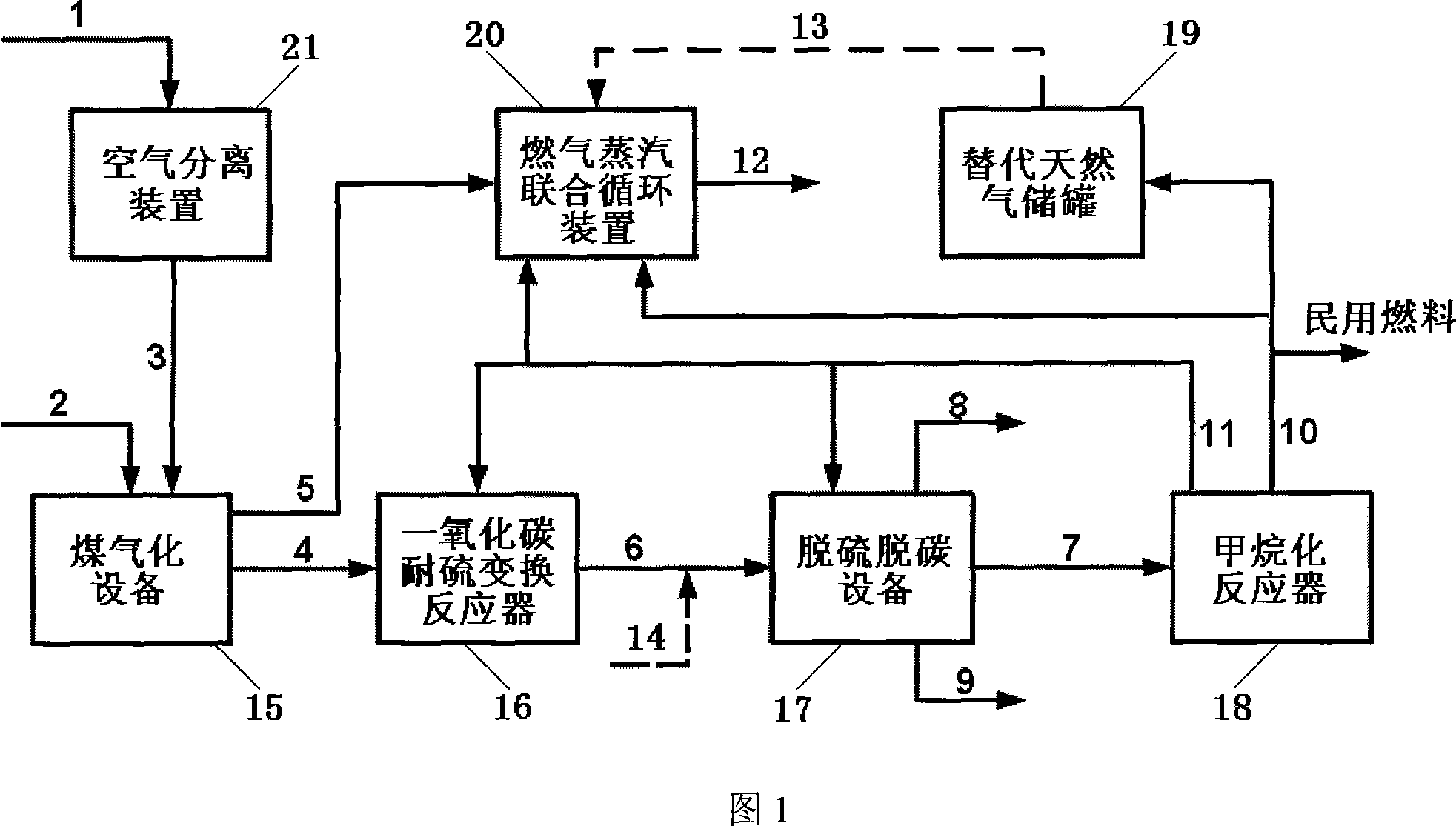

Combined system and process for producing electric-substituted natural gas based on coal gasification and methanation

A technology that replaces natural gas and coal gasification. It is applied in the direction of combustible gas purification, combustible gas chemical modification, combustible gas purification/transformation, etc. It can solve the problems of polluting the environment, coke oven gas not being effectively used, and wasting resources. Decrease in investment costs, enhance corporate competitiveness and economic benefits, and the effect of efficient and clean utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Based on the raw coal consumption of 5000 tons / day and the gas-steam combined cycle of Siemens V94.3a as the basis, the calculation of the overall performance of the system at base load is carried out for the embodiment.

[0032] The oxygen 3 produced by the air 1 entering the air separation device 21 is pressurized to 60-70 bar and enters the coal gasification equipment 15 together with the coal water slurry 2 with a concentration of 60-70%. The coal gasification equipment can adopt various structural forms, For example, two-stage, four-nozzle opposed type or Texaco type, etc., the gasification pressure is 55-65bar, the temperature is 1300-1500℃, and the crude gasification gas produced is recovered by sensible heat to produce high-pressure steam of 80-140bar5 Send it to the gas-steam combined cycle device 20; the crude gasified gas 4 after cooling is 150-400 ° C, and enters the carbon monoxide sulfur-resistant shift reactor 16 to undergo a shift reaction. Th...

Embodiment 2

[0035] Example 2: Taking the situation where gasification gas 6 and coke oven gas 14 are directly mixed to adjust the hydrogen-carbon ratio to 3:1 as an example, so as to reduce the load of the carbon monoxide sulfur-tolerant shift reactor for shift reaction, other organizational forms of the process flow And processing parameters are defined as embodiment 1. In Example 2, the raw material consumption and overall system performance are calculated based on the product output calculated in Example 1.

[0036] The coke oven gas composition and lower calorific value used in Example 2 are shown in Table 2.

[0037] H 2

CH 4

CO

CO 2

N 2

O 2

h 2 o

C m h n

LHV(MJ / kg)

58.10

24.90

5.86

2.35

3.90

0.39

2.35

2.15

37.9

[0038] Through calculation, the overall performance of the system and process method of the present invention in Embodiment 1 and Embodiment 2 is sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com