Novel combined bed biomass gasification system and method thereof

A gasification system and biomass technology, which is applied in the field of new combined bed biomass gasification system, can solve the problem of not being able to effectively reduce tar content, and achieve the effects of reducing tar content, clean utilization, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

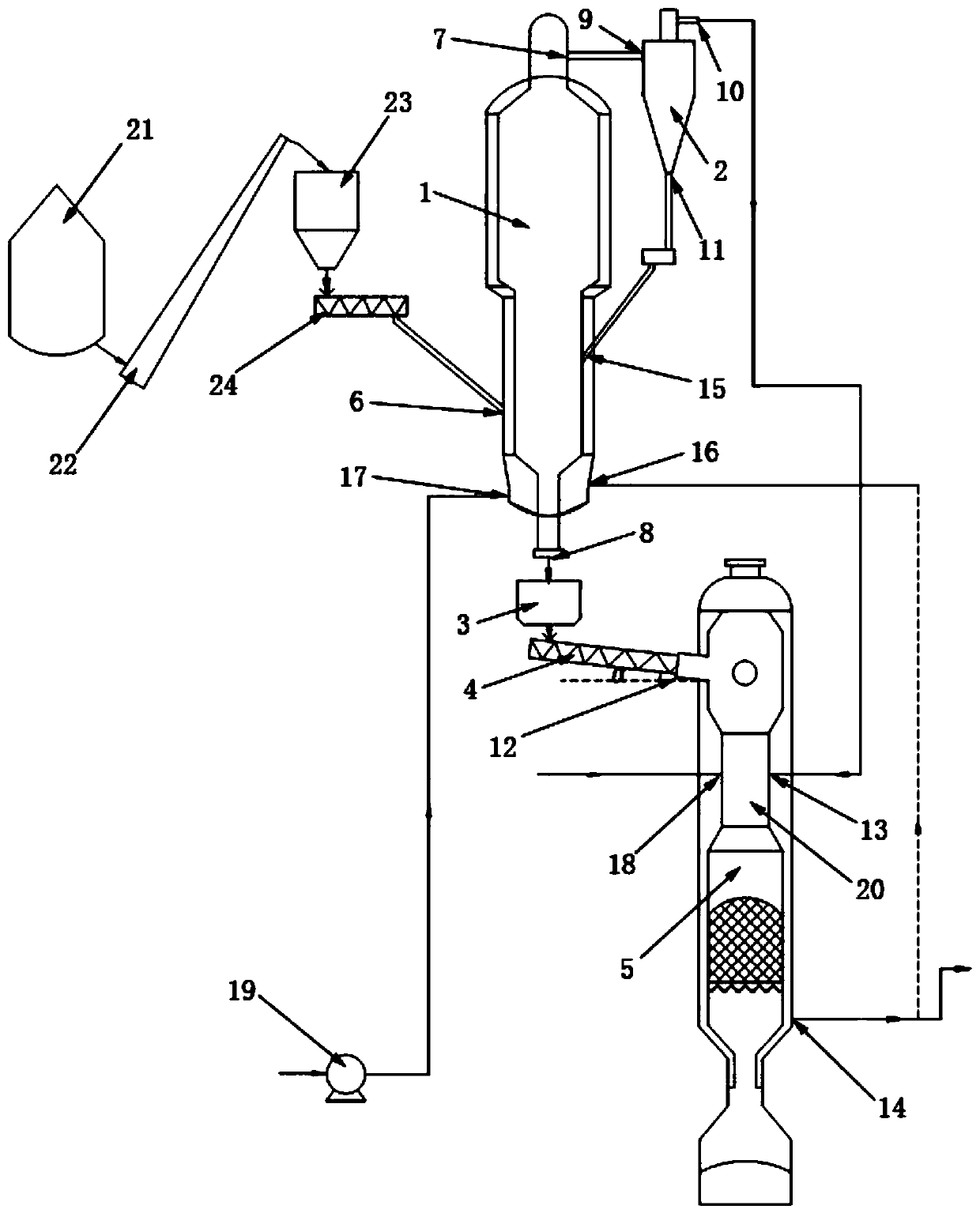

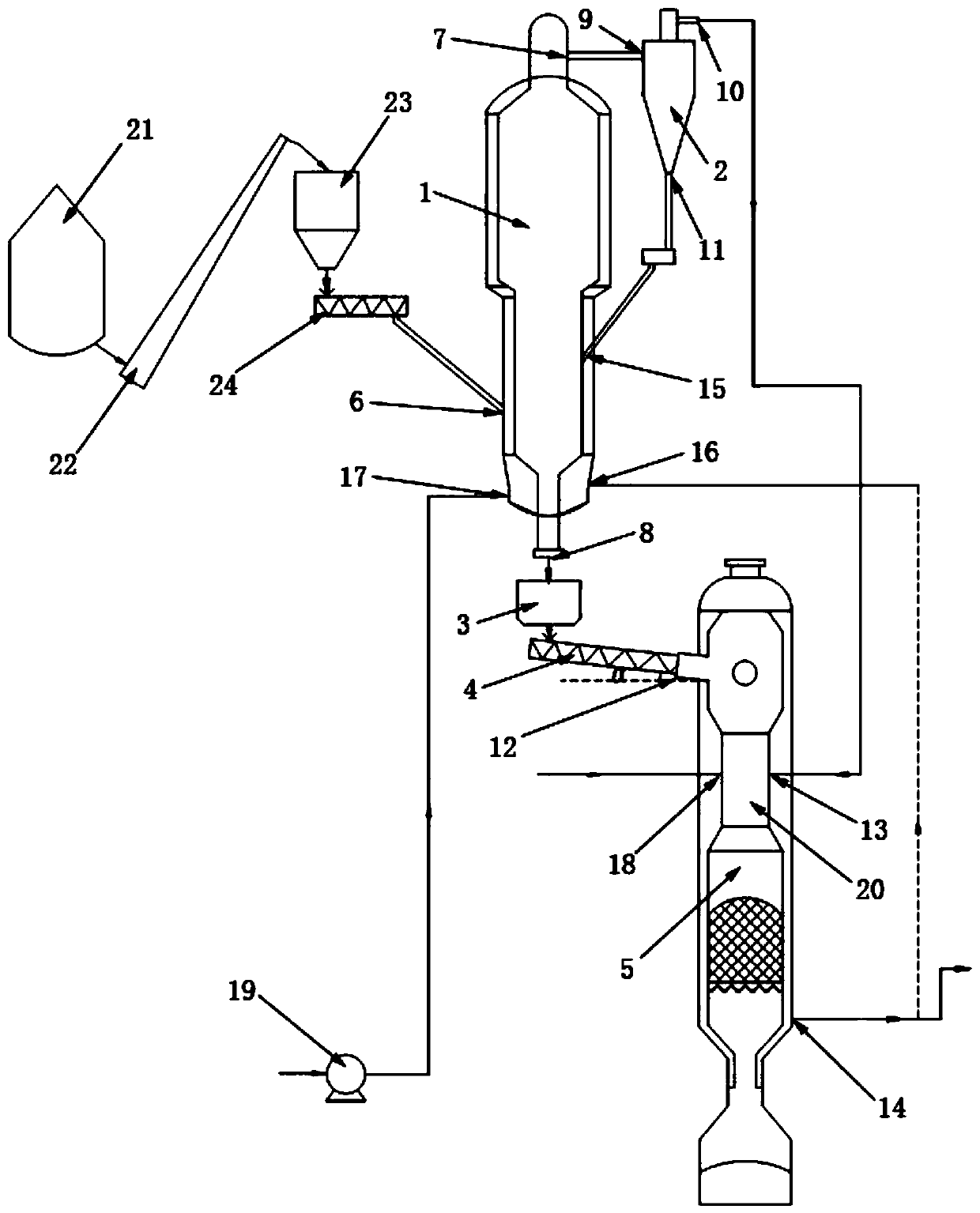

[0049] In further embodiments of the present invention, please continue to refer to figure 1 As shown, the downdraft fixed-bed gasifier 5 is also provided with a second gasification agent inlet 18, and the second gasification agent inlet 18 is used for introducing air or oxygen-enriched air.

[0050] In a further embodiment of the present invention, the downdraft fixed-bed gasifier 5 includes a throat section 20 , and the inlet of the second gasification agent 18 and the inlet of the pyrolysis gas 13 are located at the throat section 20 .

[0051] In a further embodiment of the present invention, an angle α is formed between the first screw feeder 4 and the coke inlet 12, and the angle range of the angle α is between 0° and 60°. Preferably, the biomass pyrolysis fluidized bed gasifier 1 and the downdraft fixed bed gasifier 3 are connected through a coke hopper 3 and a first screw feeder 4 .

[0052] In a further embodiment of the present invention, it also includes: a biomass...

Embodiment 1

[0061] Take a combined bed biomass gasification system with a daily biomass processing capacity of 85 tons as an example, which is used for internal combustion engine power generation. Biomass is corn stover. The design parameters of the pyrolysis-gasification reaction device are as follows:

[0062] Matching fuel gas power generation: 3MW

[0063] Feed biomass water content: 20%;

[0064] Feed biomass particle size: <10mm;

[0065] Fluidized bed pyrolysis furnace temperature: 450°C;

[0066] Downdraft fixed bed gasification temperature: 800°C;

[0067] Operating pressure: 10kPa;

[0068] Calorific value of fuel: 3000kCal / kg;

[0069] Gasification agent: normal temperature air.

[0070] after treatment

[0071] Total gasification efficiency: 84.1%;

[0072] Calorific value of fuel gas: ~6000kJ / Nm3;

[0073] Dust content in gas: less than 5g / Nm3;

[0074] Tar content in gas: less than 100mg / Nm3, preferably 50mg / Nm3;

[0075] Decombustion gas volume: 6000Nm3 / h;.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com