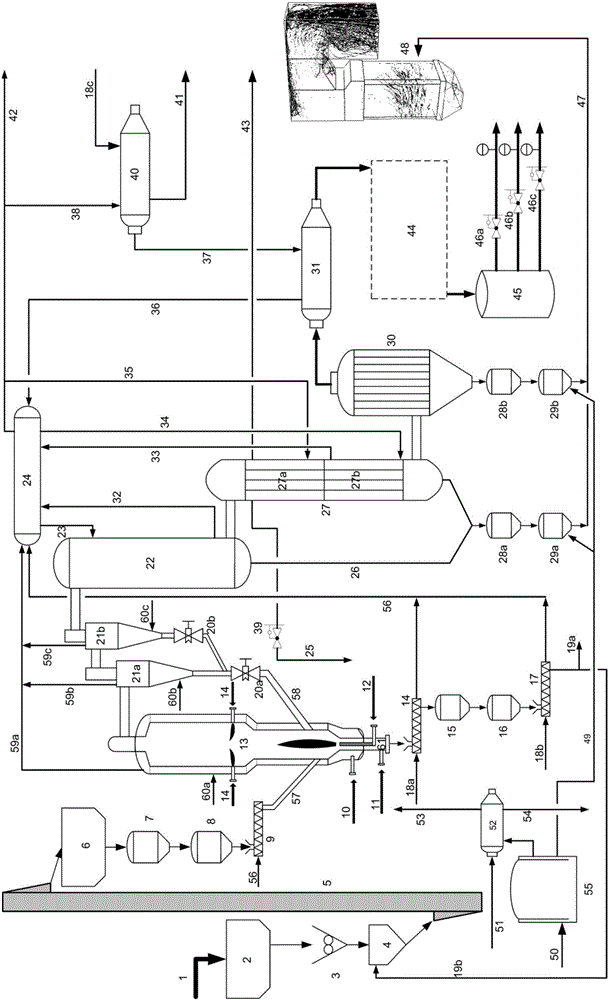

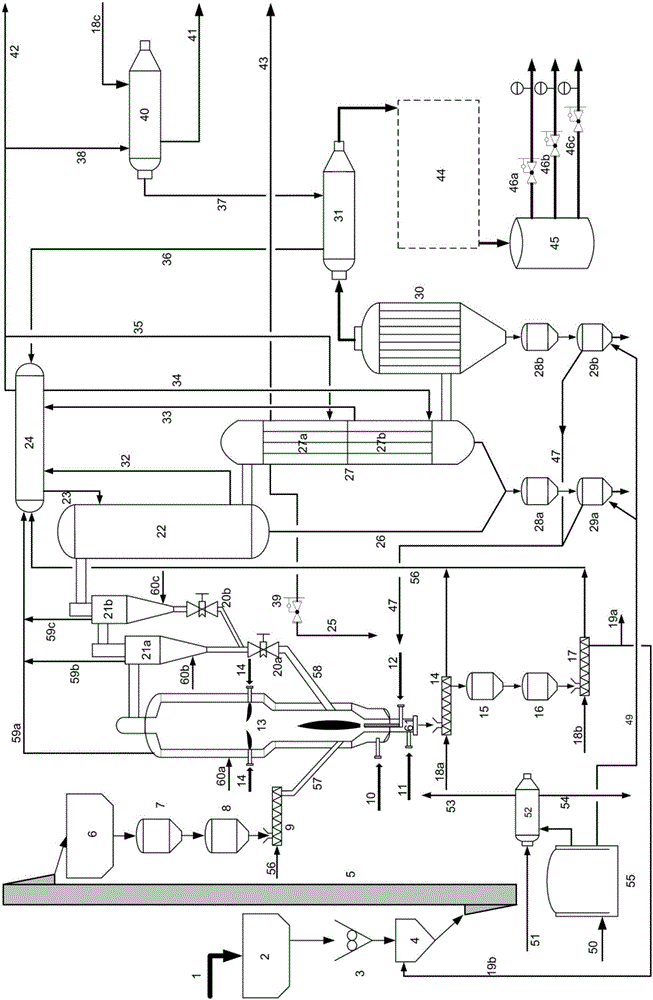

Circulating fluidized bed gasifying system and gasifying method thereof

A circulating fluidized bed and fluidized bed gasification technology, applied in the field of coal gasification, can solve the problems of high fly ash residual carbon content, low reliability, poor operating conditions, etc., to improve carbon conversion rate and energy utilization efficiency , The effect of reducing equipment operation and maintenance costs and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Take a circulating fluidized bed gasification process system with a daily coal processing capacity of 500 tons (air-dry basis) as an example. The coal quality data of fuel coal are shown in Table 1. The design parameters of the gasification reaction device are as follows:

[0054] Operating pressure: 0.3MPaG;

[0055] Operating temperature: 1000°C;

[0056] Gasification agent: enriched oxygen 35% and water vapor;

[0057] Particle size of crushed coal fuel: 0~10mm, average particle size 6mm, accounting for 80% of the total mass;

[0058] Pulverized coal fuel particle size: 0~200 mu m, average particle size 65 mu m, the total mass accounts for 15%, using N 2 delivery;

[0059] All the fly ash is sent to the boiler for combustion.

[0060] Gasification agent distribution: center jet gasification burner accounts for 50%, air distribution plate 25%, second stage burner chamber 15%, slag discharge pipe 10%;

[0061] Slagging temperature: 950°C;

[0062] Oxygen-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com