Method and system for low-temperature dry distillation and separation recycling of solid thermal carrier low-rank coal and oil shale

A technology of solid heat carrier and low-rank coal, which is applied in the direction of direct heating dry distillation, special form dry distillation, petroleum industry, etc., and can solve the problems of increasing power generation cost, reducing power generation efficiency, and degrading the flammability of lignite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

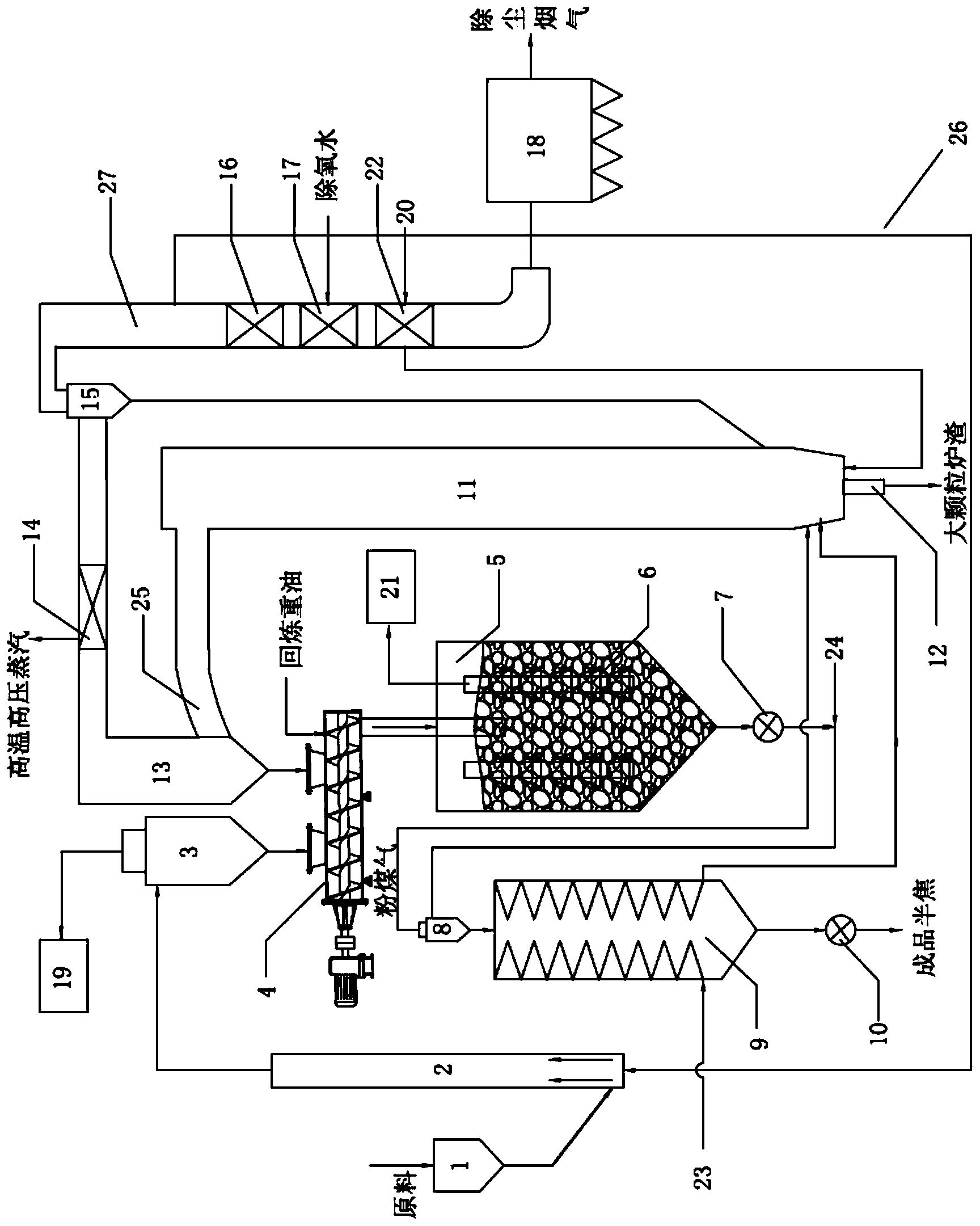

[0064] This embodiment provides a low-rank coal and oil shale low-temperature dry distillation fractionation utilization system with solid heat carrier, its structure is as follows figure 1 shown.

[0065] The system includes: raw material bin 1, Venturi tube dryer 2, dry coal separator 3, screw feeder 4, dry distillation chamber 5, raw gas outlet pipe 6, first locker 7, cyclone separator 8, Cold coke device 9, second locker 10, circulating fluidized bed 11, slag discharge pipe 12, high temperature separator 13, high temperature superheater 14, medium temperature separator 15, low temperature superheater 16, economizer 17, dust collector 18. Air preheater 22, settling flue 25, flue gas pipe 27, cold gas input pipe 24, secondary air input pipe 23; where:

[0066] The outlet of the raw material bin 1 is connected to the raw material inlet at the bottom of the venturi dryer 2;

[0067] The top outlet of the venturi dryer 2 is connected to the inlet of the dry coal separator 3; ...

Embodiment 2

[0083] This embodiment provides a method for utilizing solid heat carrier low-rank coal and oil shale low-temperature dry distillation fractions, which is carried out by using the system in Embodiment 1. The method includes the following steps:

[0084] After the low-rank coal is crushed, it is screened into raw coal with a particle size of 0-60mm;

[0085] The prepared raw coal is input into the raw material bin 1 for storage;

[0086] The medium-temperature flue gas at 200-500°C drawn from the flue gas pipe 27 at the front end of the low-temperature superheater 16 is used as a drying heat source and sent to the bottom of the Venturi dryer 2 through the medium-temperature flue gas pipe 26. The raw coal in the raw material bin 1 is lifted into the Venturi dryer 2, and the raw coal completes the drying process during the lifting process;

[0087] The medium-temperature flue gas carries the raw coal through the Venturi dryer 2, then enters the dry coal separator 3 for gas-soli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com