Solid oxide fuel cell combined system based on solar methanol reforming hydrogen production

A solid oxide and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of high energy consumption, high cost of hydrogen production, difficult to promote, etc., to achieve flexible control and compact structure , The effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

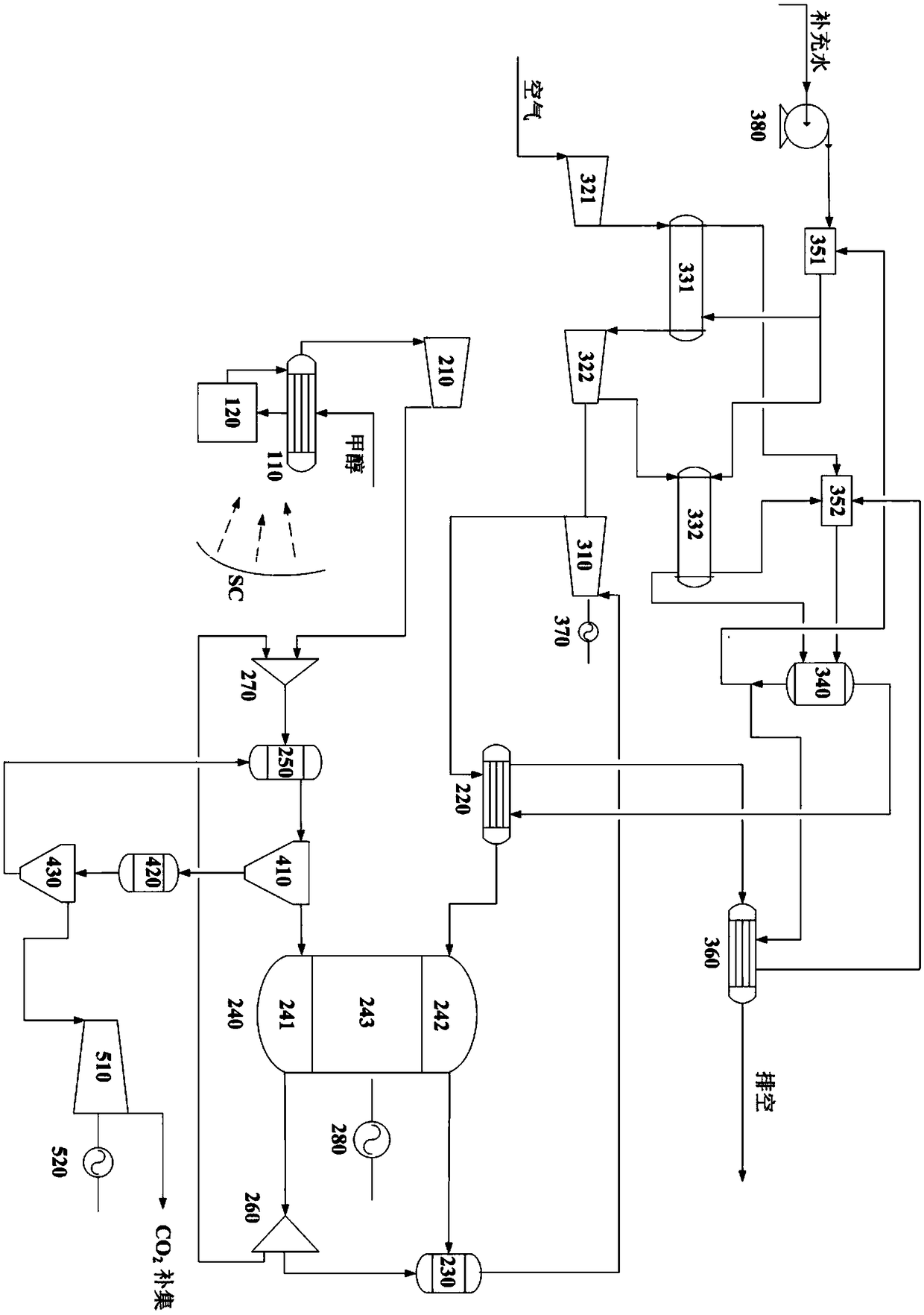

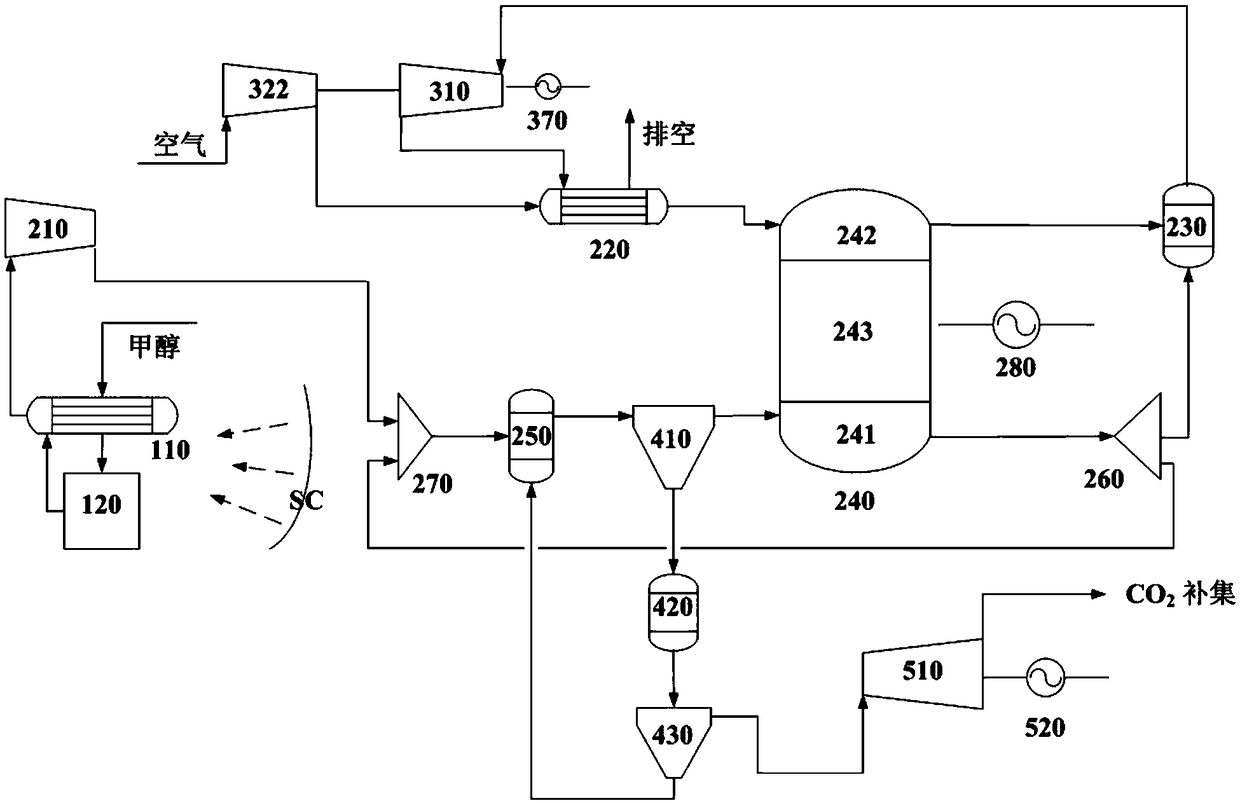

[0047] figure 1 It is a schematic structural diagram of a solid oxide fuel cell combined system based on solar methanol reforming hydrogen production provided in this embodiment. Such as figure 1 As shown, this embodiment provides a solid oxide fuel cell combined system based on solar methanol reforming hydrogen production, including methanol reforming hydrogen production subsystem, solid oxide fuel cell subsystem and humid air turbine circulation subsystem:

[0048] The methanol reforming hydrogen production subsystem includes at least a first heat exchanger 110 and a methanol reforming reactor 120;

[0049] The solid oxide fuel cell subsystem includes at least a cell stack (not shown), a fuel compressor 210, a second heat exchanger 220, an afterburner 230, and a pre-reformer 250; the cell stack includes a plurality of solid oxide fuel cells 240. The solid oxide fuel cell 240 has a cathode inlet, a cathode outlet, an anode inlet, and an anode outlet;

[0050] The humid air...

Embodiment 2

[0100] The joint system in the first embodiment is used for energy utilization, and the structural diagram of the joint system is as follows figure 1 As shown, the main simulation conditions of the joint system under specific working conditions are shown in Table 1, and the corresponding energy balance table is shown in Table 2.

[0101] Table 1 The main process conditions of the combined system

[0102]

[0103]

[0104] Table 2 System Energy Balance Table

[0105]

[0106] In Table 2, the power generation of SOFC refers to the power generation of solid oxide fuel cell; the net power generation of GT is the sum of the net power generation of the first gas turbine and the second gas turbine; correspondingly, the power generation efficiency of SOFC is The power generation efficiency of the solid oxide fuel cell; GT power generation efficiency refers to the overall power generation efficiency of the first gas turbine and the second gas turbine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com