Proton exchange membrane fuel cell combined system for hydrogen production based on solar thermochemical methanol reforming

A fuel cell system and proton exchange membrane technology, applied in the field of resource integration, can solve the problems of relatively strict hydrogen purity requirements and immature co-production technology, and achieve the effect of solving transportation and fuel cost problems, compact structure and efficient utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

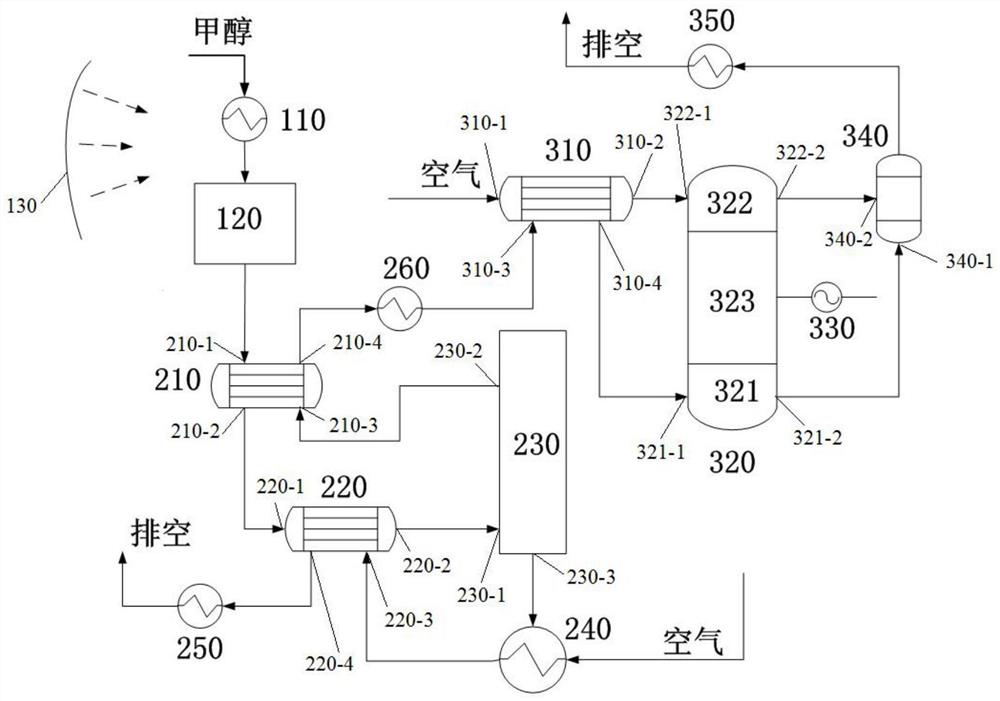

[0033] The invention provides a proton exchange membrane fuel cell combined system based on solar thermochemical methanol reforming for hydrogen production, including a methanol reforming hydrogen production system, a hydrogen permeable alloy membrane system and a proton exchange membrane fuel cell system connected in sequence;

[0034] The hydrogen permeable alloy membrane system includes a heat exchanger 210, a superheater 220 and a hydrogen permeable alloy membrane 230;

[0035] The proton exchange membrane fuel cell system includes an air preheater 310 and a proton exchange membrane fuel cell stack;

[0036] The proton exchange membrane fuel cell stack includes ≥ 1 proton exchange membrane fuel cell 320;

[0037] The proton exchange membrane fuel cell 320 includes an anode 321, an electrolyte 323 and a cathode 322;

[0038] The methanol reforming hydrogen production system, heat exchanger 210, superheater 220 and hydrogen permeable alloy membrane 230 are sequentially conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com