Novel biomass gasification combustion furnace for door

A combustion furnace and biomass technology, applied in the field of new household biomass gasification combustion furnace, can solve the problems of environmental pollution, high processing cost, large smoke and dust, and achieve the effects of high efficiency, low cost, simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

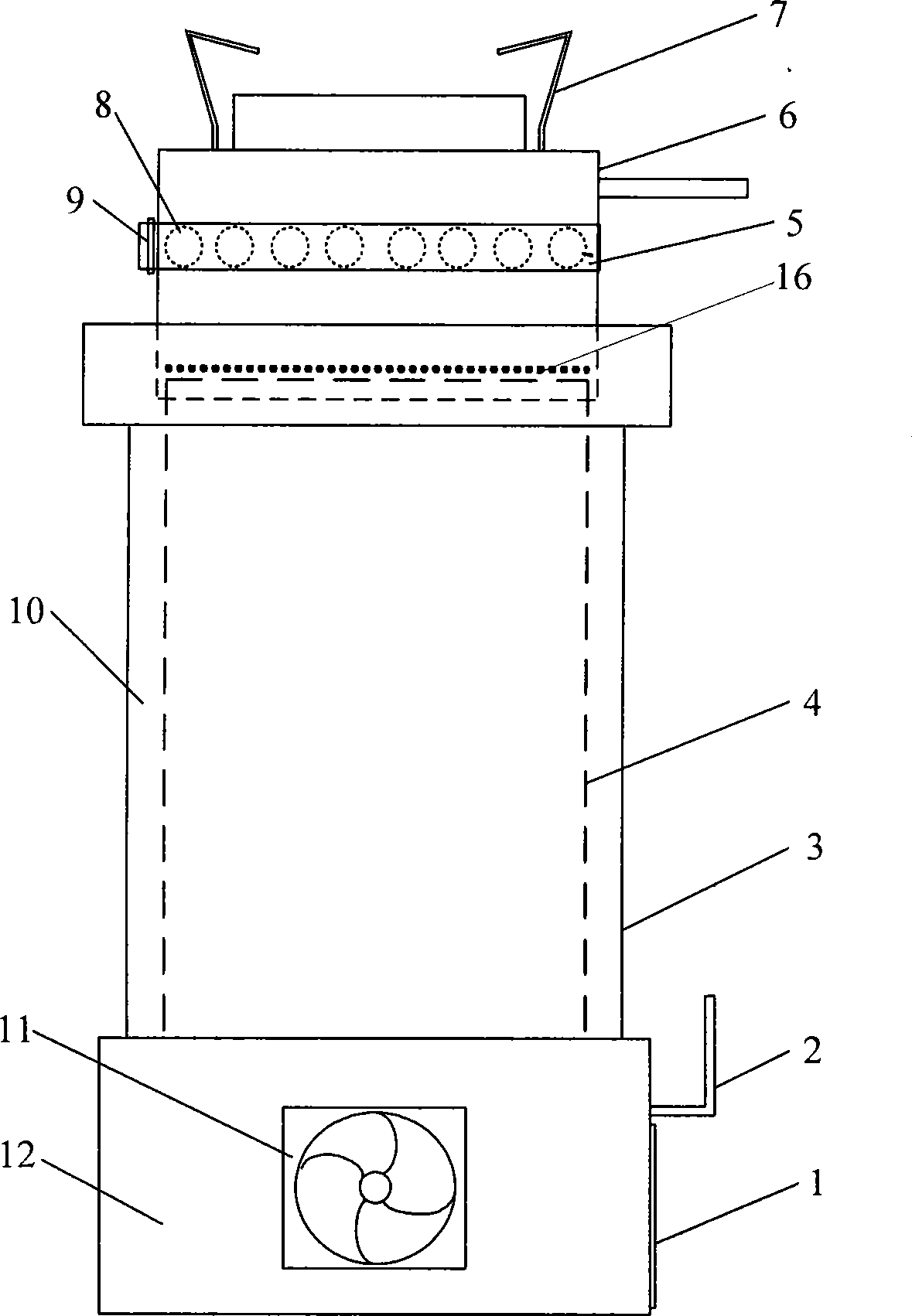

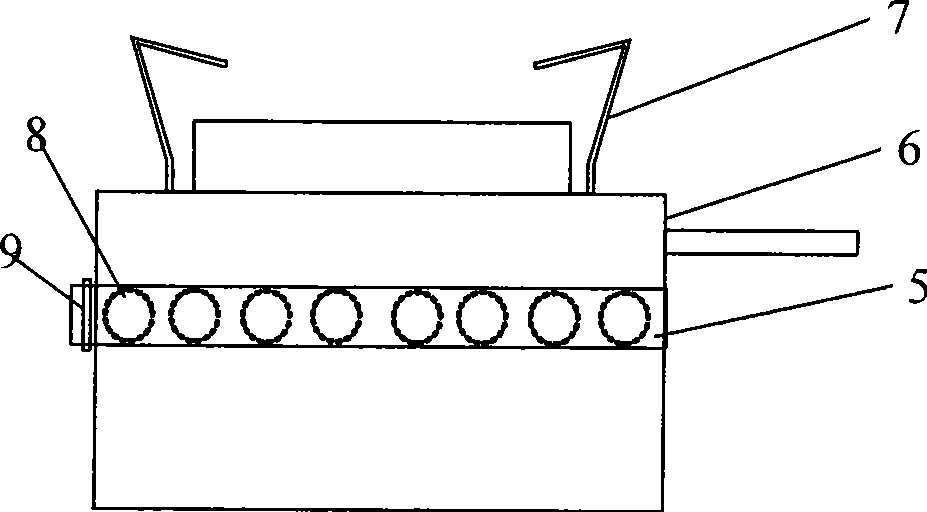

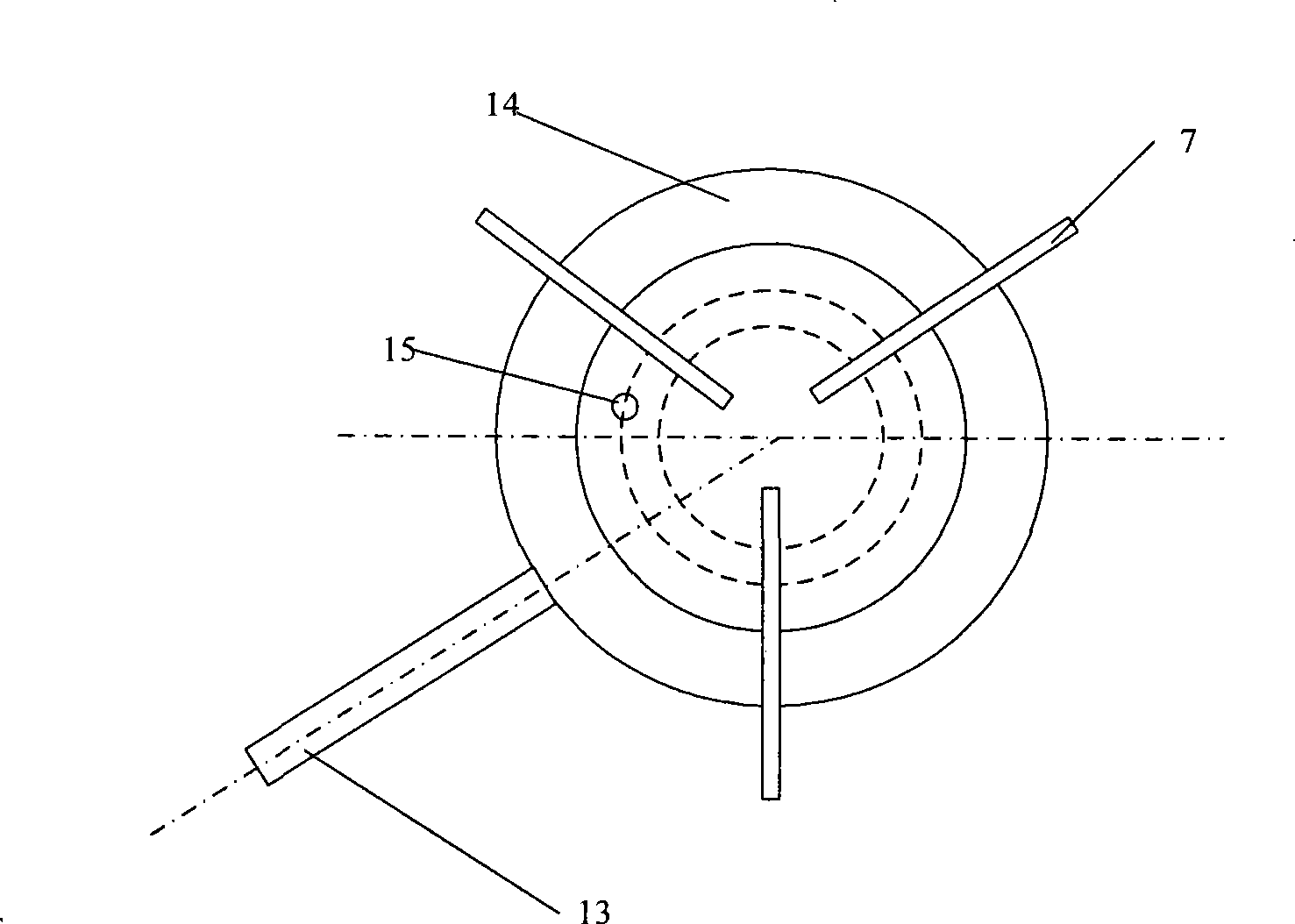

[0017] The present invention provides a novel household biomass gasification combustion furnace. The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] like figure 1 As shown, the combustion furnace of the present invention is composed of ash discharge port 1, ash discharge control device 2, furnace body shell 3, furnace body shell 4, air regulating device 5, furnace cover 6, support 7, air supply port 8, adjustment plate 9, Heat insulation layer or water jacket 10, blower fan 11, bottom ash bin 12 etc. are formed. The body of furnace of described combustion furnace comprises body of furnace shell 3, and its equivalent diameter is 150~500mm; Furnace body shell 4, its equivalent diameter is at 100~450mm; Furnace body shell 3 and furnace body shell 4 can adopt cylinder or cuboid or The bottom surface is a polygonal cylinder, and the furnace body shell 4 is installed inside the furnace body shell 3; between the fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com