System and process for producing oxygen-containing organic matters by carbon dioxide and coal

A technology of carbon dioxide and organic matter, applied in the direction of gasification process, liquid production bioreactor, biofuel, etc., can solve the problems of increasing carbon dioxide emissions, reducing the utilization rate of carbon resources, increasing the demand for water resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

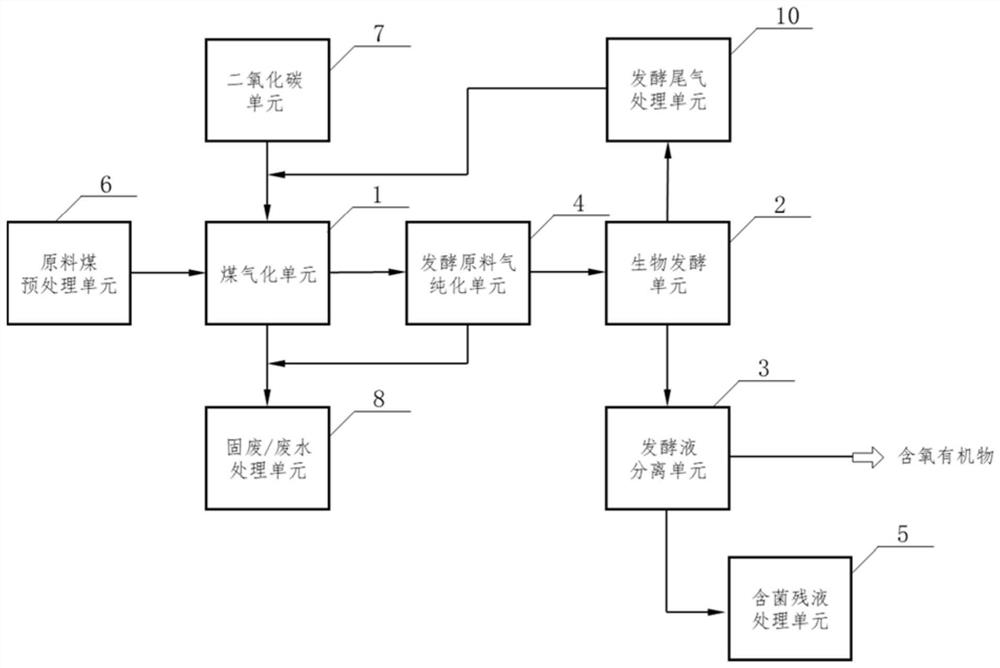

[0042] figure 1 Schematic of the system for producing oxygenated organics for carbon dioxide and coal. In the system of this embodiment, it includes a coal gasification unit 1, a biological fermentation unit 2, a fermentation feed gas purification unit 4, a fermentation liquid separation unit 3, a carbon dioxide unit 7, a solid waste / wastewater treatment unit 8, and bacteria-containing residual liquid treatment Unit 5.

[0043] Such as figure 1As shown, the gas phase outlet of the carbon dioxide unit 7 is connected to the gas phase inlet of the coal gasification unit 1, the gas phase outlet of the coal gasification unit 1 is connected to the gas phase inlet of the fermentation feed gas purification unit 4, and the gas phase outlet of the fermentation feed gas purification unit 4 is connected to the gas phase inlet of the fermentation feed gas purification unit 4. The gas phase inlet of the biological fermentation unit 2 is connected, and the liquid phase outlet of the biolog...

Embodiment 2

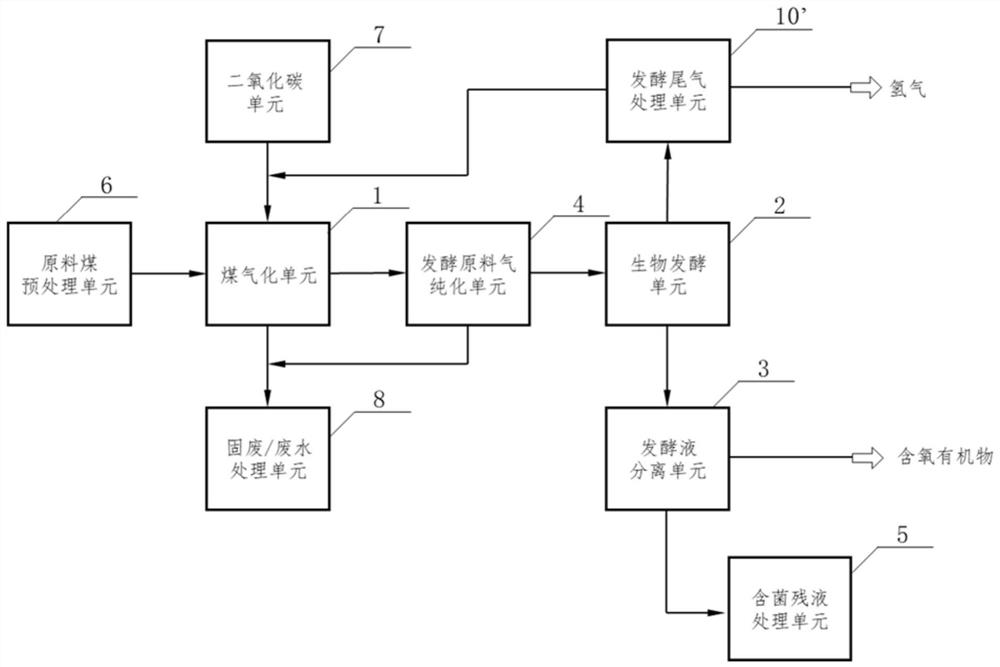

[0049] In the system of this embodiment, it includes a coal gasification unit 1, a biological fermentation unit 2, a fermentation feed gas purification unit 4, a fermentation liquid separation unit 3, a carbon dioxide unit 7, a solid waste / wastewater treatment unit 8, and bacteria-containing residual liquid treatment Unit 5.

[0050] In this implementation reaction system, the gas phase outlet of the carbon dioxide unit 7 is connected to the gas phase inlet of the coal gasification unit 1, the gas phase outlet of the coal gasification unit 1 is connected to the gas phase inlet of the fermentation feed gas purification unit 4, and the fermentation feed gas purification unit 4 The gas phase outlet of the biofermentation unit 2 is connected with the gas phase inlet of the biological fermentation unit 2, and the liquid phase outlet of the biological fermentation unit 2 is connected with the liquid phase inlet of the fermentation separation unit 3.

[0051] In this implementation r...

Embodiment 3

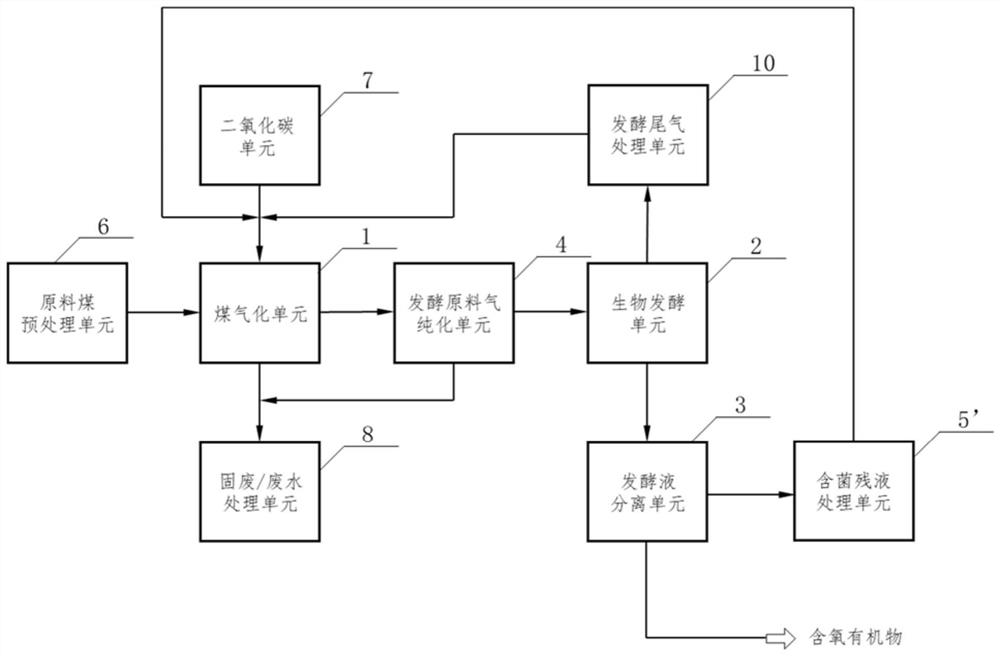

[0056] In the system of this embodiment, it includes a coal gasification unit 1, a biological fermentation unit 2, a fermentation feed gas purification unit 4, a fermentation liquid separation unit 3, a carbon dioxide unit 7, a solid waste / wastewater treatment unit 8, and bacteria-containing residual liquid treatment Unit 5.

[0057] In this implementation reaction system, the gas phase outlet of the carbon dioxide unit 7 is connected to the gas phase inlet of the coal gasification unit 1, the gas phase outlet of the coal gasification unit 1 is connected to the gas phase inlet of the fermentation feed gas purification unit 4, and the fermentation feed gas purification unit 4 The gas phase outlet of the biofermentation unit 2 is connected with the gas phase inlet of the biological fermentation unit 2, and the liquid phase outlet of the biological fermentation unit 2 is connected with the liquid phase inlet of the fermentation separation unit 3.

[0058] In this implementation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com