Power generation method and electric power generation method

A production method and power technology, which can be used in machines/engines, steam engine installations, gas turbine installations, etc., can solve problems such as low energy utilization efficiency, and achieve the effects of improving energy conversion efficiency, improving energy conversion efficiency, and reducing emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

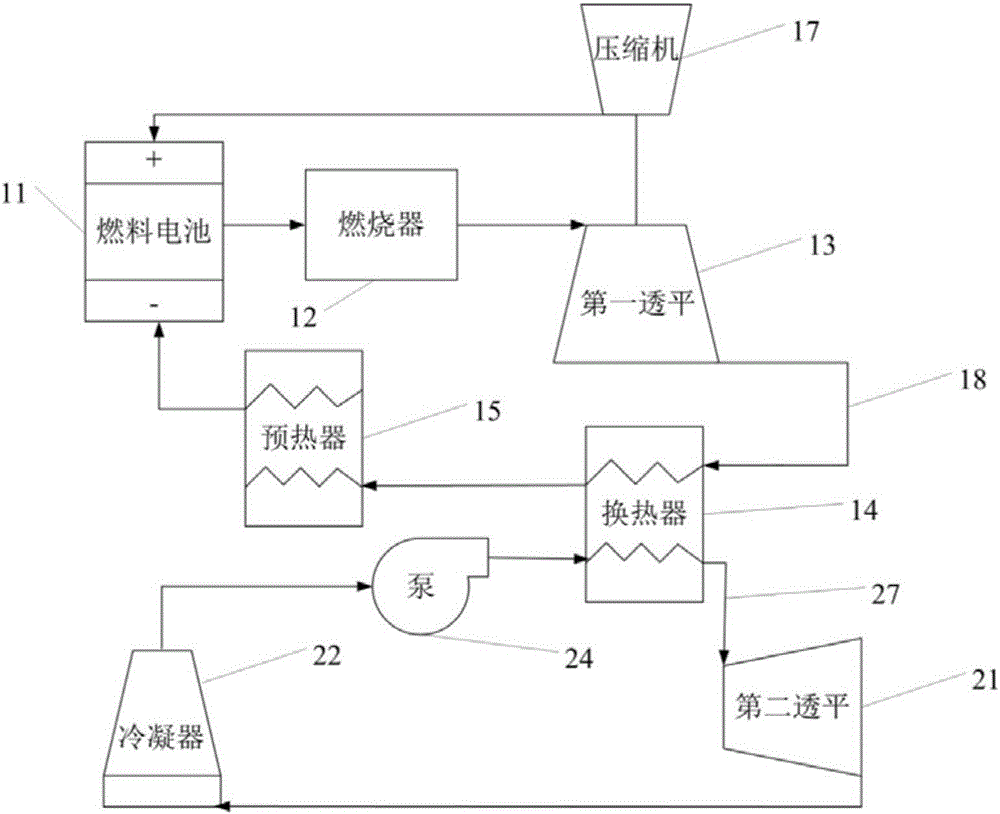

[0018] Embodiment one, such as figure 1 As shown, a triple compound power system fuel cell-gas turbine-organic Rankine cycle coupling method configured to facilitate efficient utilization of waste heat recovery, including a fuel cell-gas turbine hybrid cycle system configured to generate hybrid power, Including: a fuel cell and gas turbine (SOFC-GT) circulation loop and an organic Rankine cycle (ORC) loop, the fuel cell and gas turbine (SOFC-GT) circulation loop includes a fuel cell 11, and the fuel cell 11 is a solid oxide fuel cell, Solid Oxide Fuel Cell (SOFC) is suitable for efficiently converting chemical energy stored in fuel and oxidant into electrical energy at medium and high temperatures. Fuel cell 11 comprises positive pole and negative pole in order to carry out electrochemical reaction, combustible gas and air pass into fuel cell 11 to react by fuel cell 11 positive pole and negative pole respectively, combustible gas can be hydrogen, carbon monoxide, methane, coa...

Embodiment 2

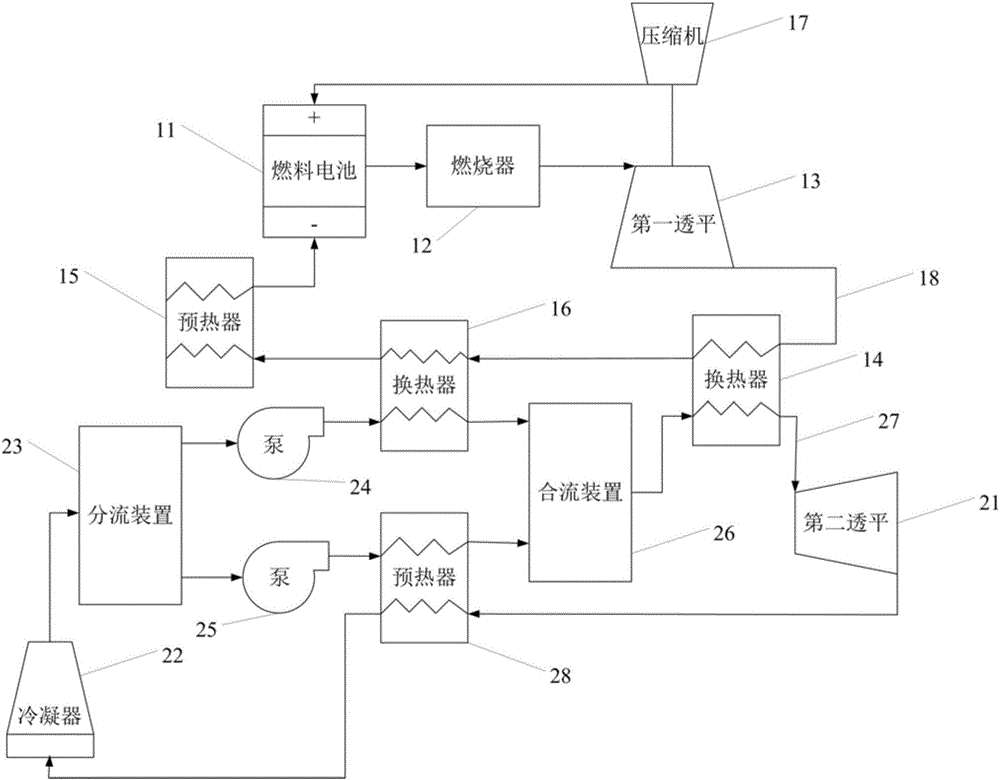

[0020] Embodiment two, such as figure 2 As shown, a triple compound power system SOFC-Gas Turbine-ORC coupling method constructed to facilitate efficient utilization of waste heat recovery, the method includes SOFC and gas turbine cycle, and ORC, The system includes a Solid Oxide Fuel Cell and Gas Turbine (SOFC-GT) loop, and an Organic Rankine Cycle (ORC) loop. The solid oxide fuel cell and gas turbine (SOFC-GT) circulation loop includes a first preheater 15, a compressor 17, a solid oxide fuel cell 11, a combustor 12, a first turbine 13 and a first heat exchanger 14, The solid oxide fuel cell and gas turbine (SOFC-GT) circulation loop is combined with the Organic Rankine Cycle (ORC) loop through the first heat exchanger 14 and preheater 15, and the solid oxide fuel cell 11 is suitable for storing The chemical energy in the fuel and oxidant is efficiently converted into electrical energy, and the compressor 17 presses air into the positive electrode of the solid oxide fuel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com