Treatment technology of powdered built biocarrier fluidized bed A/O sewage

A biological carrier and sewage treatment technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the conflicting problems of removing N and removing P, and achieves convenient operation, simple equipment, and reduced volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

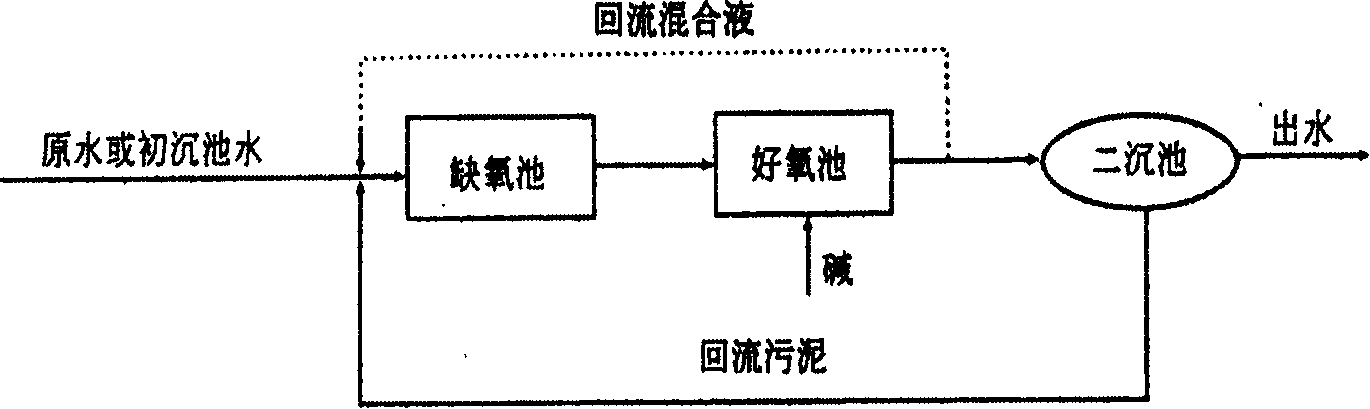

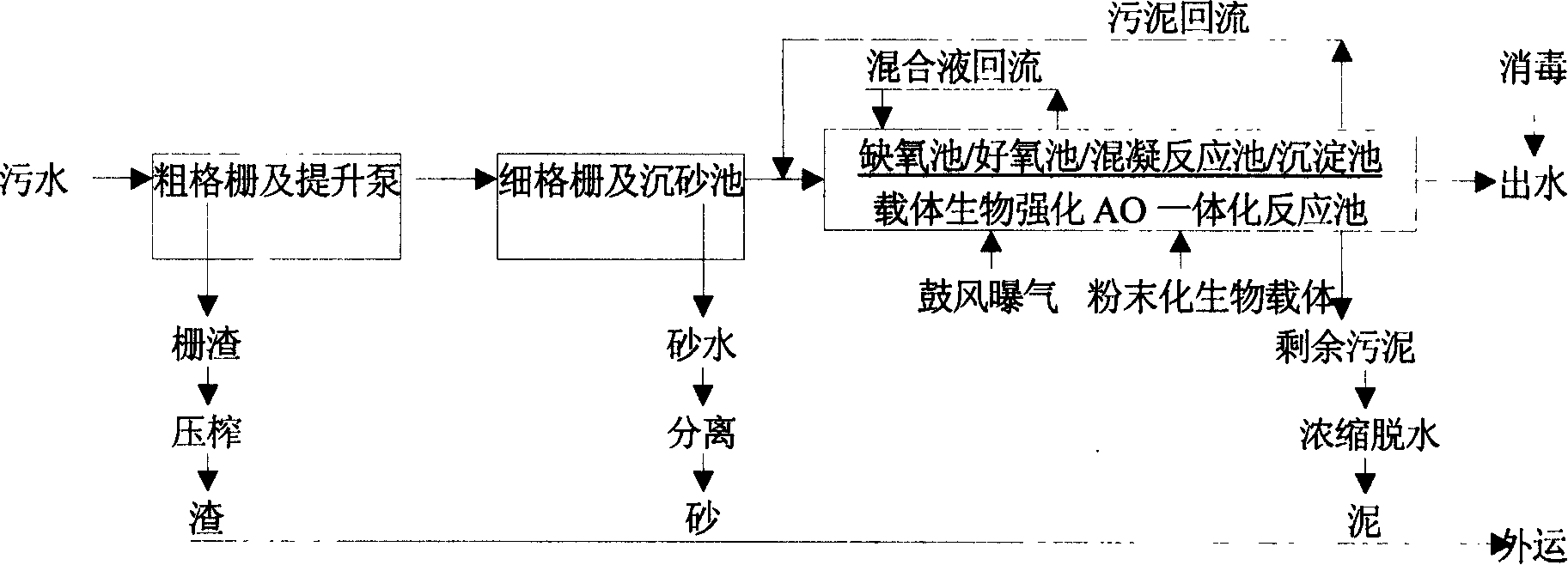

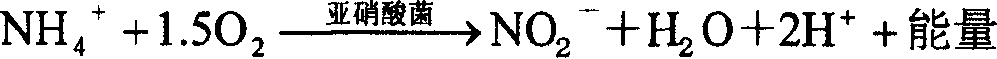

[0015] Such as figure 1 Shown, the present invention comprises anoxic biochemical reaction, aerobic biochemical reaction, coagulation reaction, precipitation, in the application of A / O process flow of the present invention (anoxic biochemical reaction+aerobic biochemical reaction is called A / O process) , the raw sewage first enters the anoxic tank, then enters the aerobic tank, and returns the mixed solution of the aerobic tank and the sludge of the sedimentation tank to the anoxic tank at the same time. The production of organisms and aerobic organisms ensures that there is a sufficient number of microorganisms in the anoxic pool and the aerobic pool, and makes the anoxic pool obtain the nitrate produced by nitrification in the aerobic pool. The direct entry of raw sewage and mixed solution provides sufficient carbon source organic matter for denitrification in the anoxic pool, enabling the denitrification reaction to proceed in the anoxic pool. The effluent after the denitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com