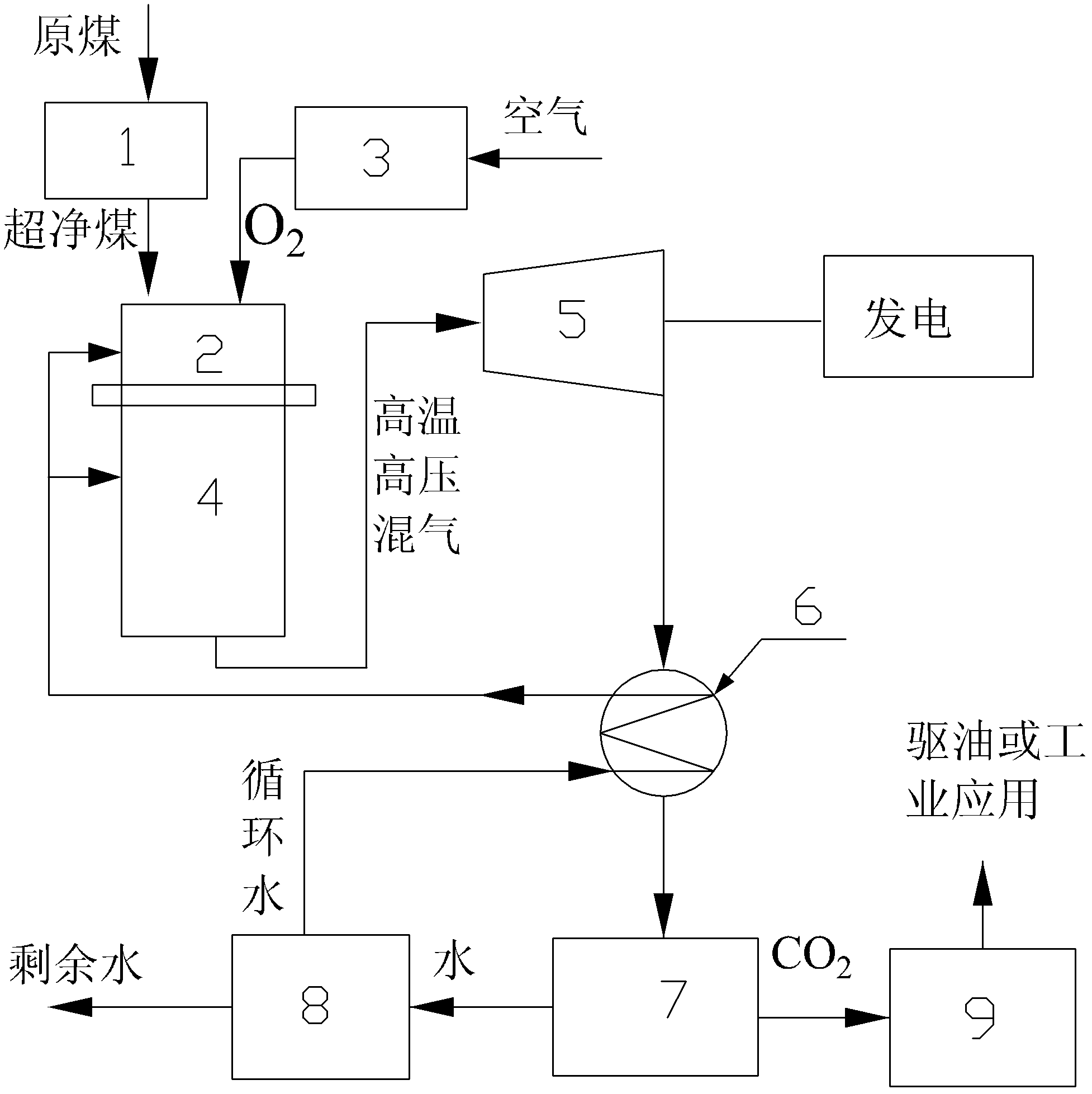

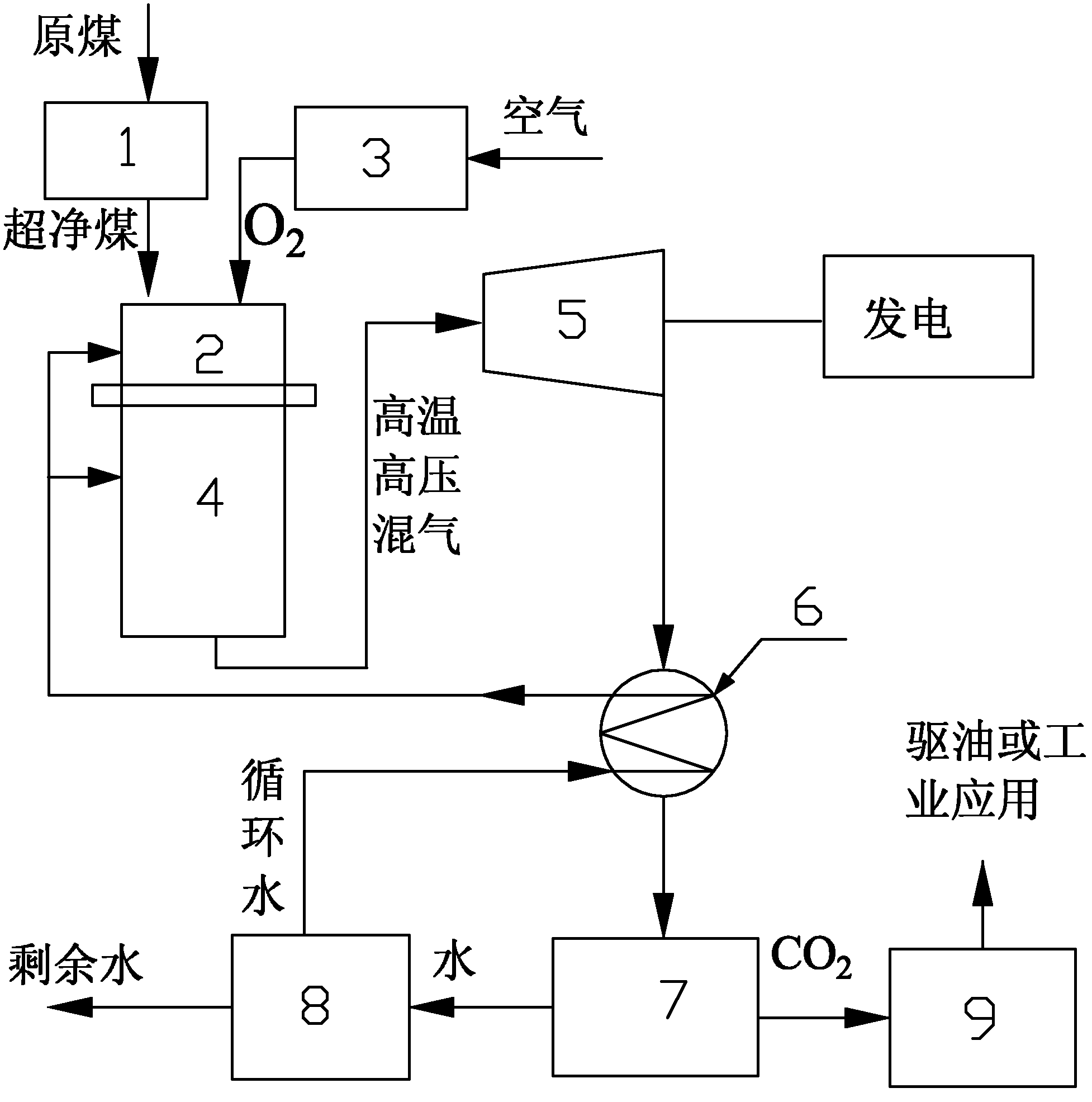

Coal-based fuel near zero emission power generation system and method

ActiveCN102628401AAchieving zero emissionsAchieve emissionsGas turbine plantsEngine componentsHigh concentrationCombustion chamber

The invention provides a coal-based fuel near zero emission power generation system and a method, and the invention relates to the technical field of coal-based fuel CO2 zero emission power generation. The method comprises the following steps: raw coal is subjected to demineralization pretreatment to be produced into ultra-clean coal; the ultra-clean coal is combusted in a high-pressure combustion chamber under pure oxygen condition; water sprayed into the combustion chamber step by step is directly heated into high temperature and high pressure mixed gas and an advanced turbine is pushed by the mixed gas to do work; exhaust gas is condensed by using a condenser to be produced into high concentration CO2; and zero emission of atmospheric pollutant is finally realized. The invention also provides a system for realizing the above processes. The system mainly consists of a demineralization pretreatment system, an ultra-clean coal pure oxygen combustor, an air separation system, the high-pressure combustion chamber, the advanced turbine, the condenser, a water purification treatment system and a CO2 recovery processing device. According to the invention, problems of conventional power generation methods, such as high pollutant emission and high CO2 capture cost, are solved. Furthermore, efficient and clean usage and zero pollutant emission of combusted coal are realized.

Owner:HARBIN INST OF TECH

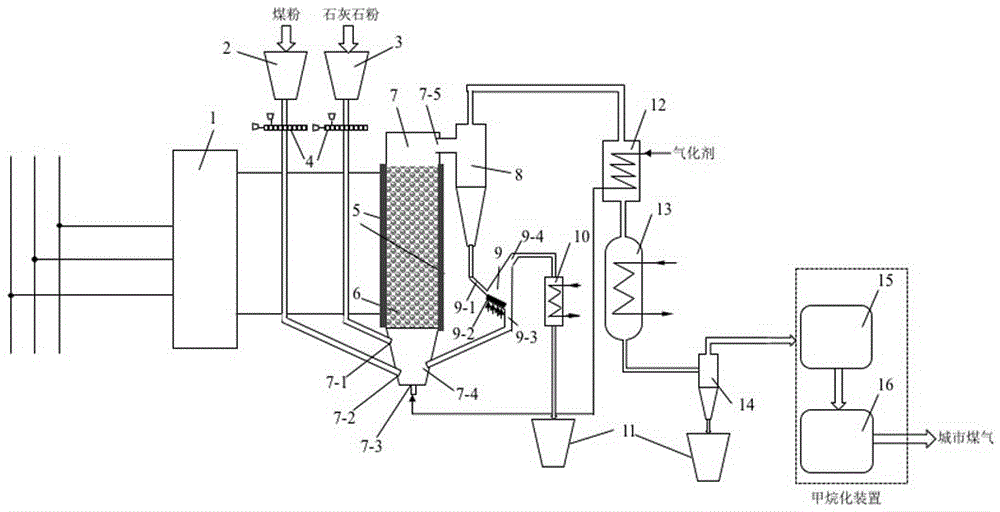

Combined system and process for producing electricity-substituted natural gas based on coal gasification and methanation

ActiveCN100582201CEfficient and clean utilizationEfficient use ofCombustible gas chemical modificationCombustible gas purificationMethanationSlurry

An electric-substituting natural gas combined system and process based on coal gasification and methanation are disclosed. The process is carried out by delivering oxygen, powdered coal or water-gas slurry into gasified apparatus, recovering for crude gasified gas by wet heat, delivering into sulfur-resisting carbon monoxide carbon reactor, adjusting hydrogen-carbon ratio, entering into desulfurizing decarbonizer, recovering elementary sulfur while enriching carbon dioxide, delivering synthetic gas into methane reactor to generate substituted natural gas as domestic gas partially, entering into gas and steam combined circulator partially, and entering into substituted natural gas storage tank partially. It integrates coal gasified, methanation and gas steam combined circulation together, it's efficient and clean, has better utilizing rate, no CO2 discharge and need for changing gas turbine or load.

Owner:TSINGHUA UNIV

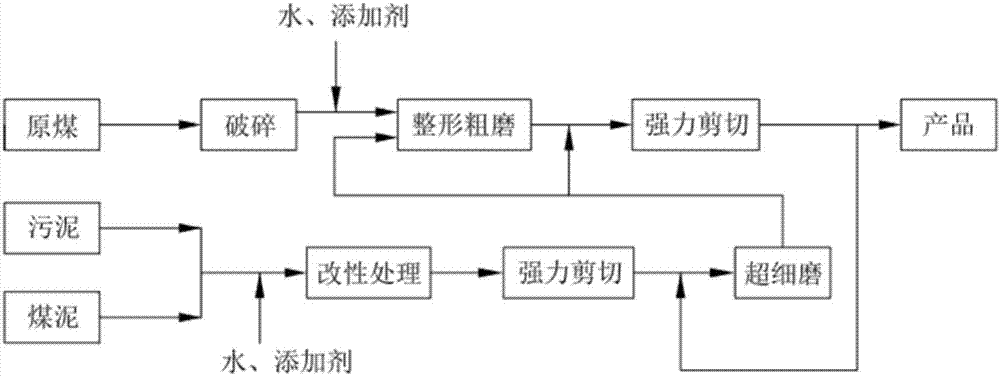

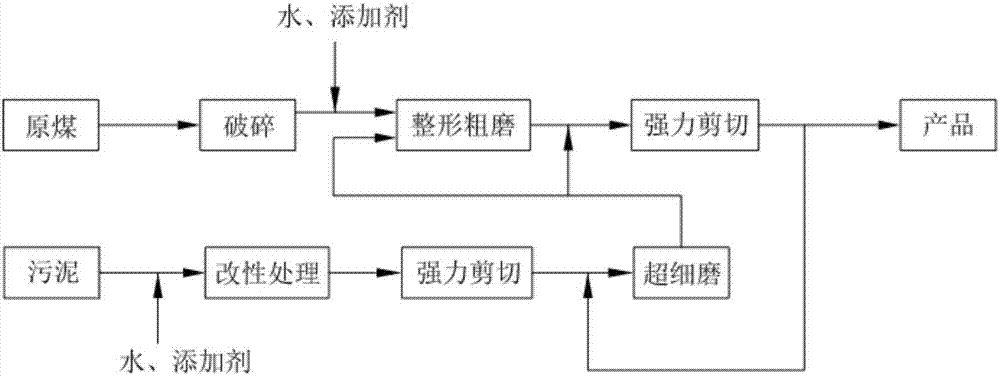

Method for preparing novel coal water slurry product from multiple materials

ActiveCN107267235AQuality improvementEfficient and clean utilizationLiquid carbonaceous fuelsCoal waterMulti material

The invention provides a method for preparing a novel coal water slurry product from multiple materials. The method includes the following steps: (1) after raw coal is crushed, a material A is obtained; (2) after being modified together, sludge, optional coal slime, water and additive then undergo strong shear treatment, so that a material B is obtained; (3) the material B is ultrafinely ground, so that a material C is obtained; (4) the material A, part of the material C, water and additive are shaped and roughly ground, so that a material D is obtained; (5) after being mixed, the material D and the remaining material C undergo strong shear, and thereby the coal water slurry product is obtained. The grain size distribution of the multi-material coal water slurry prepared by the preparation method is reasonable, and the novel coal water slurry product has good stability, flowability and good atomizing effect, and is also applicable to the preparation of fuel and gasified coal water slurry; in addition, the preparation method is easy to implement, energy consumption is low, and the problem on how to utilize sludge and coal slime on a large scale can be reasonably solved.

Owner:CCTEG CLEAN ENERGY CO LTD

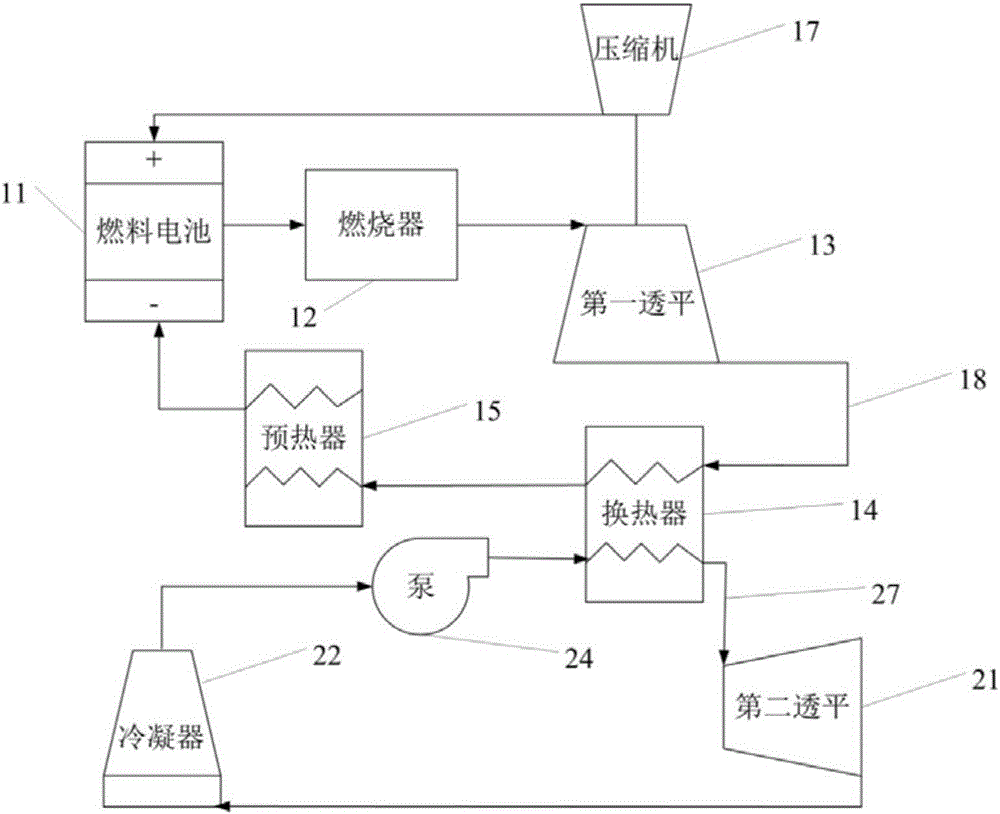

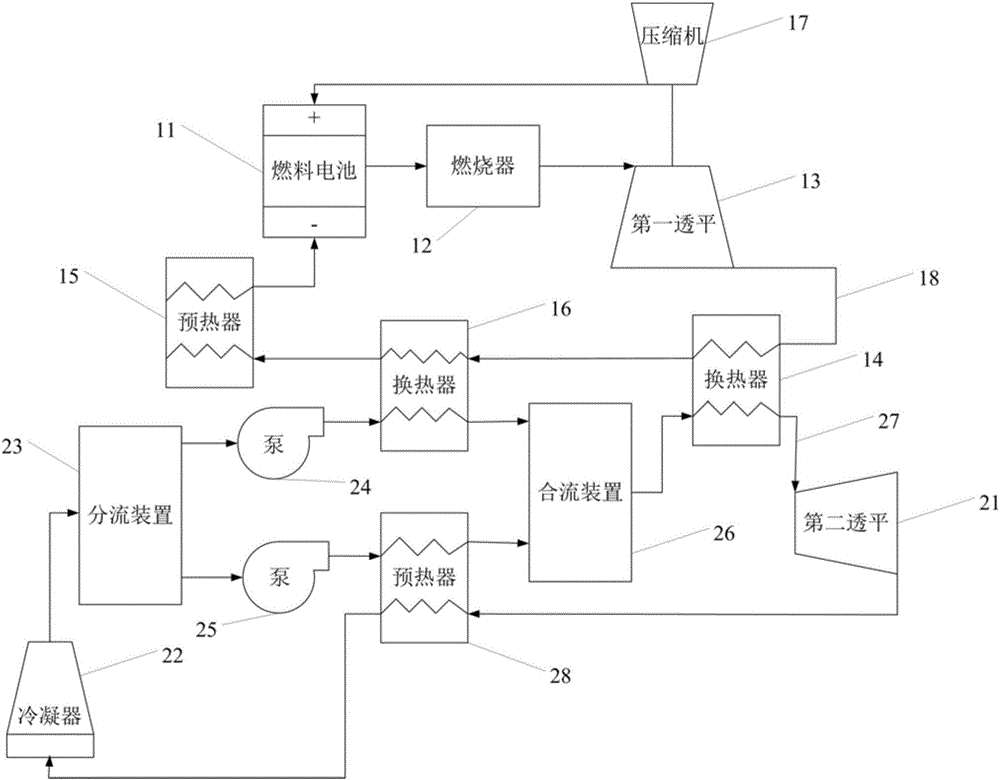

Power generation method and electric power generation method

InactiveCN106499454AImprove conversion efficiencyEmission reductionGas turbine plantsSteam engine plantsFuel cellsOrganic Rankine cycle

The invention discloses a power generation method and an electric power generation method. By means of the power generation method and the electric power generation method, the energy conversion efficiency is remarkably improved, pollutant discharge is reduced, due to the fact that high-temperature exhaust of a fuel battery and a combustion gas turbine circulation loop still has a quite high temperature grade and belongs to medium and low temperature waste heat, the organic Rankine cycle is adopted for recycling the medium and low temperature waste heat, the energy conversion efficiency can be greatly improved, and emission of pollutants to the environment is reduced. Besides, the power generation method and the electric power generation method achieve comprehensive gradient conversion and efficient and clean utilization of energy through system integration and procedure improvement.

Owner:XIAMEN UNIV +1

Method for deeply extracting vanadium by utilizing alkaline tailings

InactiveCN109825723AEfficient and clean utilizationRealize resource utilizationProcess efficiency improvementEconomic benefitsMaterials science

The invention relates to a method for deeply extracting vanadium by utilizing an alkalinetailings. The method comprises the steps of mixing the alkaline tailings and a vanadium-containing material, and then roasting an obtained mixture; and leaching the roasted clinker through water so as to obtain a vanadium-containing solution and a leaching residue. According to the method for deeply extractingthe vanadium by utilizing the alkaline tailings provided by the invention, the alkaline extracted vanadium tailings is directly used as a raw material and is mixed with the vanadium-containing material so as to carry out reaction, so that compared with a traditional tailings treatment technology, the method provided by the invention has remarkable advantages. The method for deeply extracting thevanadium by utilizing the alkaline tailings is simple in process and short in flow, sodium slat in the alkaline extracted vanadium tailings is recycled, meanwhile, a vanadium element in the extractedvanadium tailings is high-efficiently recovered, vanadium is high-efficiently cleaned and utilized, the cost is reduced favorably, and the method has favorable economic benefit and application prospect.

Owner:HEBEI IRON AND STEEL

Solid oxide fuel cell combined system based on solar methanol reforming hydrogen production

PendingCN109004244AReasonable clean useEfficient and clean utilizationFuel cell heat exchangeElectric powerHydrogen production

The invention provides a solid oxide fuel cell combined system based on solar energy methanol reforming hydrogen production. The methanol reforming hydrogen production subsystem comprises at least a first heat exchanger and a methanol reforming reactor. A solid oxide fuel cell subsystem includes at least a plurality of solid oxide fuel cells, a fuel compressor, a second heat exchanger, an afterburning chamber, and a prereformer; A wet air turbine circulation subsystem includes at least a first gas turbine and a wet air generating device capable of producing wet air from air and water; The wetair outlet of the wet air generating device is communicated with the cathode inlet via the second heat exchanger, the outlet of the methanol reforming reactor is communicated with the anode inlet viathe first heat exchanger, the fuel compressor and the preformer in turn, the outlet of the afterburning chamber is communicated with the inlet of the first gas turbine, and the outlet of the first gasturbine is communicated with the inlet of the second heat exchanger. The combined system is an efficient power generation system which can output more power and has better energy saving and economy.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

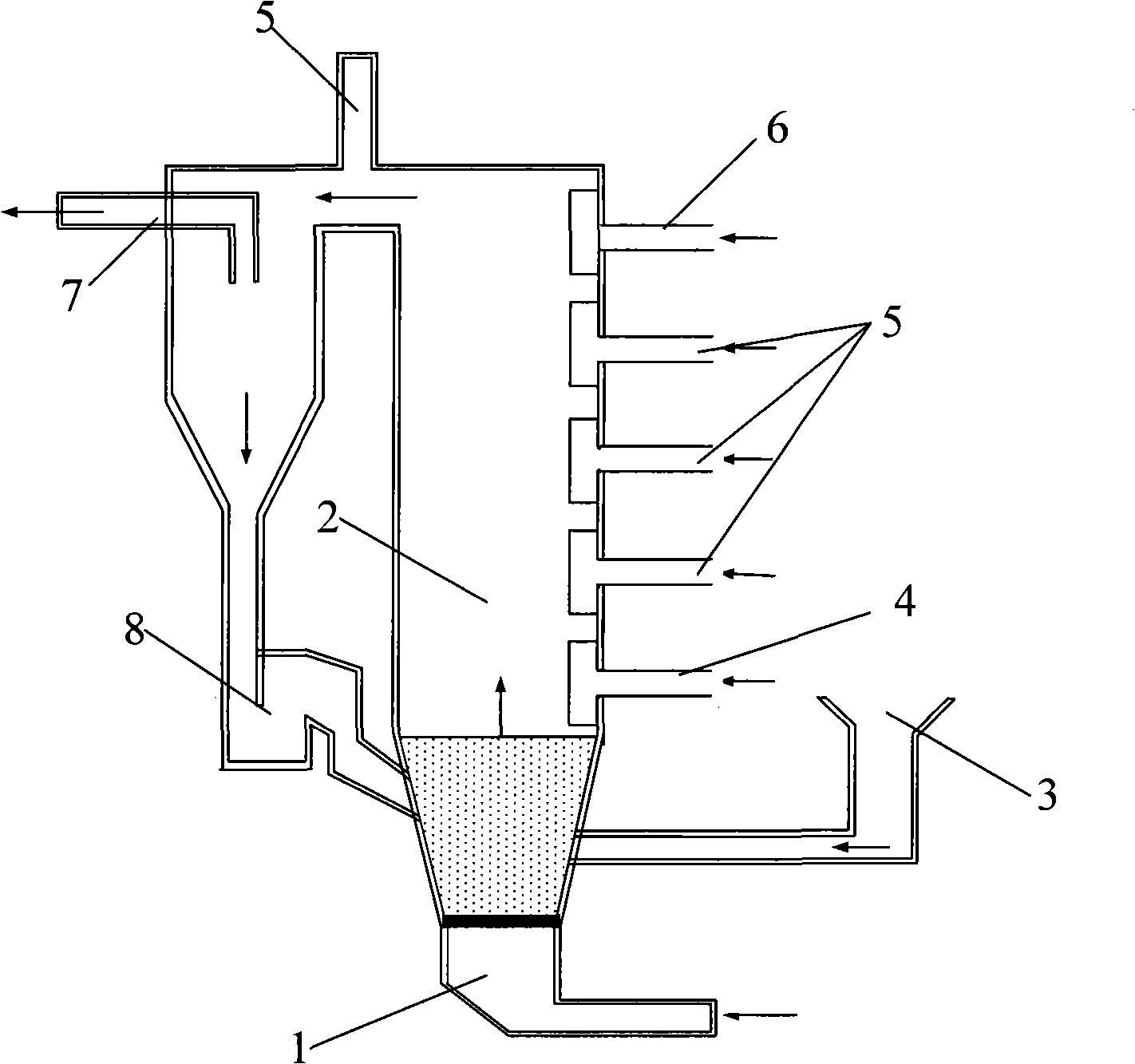

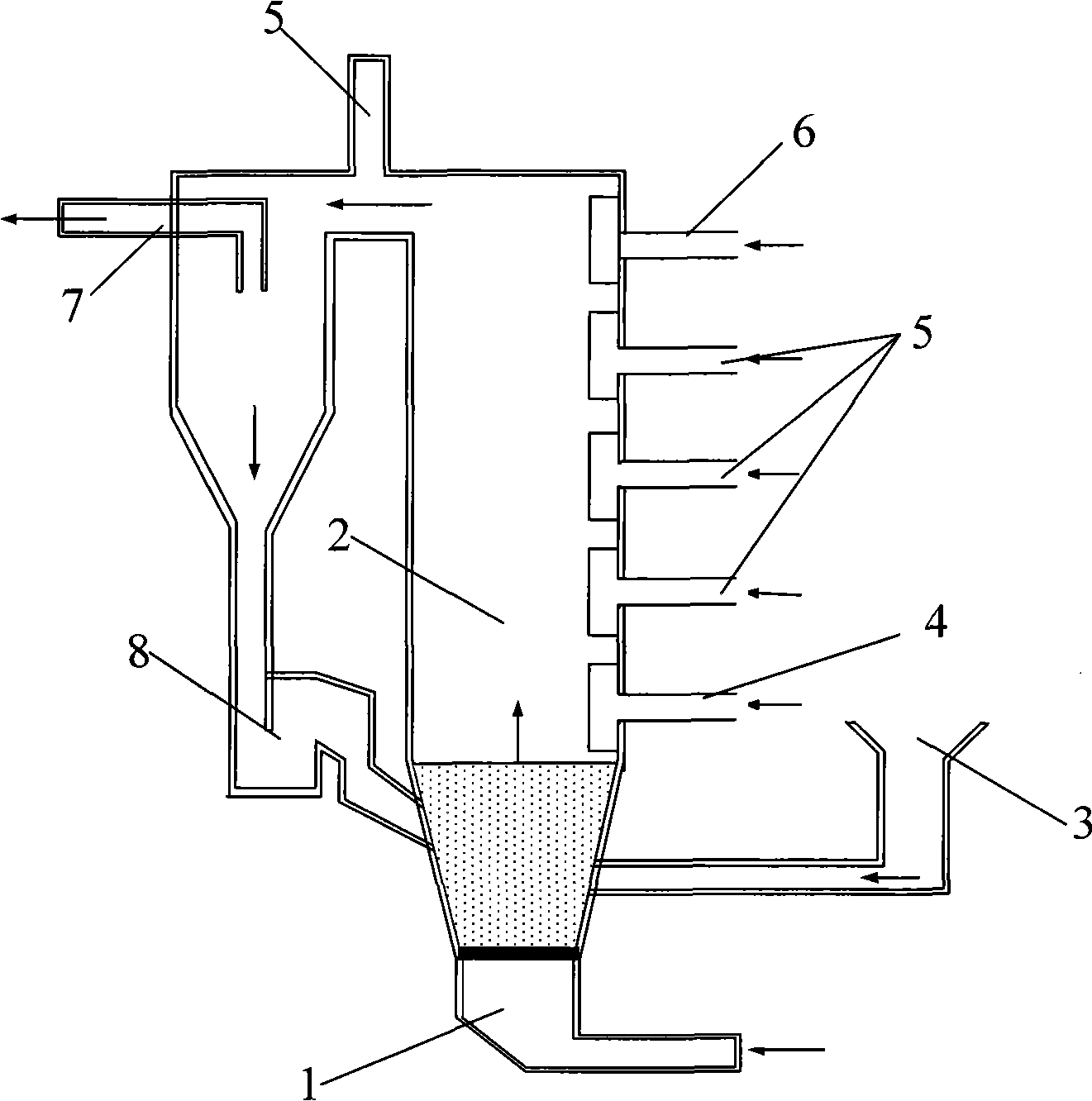

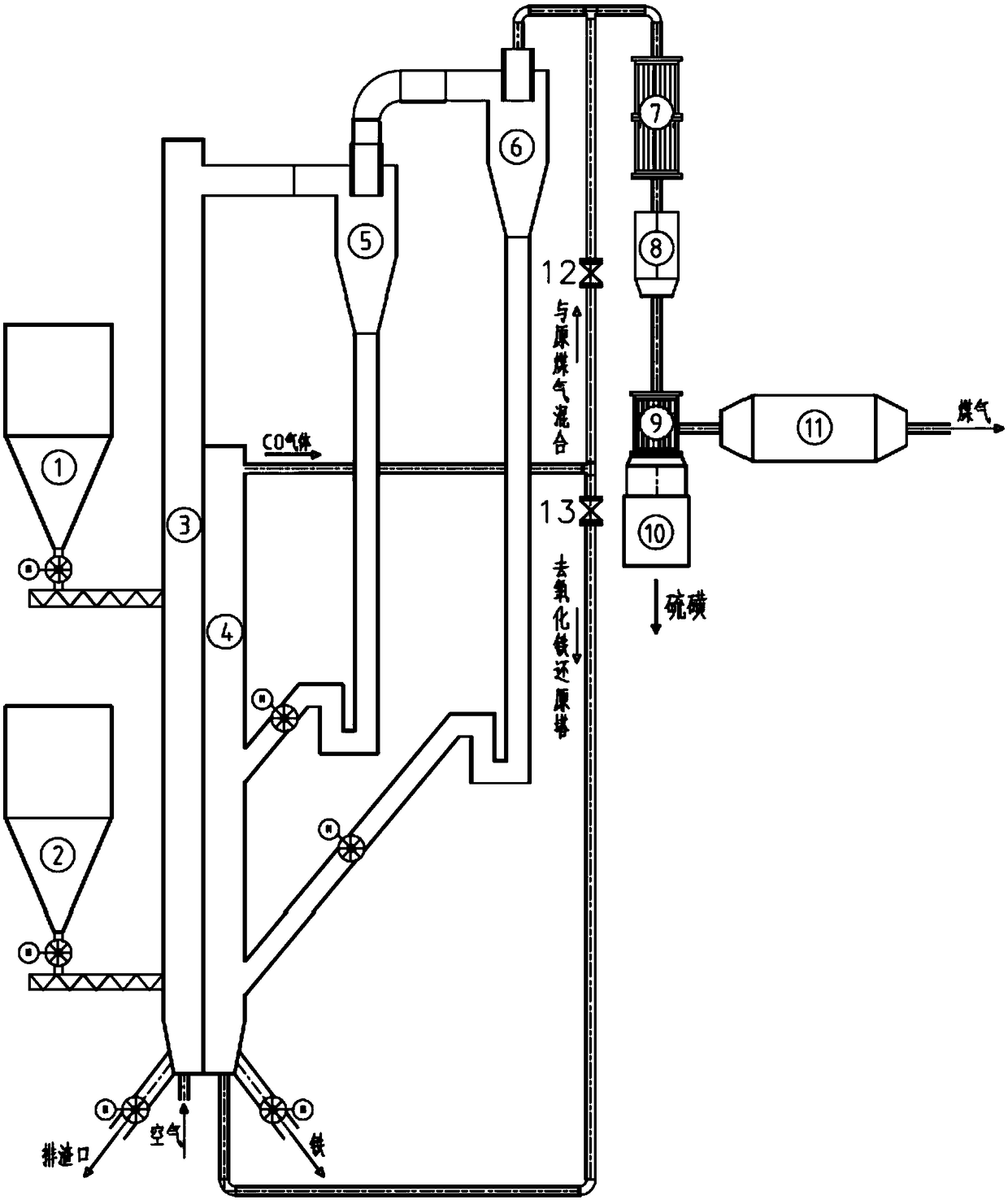

Device and method for joint production of iron, sulfur and gas in smelting process of pyrite

ActiveCN108970354AEfficient and clean utilizationAlleviate the current situation of resource shortageGas treatmentDispersed particle separationSulfur containingCoal gasification

The invention relates to a device and method for joint production of iron, sulfur and gas in the smelting process of pyrite, and belongs to the field of metal smelting. The method comprises the following steps of calcining the pyrite at the bottom part of the interior of a calcining-gasifying reaction tower, enabling pulverized coal and fly ash to generate gasifying reaction at the middle upper part, enabling the sulfur-containing flue gas to carry the high-valence oxide of iron produced by calcining at the tower bottom to the middle upper part of the reaction tower, mixing with the gas and coke produced by gasifying, and generating oxidation and reduction reaction; separating the product by an iron-based high-temperature separator and a carbon-based high-temperature separator, and sendingback into an iron oxide reduction tower; performing secondary reduction reaction on the iron oxide in the iron oxide reduction tower, and producing reduction gas, so as to obtain iron slag; purifyingthe crude gas, so as to obtain the purified gas; enabling a sulfur condenser to condense and recycle the sulfur. The method has the advantages that the joint production of iron, sulfur and gas is realized in the smelting process of the pyrite, and the pyrite can be efficiently and cleanly utilized.

Owner:SHANDONG UNIV

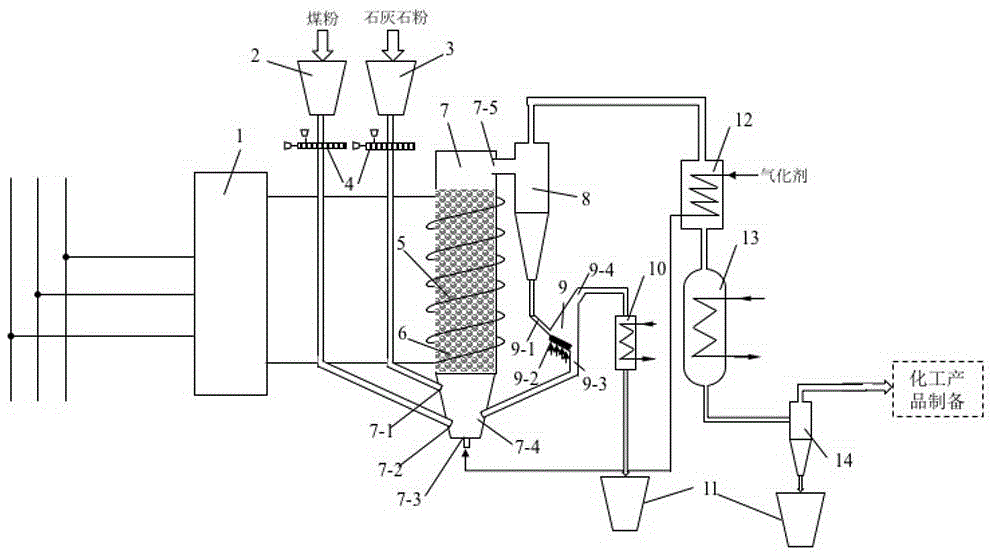

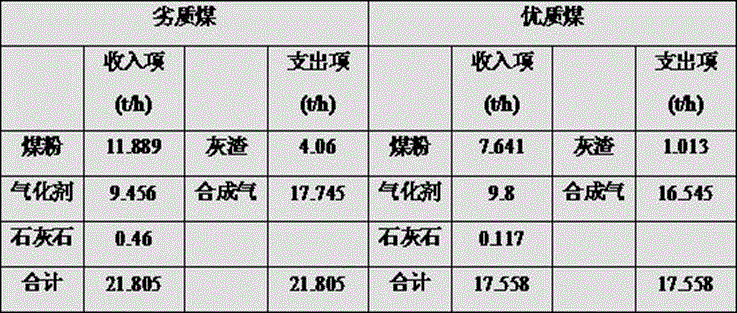

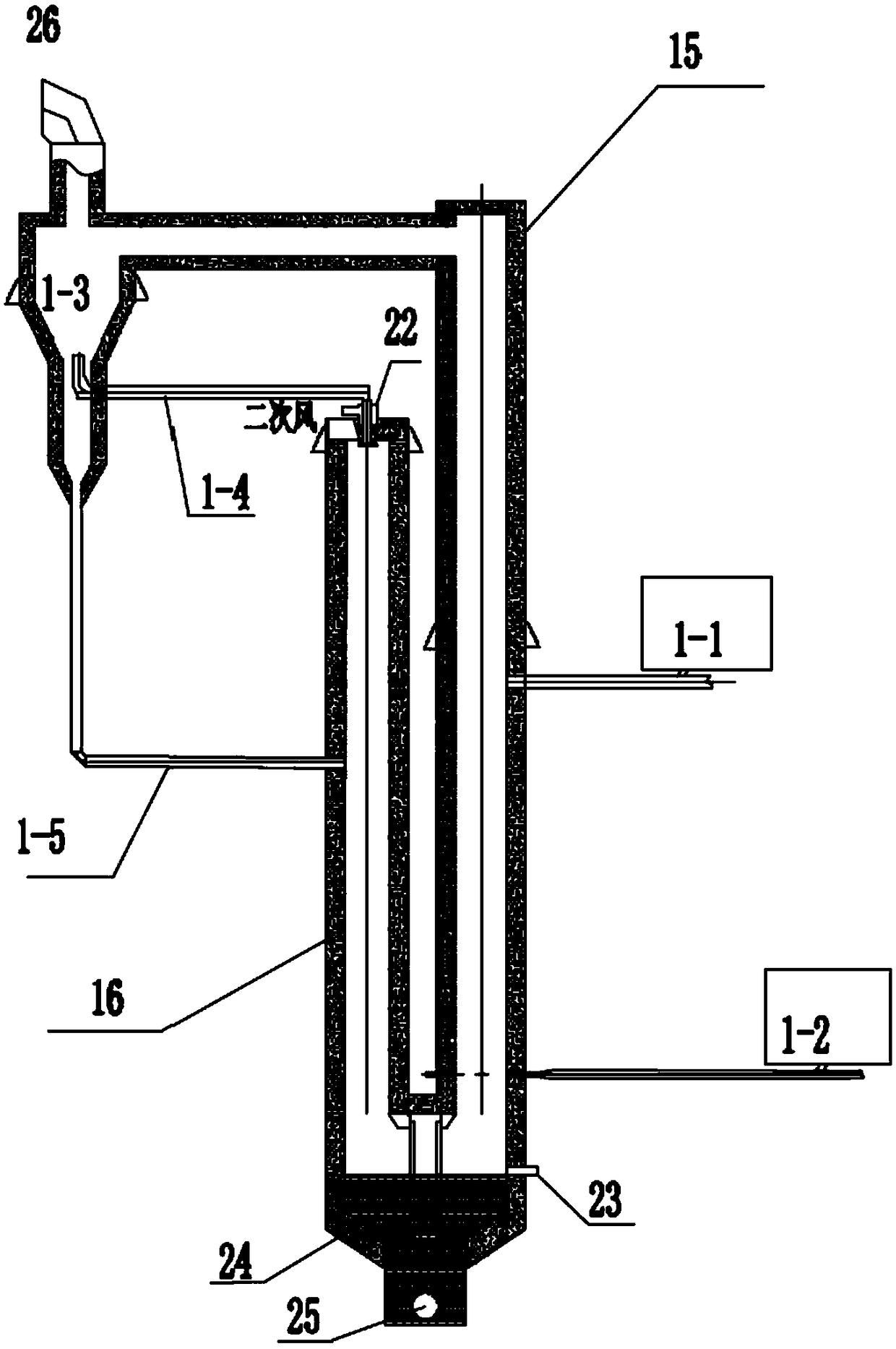

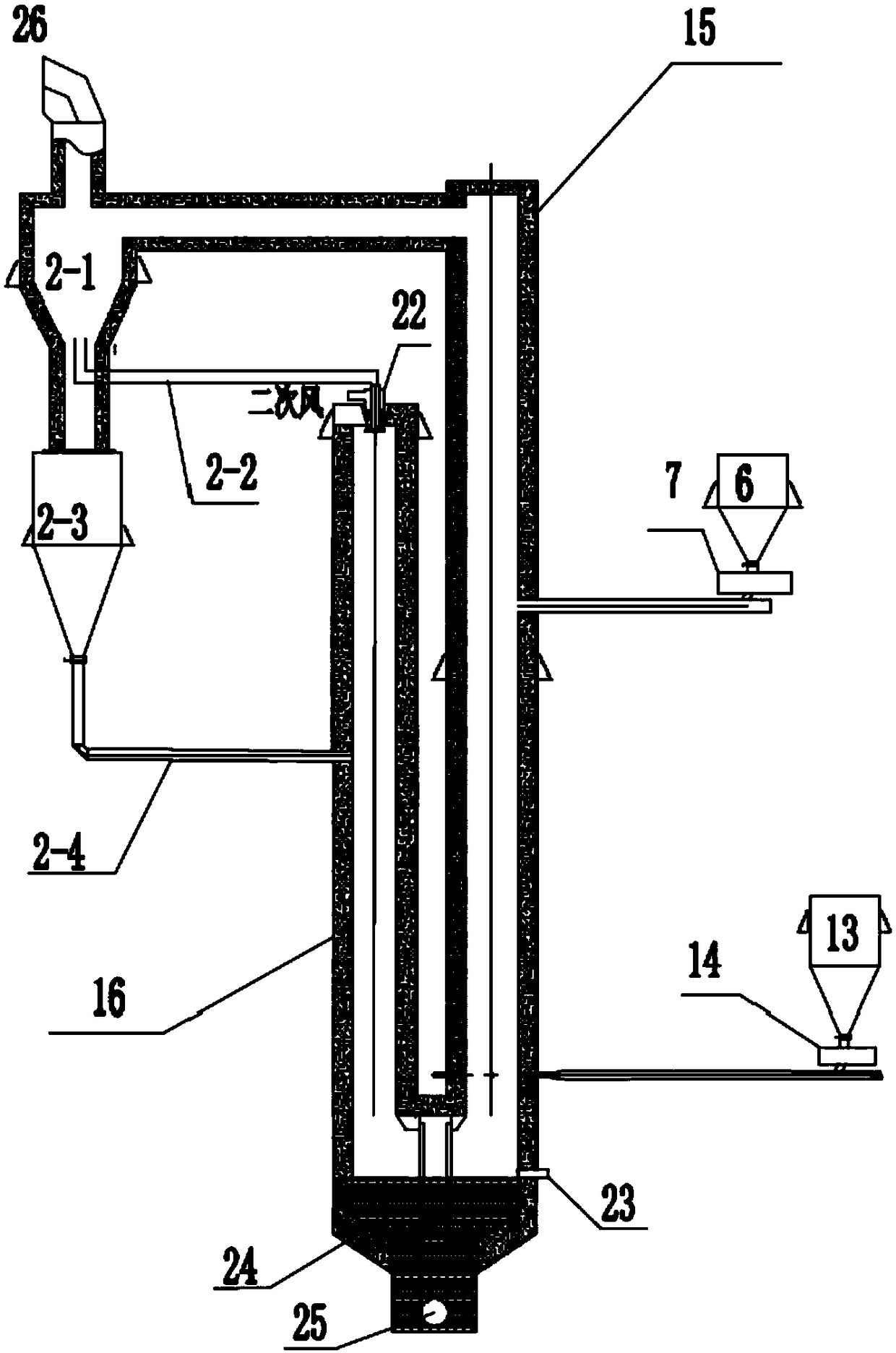

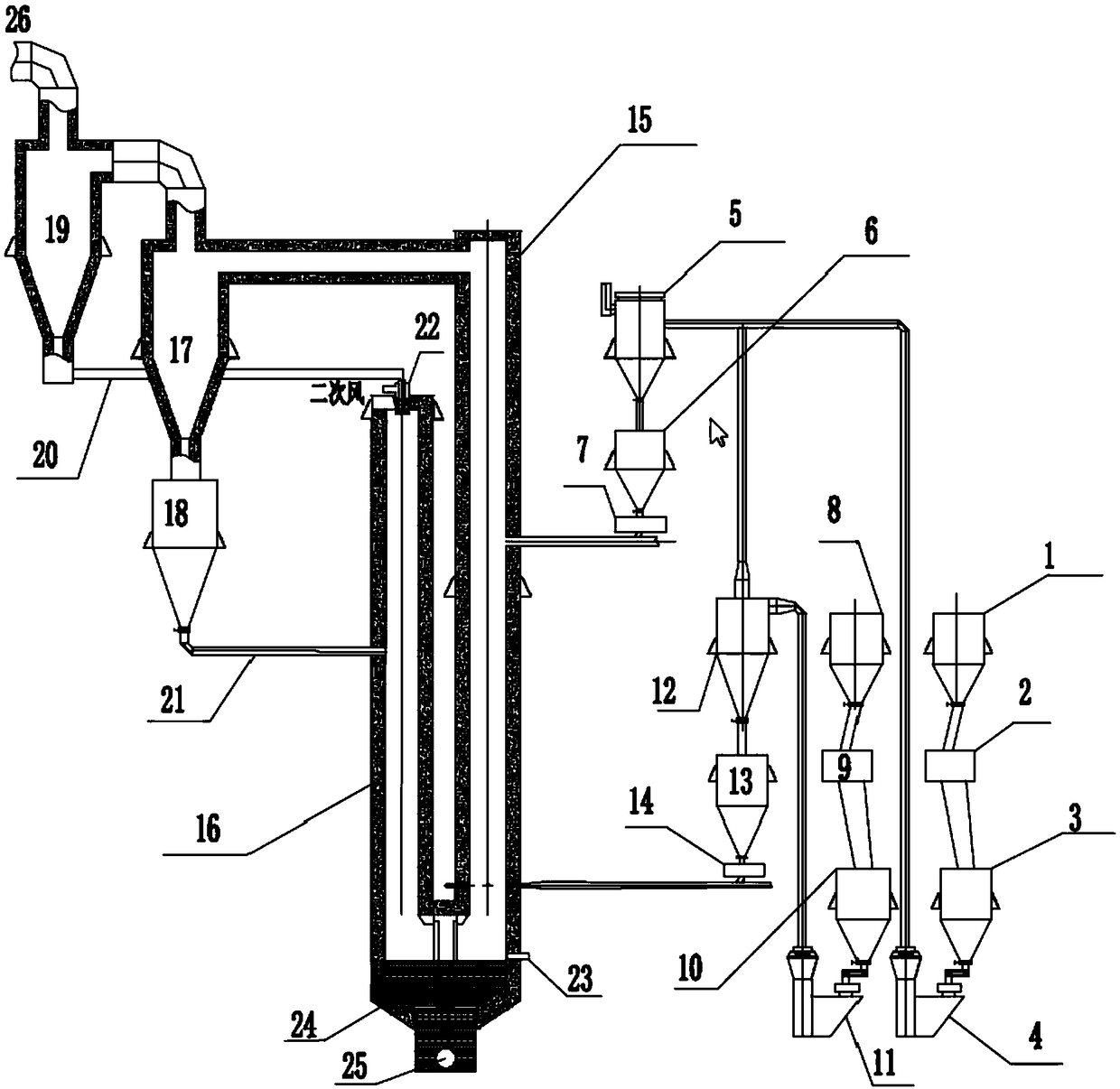

Electric power storage system and method employing coal gasification of solid heat carrier

ActiveCN106753579AEfficient use ofReduce wasteGasification processes detailsGranular/pulverulent flues gasificationHeat carrierElectric heating

The invention provides an electric power storage system and method employing coal gasification of a solid heat carrier. The system comprises a power supply device, a fluidized bed powdered coal gasifier, a cyclone dust collector, an ash discharge classifier and a fine ash collecting chamber, wherein the power supply device is connected with the fluidized bed powdered coal gasifier; the fluidized bed powdered coal gasifier comprises a gasifier body; a metal heat carrier is contained inside the gasifier body and an electric heating element is arranged outside the gasifier body; a gas outlet of the gasifier body is connected with the cyclone dust collector; a feed opening of the cyclone dust collector is connected to a feeding inlet of the ash discharge classifier; a coarse ash outlet of the ash discharge classifier is connected with a material return opening; and a fine ash outlet of the ash discharge classifier is connected with the fine ash collecting chamber. The method comprises the steps of firstly heating the fluidized bed powdered coal gasifier until the temperature reaches 800-1300 DEG C by adopting the system; carrying out coal gasification reaction by using a preheating gasification agent mixed with pulverized coal and calcium carbonate mixed powder in the coal gasifier; and finally preparing a city gas or a chemical product from the high-temperature coal gas.

Owner:NORTHEASTERN UNIV

Short-process smelting reduction type iron-making system and method

The invention relates to a short-process smelting reduction type iron-making system and a method, and belongs to the technical field of iron-making. The system comprises a coal powder preparation device, an iron ore powder preparation device, an iron ore powder direct reduction and powder coke preparation device and a gas-solid separation device; the iron ore powder direct reduction and powder coke preparation device is of a U-shaped structure with a communicating bottom, the two sides of the iron ore powder direct reduction and powder coke preparation device serve a low-temperature reductionsection and a high-temperature reduction section correspondingly, the bottom of the iron ore powder direct reduction and powder coke preparation device serves a smelting reduction section, molten ironis obtained at the bottom of the smelting reduction section, the coal powder preparation device and the iron ore powder preparation device are connected with the middle lower portion and the bottom of the low-temperature reduction section correspondingly, the low-temperature reduction section is connected with the gas-solid separation device, and the gas-solid separation device is connected witha top combustion device and the middle of the high-temperature reduction section correspondingly. Through three-stage iron ore powder reduction, the reducibility characteristics of different components of the coal powder are fully utilized, then the multi-stage reduction of the coal powder and the iron ore powder is realized, the comprehensive efficient clean utilization of the coal and the iron ore are finally realized, and the short-process iron-making process is completed on the basis that the separate full utilization of the coal powder is realized.

Owner:TANGSHAN YANSHAN IRON & STEEL CO LTD

Method for preparing oxygen carrier by using vanadium-titanium magnetite, and applications of oxygen carrier

ActiveCN104941620AAbundant and easy to get raw materialsSimple preparation processHydrogenMetal/metal-oxides/metal-hydroxide catalystsLattice oxygenMagnetite

The present invention relates to a method for preparing an oxygen carrier by using vanadium-titanium magnetite, and applications of the oxygen carrier, and belongs to the technical field of efficient comprehensive utilization of mineral resources and energy source chemistry. The method comprises: drying vanadium-titanium magnetite concentrate, crushing, adding a modifier, and calcining in air or an oxygen-rich atmosphere; and adding the treated vanadium-titanium magnetite concentrate to a carrier, an active component and an auxiliary agent, uniformly mixing to obtain a mixture, carrying out conventional molding on the mixture, and baking for 8-12 h at a temperature of 950-1300 DEG C to obtain the oxygen carrier. The oxygen carrier can be used for the methane stepwise conversion way to prepare the synthesis gas and the hydrogen gas. According to the present invention, the oxygen carrier is used for the lattice oxygen transferring in the technology for stepwise preparation of the synthesis gas and the hydrogen gas through the methane conversion, the oxygen carrier preparation method is simple and has characteristics of good reaction circulation property, good CH4 conversion rate, good CO selectivity, and good H2 selectivity.

Owner:KUNMING UNIV OF SCI & TECH

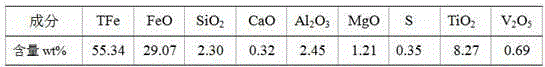

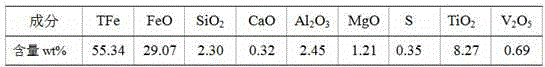

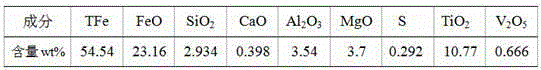

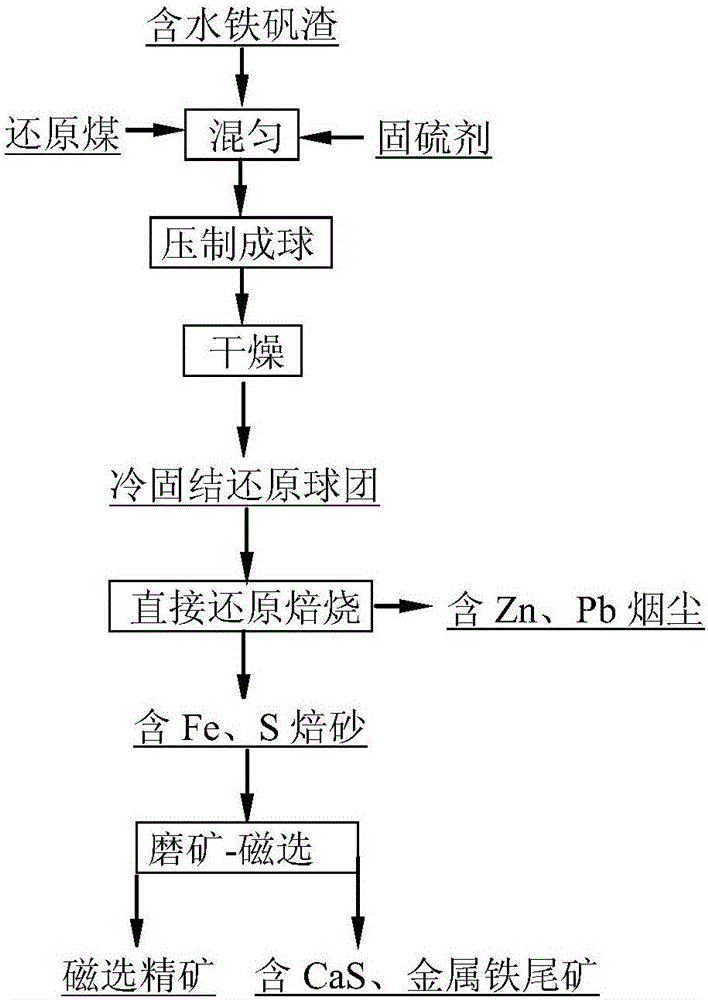

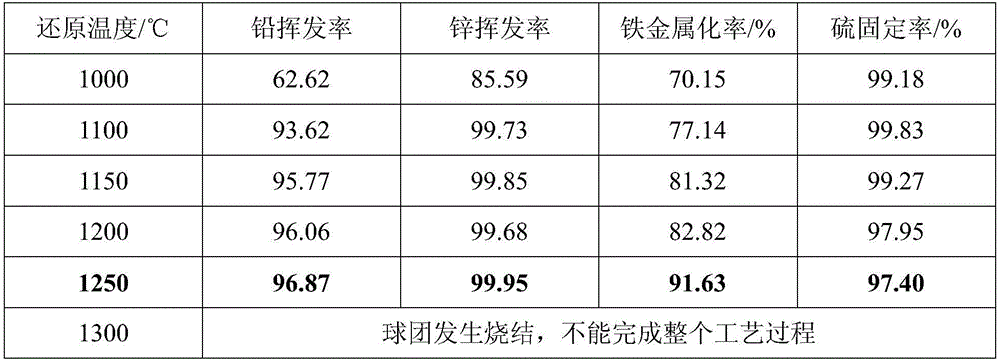

Ferroalumen slag cold-bonded and reduced pellet preparation and recycled lead, zinc and iron synchronous sulfur fixation process method

ActiveCN106755974AAvoid the problem of dehydrationEfficient and clean utilizationProcess efficiency improvementGrain treatmentsSulfurSlag

The invention relates to a ferroalumen slag cold-bonded and reduced pellet preparation and recycled lead, zinc and iron synchronous sulfur fixation process method. Firstly, ferroalumen slags, reducing coal and sulfur fixing agents are mixed and pressed into green ferroalumen slag cold-bonded and reduced pellets; the green ferroalumen slag cold-bonded and reduced pellets are dried, and preparation of ferroalumen slag cold-bonded and reduced pellets is finished; and the ferroalumen slag cold-bonded and reduced pellets are directly reduced and roasted at the temperature of 1100-1250 DEG C, smoke containing lead and zinc and roasted ore containing iron and sulfur are obtained, and ferroalumen slag cold-bonded and reduced pellet recycled lead, zinc and iron synchronous sulfur fixation is finished. The water-containing ferroalumen slags, the reducing coal and the sulfur fixing agents are made into the cold-bonded and reduced pellets, then a lead, zinc and iron chemical compound in the ferroalumen slags is directly reduced and subjected to synchronous sulfur fixation through high-temperature roasting, valuable metals including lead and zinc are recycled from the smoke, iron is recycled from the roasted ore, water difficult to remove in the ferroalumen slags is directly used, sulfur in the ferroalumen slags is fixed, and efficient and clean utilization of the valuable metals in the ferroalumen slags can also be achieved.

Owner:HANZHONG ZINC IND +1

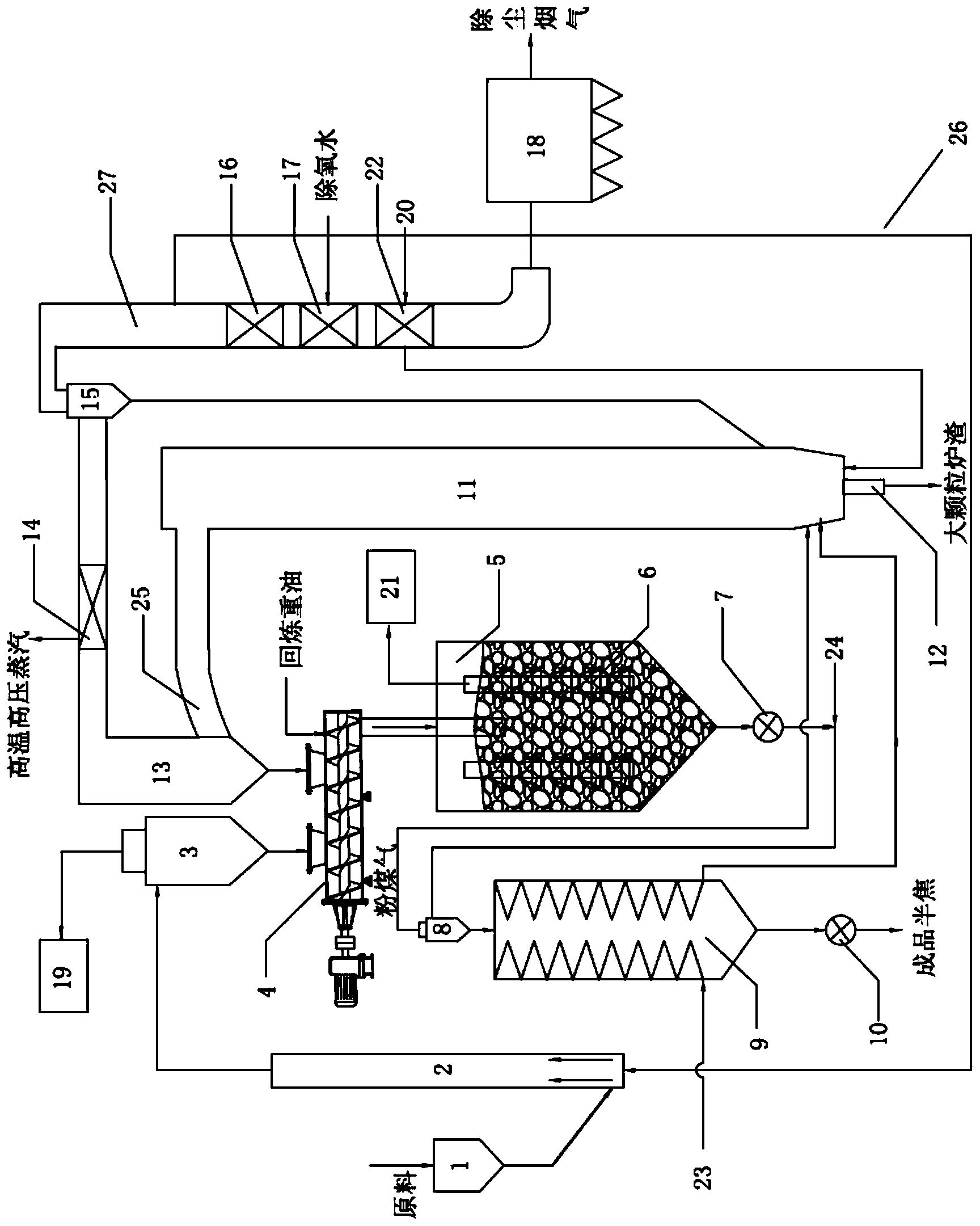

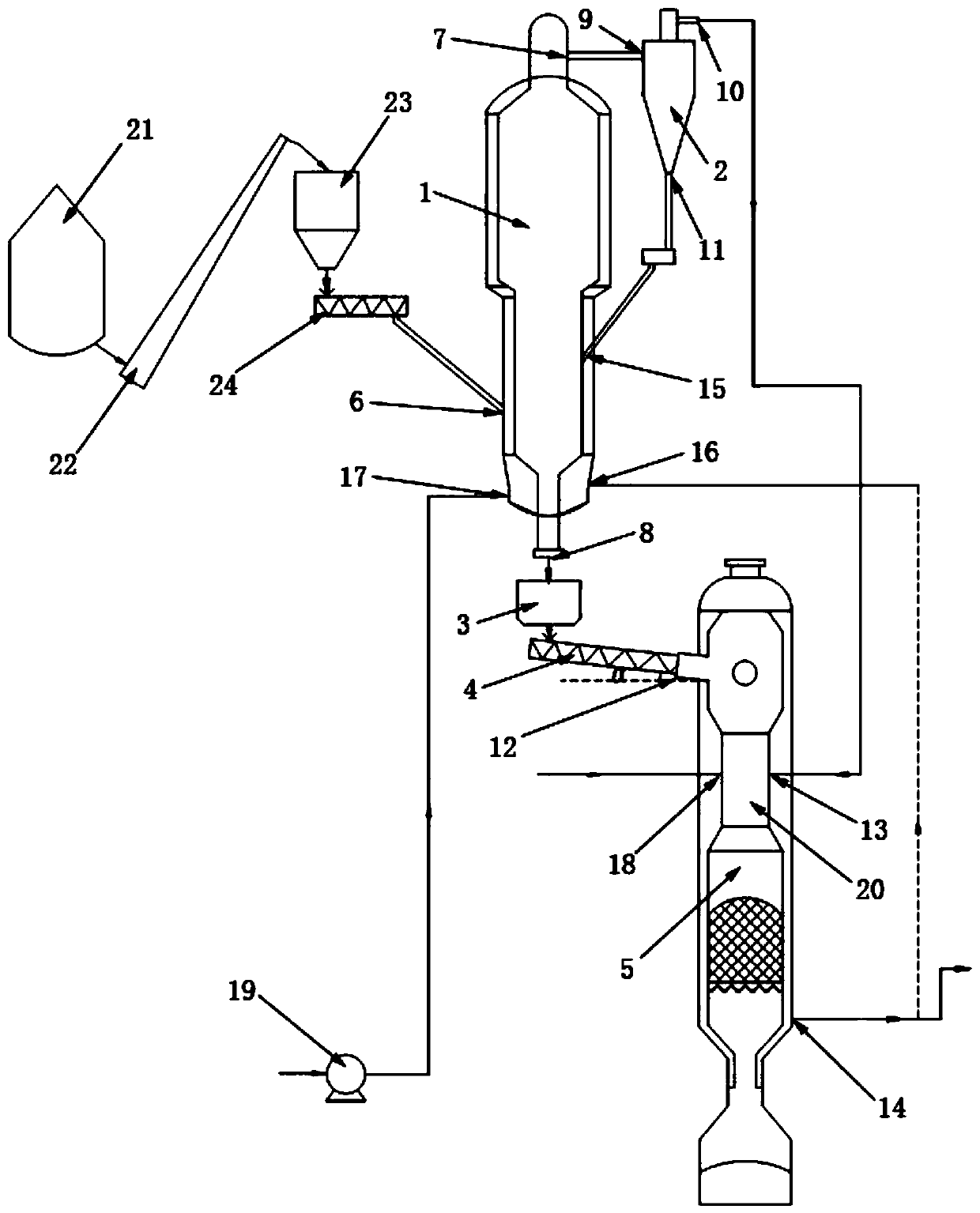

Method and system for low-temperature dry distillation and separation recycling of solid thermal carrier low-rank coal and oil shale

InactiveCN103773406AReduce dust contentHigh calorific valueDirect heating destructive distillationEnergy inputGas solidFluidized bed

The invention discloses a method and a system for low-temperature dry distillation and separation recycling of solid thermal carrier low-rank coal and oil shale. The method comprises the following steps: by taking the low-rank coal and / or the oil shale as raw materials, drying the raw materials by middle-temperature smoke; carrying out gas-solid separation to obtained dried grains; mixing the dried grains, high-temperature circulating ash dreg and recycled heavy oil and conveying into a dry distillation chamber; raising the temperature to carry out the dry distillation; leading out dry distillation gas and separating to obtain coal gas and tar; discharging a semi-coke and ash dreg mixture generated by the dry distillation out of the dry distillation chamber; enabling separated semi-coke to fall off, and further cooling and discharging; conveying the semi-coke and ash dreg mixture into a circulating fluidized bed to be fluidized and combusted; carrying out gas-solid separation on high-temperature dust-containing smoke obtained by fluidizing and combusting to obtain high-temperature circulating ash dreg; providing heat to the dry distillation by taking the high-temperature circulating ash dreg as the solid thermal carrier; and separating the obtained high-temperature smoke and carrying out secondary gas-solid separation and residual heat recycling, and furthermore, carrying out subsequent smoke treatment. The invention further provides a low-temperature dry distillation and separation recycling system used for the method.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Thermal power plant peak regulating system based on water-electrolysis hydrogen production

InactiveCN110686231APromote digestionReduce loadElectrical storage systemElectrolysis componentsElectrolysed waterFlue gas

The invention discloses a thermal power plant peak regulating system based on water-electrolysis hydrogen production. The system comprises a coal-fired boiler, a hydrogen production unit arranged in the upstream position of the process of the coal-fired boiler and a flue gas recovery unit arranged in the downstream position of the process of the coal-fired boiler; the hydrogen production unit comprises multiple hydrogen storage tanks; the multiple hydrogen storage tanks are connected in parallel and communicate with water-electrolysis hydrogen production equipment through pipelines to receiveand store hydrogen; the hydrogen production unit communicates with a buffer tank through a pipeline; the buffer tank is located in the downstream position of the process of the hydrogen storage tanks;a valve group is mounted on the hydrogen production unit; and the communication states of the hydrogen storage tanks are switched by the aid of the valve group. According to the system, the multiplehydrogen storage tanks and the buffer tank communicating with the multiple hydrogen storage tanks through series connection are arranged, the multiple hydrogen storage tanks can realize the effect that multiple hydrogen storage tanks are opened while multiple hydrogen storage tanks are standby, and thus later overhauling is facilitated; and stabilized-pressure delivery of hydrogen output by the opened hydrogen storage tanks can be further performed by the buffer tank, so that the safety is improved.

Owner:BEIJING JINMAO GREEN BUILDING TECH CO LTD

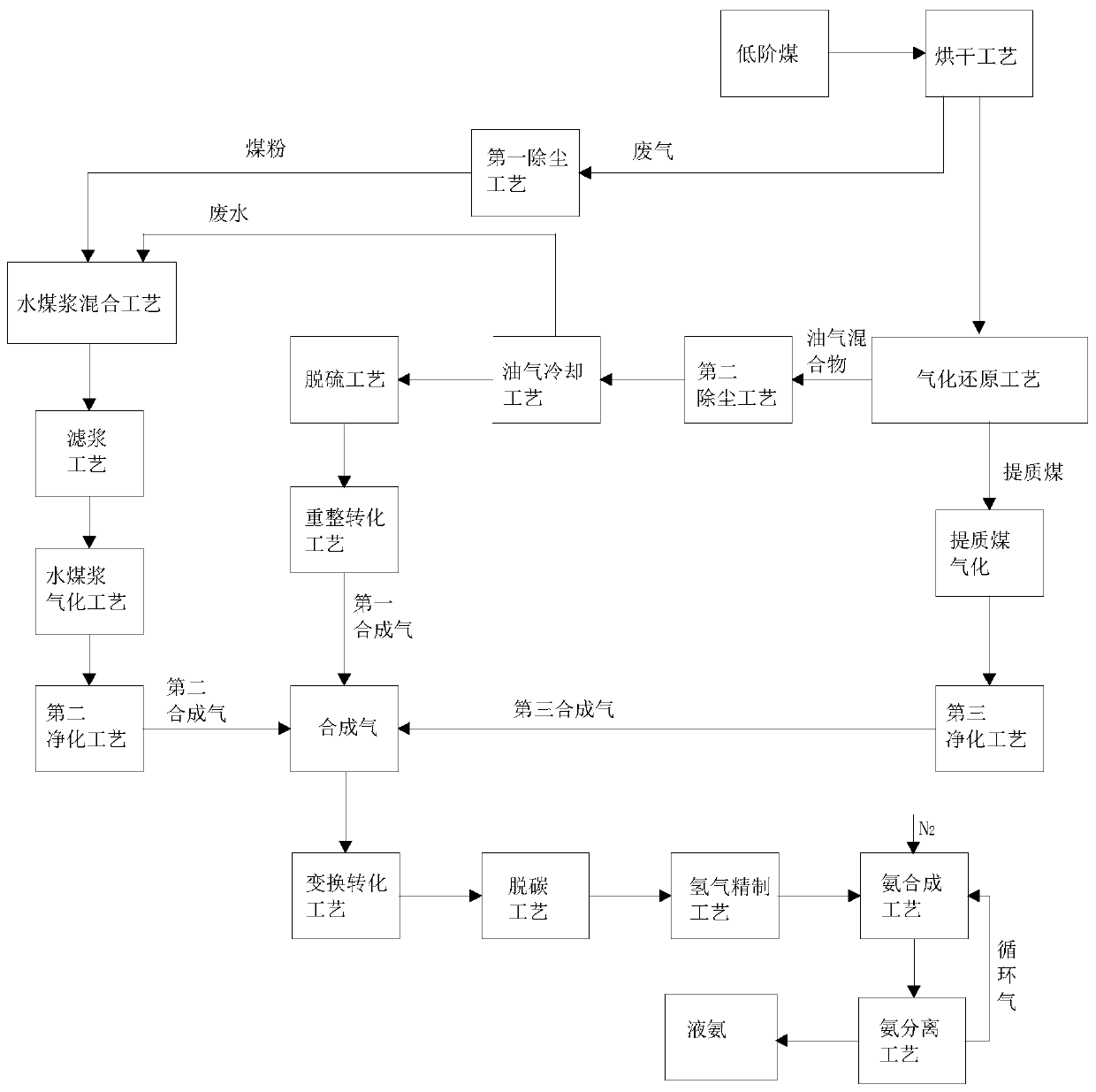

Multi-way method for synthesizing ammonia by utilizing low-rank coal

PendingCN109762603AWide variety of sourcesLow priceEnergy inputSpecial form destructive distillationSyngasCoal water

The invention provides a multi-way method for synthesizing ammonia by utilizing low-rank coal. The multi-way method comprises the following steps: drying the low-rank coal to obtain dried low-rank coal and waste gas; removing dust from the waste gas to obtain coal powder; gasifying and reducing the dried low-rank coal to obtain an oil-gas mixture and quality-improved coal, wherein a gasification and reduction technology is a chemical reaction technology for heating the dried low-rank coal under an oxygen-free or micro-aerobic condition; purifying the oil-gas mixture to obtain mixed gas and wastewater; reforming and transforming the mixed gas to prepare synthetic gas; preparing coal water slurry through the wastewater, the coal powder and a coal water slurry additive and then preparing synthetic gas; preparing synthetic gas by utilizing the quality-improved coal; after mixing the three types of synthetic gas, carrying out unconventional conversion and transformation and decarburizationand separating and purifying H2; taking the H2 and N2 as raw materials to synthesize the ammonia. According to the multi-way method, a plurality of ways for synthesizing the ammonia are provided and the cost is low; reutilization of various wastes including the wastewater and the coal powder is realized and resources are saved.

Owner:浙江天禄环境科技有限公司

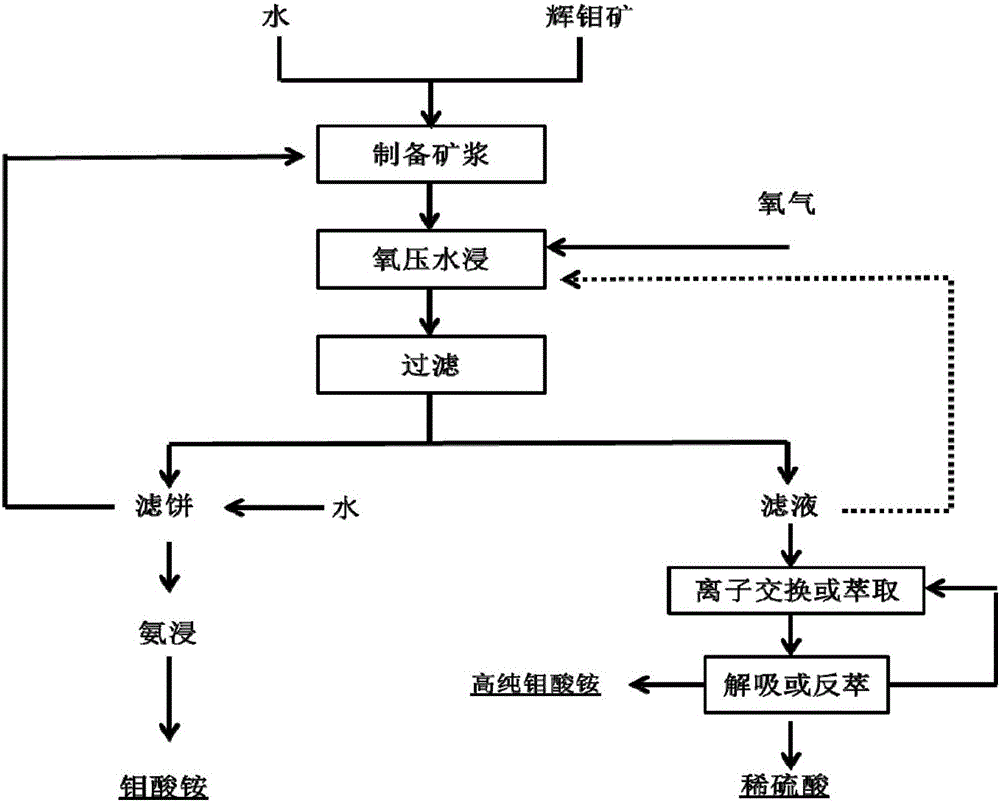

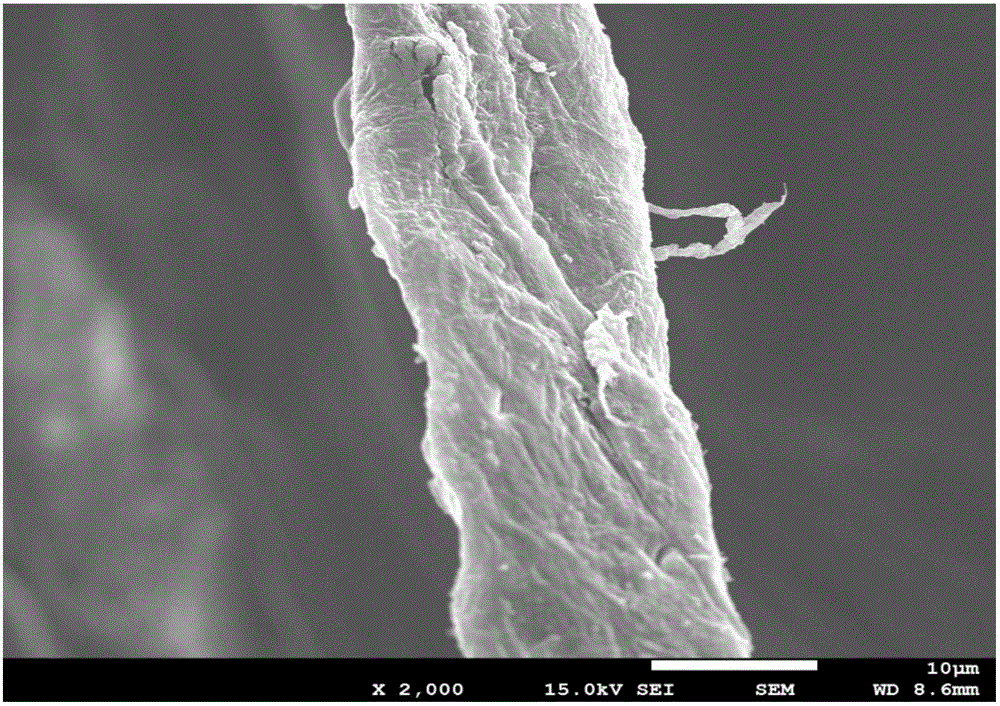

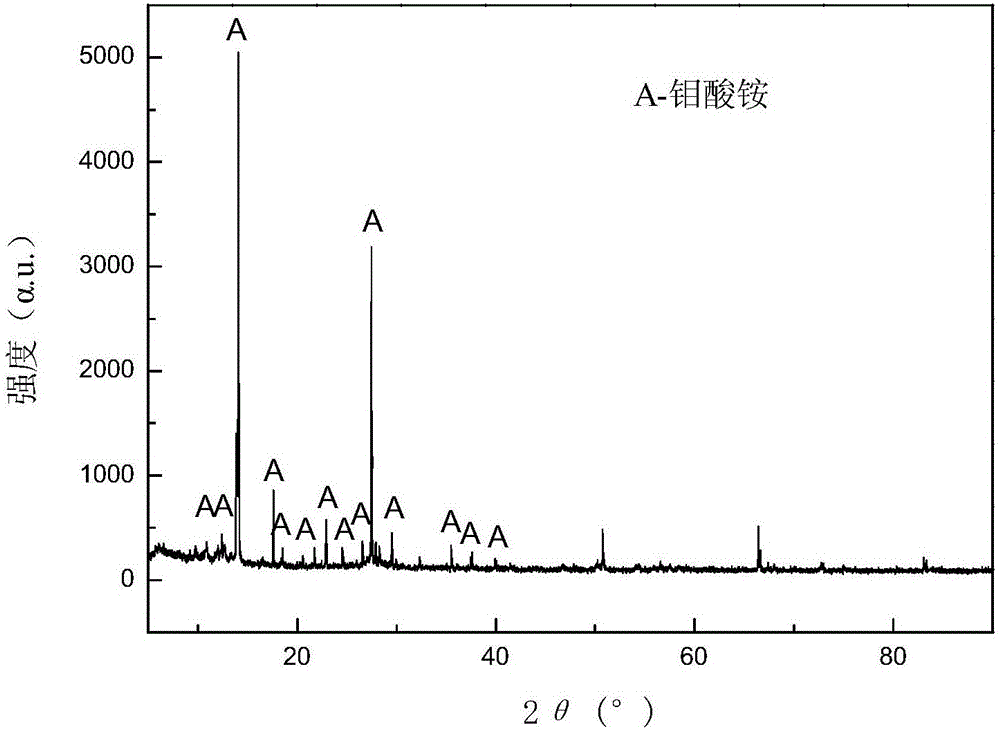

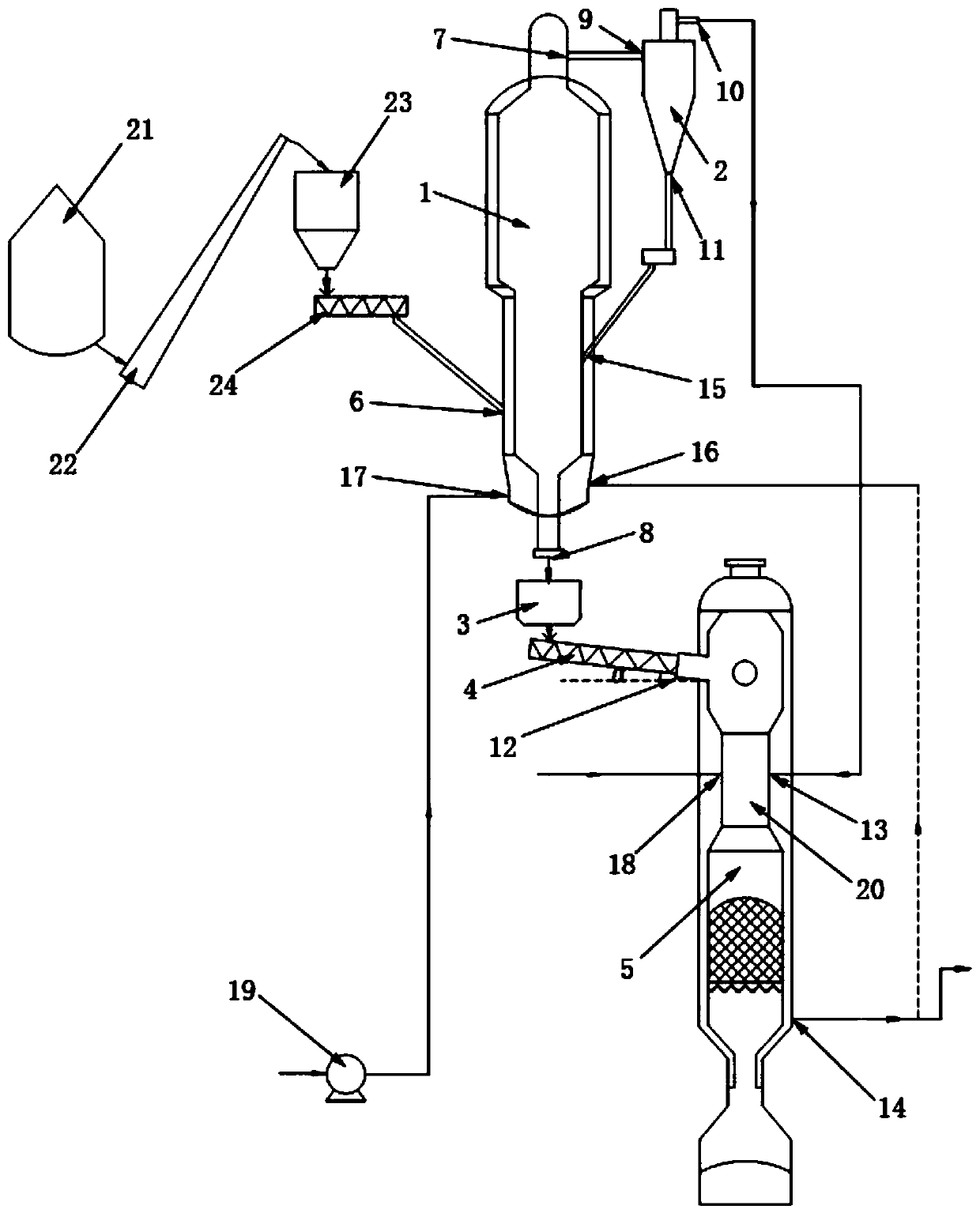

Method for co-producing ammonium molybdate and sulfuric acid through treating molybdenite by oxygen-pressure water soaking process

ActiveCN106477630AReduce corrosionImprove the operating environmentMolybdeum compoundsSulfur compoundsHigh concentrationSlurry

The invention provides a method for co-producing ammonium molybdate and sulfuric acid through treating molybdenite by an oxygen-pressure water soaking process. The method comprises the following steps: uniformly mixing molybdenite powder and water according to the solid-to-liquid ratio of (1: 2) to (1: 7), so as to prepare molybdenite slurry; injecting the molybdenite slurry into a pressure reactor, so as to subject the molybdenite slurry to an oxygen-pressure water soaking reaction with oxidizing gas; filtering the obtained slurry, so as to obtain a filter cake and filter liquor; subjecting the filter cake to ammonia leaching, filtering and crystallizing, so as to prepare the ammonium molybdate product; and subjecting the filter liquor to molybdenum removing treatment, thereby obtaining the sulfuric acid product. According to the method provided by the invention, the total recovery rate of molybdenum reaches 95% or more and even reaches up to 98% or more, meanwhile, the sulfuric acid with relatively high concentration can be obtained, and environmental pollution is not caused; and the method is simple, efficient and energy-saving and is an environment-friendly hydrometallurgical clean production process for co-producing ammonium molybdate and sulfuric acid through efficiently utilizing the molybdenite, thereby having a good industrialized application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

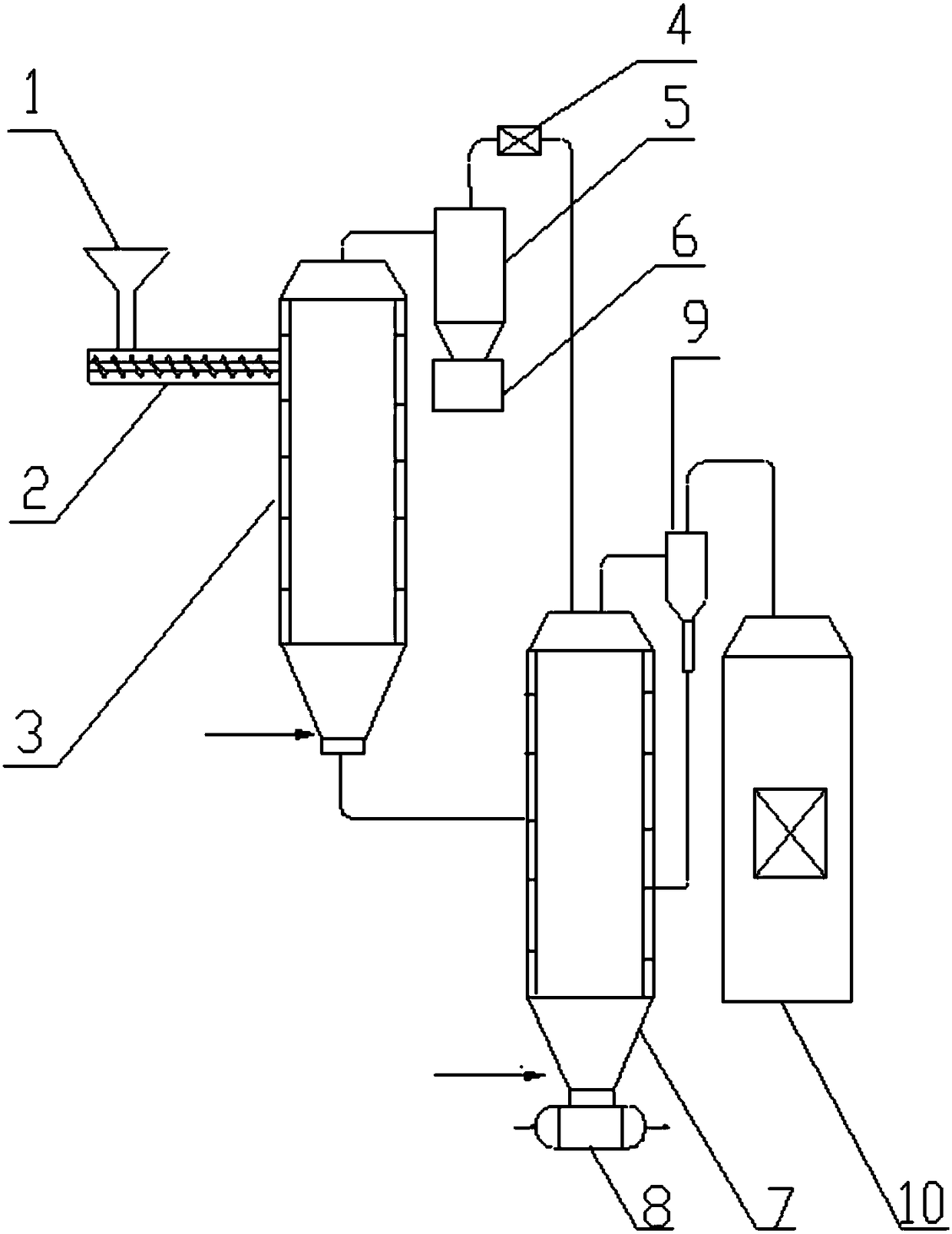

Novel combined bed biomass gasification system and method thereof

InactiveCN109971512AHigh mass and heat transfer strengthEasy to scale upGasification processes detailsCombustible gas productionTarProcess engineering

The invention discloses a novel combined bed biomass gasification system and a method thereof. The novel combined bed biomass gasification system comprises a biomass pyrolysis fluidized bed gasification furnace, a cyclone separator, a coke hopper, a first screw feeder and a downdraft fixed bed gasification furnace; the biomass pyrolysis fluidized bed gasification furnace is provided with a biomassinlet, a crude pyrolysis gas outlet and a coke outlet; the cyclone separator is provided with a crude pyrolysis gas inlet, a pyrolysis gas outlet and an ash outlet; the coke hopper is communicated with the coke outlet; the first screw feeder is communicated with the coke hopper; the downdraft fixed bed gasification furnace is provided with a coke inlet, a pyrolysis gas inlet and a fuel gas outlet, and the coke inlet is communicated with the first screw feeder. The novel combined bed biomass gasification system and the method thereof effectively reduce the tar content in crude fuel gas, effectively improve the gasification efficiency and realize the efficient and clean utilization of biomass.

Owner:SHANGHAI ELECTRICGROUP CORP

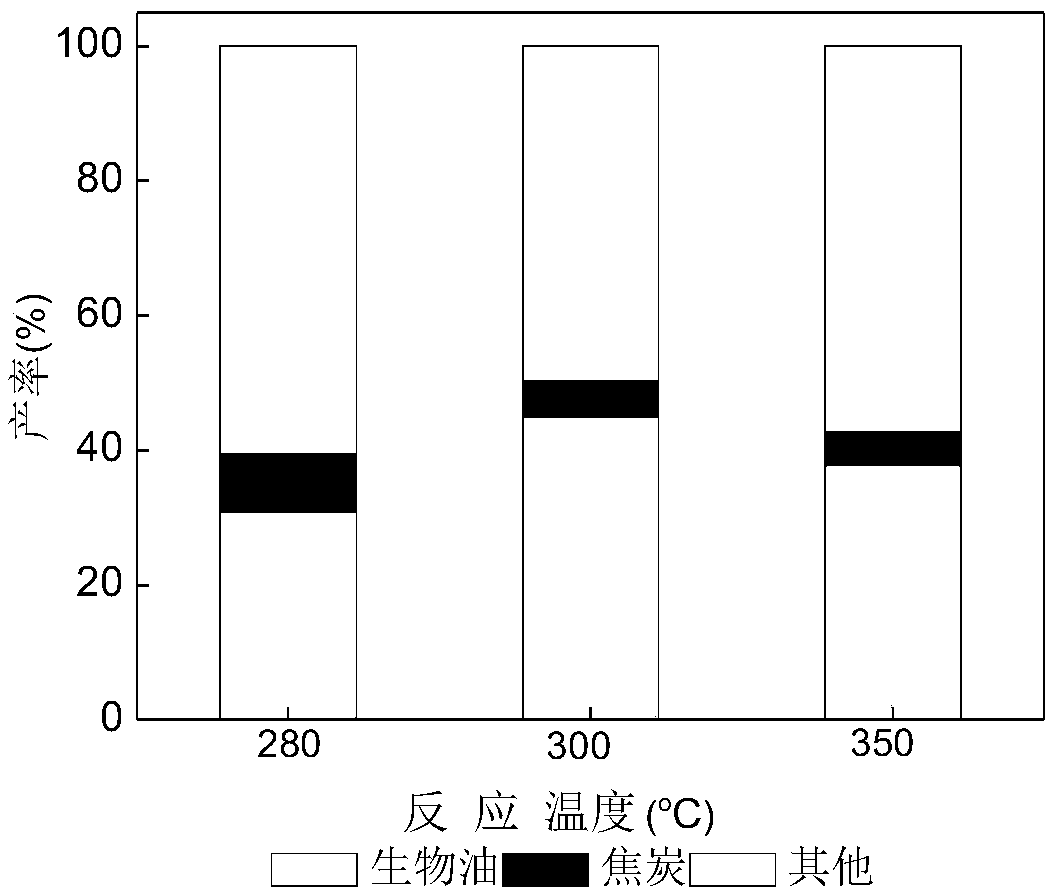

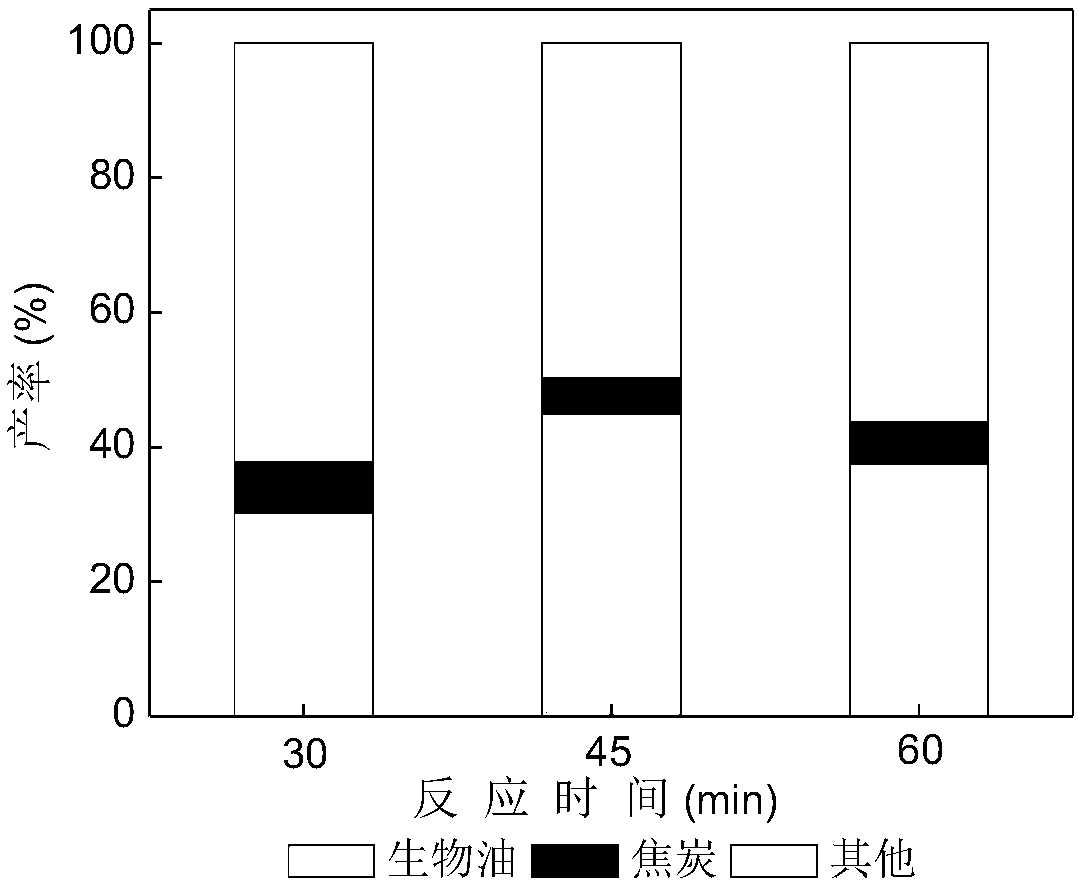

Seaweed pyrolysis oil making system and method thereof

ActiveCN108913172AFast heating efficiencyImprove efficiencyDirect heating destructive distillationBiofuelsOil productionCyclonic separation

The invention provides a seaweed pyrolysis oil making system and a method thereof. The seaweed pyrolysis oil making system comprises a pyrolysis device, an oil-gas separator, an oil storage device, agas purification device, a gasification device, a cyclone separation device and a hydrothermal device, wherein the upper end of the pyrolysis device is connected with the oil-gas separator; the upperend of the oil-gas separator is connected with the gasification device through the gas purification device, and the lower end of the oil-gas separator is connected with the oil storage device; the lower end of the pyrolysis device is connected with the gasification device; the gasification device is connected with the hydrothermal device through the cyclone separation device; noncondensable gas generated by the pyrolysis of the pyrolysis device can be used as gasification agent used for gasification reaction, semicoke generated by pyrolysis is taken as a gasification raw material, reductive gas generated by gasification participates in hydrothermal reaction to improve the oil production efficiency of a hydrothermal liquidation process. According to the seaweed pyrolysis oil making system,byproducts in a seaweed pyrolysis process can be effectively utilized, in addition, the oil product and the yield of hydrothermal liquefaction bio-oil can be improved, and meanwhile, system energy useefficiency is high.

Owner:JIANGSU UNIV

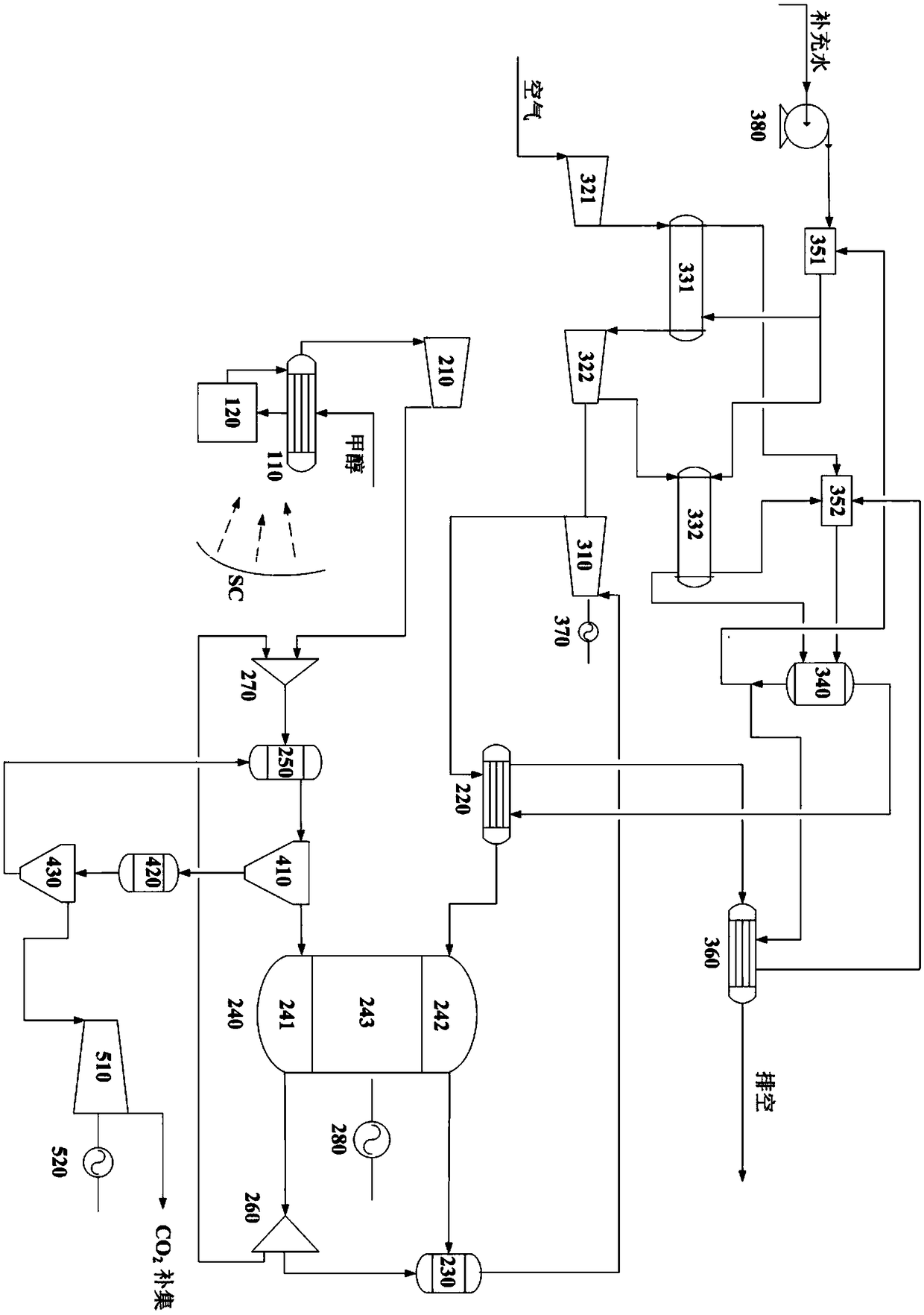

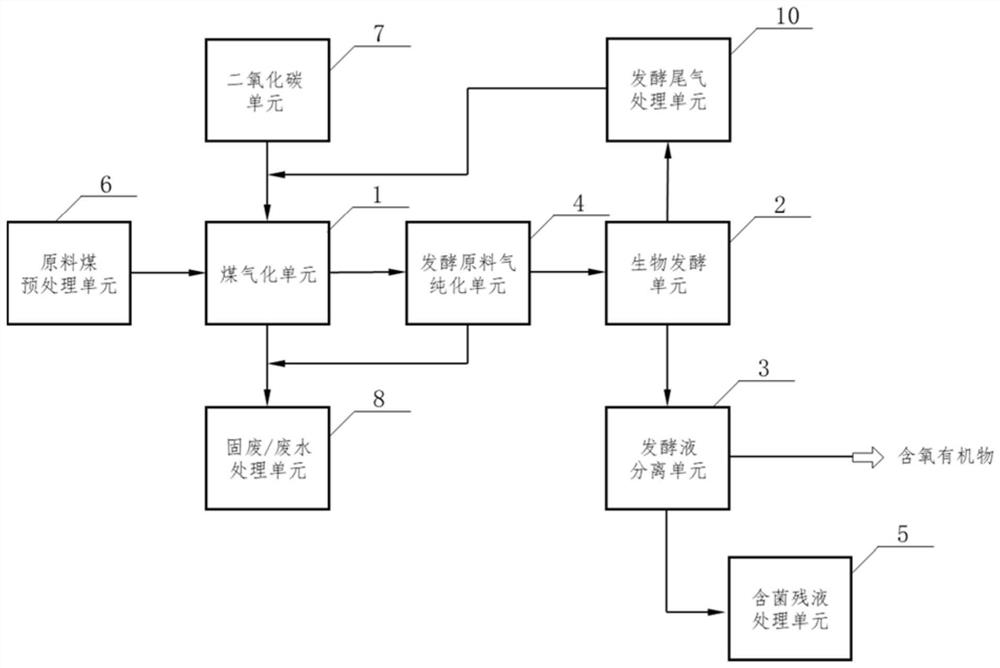

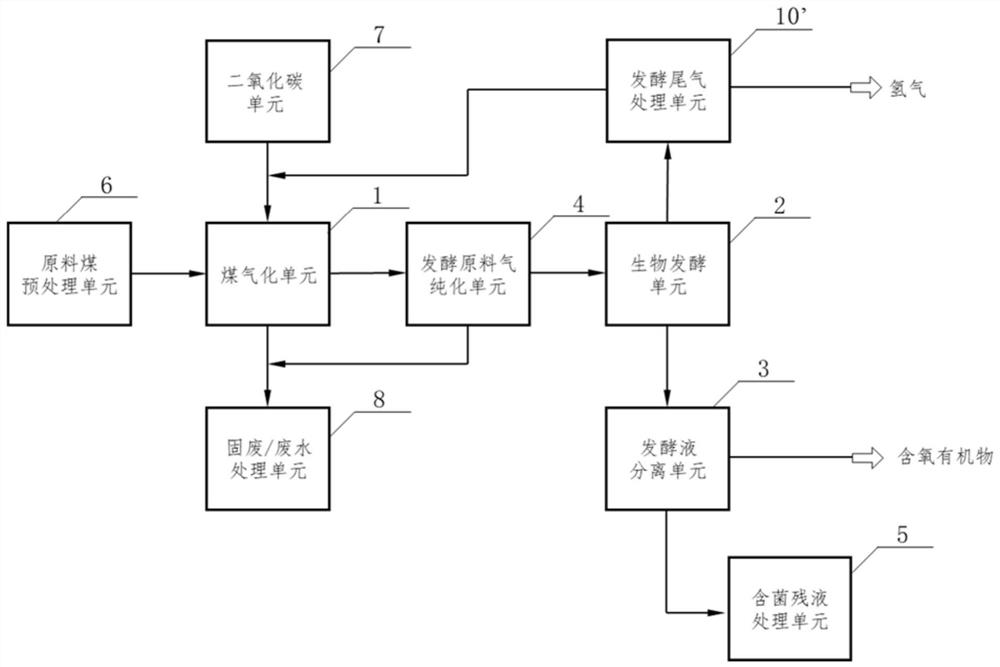

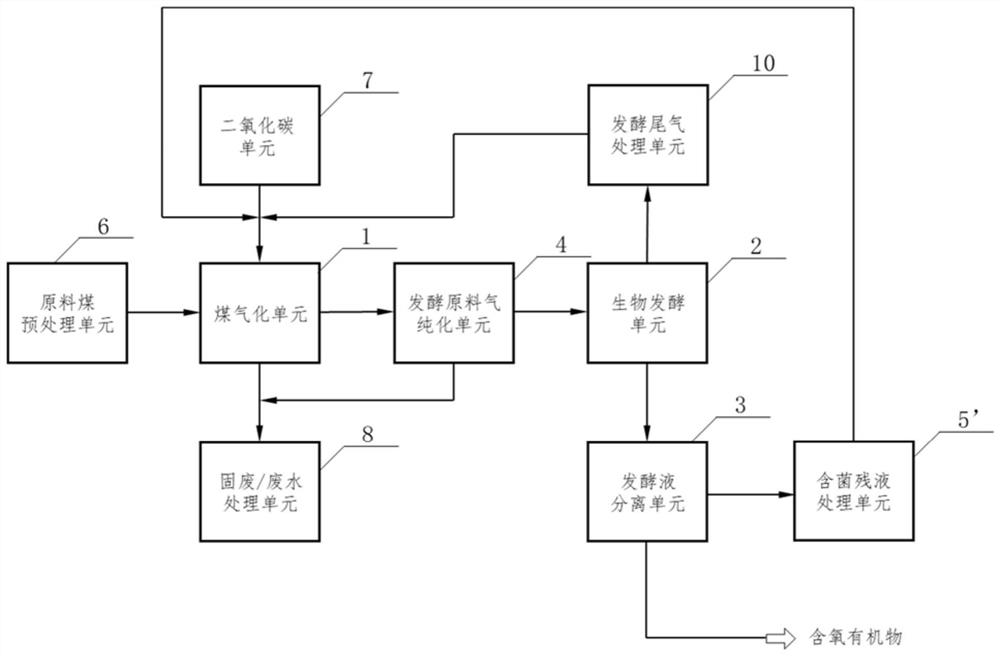

System and process for producing oxygen-containing organic matters by carbon dioxide and coal

ActiveCN112812930AEmission reductionIncrease profitBioreactor/fermenter combinationsBiological substance pretreatmentsFluid phaseProcess engineering

The invention provides a system and a process for producing oxygen-containing organic matters by carbon dioxide and coal. The system comprises a coal gasification unit (1), a biological fermentation unit (2), a fermentation liquid separation unit (3) and a carbon dioxide unit (7), wherein a gas phase outlet of the carbon dioxide unit (7) is connected with a gas phase inlet of the coal gasification unit (1); a gas phase outlet of the coal gasification unit (1) is connected with a gas phase inlet of a fermentation raw material gas purification unit (4); a gas phase outlet of the fermentation raw material gas purification unit (4) is connected with a gas phase inlet of the biological fermentation unit (2); a liquid phase outlet of the biological fermentation unit (2) is connected with a liquid phase inlet of the fermentation separation unit (3); a coal gasification process is carried out in the coal gasification unit (1); a gasification agent in the coal gasification process contains carbon dioxide; and the carbon dioxide contained in the gasification agent is provided by the carbon dioxide unit (7).

Owner:TSINGHUA UNIV

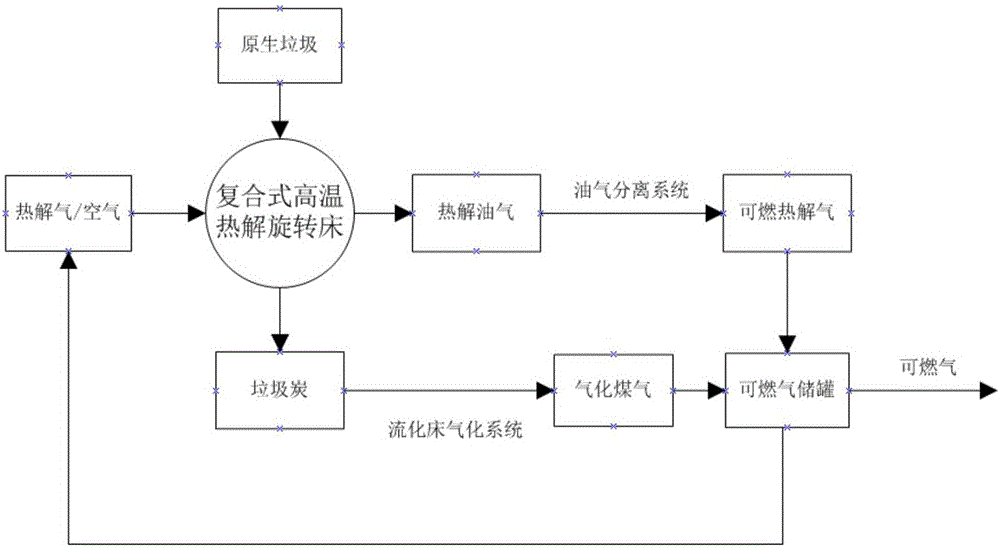

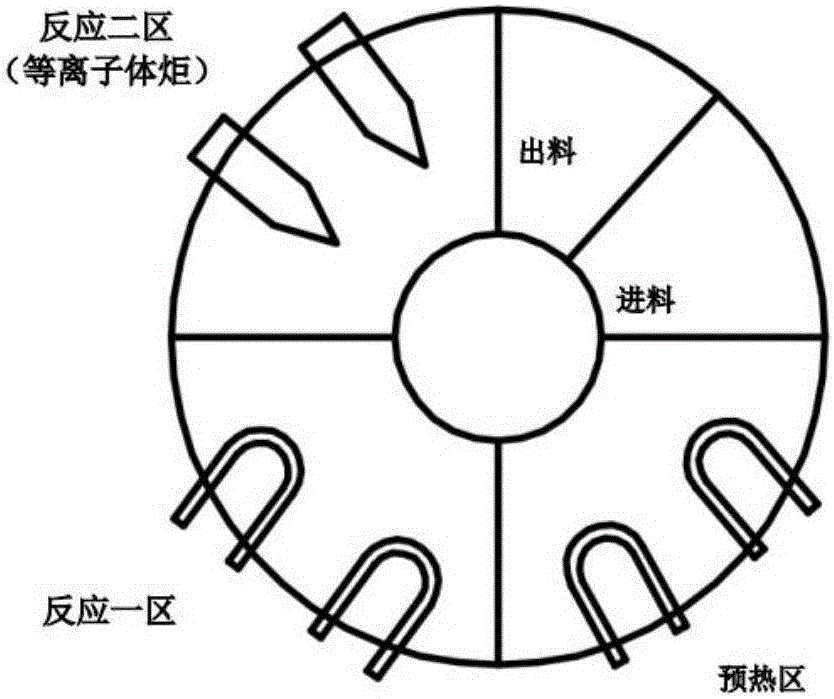

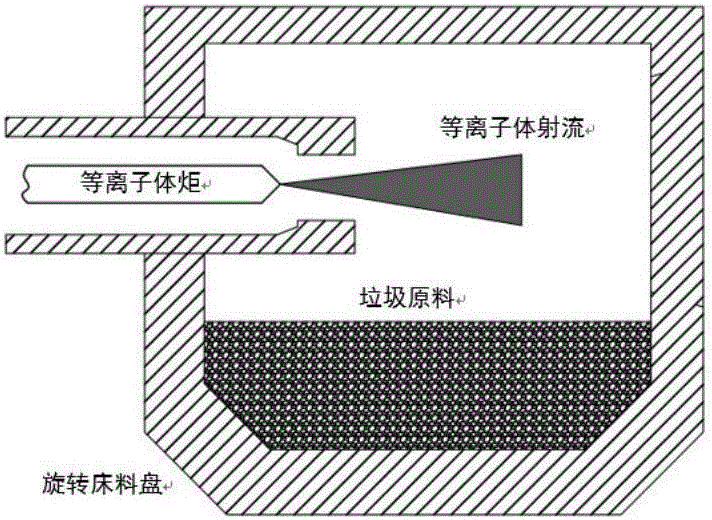

System and method for pyrolysis of household refuses

PendingCN106433704AImprove economyEfficient and clean utilizationDirect heating destructive distillationSpecial form destructive distillationResource utilizationNo production

The invention relates to a system and a method for pyrolysis of household refuses. The system comprises a combined type high-temperature pyrolysis rotating bed, an oil-gas separating device, a fluidized bed and a combustible gas storage tank, wherein the combined type high-temperature pyrolysis rotating bed comprises a material feeding opening, a material discharging opening and a high-temperature oil-gas outlet, a preheating area, a reaction area I and a reaction area II are arranged in a furnace body in sequence according to the rotating direction of the rotating bed, and a plasma torch is arranged on a furnace wall of the reaction area II. The system disclosed by the invention has the advantages of low operation cost, high resource utilization and energy regeneration level, good economic benefits of products, less secondary pollution, no production of dioxin and easiness for realizing industrialization and scale management of refuse pyrolysis.

Owner:SHENWU TECH GRP CO LTD

Novel biomass gasification combustion furnace for door

InactiveCN101464006AEfficient gasification combustionEfficient and clean utilizationStove/ranges for heating waterSpecial form destructive distillationBottom ashCombustion

The invention discloses a novel household biomass gasification combustion furnace which belongs to the field of biomass energy utilization. The novel household biomass gasification combustion furnace comprises an ash discharge outlet, an ash discharge control device, an outer casing of a furnace body, an inner casing of the furnace body, an air register, a furnace cover and a bottom ash bin. The combustion furnace is applicable to a variety of biomass fuels and can be widely applied in regions which are rich in biomass resources. Furthermore, the gasification and the combustion of biomass achieve the integration, the problem of tar formation is solved during the process, and flue gas after the combustion does not contain the tar, thereby not needing the treatment of the tar; a filter mesh is added in the furnace, thereby well filtering fly ash and greatly reducing the emissions of smoke, dust and other solid small particles. The high-efficient gasification combustion of the biomass and the high-efficient clean utilization are achieved through the adjustment. Therefore, the invention has the characteristics of high efficiency, low cost, simple and safe operation, etc.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

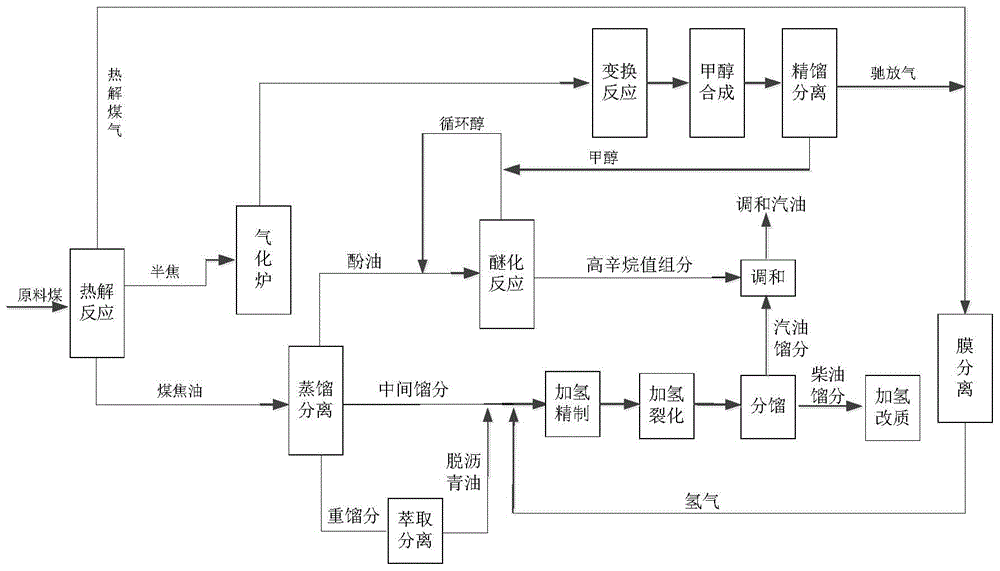

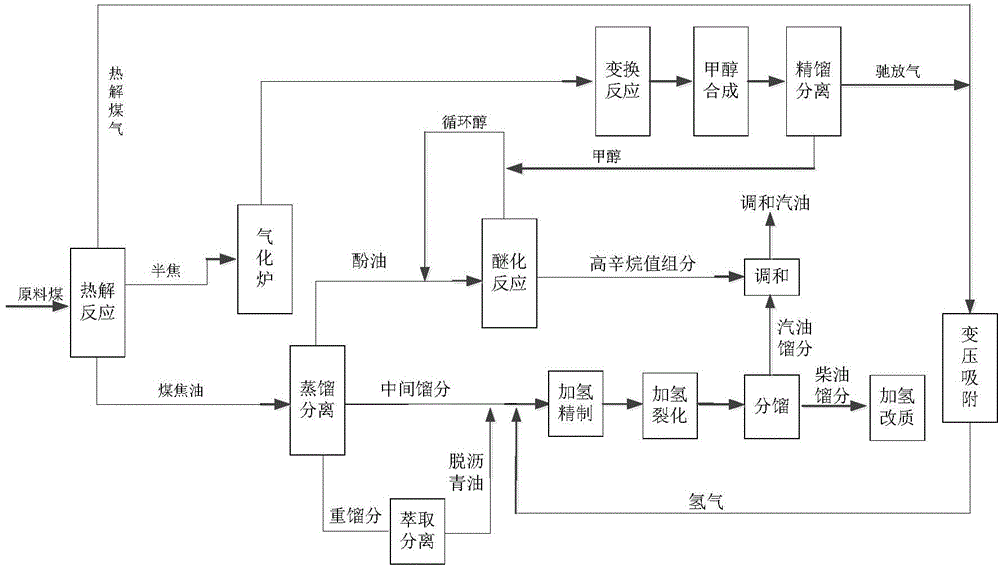

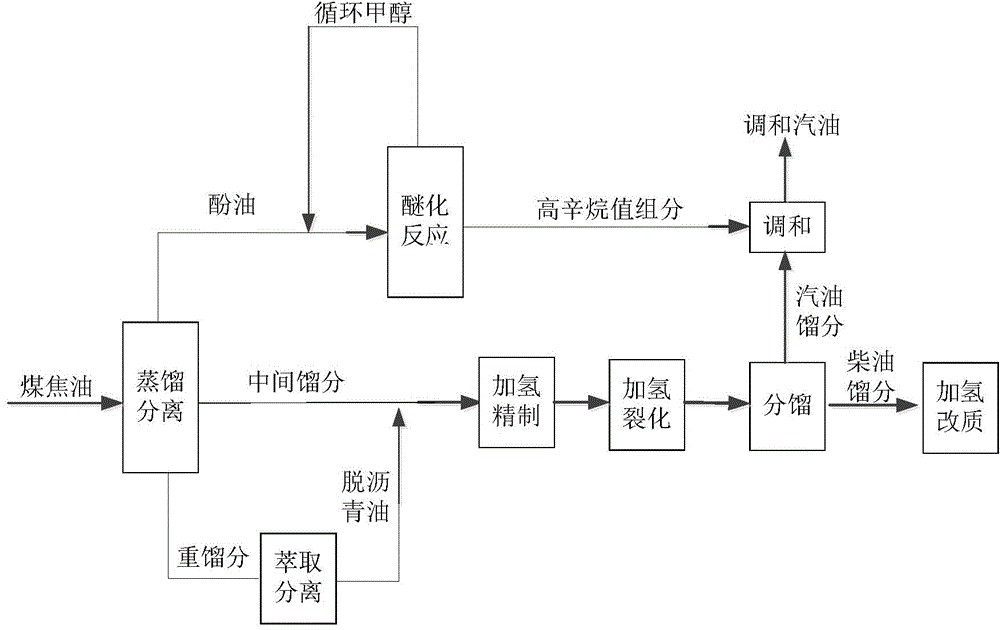

Method for preparing clean fuel from coal tar, method for preparing clean fuel from coal and prepared clean fuel

InactiveCN106147840AImprove qualityMaximize utilizationLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesProcess engineeringCoal tar

The invention discloses a method for preparing clean fuel from coal tar and a method for preparing the clean fuel from coal. The method for preparing the clean fuel from the coal tar comprises following steps: the coal tar is subjected to distillation separation, and a carbolic oil fraction, an intermediate fraction and a heavy fraction are obtained; the carbolic oil fraction and methyl alcohol are subjected to etherification, and a high-octane component is obtained; the heavy fraction is subjected to extraction separation, and deasphalted oil is obtained; the intermediate fraction and the deasphalted oil are subjected to hydrorefining and hydrocracking, a mixture is subjected to fractional distillation, and a gasoline fraction and a diesel fraction are obtained; the high-octane component is added to the gasoline fraction, and blended gasoline is obtained. According to the method for preparing the clean fuel from the coal, the raw material coal is pyrolyzed, and the coal tar, semicoke and pyrolysis gas are obtained. With the adoption of the technical scheme, sufficient deep processing of the coal tar resource and the coal resource are realized, the high-octane component is obtained, and the gasoline fraction meeting the national standard is obtained.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com