High-efficiency fuel cell combined cycle process system for burning coke oven gas

A fuel cell and coke oven gas technology, which is applied in thermal equipment and its systems, chemical technology, and comprehensive energy supply and demand fields, can solve problems such as energy loss, bad chemical components of thermal energy, etc., and achieve clean utilization, easy compact layout, and flexible control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

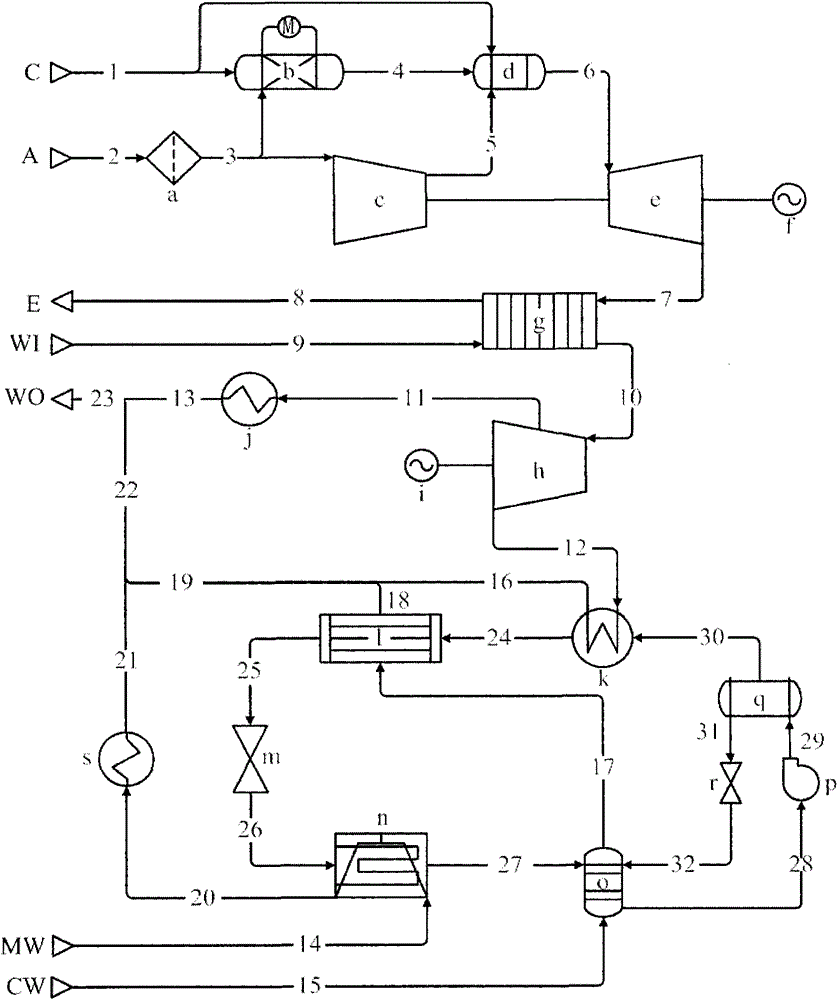

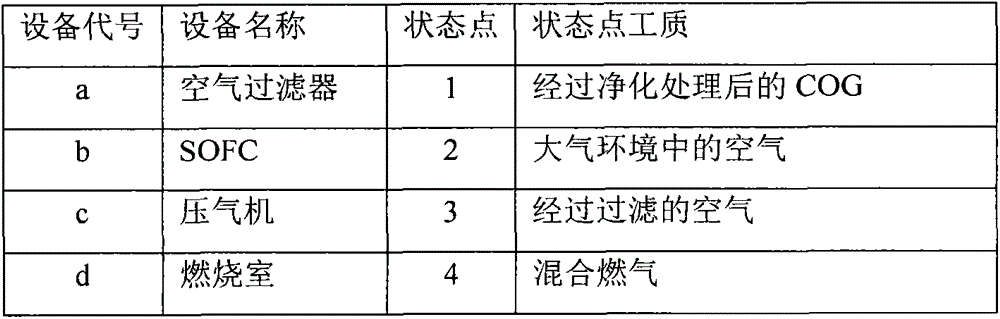

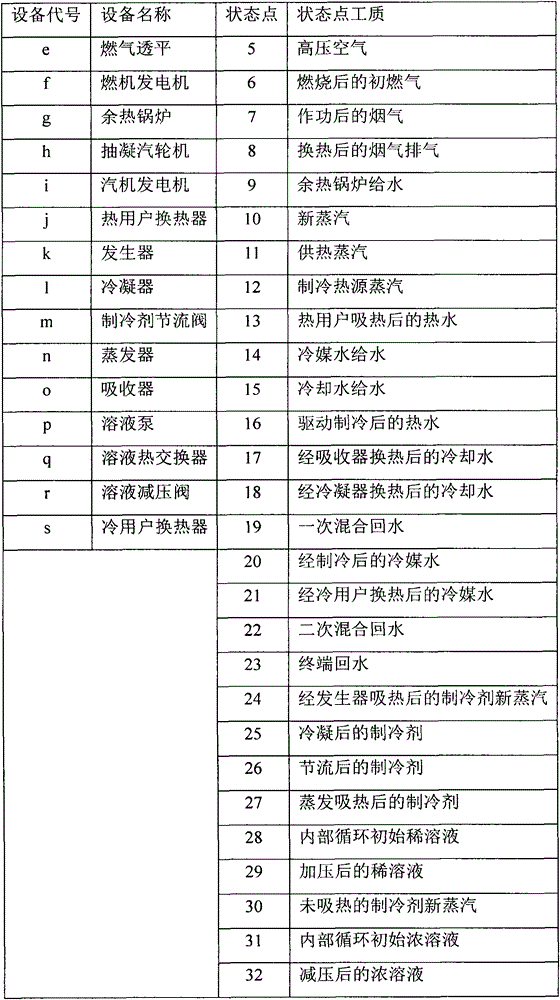

[0036] A high-efficiency fuel cell combined cycle system for burning coke oven gas of the present invention, the system includes:

[0037] The coke oven gas conversion-power generation sub-system is used to convert fuel COG into high-temperature and high-pressure gas through SOFC reforming hydrogen and gas turbine post-combustion COG, and make it generate electricity through gas turbine pressure relief. The specific process arrangement is as follows: the solid oxide fuel cell (b) has a fuel inlet (1) and a clean air inlet (3), and its reacted gas outlet (4) is connected with the gas turbine combustor (d), and the generated electric energy It is directly used for industrial loads; the compressor (c) of the gas turbine unit is coaxially arranged with the gas turbine (e) and connected to the generator set (f); the inlet air of the compressor and the clean air of the solid oxide fuel cell share the same gas Source, the high-pressure air outlet (5) leads to the combustion chamber; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com